Lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery and separator technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as wrinkling and uneven shrinkage, prevent whitening, improve porosity and air permeability, and control the heating rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

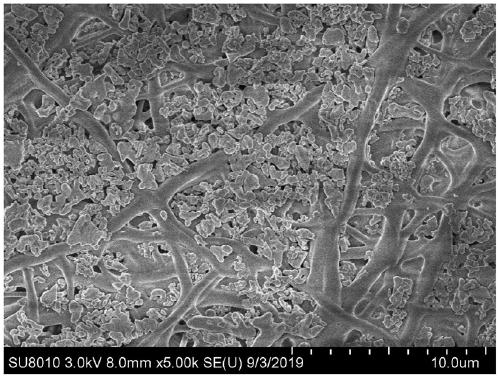

Image

Examples

Embodiment 1

[0031] This embodiment provides a lithium-ion battery separator, the preparation method of which comprises the following steps:

[0032] Alumina powder is added to the polyimide resin and stirred and mixed to obtain a slurry. When stirring and mixing, a planetary stirring mill or an electric mechanical stirrer is used for mixing. The mixing time is 0.5h, wherein the polyimide The concentration of resin is 3%, and wherein, the solvent that polyimide resin uses is DMAC scientific name dimethylacetamide and NMP (N-methylpyrrolidone), and the quality of described aluminum oxide powder is no more than polyimide 30% of resin mass;

[0033] Coat the slurry on the base film, the coating method is wire bar coating or micro-gravure coating, control the air humidity in the room to not exceed 50%, and then heat and dry the base film after coating the slurry at 30°C to Constant quality;

[0034] The base film after drying is fixed on the glass substrate for curing to prepare a high-tempe...

Embodiment 2

[0040] This embodiment provides a lithium-ion battery diaphragm, the preparation method of which comprises the following steps:

[0041] Alumina powder is added to polyimide resin, and the slurry is obtained after stirring and mixing. When stirring and mixing, a planetary stirring mill or an electric mechanical stirrer is used for mixing. The mixing time is 1h, wherein the polyimide The concentration of the resin is 5%, and the mass of the alumina powder does not exceed 30% of the mass of the polyimide resin;

[0042] Coat the slurry on the base film, the coating method is wire bar coating or micro-gravure coating, control the air humidity in the room to not exceed 50%, and then heat and dry the base film after coating the slurry at 50°C to Constant quality;

[0043] The base film after drying is fixed on the glass substrate for curing to prepare a high-temperature-resistant and high-strength lithium-ion battery separator, which can be applied not only to conventional lithium...

Embodiment 3

[0049] This embodiment provides a lithium-ion battery separator, the preparation method of which comprises the following steps:

[0050] Alumina powder is added to polyimide resin, and the slurry is obtained after stirring and mixing. When stirring and mixing, a planetary stirring mill or an electric mechanical stirrer is used for mixing. The mixing time is 0.5h, wherein the polyimide The concentration of the amine resin is 3%, and the mass of the alumina powder does not exceed 30% of the mass of the polyimide resin;

[0051] Coat the slurry on the base film, the coating method is wire bar coating or micro-gravure coating, control the air humidity in the room to not exceed 50%, and then heat the base film after coating the slurry at 30-80°C Dry to constant mass;

[0052] Fix the dried base film on the glass substrate for curing to prepare a high-temperature-resistant and high-strength lithium-ion battery separator, which can be applied not only to conventional lithium-ion bat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com