Edge covering type ferrite product and processing method thereof

A ferrite and edge-wrapping technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems that affect the normal use of mobile phones, drop on the circuit board, affect the appearance of the product, etc., and achieve structural Simple, enhanced hemming effect, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

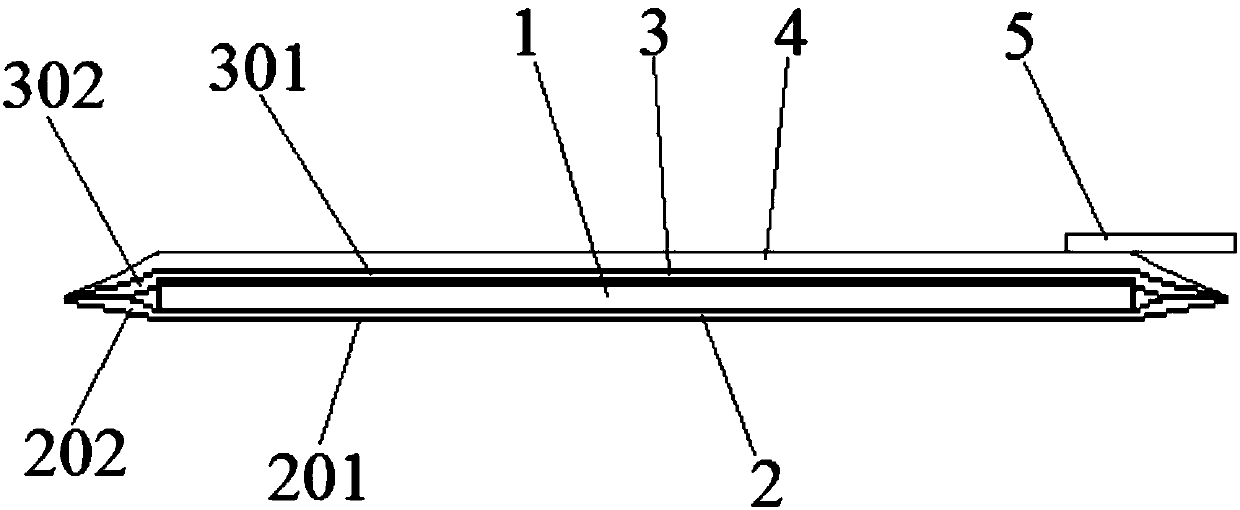

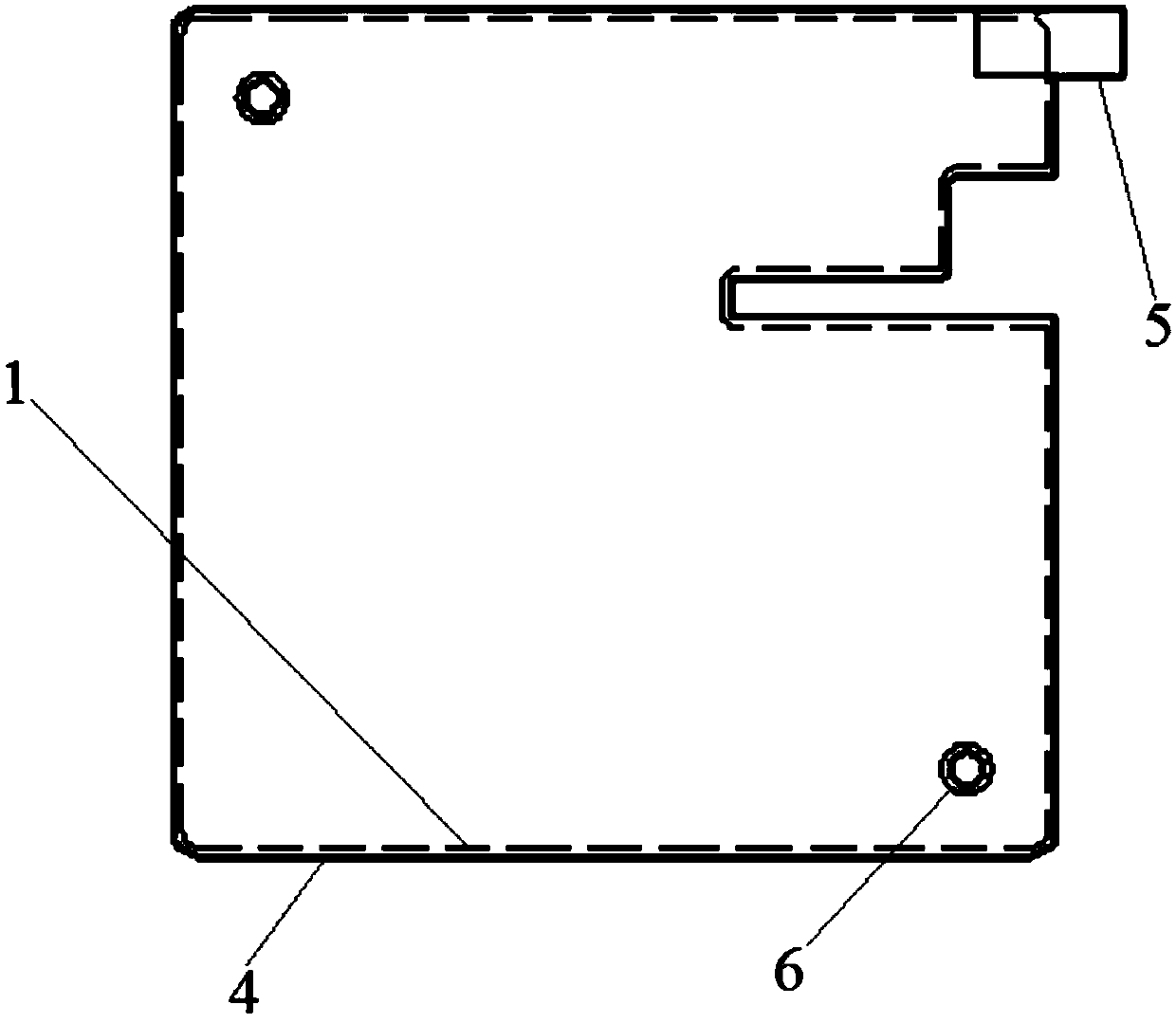

[0036] Such as figure 1 , figure 2 A edging type ferrite product is shown. The ferrite product includes a ferrite 1 and a single-sided adhesive 2 and a double-sided adhesive 3 respectively attached to both sides of the ferrite 1. The double-sided adhesive The edge of 3 and the edge of the single-sided adhesive 2 are attached together, and the edge of the ferrite 1 is completely wrapped between the single-sided adhesive 2 and the double-sided adhesive 3.

[0037] Among them, the single-sided adhesive 2 includes a single-sided adhesive bonding part 201 that is bonded to one side of the ferrite 1 and a single-sided adhesive attached to the periphery of the single-sided adhesive bonding part 201 and connected to the single-sided adhesive bonding part 201 Adhesive edging part 202, double-sided tape 3 includes a double-sided tape attaching part 301 attached to the other side of ferrite 1, and a double-sided tape attaching part 301 around the periphery of the double-sided tape attaching...

Embodiment 2

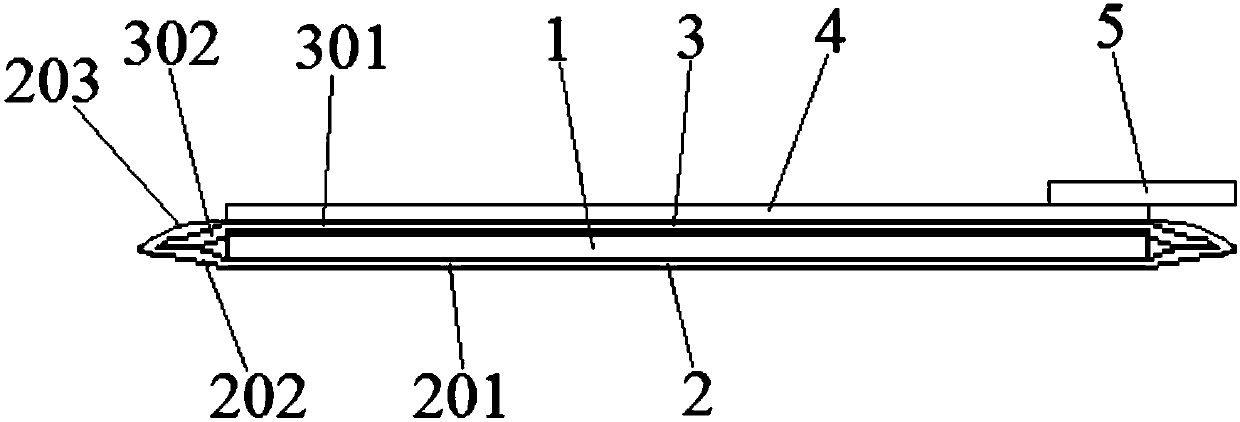

[0045] In this embodiment, such as image 3 As shown, the single-sided adhesive edging portion 202 is provided with a single-sided adhesive flanging portion 203, one side of the double-sided adhesive edging portion 302 is attached to the single-sided adhesive edging portion 202, and the other side is attached to the single-sided adhesive The flange portion 203 is attached to each other, and the rest is the same as in Embodiment 1.

Embodiment 3

[0047] In this embodiment, the distance between the edge of the double-sided tape 3 and the edge of the ferrite 1 is 0.4 mm, and the rest is the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com