Wafer film covering device

A technology for laminating devices and wafers, which is applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., and can solve the problems of film deformation, wrinkles, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

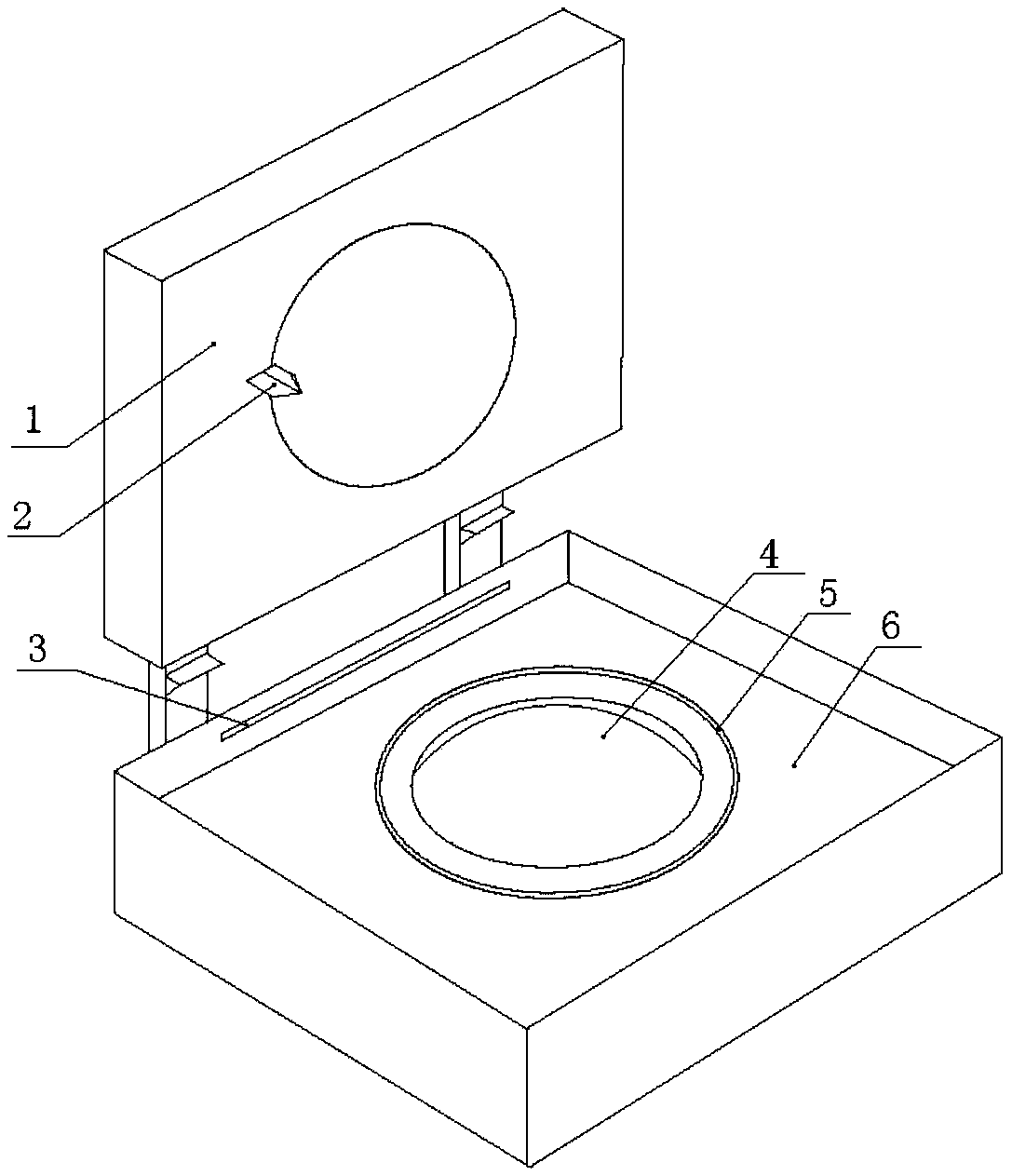

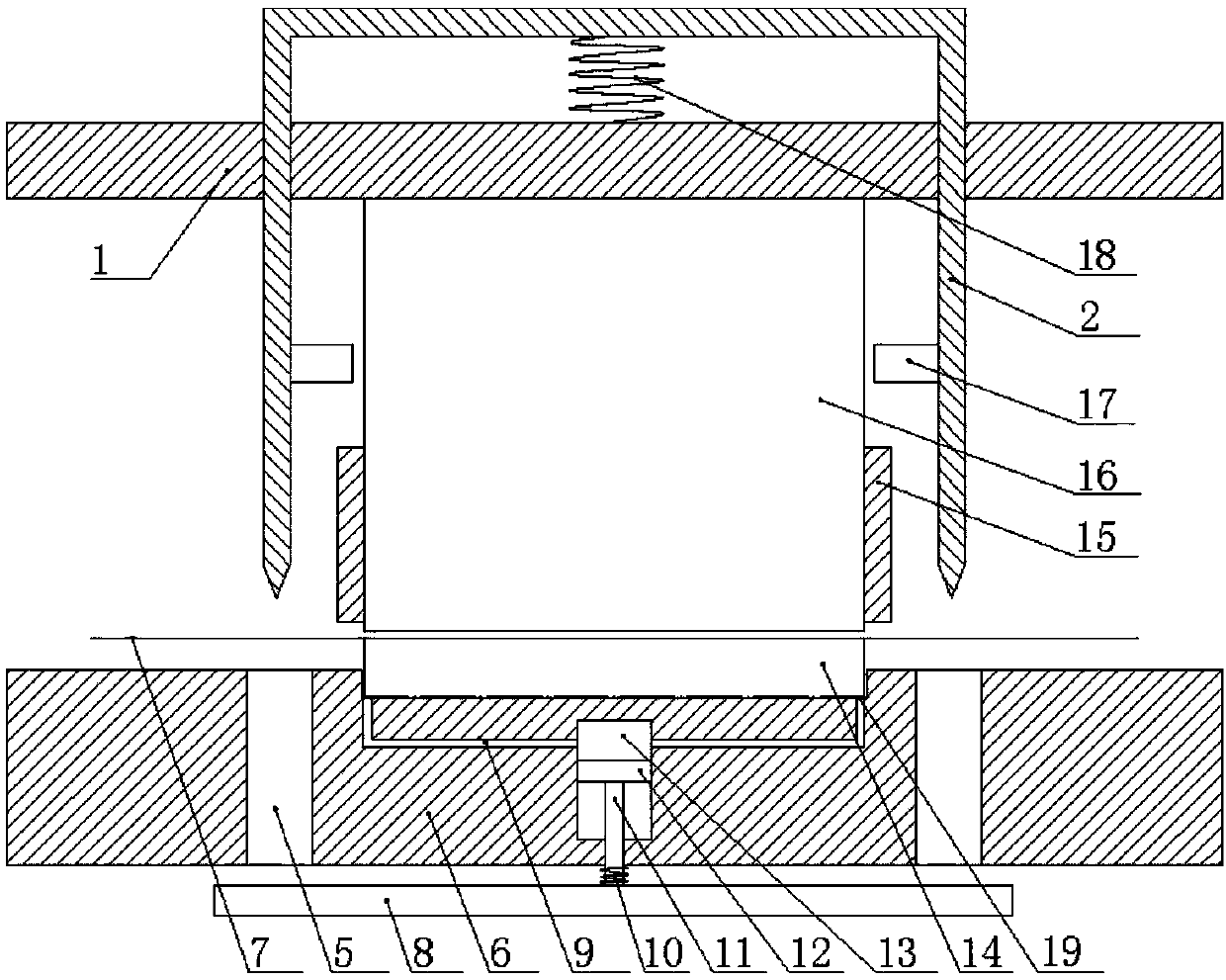

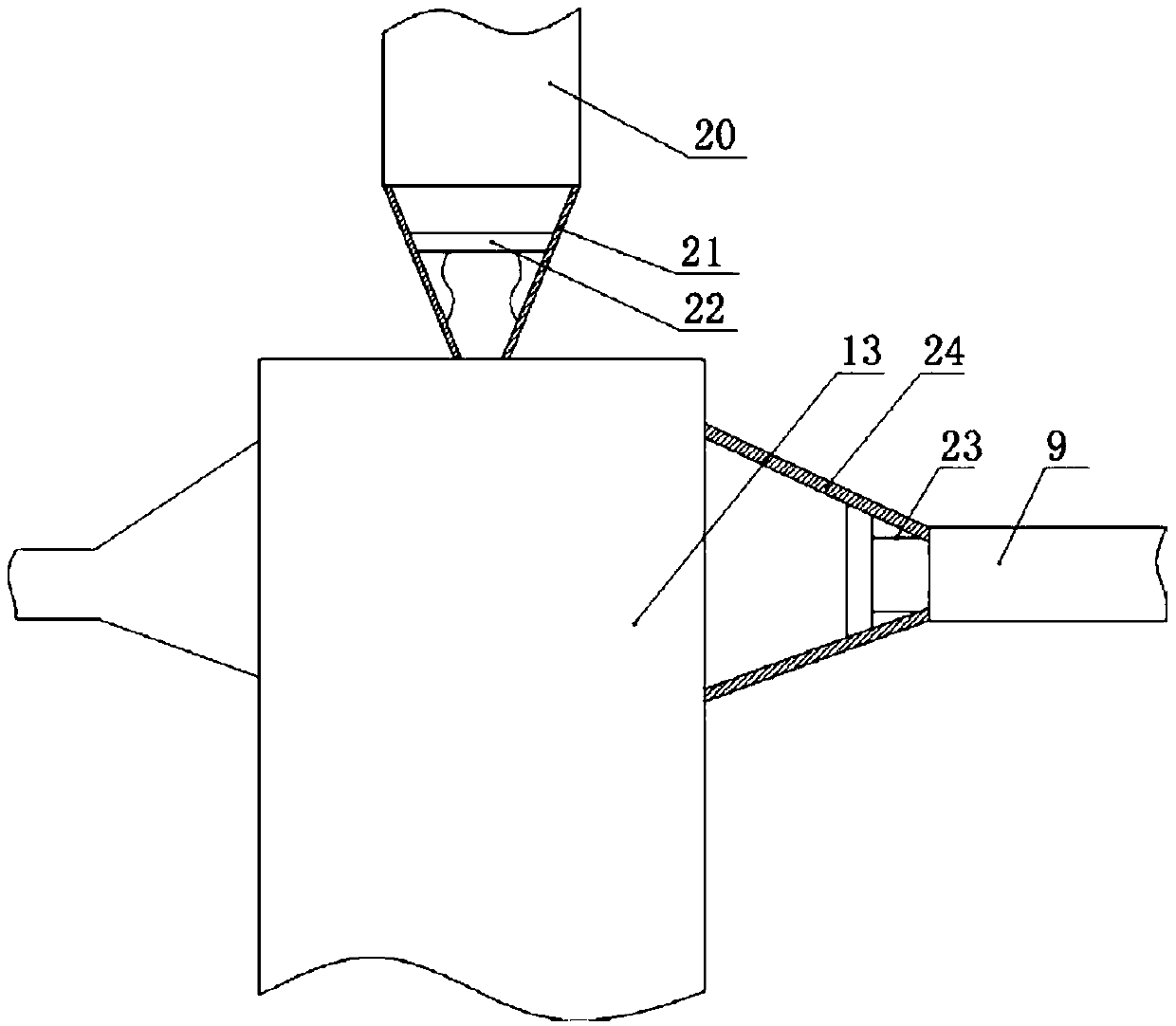

[0021] The reference signs in the drawings of the description include: cover body 1, cutter 2, feeding hole 3, placement groove 4, cutting hole 5, bottom box 6, film 7, bottom plate 8, suction channel 9, negative pressure spring 10, Piston rod 11, piston 12, negative pressure chamber 13, wafer 14, hemming cylinder 15, pressure column 16, push plate 17, cutting spring 18, suction hole 19, air outlet pipe 20, air outlet connecting pipe 21, sealing plate 22 , elastic cord 23, air intake connecting pipe 24.

[0022] Such as figure 1 As shown, the laminating machine in the prior art includes a bottom box 6, and the side wall of the bottom box 6 is provided with a feed hole 3, and the bottom box 6 is provided with a placement groove 4 for placing a wafer 14, and the placement groove 4 is concentric with it An annular cutting hole 5 is provided, and a cover body 1 is hinged on one side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com