Flanging machine for carbon contact strip carriers

A carbon skateboard and edge folding machine technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of high labor intensity of operators, poor product consistency, and danger of operators, so as to achieve good product consistency, The effect of low manufacturing cost and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

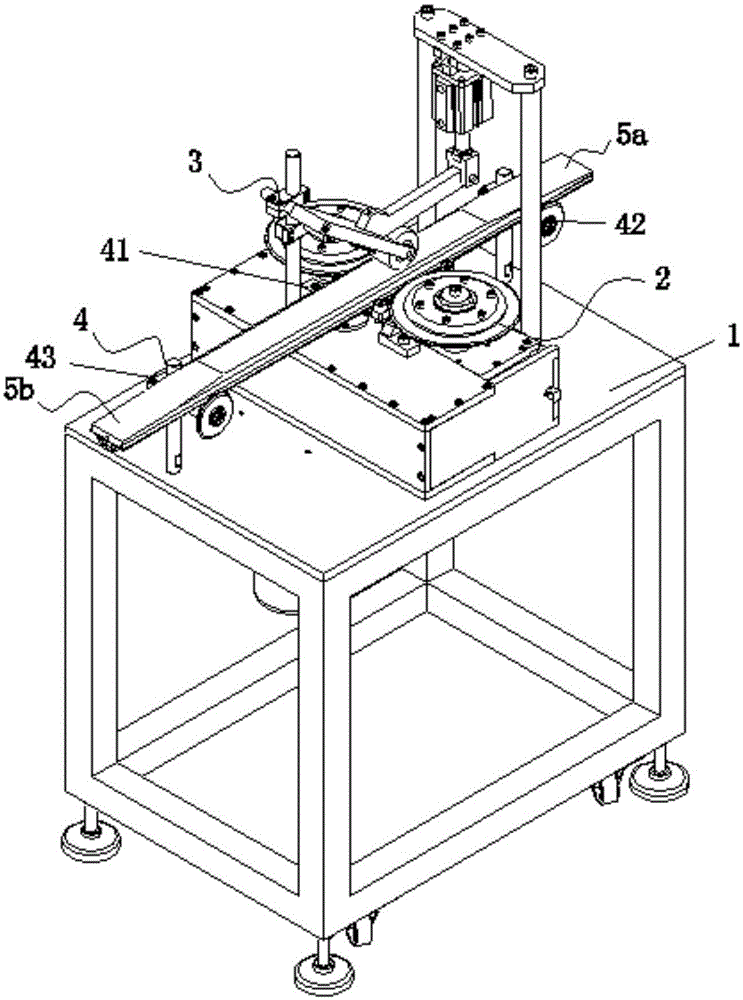

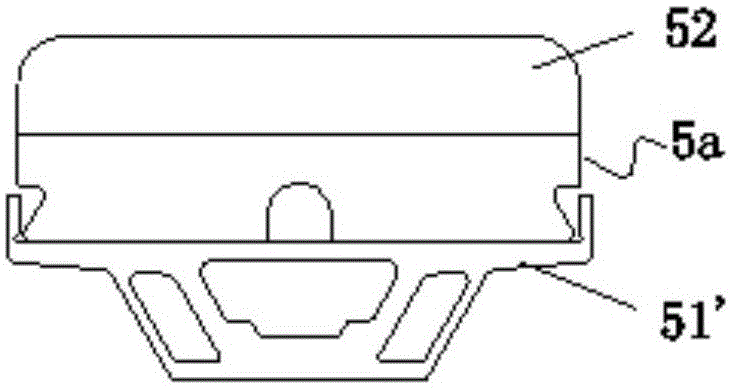

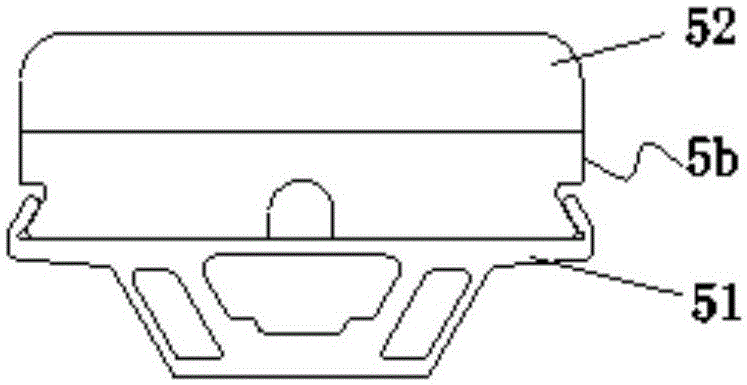

[0033] Such as figure 1 As shown, it is a three-dimensional perspective view of the carbon skateboard bracket folding machine of the present invention. As can be seen from the figure, the carbon skateboard bracket folding machine includes: a workbench 1 on which a folding station is arranged; The support device 4 for supporting the bottom of the carbon skateboard has first, second and third support assemblies 41, 42, 43; a pressing device 3 installed on the workbench 1 and above the hemming station , when the head of the carbon slide plate on the support device 4 reaches the hemming station, the pressing device 3 starts to press down, so as to press down the carbon slide plate from the head of the carbon slide plate; it is installed on the workbench 1 for The hemming transfer device 2 that squeezes both sides of the carbon skateboard bracket located on the hemming station, which applies relative extrusion force to the two sides of the carbon skateboard bracket and pushes the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com