Anti-static floor made of composite materials and provided with hollow interlayer and manufacture method thereof

An anti-static floor and composite material technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of easy dust absorption, unstable conductivity, and poor anti-static performance of the floor, and achieve unbreakable, light weight, The effect of stabilizing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

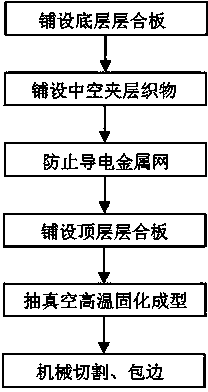

Method used

Image

Examples

Embodiment

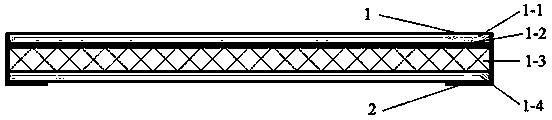

[0019] A kind of antistatic floor of hollow interlayer composite material, its structure is as follows figure 1 As shown, it includes floor main body 1 and metal edging 2.

[0020] The floor body 1 is composed of a top laminate 1-1, a conductive layer 1-2, a hollow interlayer 1-3 and a bottom laminate 1-4 from top to bottom, wherein the conductive layer 1-2 is coated with a conductive metal mesh Epoxy resin glue is cured to form;

[0021] The top layer laminate 1-1 and the bottom layer laminate 1-4 are all formed by laminating glass fiber cloth and epoxy resin glue through a certain laying angle, and the laying sequence is [(0 / 90)(±45) (0 / 90)(±45)(0 / 90)];

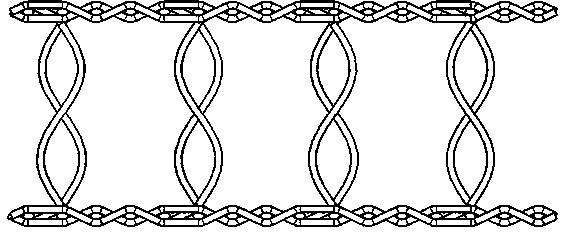

[0022] like figure 2 As shown, the hollow interlayer 1-3 is composed of an upper fiber panel, a lower fiber panel, and "8" shaped fiber bundles arranged at intervals connecting the upper fiber panel and the lower fiber panel, wherein the upper fiber panel is composed of upper fiber bundles and epoxy The lower fiber pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com