Enhanced modified ABS resin and preparation method thereof

An ABS resin and reinforced technology, applied in the field of reinforced modified ABS resin and its preparation, can solve the problems of partial color whitening and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

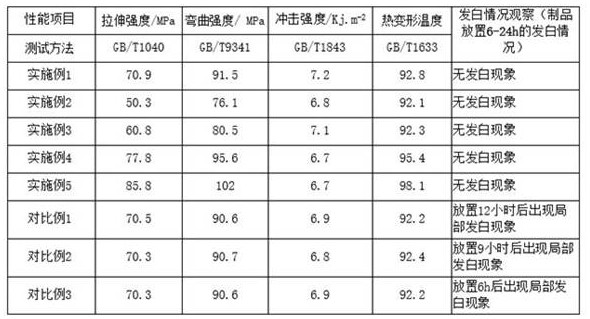

Examples

Embodiment 1

[0035] A preferred reinforced modified ABS resin, comprising in parts by weight: 100 parts of ABS resin, 25 parts of acrylonitrile-styrene resin, 37 parts of glass fiber, 5 parts of glass microbeads, styrene-maleic anhydride copolymer 7 parts of material, 5.5 parts of maleic anhydride grafted polypropylene, 5 parts of ABS high rubber powder, 1.2 parts of auxiliary agent, and 0.05 part of pigment. The ABS resin includes ABS resin HI-121H and ABS resin HP-181 with a weight ratio of 1:3; the particle size of the glass microbeads is 30-60 μm; the auxiliary agent includes a weight ratio of 1:1:2 The anti-oxidant, coupling agent, and melt-finger regulator, the antioxidant comprises antioxidant 1010 and antioxidant 168 in a weight ratio of 1:1, and the melt-finger regulator comprises ethylene bismuth in a weight ratio of 1:2 Stearic acid amide and calcium stearate.

[0036] The preparation method of the reinforced modified ABS resin, the method comprises the steps of: taking each co...

Embodiment 2

[0038] A reinforced modified ABS resin, comprising in parts by weight: 80 parts of ABS resin, 20 parts of acrylonitrile-styrene resin, 13 parts of glass fiber, 4.5 parts of glass microbeads, and 6 parts of styrene-maleic anhydride copolymer 4.5 parts of maleic anhydride grafted polypropylene, 4.5 parts of ABS high rubber powder, 1.1 parts of auxiliary, 0.01 part of pigment. The ABS resin includes 25 parts of ABS resin HI-121H and 55 parts of ABS resin HP-181; the auxiliary agent includes an antioxidant, a coupling agent, and a melt finger regulator in a weight ratio of 1:1:2, so The antioxidant includes antioxidant 1010 and antioxidant 168 in a weight ratio of 1.2:1, and the melt index modifier includes ethylene bisstearic acid amide and calcium stearate in a weight ratio of 1.5:2.

[0039] The preparation method of the reinforced modified ABS resin is the same as that of Example 1, except that the temperature of each section in the screw extruder is different, specifically: 1...

Embodiment 3

[0041] A reinforced modified ABS resin, comprising in parts by weight: 120 parts of ABS resin, 30 parts of acrylonitrile-styrene resin, 31 parts of glass fiber, 6 parts of glass microbeads, and 8 parts of styrene-maleic anhydride copolymer parts, 6 parts of maleic anhydride grafted polypropylene, 6 parts of ABS high rubber powder, 1.5 parts of auxiliary, 0.1 part of pigment. The ABS resin includes 40 parts of ABS resin HI-121H and 80 parts of ABS resin HP-181; the auxiliary agent includes an antioxidant, a coupling agent, and a melt finger regulator in a weight ratio of 1:1:2, so the The antioxidant includes antioxidant 1010 and antioxidant 168 in a weight ratio of 1:1.2, and the melt index modifier includes ethylene bisstearic acid amide and calcium stearate in a weight ratio of 1:2.5.

[0042] The preparation method of the reinforced modified ABS resin is the same as that of Example 1, except that the temperature of each section of the screw extruder is different, specifical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com