Patents

Literature

109results about How to "Avoid Separation Situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

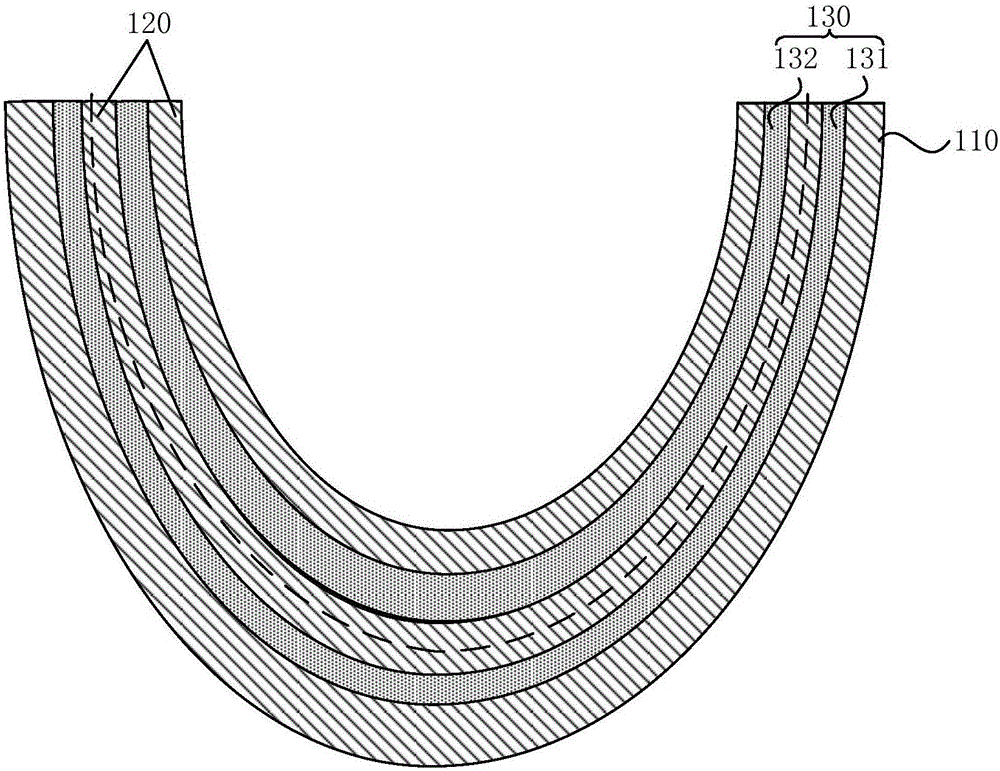

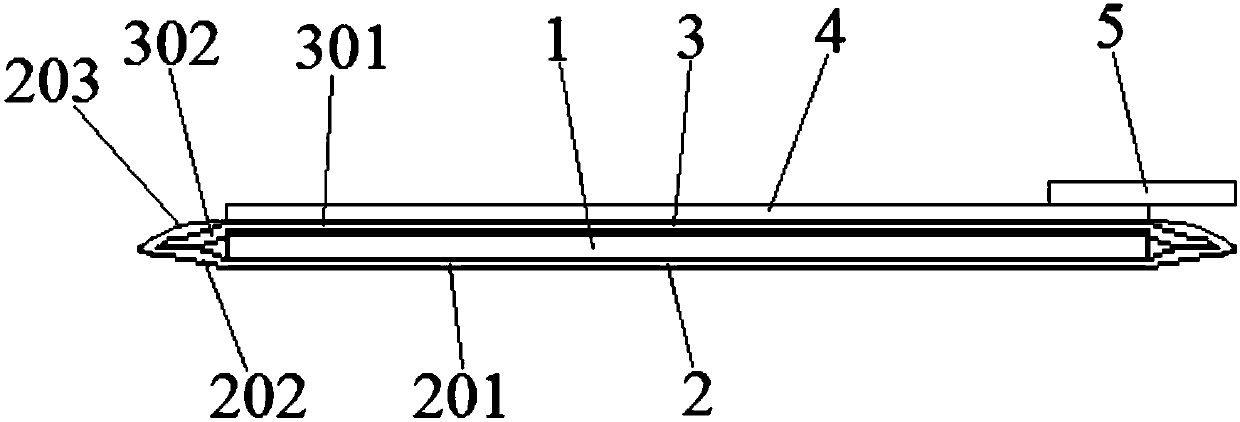

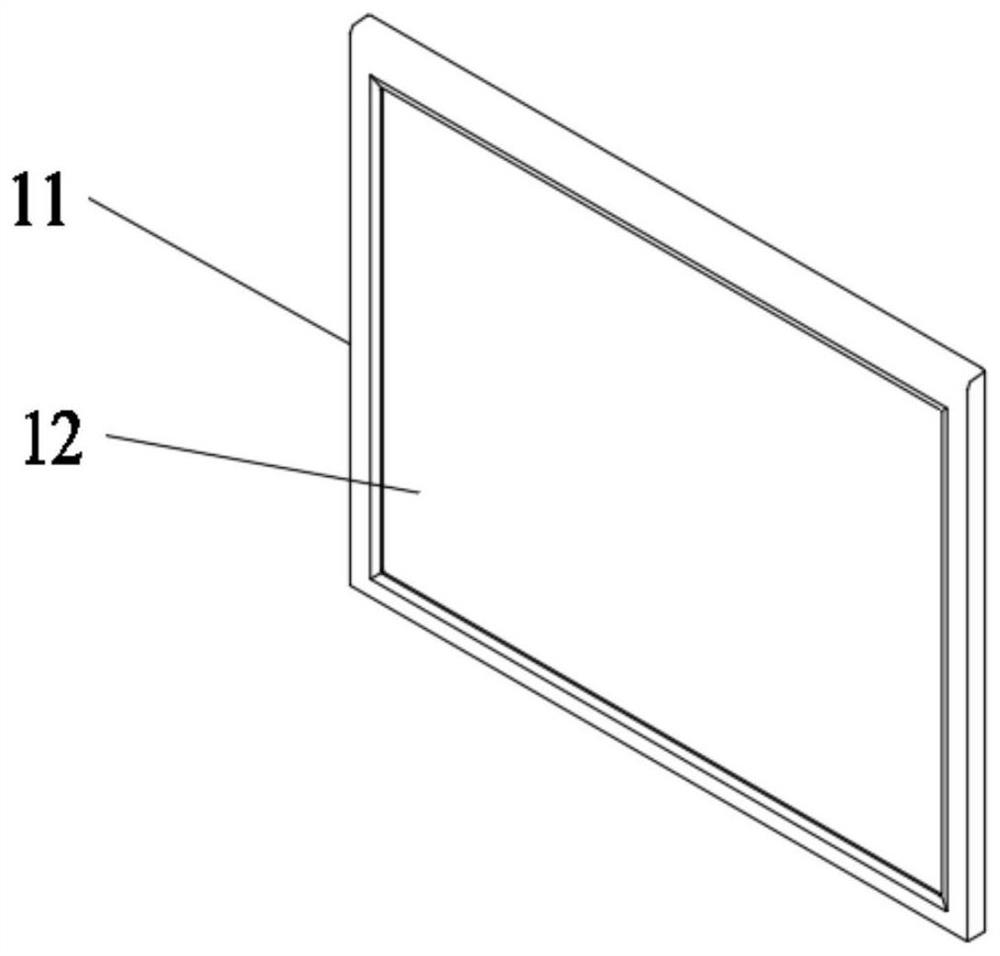

Curved-surface display device

ActiveCN106530973AIncrease elasticityIncrease stickinessIdentification meansSurface displayComputer science

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

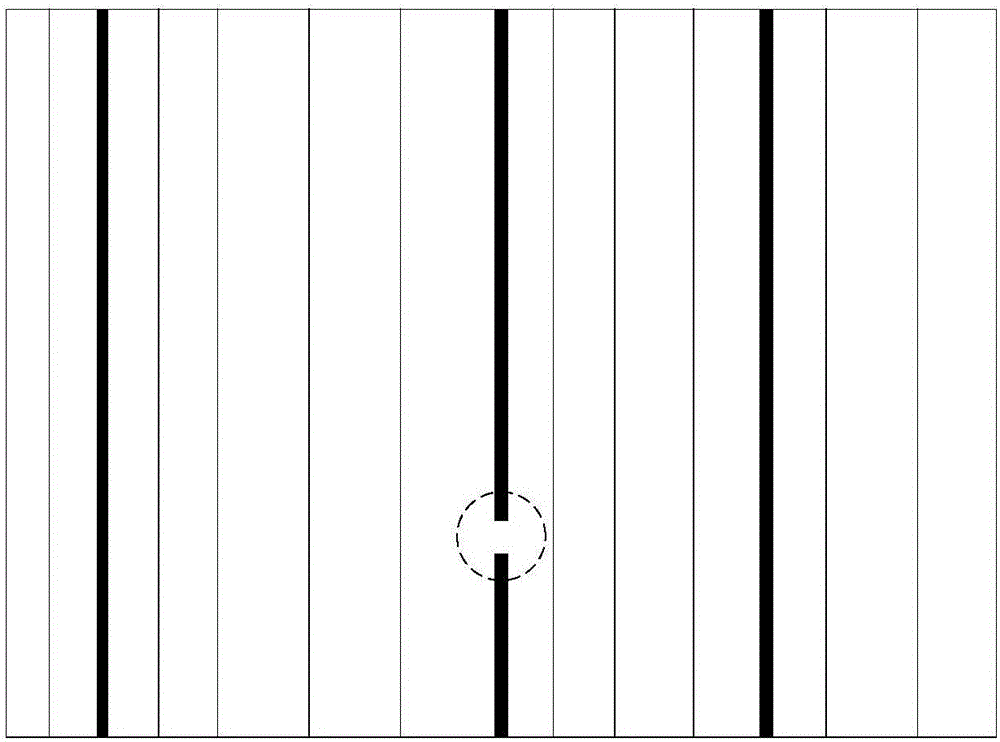

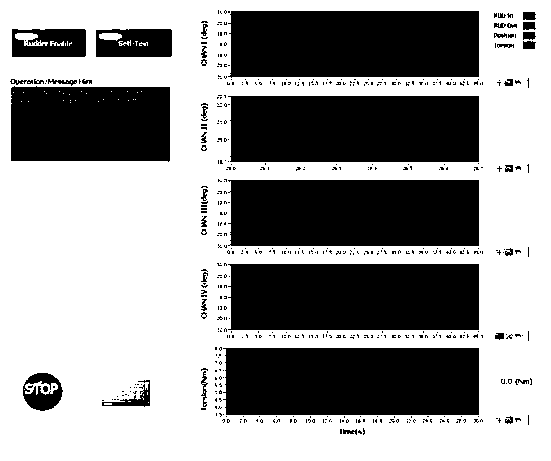

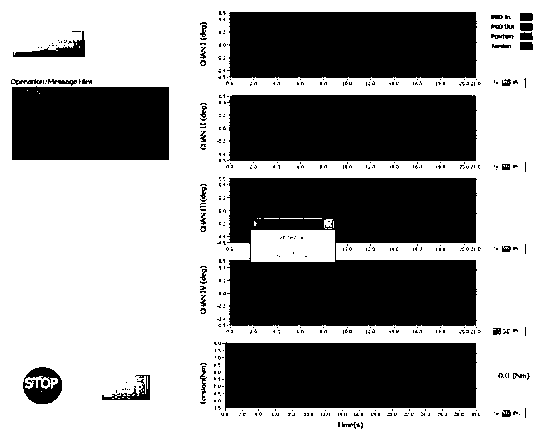

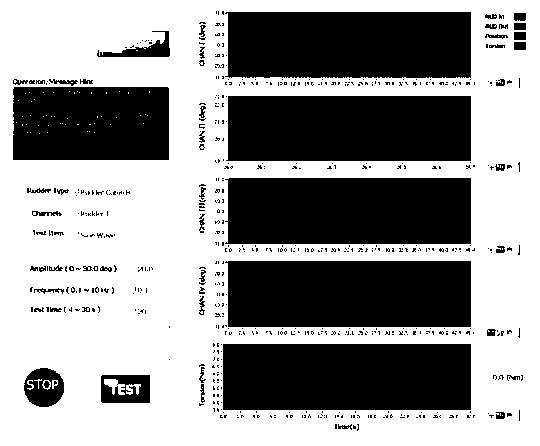

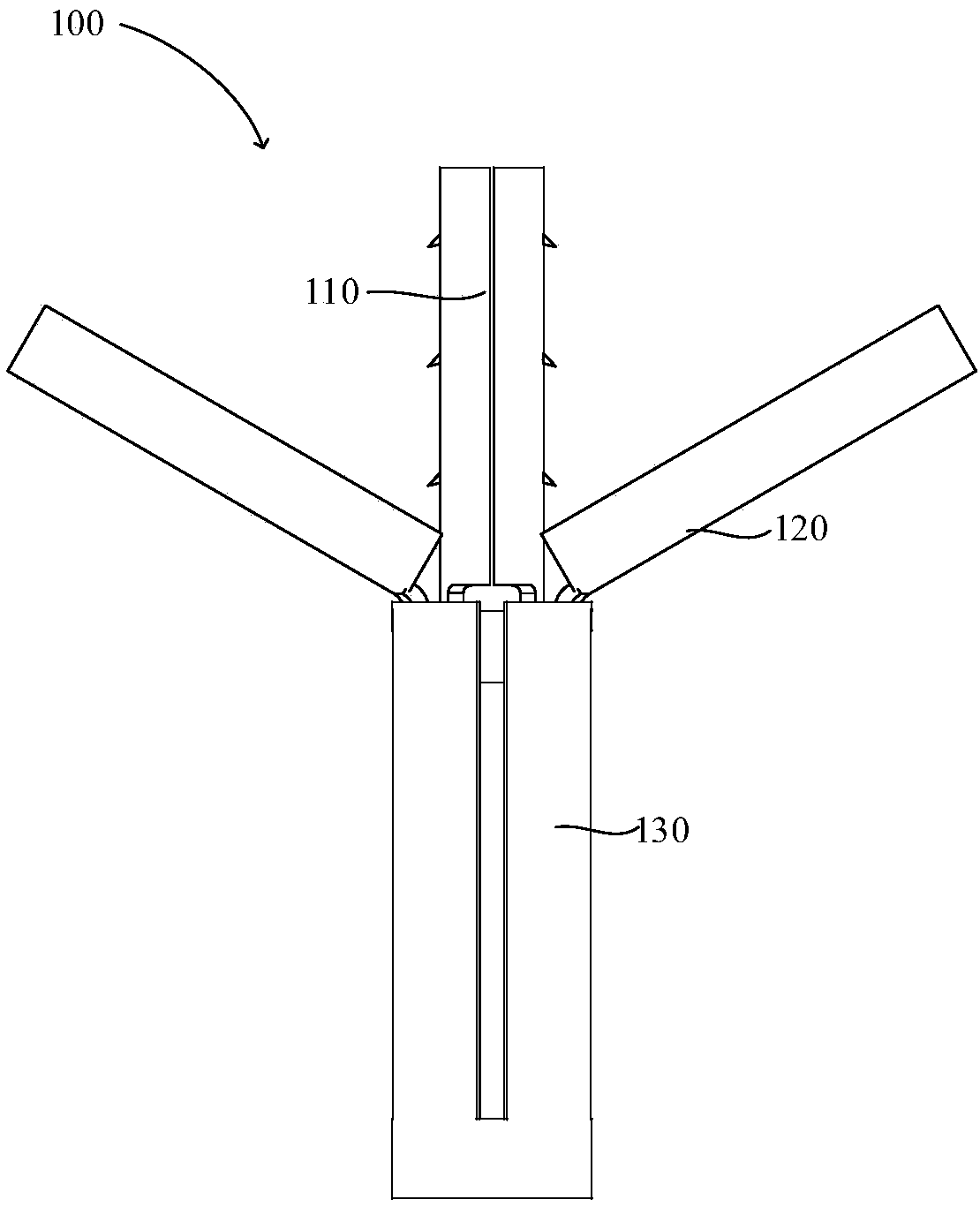

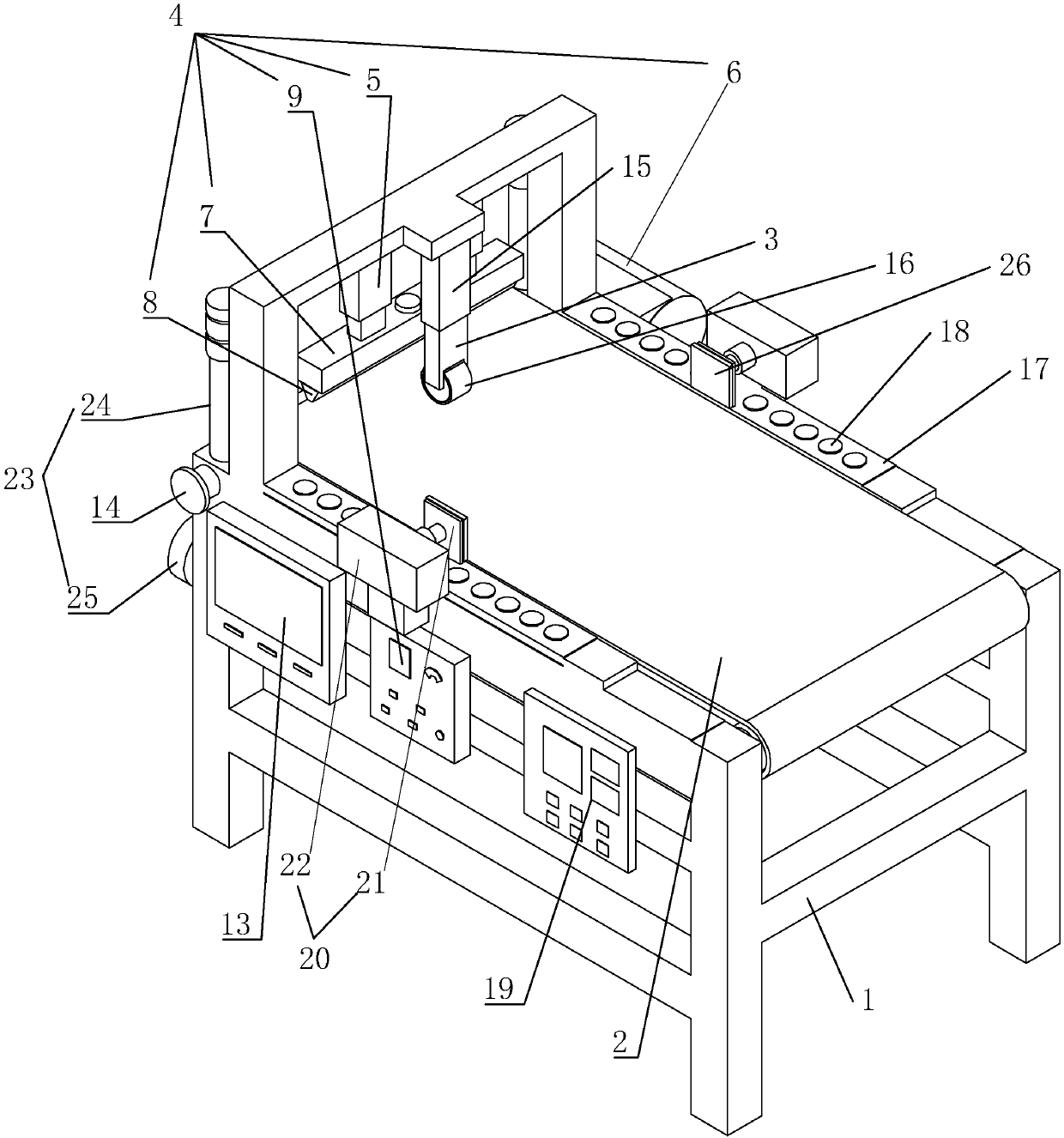

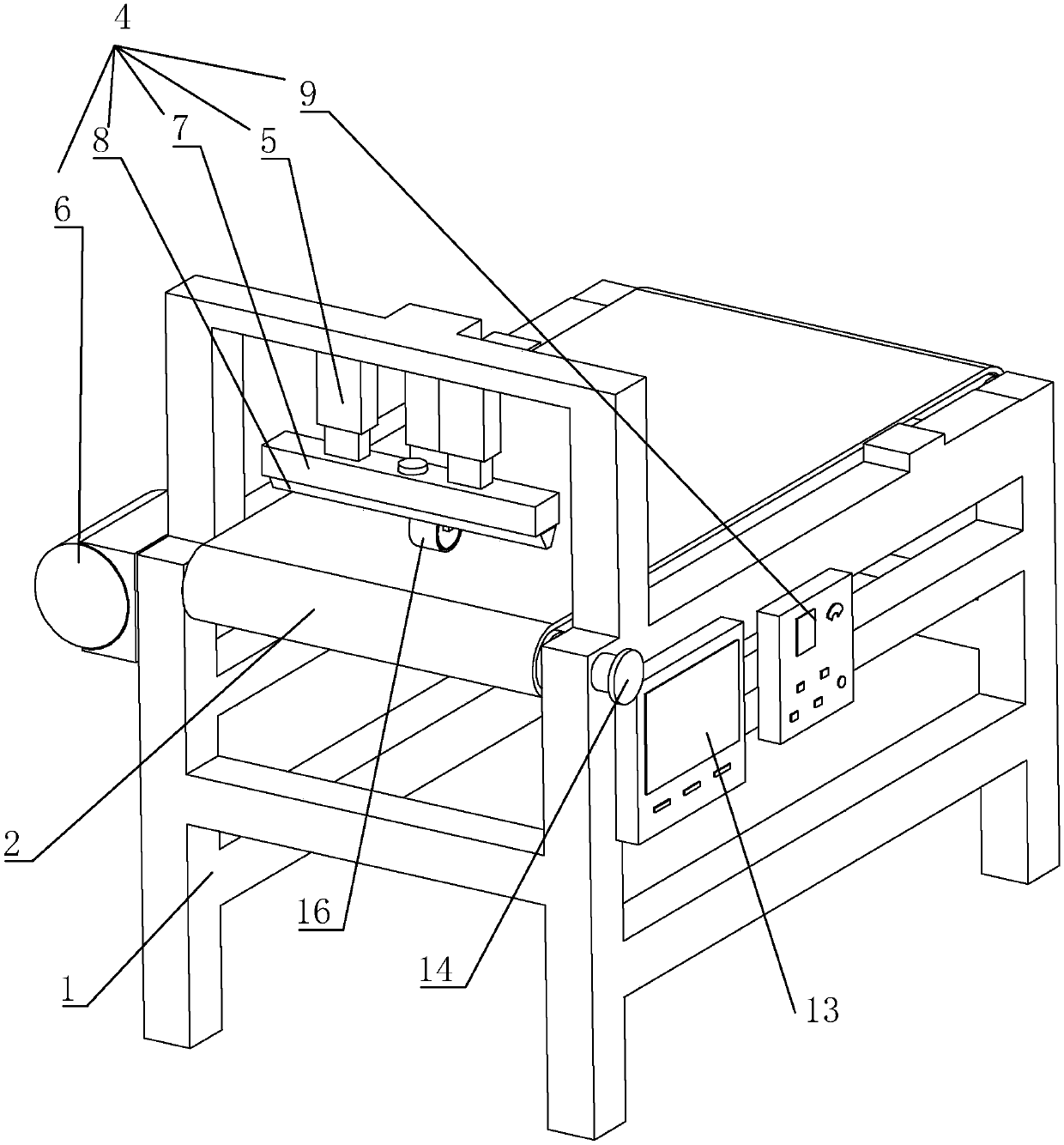

Steering engine tester and testing method thereof

ActiveCN103076195AEasy to observe test resultsAvoid lossStructural/machines measurementKey pressingEngine testing

The invention relates to a steering engine tester and a testing method thereof, which belong to the technical field of guided bombs. The tester comprises a control cabinet and a simulation load table, wherein the control cabinet comprises a steering engine controller, a regulated power supply, an industrial control computer, a display, a keyboard and a main power supply switch; the simulation load table comprises a photoelectric encoder, a torque sensor and a magnetic powder brake; a steering engine shaft of a steering engine to be tested is mechanically connected with a rotating shaft of the photoelectric encoder through a shaft coupling; the steering engine to be tested is in digital signal communication with the steering engine controller through a data line; and steering engine testing software is installed in the industrial control computer. The tester provided by the invention has the advantages of more plentiful testing contents, more complete testing equipment, more intelligent testing software, prompting of operating information on a software interface, shielding of keys which are required to be operated, change of parameter input items according to selected testing items, information prompt for improper operation, and great reduction in the probability of error operation.

Owner:CHINA AEROSPACE TIMES ELECTRONICS CORP

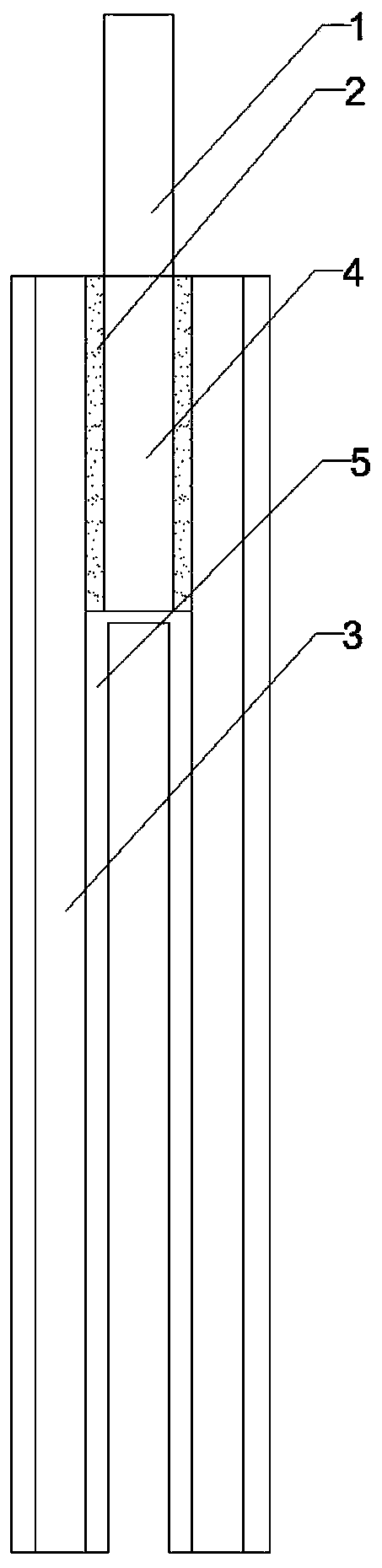

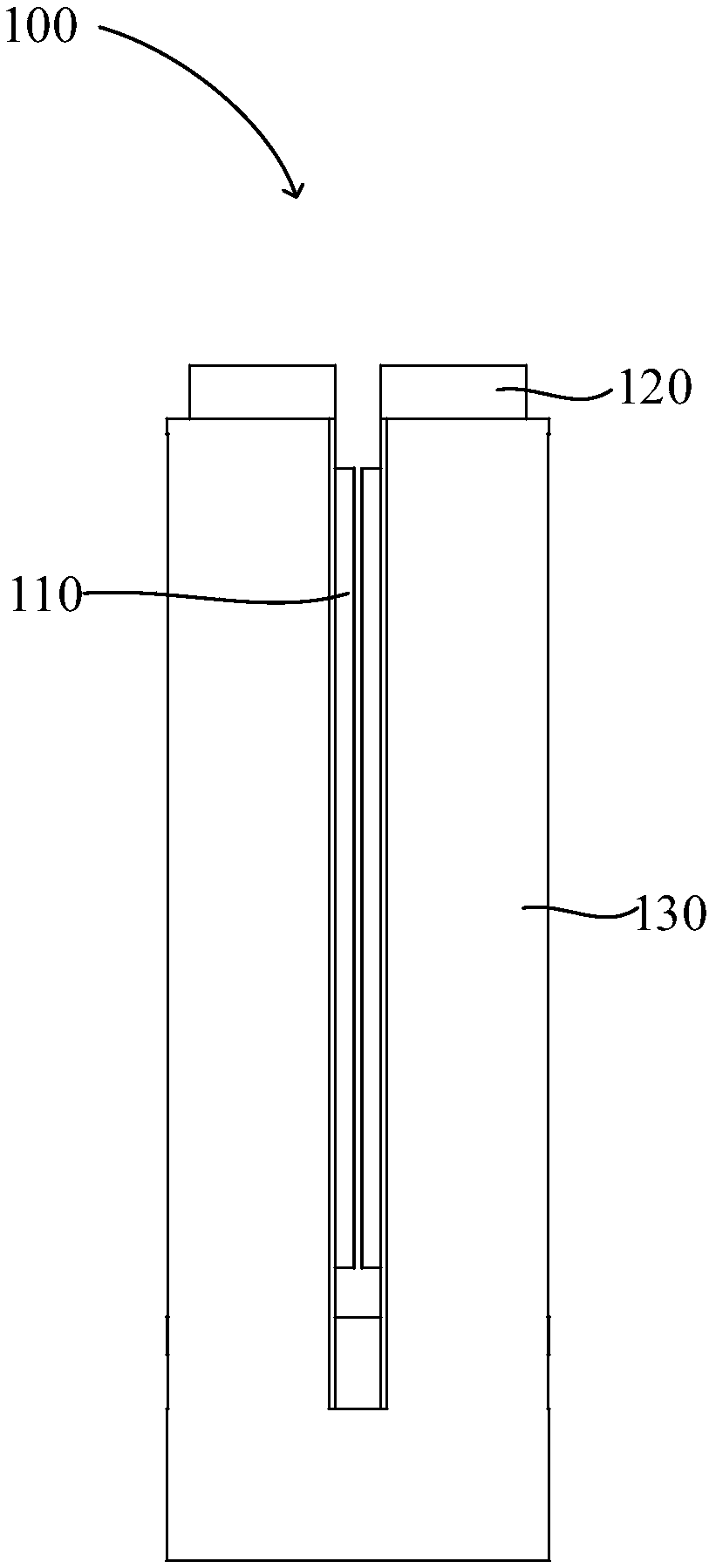

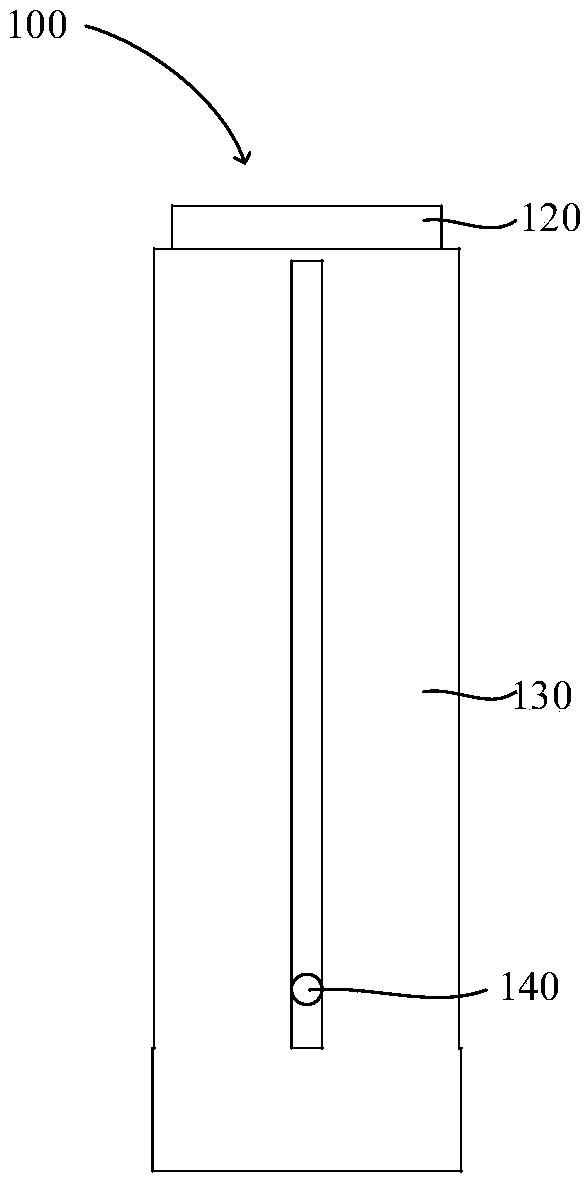

Current collector electrode structure, secondary battery and preparation method thereof

PendingCN110828775AAvoid Separation SituationsWon't breakFinal product manufactureElectrode carriers/collectorsElectrolysisEngineering

The invention discloses a current collector electrode structure, and relates to the technical field of secondary batteries. The current collector electrode structure in the application comprises a current collector and a tab. The current collector comprises an insulating layer and a conductive layer used for carrying an electrode active material and arranged on at least one surface of the insulating layer. The tab is arranged on the current collector and connected with the current collector through an electrolysis-resistant binder or conductive adhesive, and the bonding strength of the binderor the conductive adhesive is not less than 7N / cm. The tab and the current collector are connected by the binder or the conductive adhesive, so that welding is avoided, and the conductive layer on thesurface of the insulating layer cannot be damaged by the connecting structure of the tab. Besides, the binder or the conductive adhesive used in the application has electrolysis resistance, and the bonding strength of the binder or the conductive adhesive is not less than 7N / cm, so that the connection strength between the tab and the current collector is ensured, and the situation in which the tab is separated from the current collector in the subsequent assembly and use process is avoided.

Owner:JIANGSU ADVANCED MATERIAL TECH CO LTD

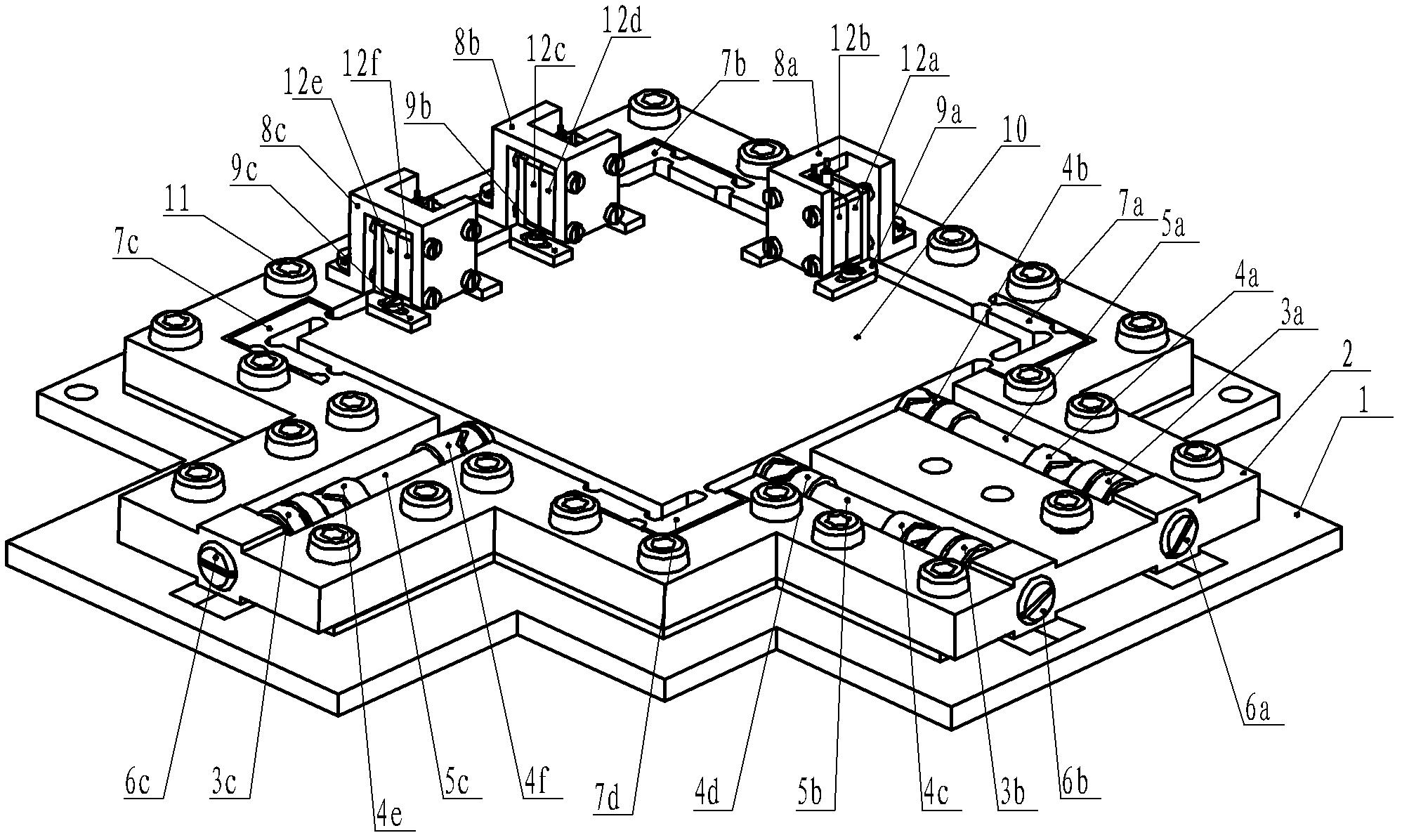

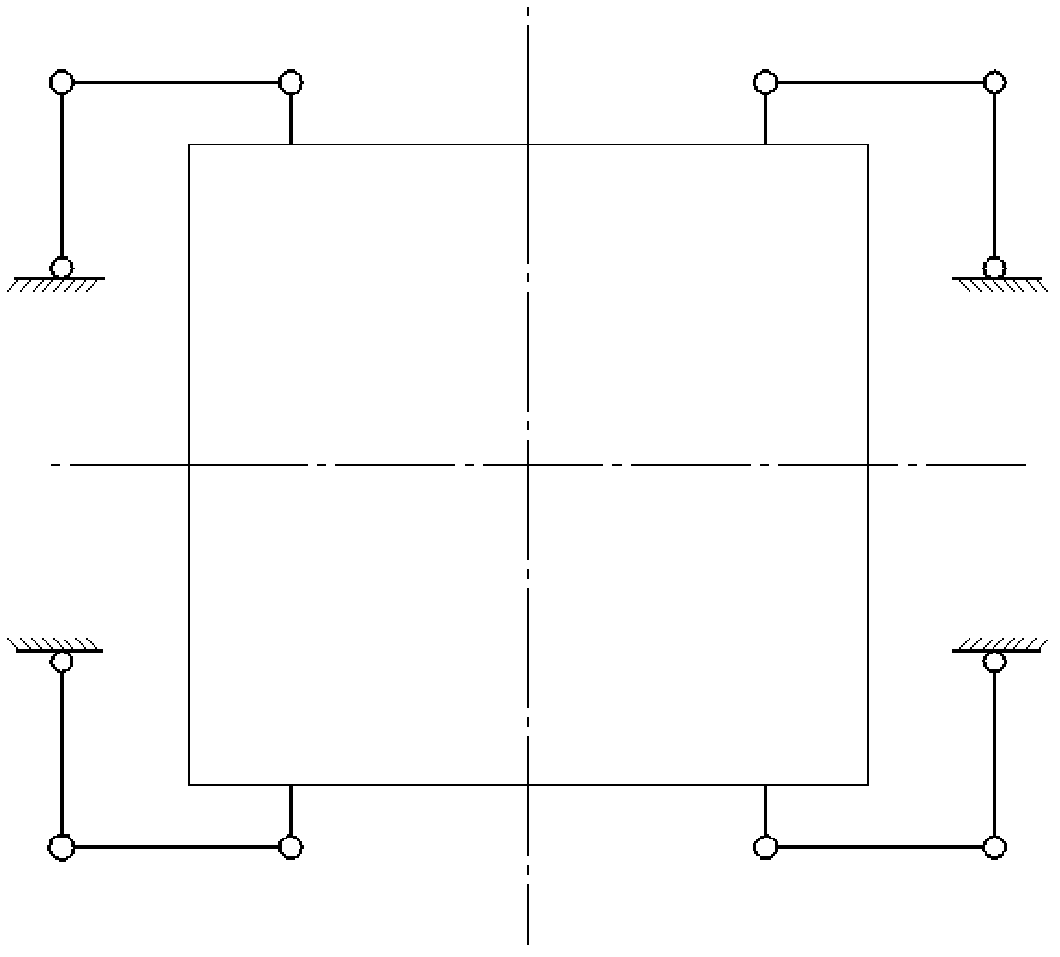

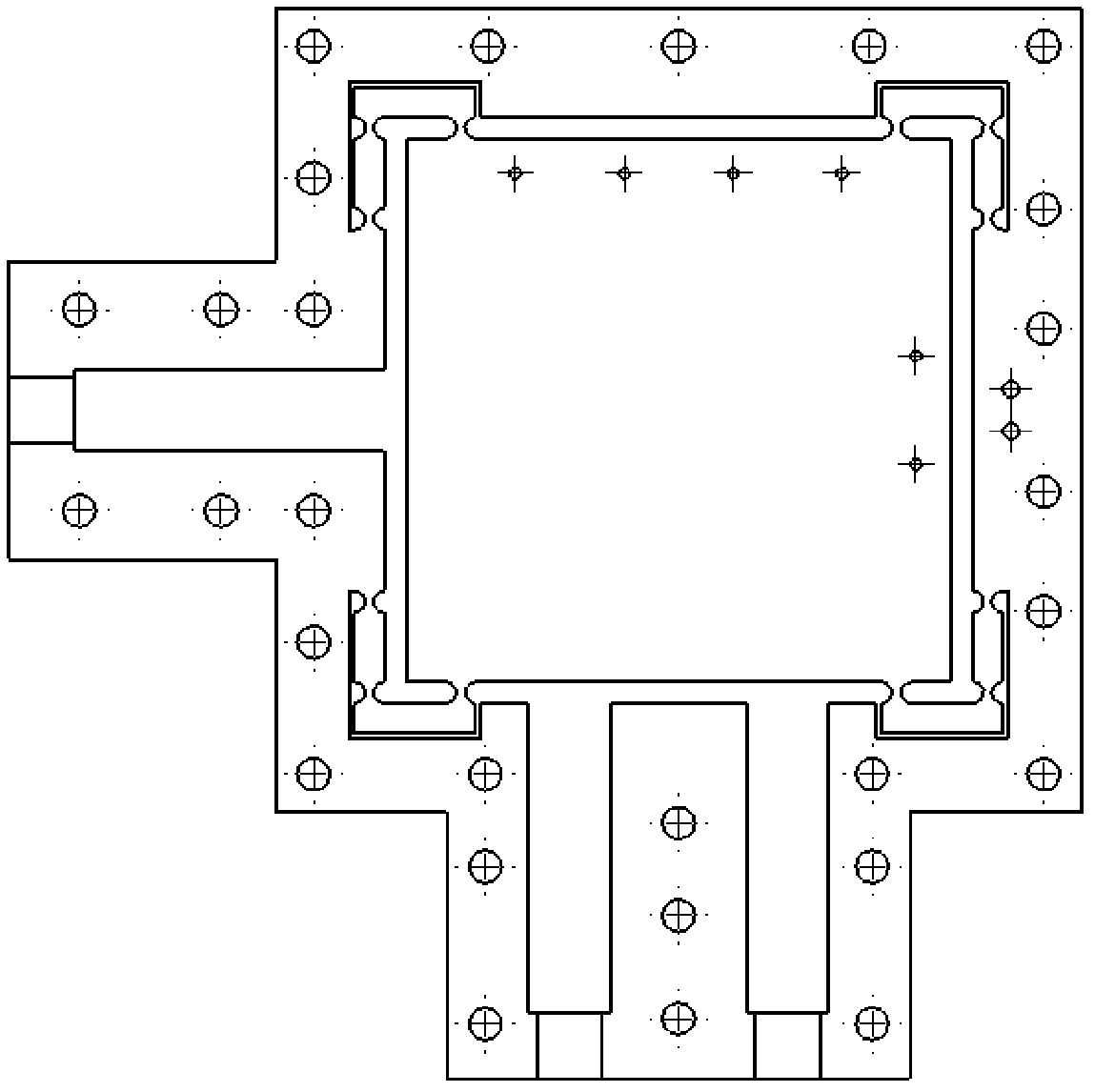

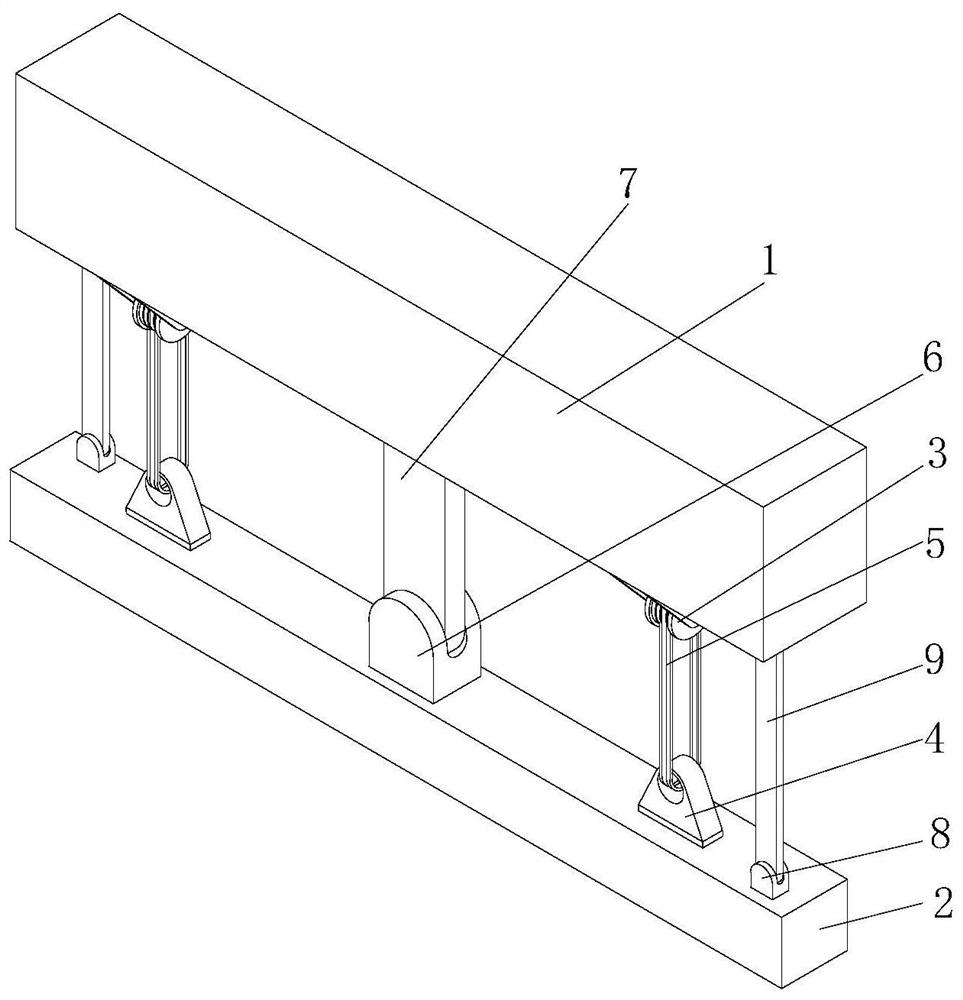

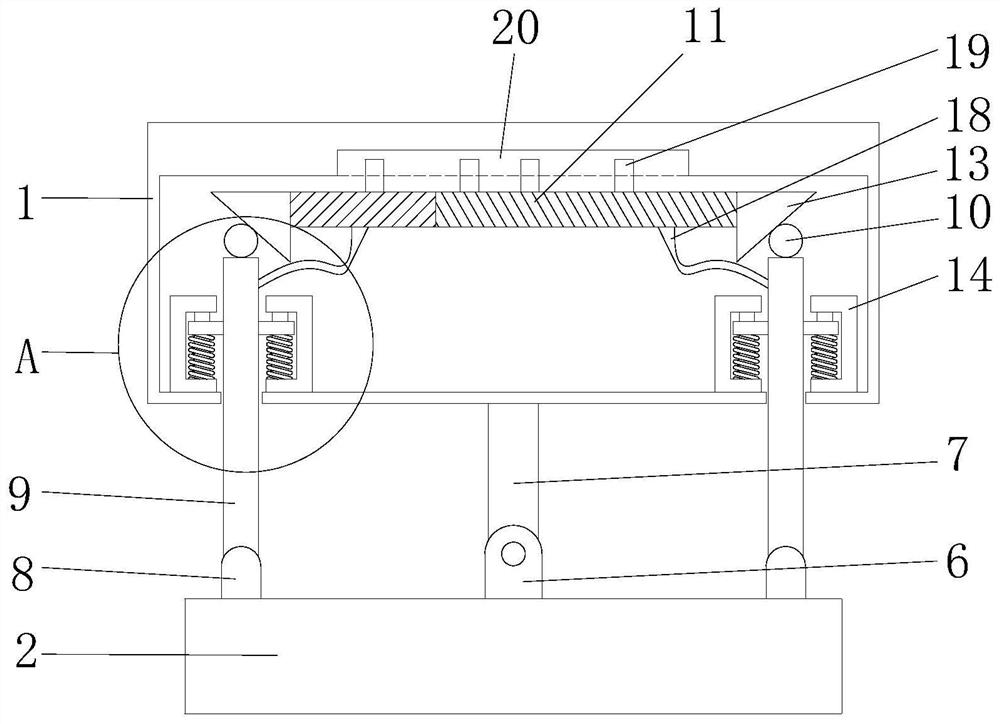

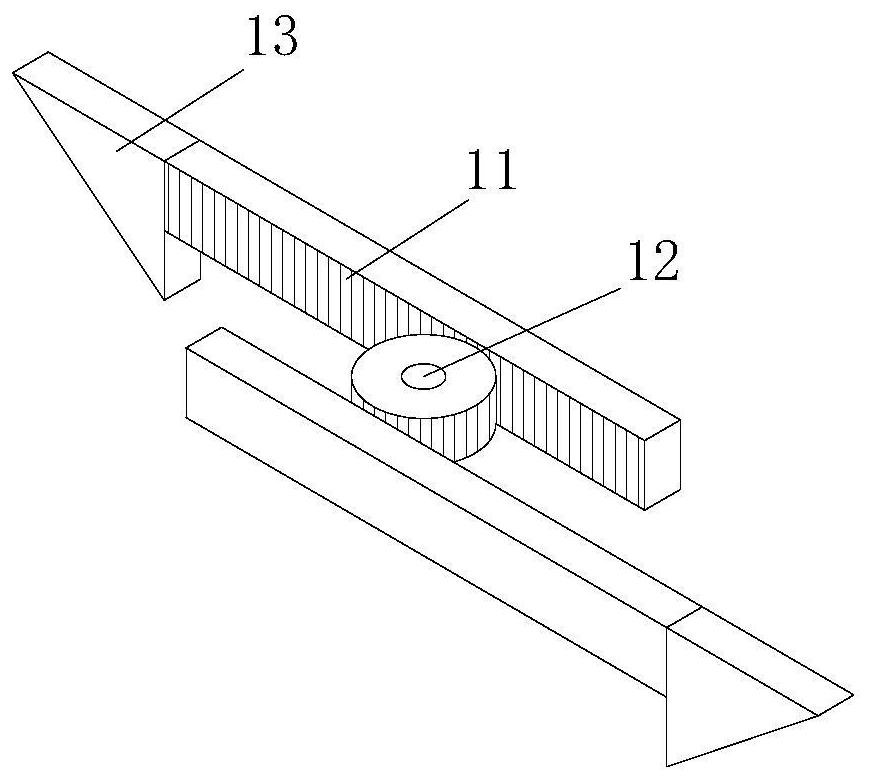

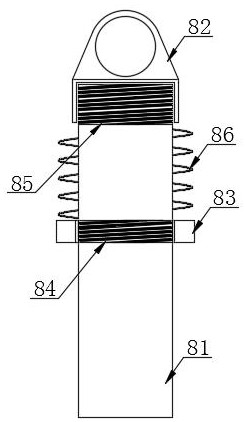

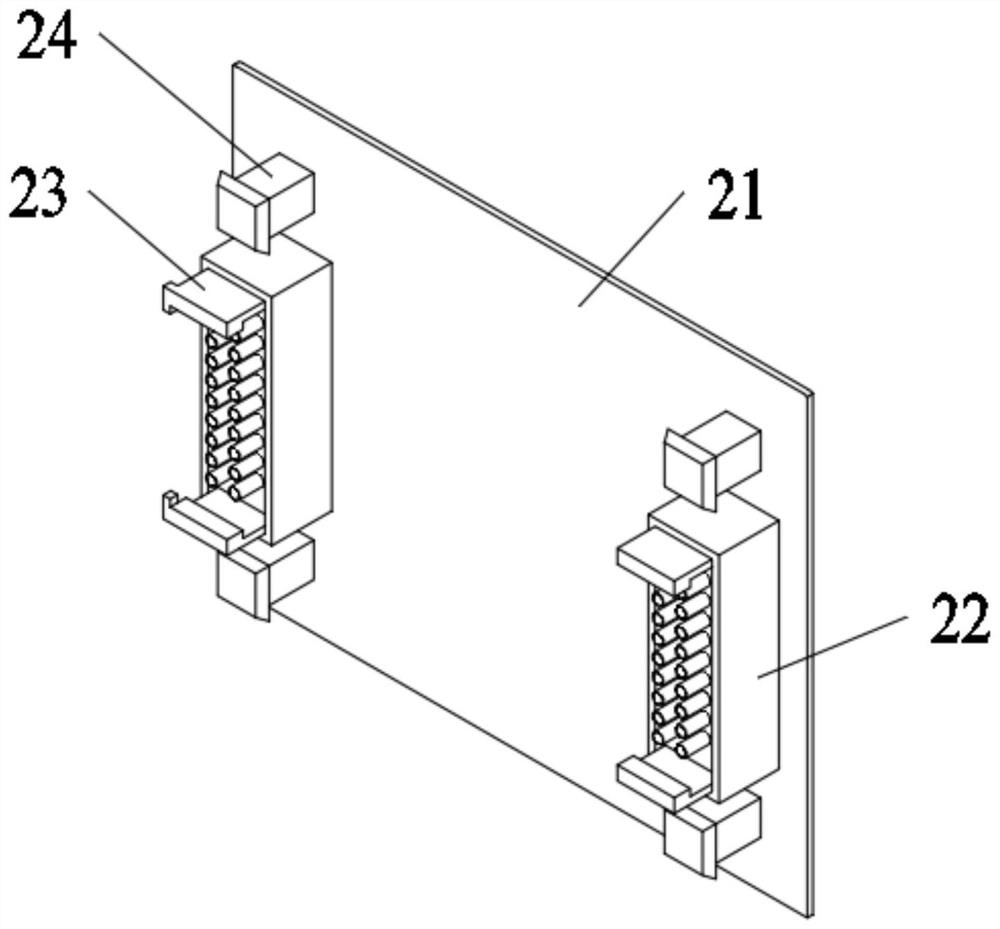

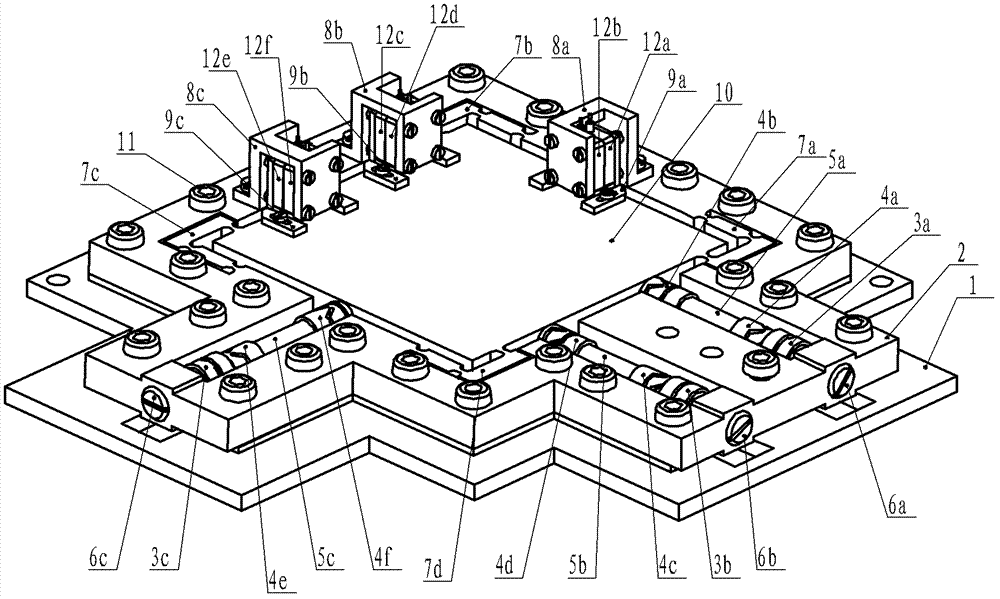

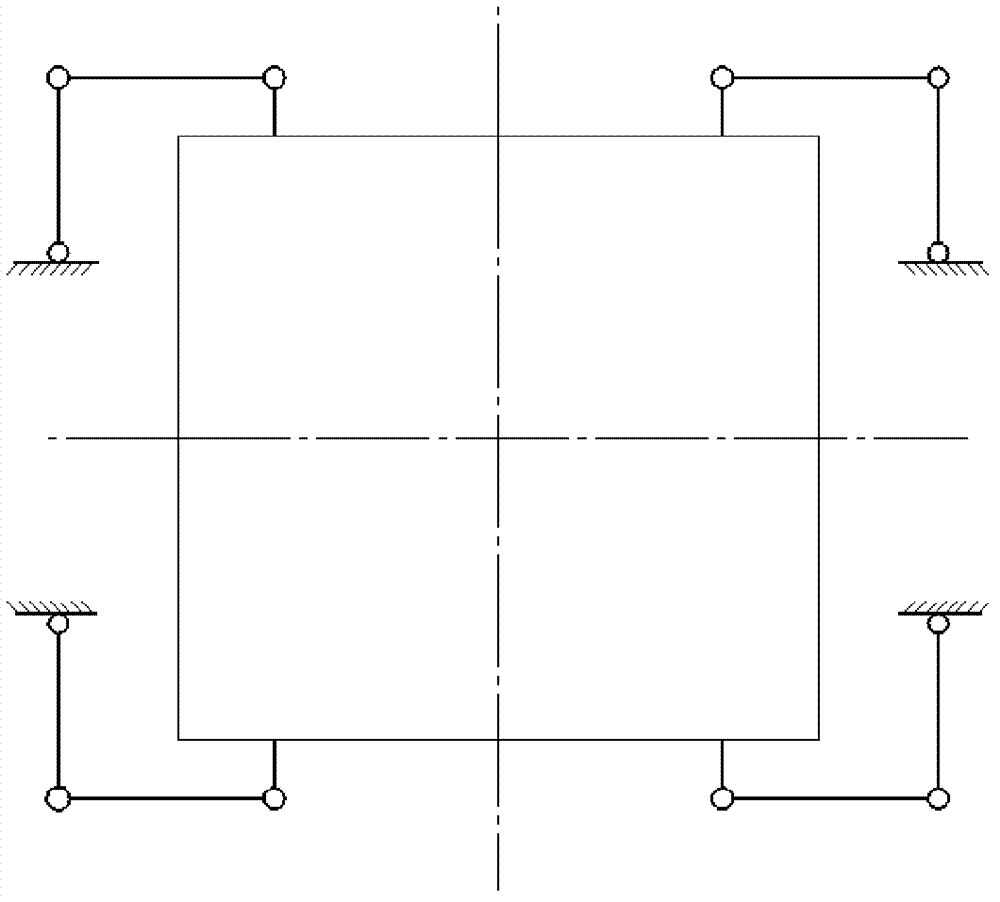

Parallel micro-positioning platform based on driving of piezoelectric ceramic driver and micro-positioning platform system

ActiveCN102324253AHigh positioning accuracyImproved straightness of motionInstrumental componentsElectricityLoop control

The invention relates to a parallel micro-positioning platform based on the driving of piezoelectric ceramic drivers and a system, which comprises a micropositioner, a baseplate and a control system, wherein the micropositioner comprises a movable platform and four flexible hinges, a single piezoelectric ceramic driver and a pair of side-by-side piezoelectric ceramic drivers are respectively arranged at the two adjacent sides of the movable platform, one end of each piezoelectric ceramic driver and the movable platform are connected through a universal hinge, the other end of each piezoelectric ceramic driver is connected with a pre-tightening spring through the other universal hinge, and the pre-tightening spring is pre-tightened through a bolt; a capacitance sensor is respectively arranged on the upper surface of the movable platform along the axis direction of each piezoelectric ceramic driver; and one capacitance sensor is positioned on a sensor bracket fixed at the outer side of the micropositioner, the other capacitance sensor is positioned on the other sensor bracket fixed on the upper surface of the movable platform, and computer closed-loop control is adopted. Through theparallel micro-positioning platform and system, the displacement straightness accuracy and the positioning precision are effectively improved, coupling is eliminated, driver separation is avoided, and piezoelectric drivers are protected. By adopting an LQG (Linear Quadratic Gaussian) algorithm of an augmented noise model, narrowband foundation disturbance is effectively inhibited, and the positioning precision is improved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Cake type mooncake and preparation method thereof

ActiveCN104222241AExtended shelf lifeSolve the defect that can not be stuffedDough treatmentBakery productsYolkPreservative

The invention discloses cake type mooncake and a preparation method of the cake type mooncake. The cake type mooncake comprises soft stuffing and cake type mooncake skin covering the soft stuffing. The cake type mooncake skin comprises, by weight, 24% to 26% of weak strength flour, 4% to 6% of high gluten flour, 20% to 22% of egg pulp, 2% to 3% of yolk, 20% to 22% of castor sugar, 20% to 22% of shortening, 1% to 2% of milk powder, 0.2% to 0.3% of salt, 0.4% to 0.5 % of baking powder, 0.1% to 0.2% of cake emulsifier, 0.05% to 0.08% of thickener and 0.1% of corrosion remover. Before the cake type mooncake is baked, encrusting is conducted through a universal encrusting machine, the cake type mooncake is directly baked after encrusting, the stuffing does not fall to the bottom or deform, the taste of fragrant, sweet and soft of cake is kept, the defect that traditional cake is short in shelf life is overcome, and the shelf life of the cake type mooncake can reach six to twelve months under the condition of normal temperature and sealed package.

Owner:GUANGZHOU RESTAURANT GRP LIKOUFU FOOD

Novel mobile phone back cover and production process thereof

PendingCN110077068ANo warpingThere is no warpage fromSynthetic resin layered productsLaminationVapor barrierUV curing

The invention provides a novel mobile phone back cover and a production process thereof, and relates to the technical field of photoelectric products. The novel mobile phone back cover comprises an anti-explosion base material layer and a PC board layer; the anti-explosion base material layer is an aliphatic TPU film formed through tape casting or coating or an acrylic acid resin film which is coated with acrylic acid resin and formed through UV curing or a PC base material; the anti-explosion base material layer is coated with an adhesive layer formed by acrylic acid pressure-sensitive adhesive or hot melt adhesive; and one side of the PC board layer is coated with one hardening layer and the other side of the PC board layer is coated with one vapor barrier coating and is compounded withthe adhesive layer. Warping deformation of the material in the processing process can be avoided to a great degree, bubble points are reduced and the product yield is increased.

Owner:HENGSHAN JIACHENG NEW MATERIAL

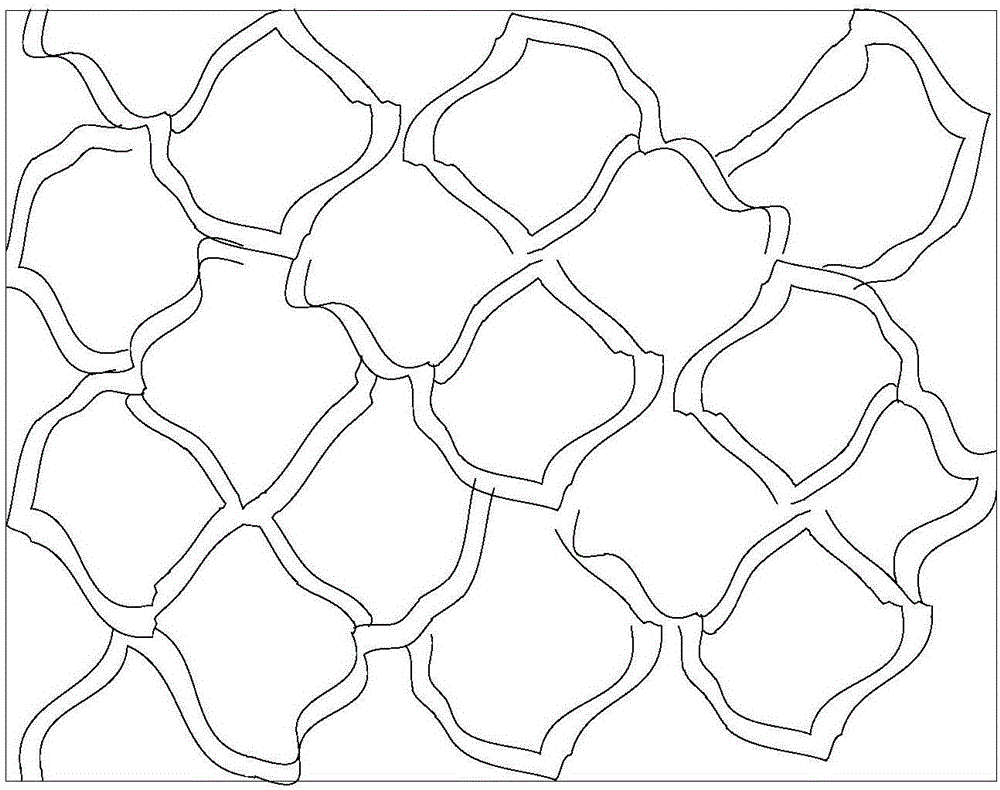

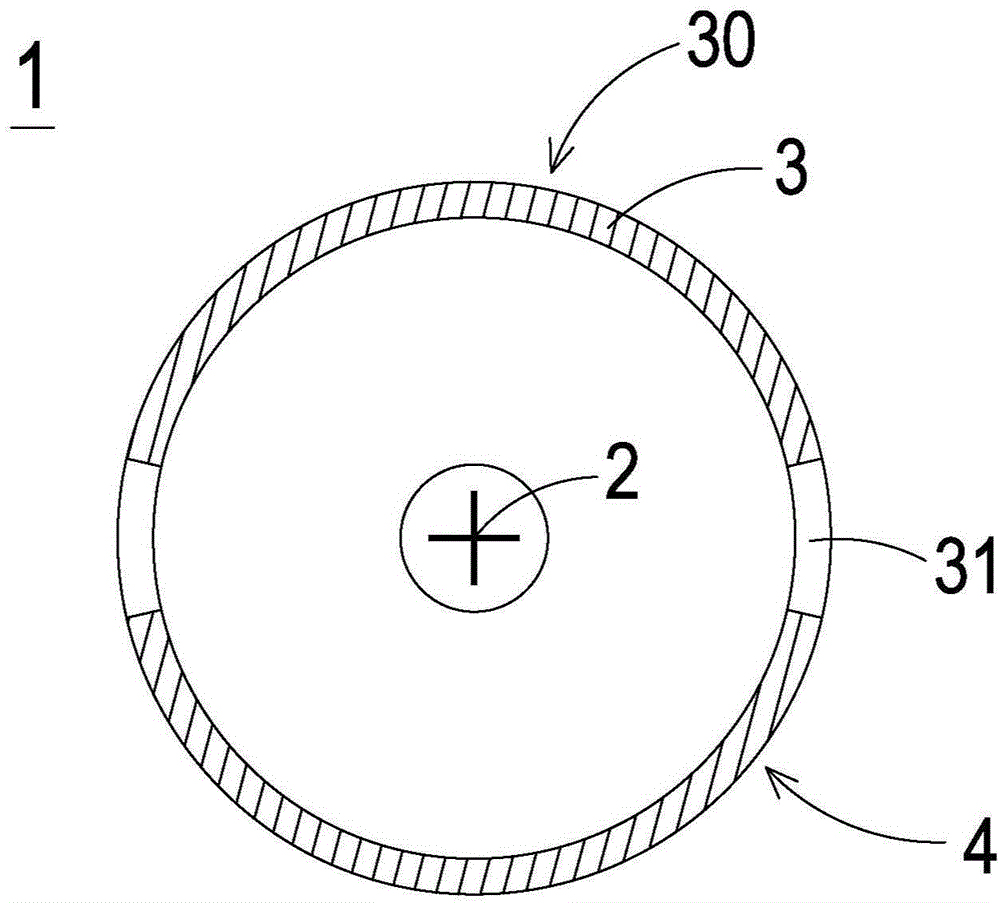

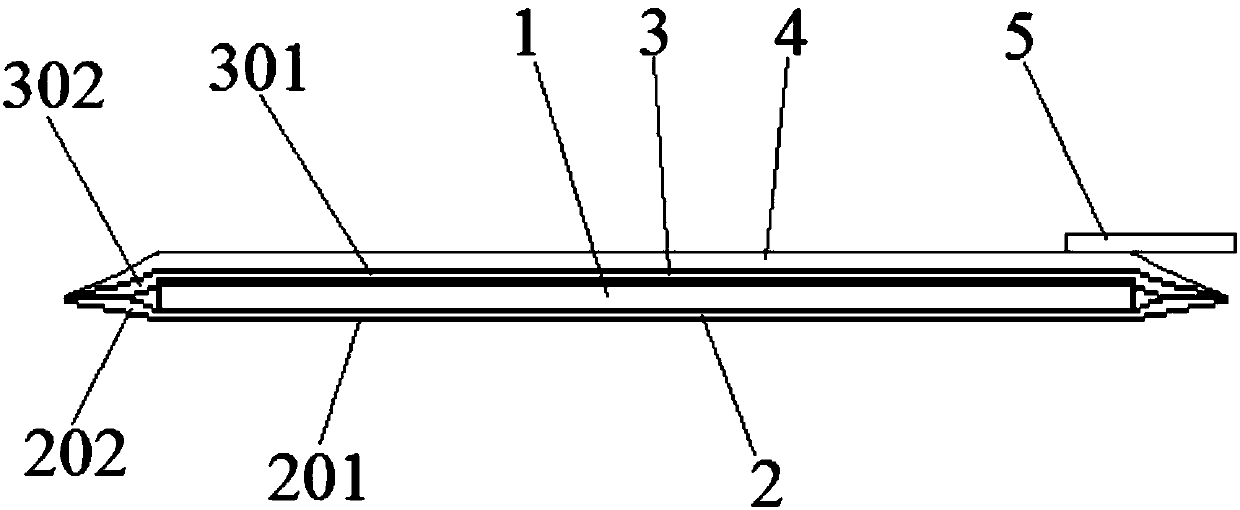

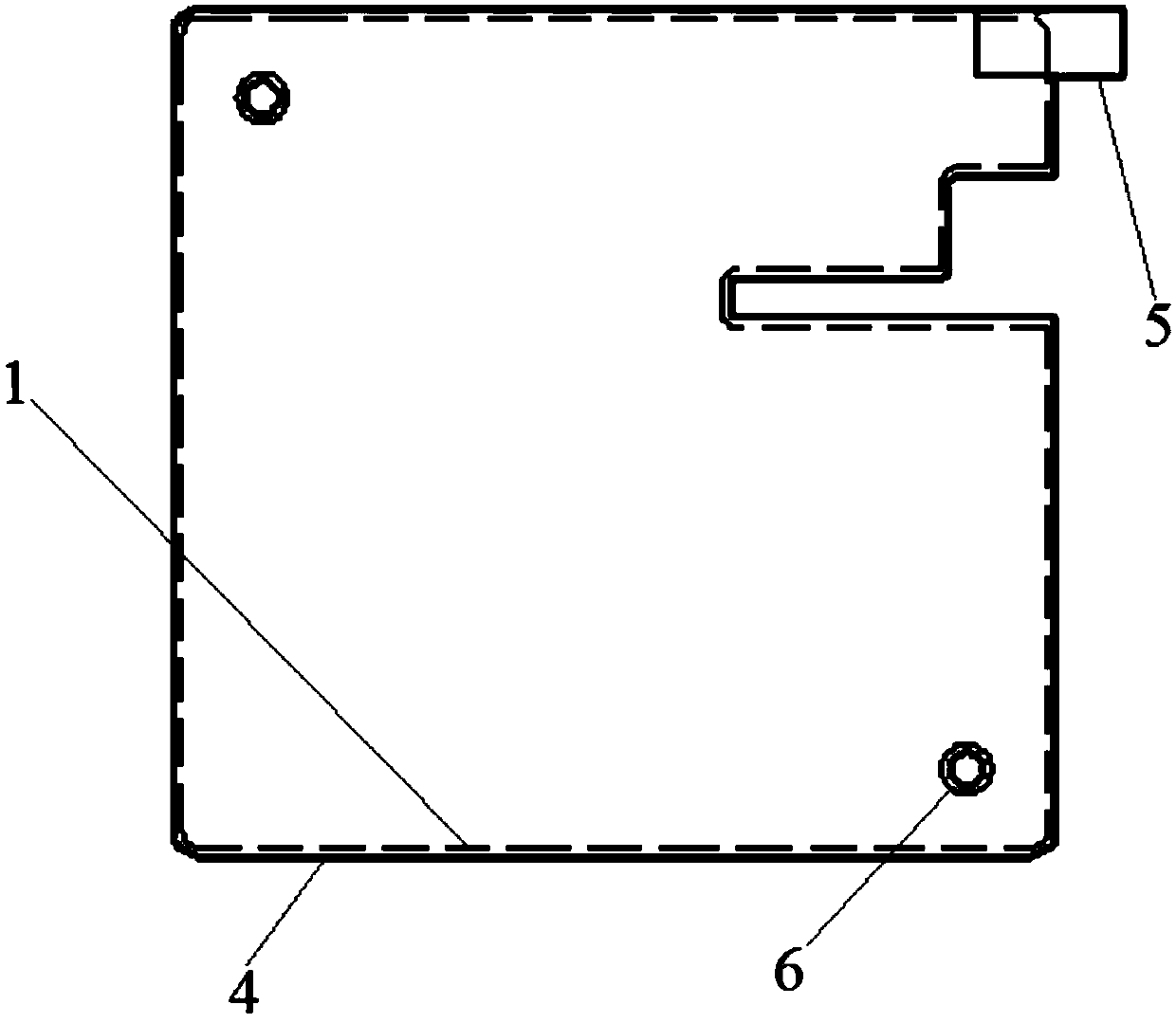

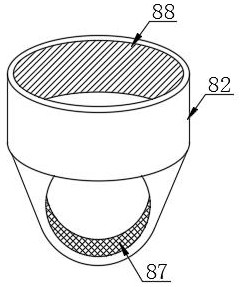

Wavelength-converting Device And Illumination System Using Same

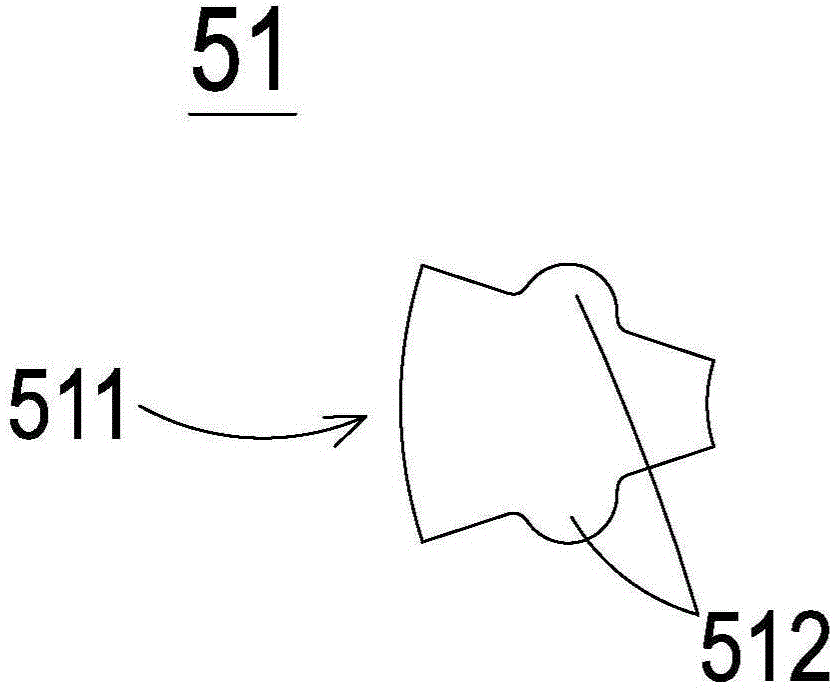

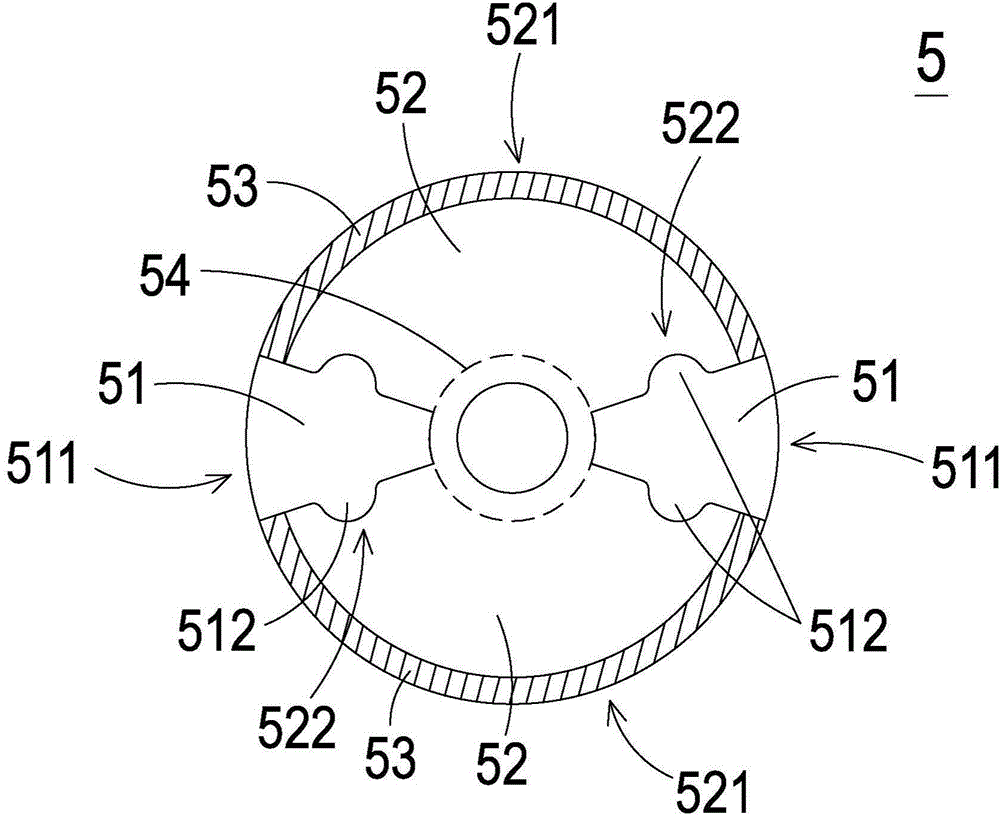

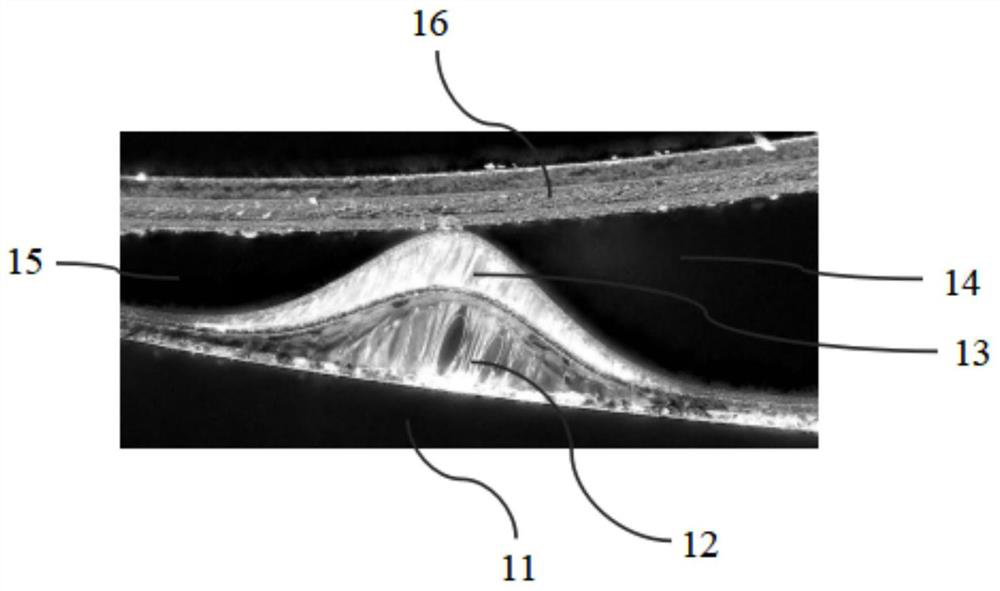

ActiveCN106154718AReduce wind noiseAvoid Separation SituationsProjectorsSpectral modifiersEngineeringLength wave

The present invention relates to a wavelength-converting device and an illumination system using the same. The wavelength-converting device includes a first substrate, a second substrate and a first wavelength-converting material. The first substrate has a first region and a first engagement portion. The second substrate is disposed adjacent to the first substrate and has a second region and a second engagement portion. The second engagement portion and the first engagement portion have complementary shapes. The first wavelength-converting material is disposed on the second region for converting a light in a first waveband into a light in a second waveband. The light in the first waveband is transmitted through the first region, and the light in the second waveband is reflected by the second region. The first region and the second region are staggered, so that the first engagement portion and the second engagement portion are engaged and fixed with each other. As a result, the safety and stability are enhanced, and the noise is reduced.

Owner:DELTA ELECTRONICS INC

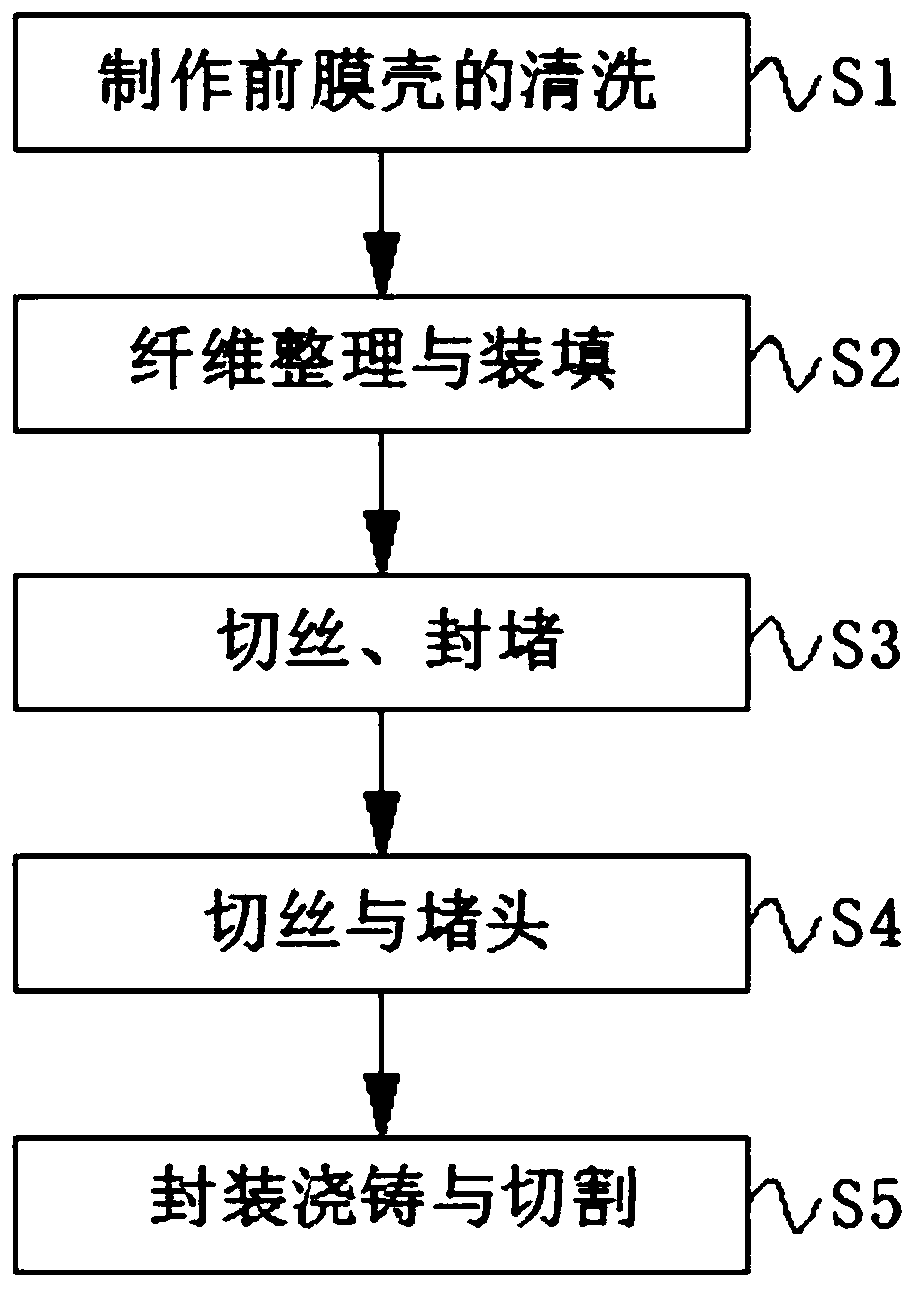

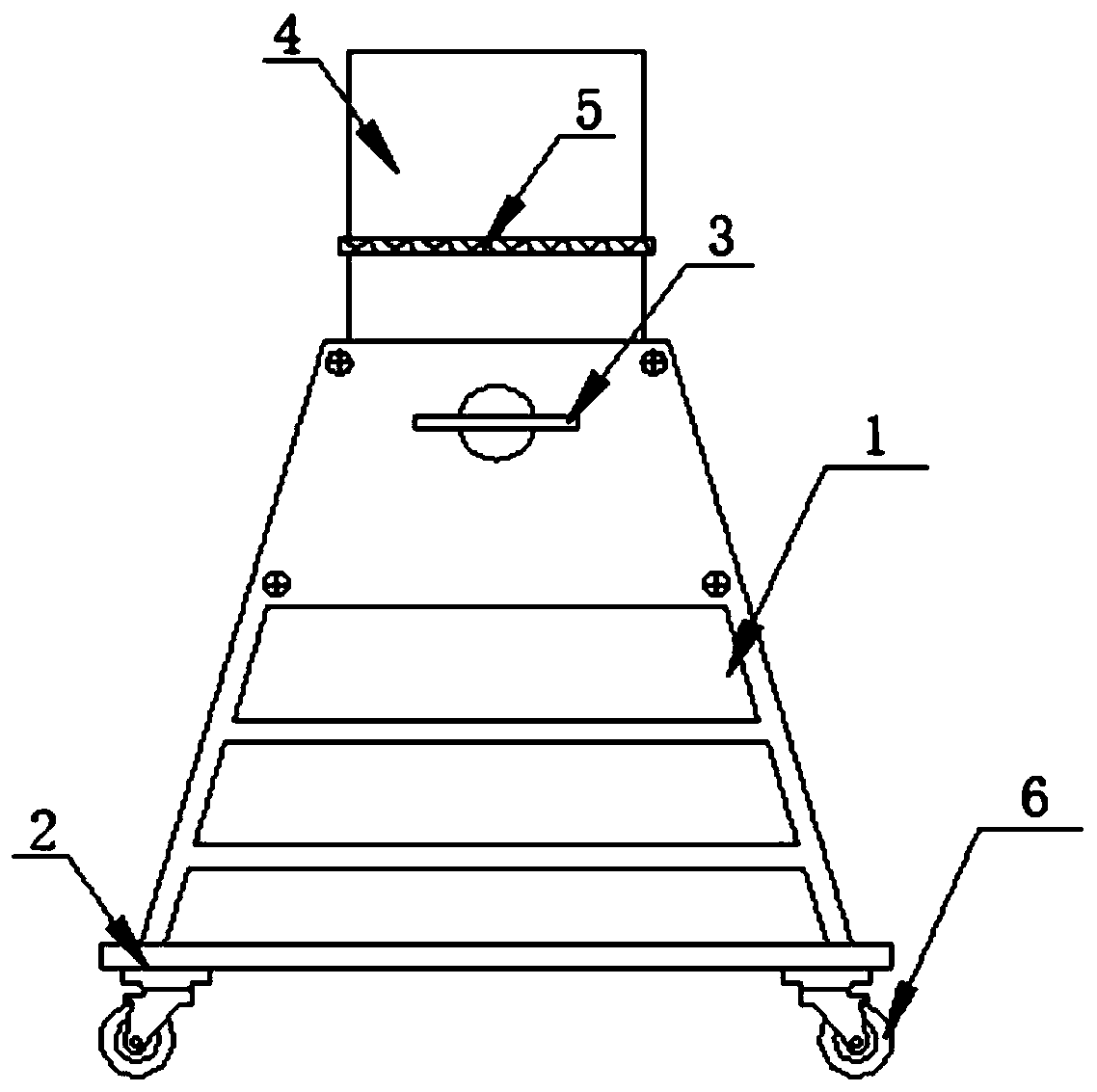

Method and apparatus for manufacturing hollow fiber membrane module

InactiveCN110694480APrevent twistingAchieve fixationSemi-permeable membranesTap waterCleansing Agents

The invention discloses a method and apparatus for manufacturing a hollow fiber membrane module. The method comprises: S1, cleaning of the membrane shell before manufacturing: tap water and a certainamount of cleaning agent are added into a first cleaning tank of an ultrasonic cleaning device to prepare a cleaning liquid with a certain concentration, pure water is added into a second cleaning tank, and the component inner shell, the outer shell and the end cover are put into the first cleaning tank for ultrasonic cleaning, which relates to the technical field of water treatment membrane separation. The method and apparatus for manufacturing a hollow fiber membrane module, two steel pipes and plastic ropes are used to fix one end of the membrane filament beam that that membrane filament ofeach partition can maintain the softness of the membrane filament after finishing, so as to prevent the membrane filament from twisting in the membrane shell, the assembly manufacturing equipment isselected to cut and block the membrane filament beam which can realize the suspension fixation and transfer of the assembly, realize semi-automatic cutting and blocking, the tie tape is fixed at the lower end with vice, and cut the membrane filament horizontally along the tie tape with wallpaper knife or other tools, which can improve the flatness of the membrane filament section.

Owner:XINJIANG DELAND

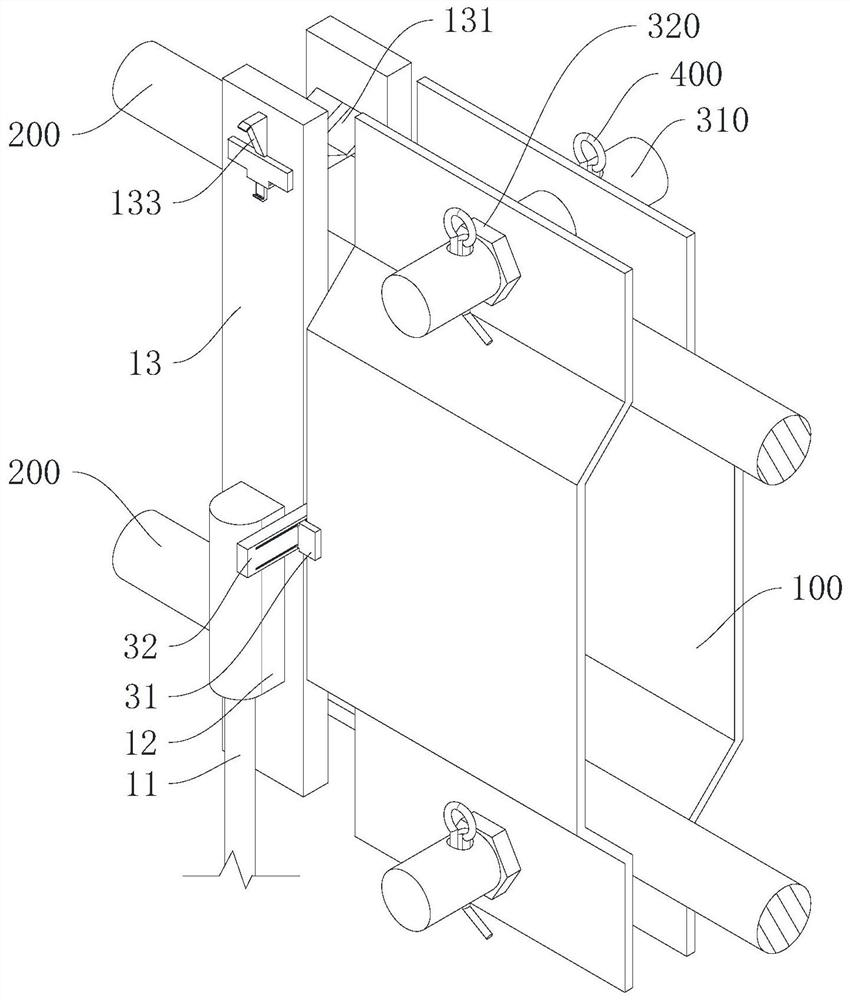

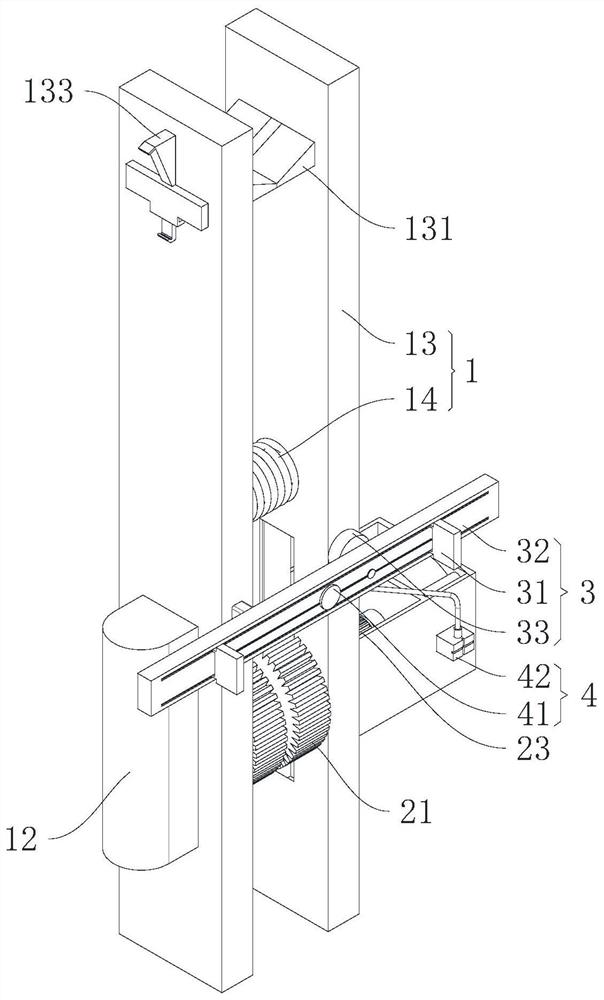

Hoisting device for green building assembly type prefabricated wallboard

The invention relates to the technical field of hoisting, and discloses a hoisting device for a green building assembly type prefabricated wallboard. A cross beam is arranged below a gravity center adjusting shell, the upper surface of the cross beam is fixedly connected with a supporting rotating block, the upper end of the supporting rotating block is rotatably connected with a center plate, the upper end of the center plate is fixedly connected to the lower surface of the gravity center adjusting shell, two connecting plates are arranged on the upper surface of the cross beam, supporting mechanisms are arranged on the outer surfaces of the connecting plates, first contact blocks are fixedly connected to the upper ends of the connecting plates, a gear is rotationally connected to the inner wall of the top of the gravity center adjusting shell, two racks are slidably connected to the inner wall of the top of the gravity center adjusting shell, and sliding mechanisms are arranged on the upper surfaces of the two racks. According to the hoisting device for the green building assembly type prefabricated wallboard, the situation that the cross beam loses balance is avoided, the stability of the wallboard in the carrying process is improved, and the personal safety of surrounding personnel is guaranteed.

Owner:TAIZHOU UNIV

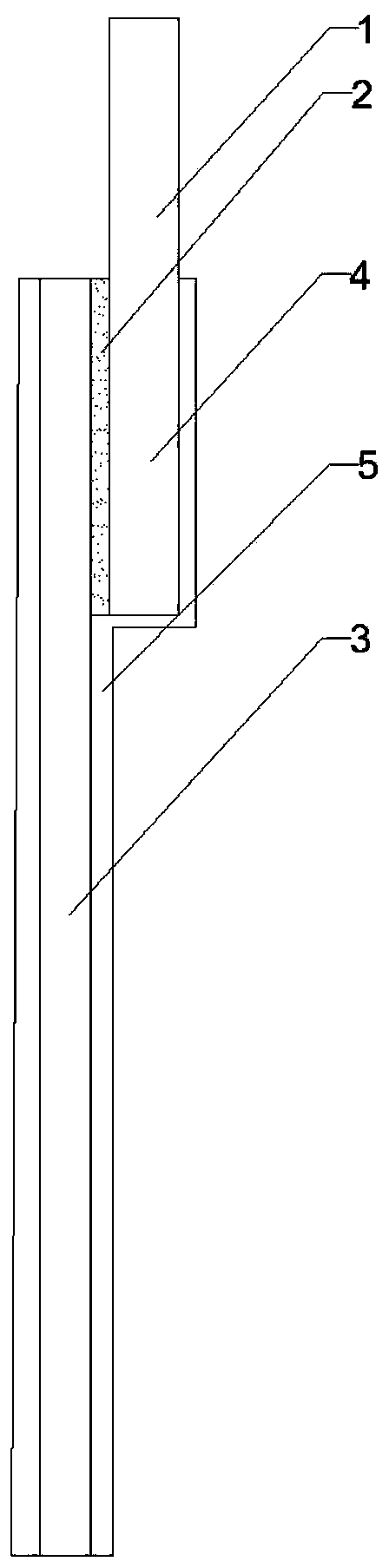

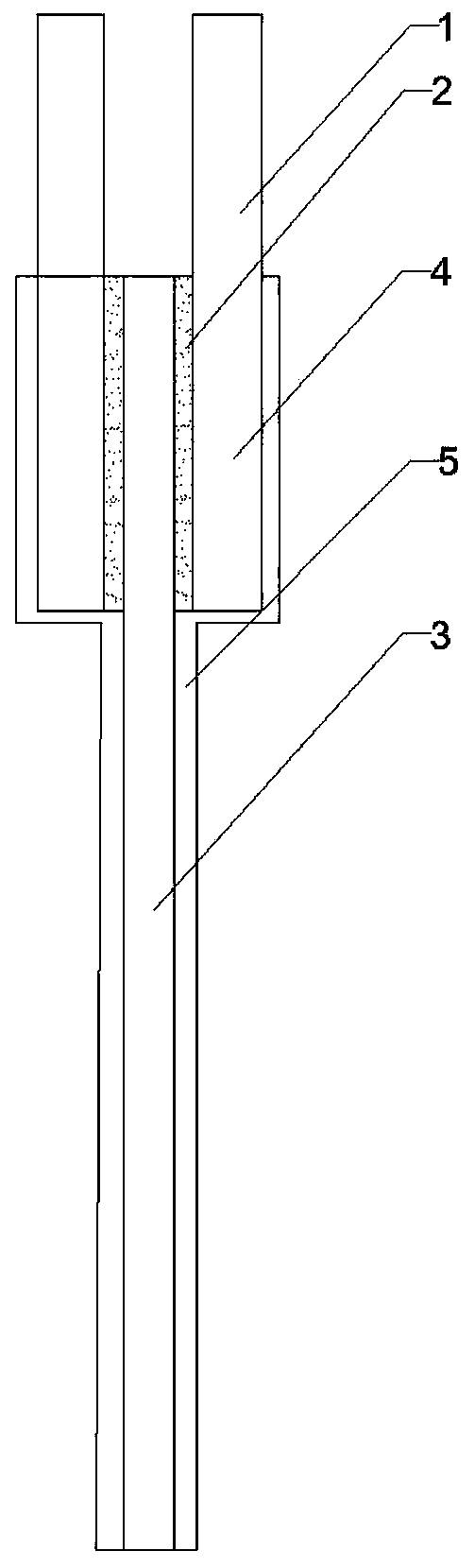

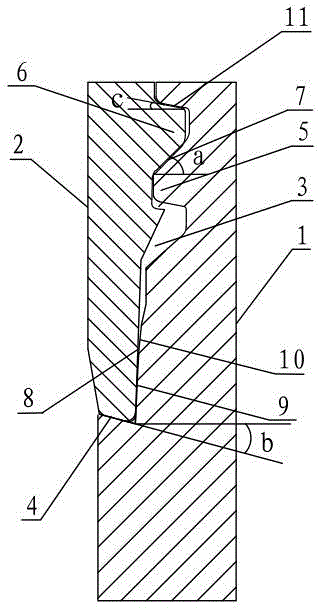

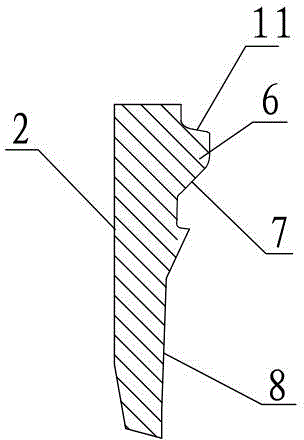

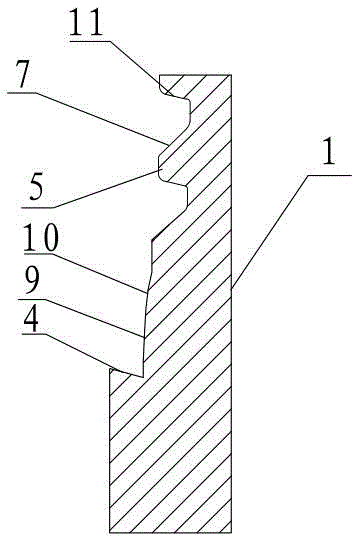

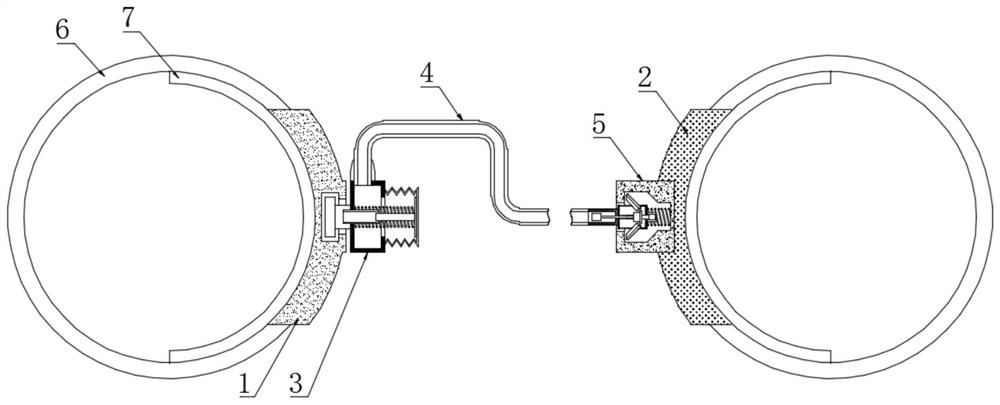

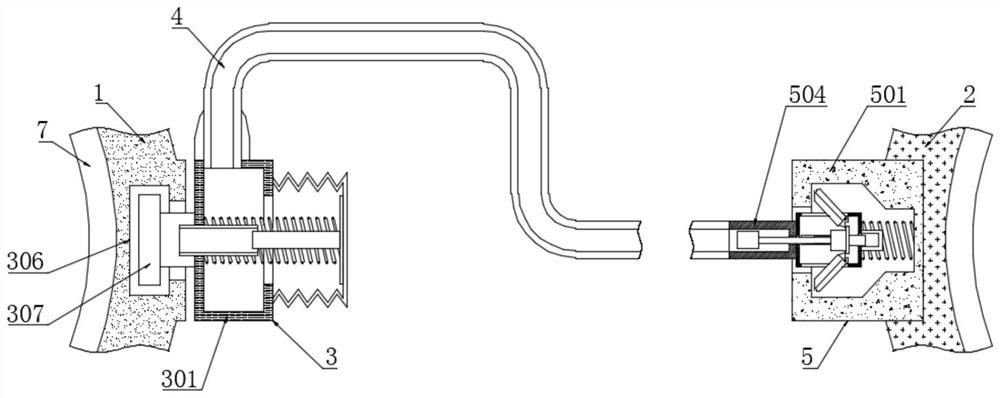

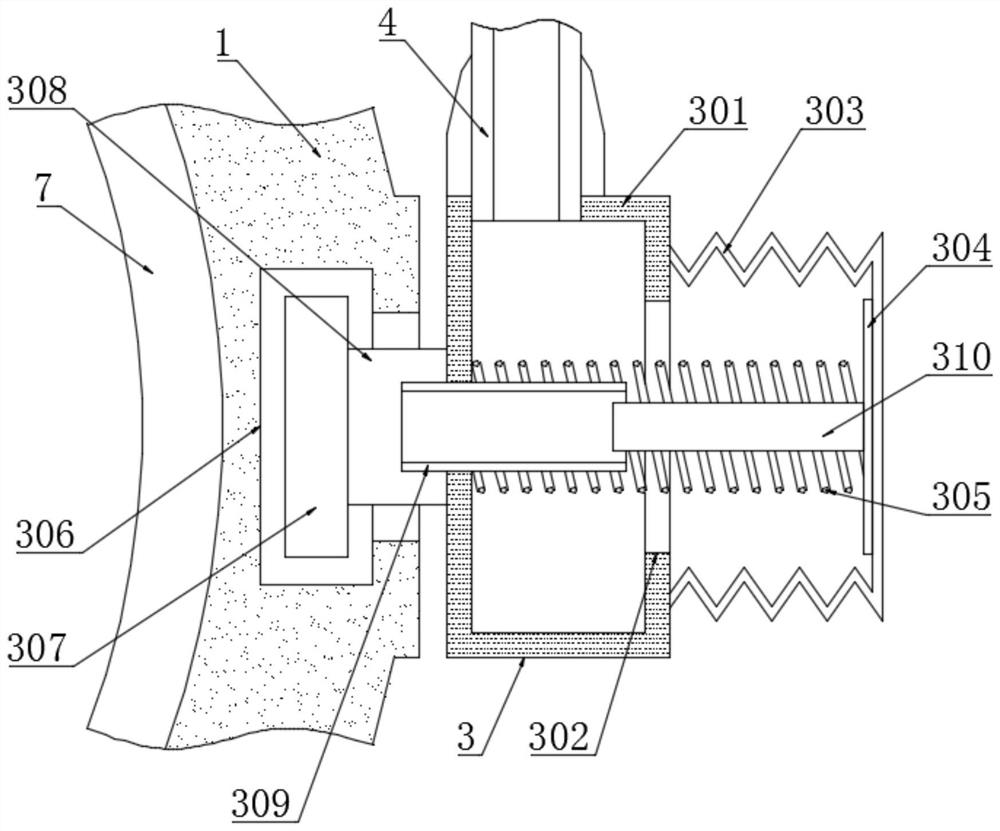

Sealing connecting structure of casing of gas well

ActiveCN104563904AAvoid damageAvoid Separation SituationsDrilling rodsDrilling casingsEngineeringConical surface

The invention discloses a sealing connecting structure of a casing of a gas well, and relates to the technical field of equipment for oil and gas wells. The sealing connecting structure comprises a male pipe connector and a female pipe connector. A threaded connecting portion, a sealing surface and a torque shoulder are sequentially arranged on contact surfaces of the male pipe connector and the female pipe connector, an oil storage tool withdrawal groove is formed in the contact surfaces of the male pipe connector and the female pipe connector, angles a of contact guide surfaces between external threads and internal threads range from 25 degrees to 45 degrees, a first conical surface on the inner wall of the female pipe connector, a spherical surface on the outer wall of the male pipe connector and a second conical surface on the outer wall of the male pipe connector are squeezed by one another and are in contact with one another so as to form the sealing surface, the conicity of the first conical surface ranges from 1 / 12 to 1 / 16, the conicity of the second conical surface ranges from 1 / 6 to 1 / 8, and the oil storage tool withdrawal groove is formed in a position between the threaded connecting portion and the sealing surface; the torque shoulder is arranged on the male pipe connector, an end of the female pipe connector and the torque shoulder are fittingly in contact with each other, and an inclination angle b of the torque shoulder ranges from -6 degrees to -15 degrees. The sealing connecting structure has the advantages that the torque shoulder and the sealing surface are optimally designed, accordingly, shortcomings of existing threaded connectors can be overcome, the sealing connecting structure is easy to screw on in a site and convenient to detect, and reliable sealing effects can be realized.

Owner:DALIPAL PIPE

Edge covering type ferrite product and processing method thereof

PendingCN109545495AEasy to useGuaranteed functionInorganic material magnetismInductances/transformers/magnets manufactureState of artAdhesive

The invention relates to an edge covering type ferrite product and a processing method thereof. The ferrite product comprises a ferrite, and a single-sided adhesive and a double-sided adhesive which are adhered to the two sides of the ferrite respectively. The edges of the double-sided adhesive are adhered to the edges of the single-sided adhesive, and the edges of the ferrite are completely covered between the single-sided adhesive and the double-sided adhesive. During the machining, the ferrite is subjected to machine-shaping at first, then the single-sided adhesive and the double-sided adhesive are adhered to the two side surfaces of the ferrite respectively, and the edges of the double-sided adhesive are adhered to the edges of the single-sided adhesive. Compared with the prior art, the ferrite are subjected to edge covering by means of the double-sided adhesive and the single-sided adhesive, thus the normal use of the ferrite is ensured, the adhesion of the ferrite product and a flexible circuit board is facilitated, and the falling of particles on a cross section of the ferrite edges formed by laser cutting or die stamping can be avoided, thereby ensuring the normal functionsof the circuit board and a mobile phone, and being easy in machining.

Owner:上海昊佰智造精密电子股份有限公司

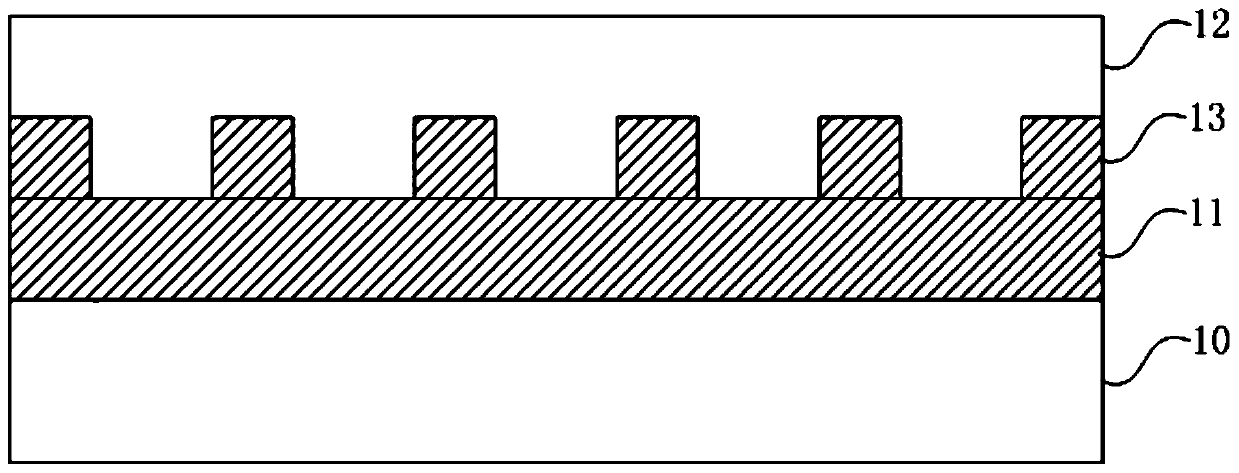

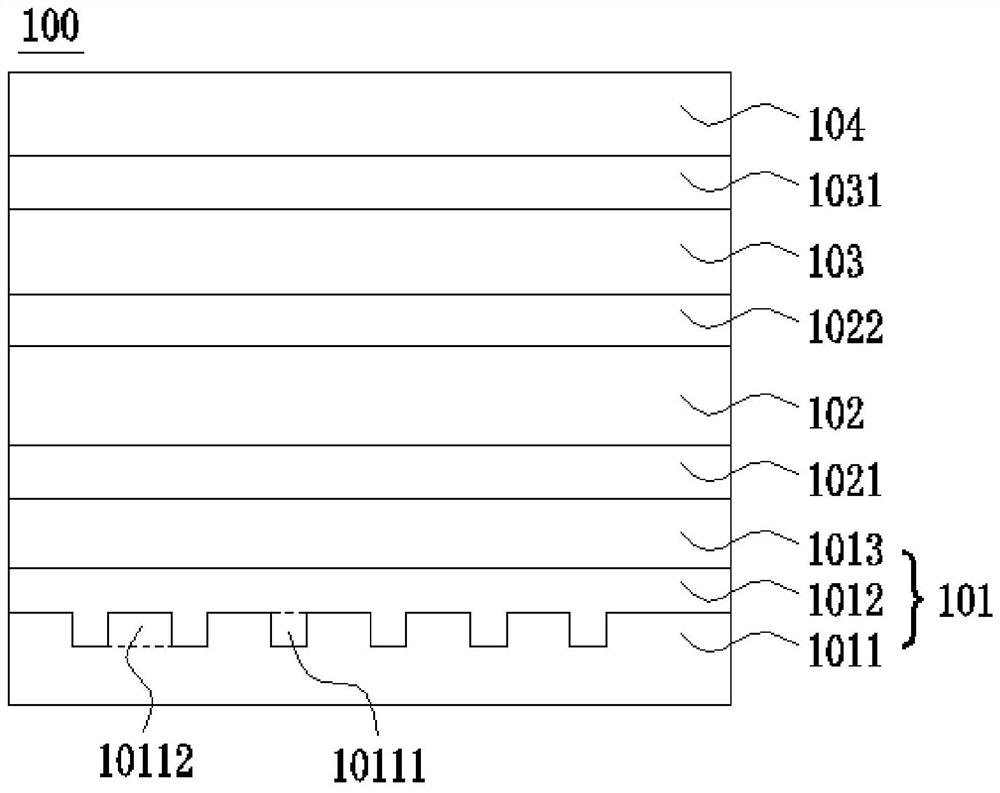

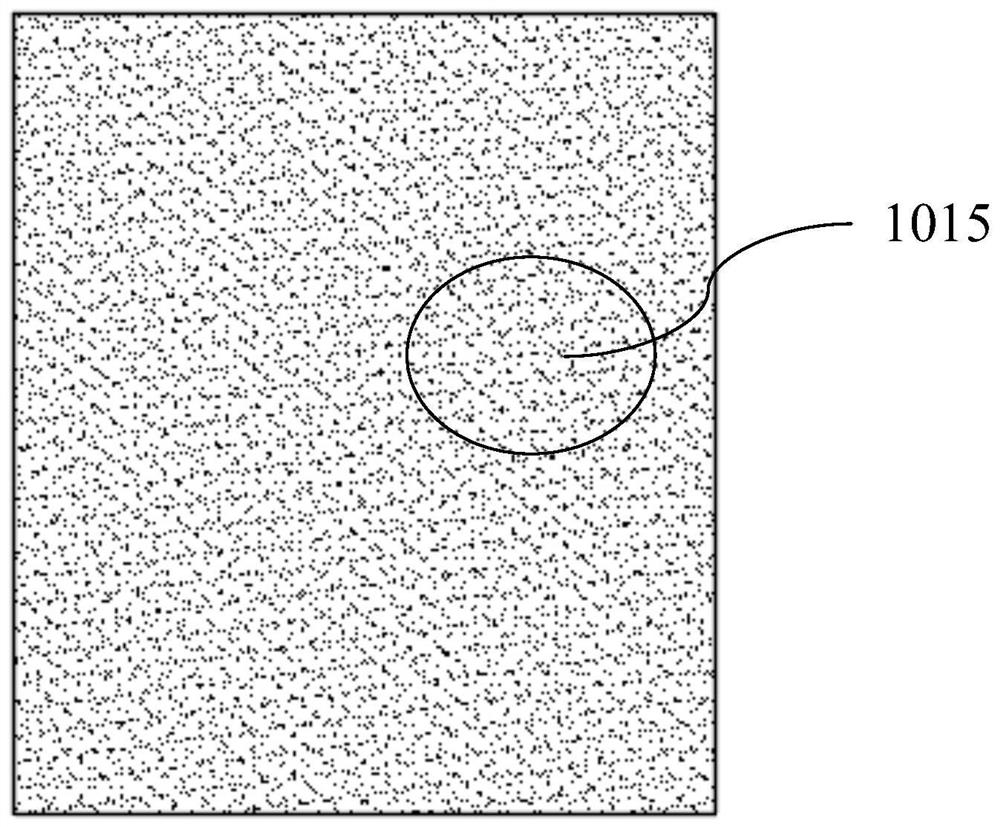

Flexible substrate and preparing method thereof

InactiveCN109859627AAvoid Separation SituationsImprove adhesionIdentification meansOxygenInorganic materials

The invention provides a flexible substrate and a preparing method thereof. The flexible substrate has the advantages that inorganic matter protrusions are embedded in the bottom of a second polymer layer, the adhesiveness between the (organic) material of the second polymer layer and the inorganic material can be improved, and it is effectively avoided that the second polymer layer and the inorganic layer are separated in the subsequent manufacturing process of display panels and other devices or the use process of the display panels and other devices; by means of the inorganic layer, water and oxygen can be effectively prevented from entering a substrate middle layer, and the reliability of the display panels and other devices is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

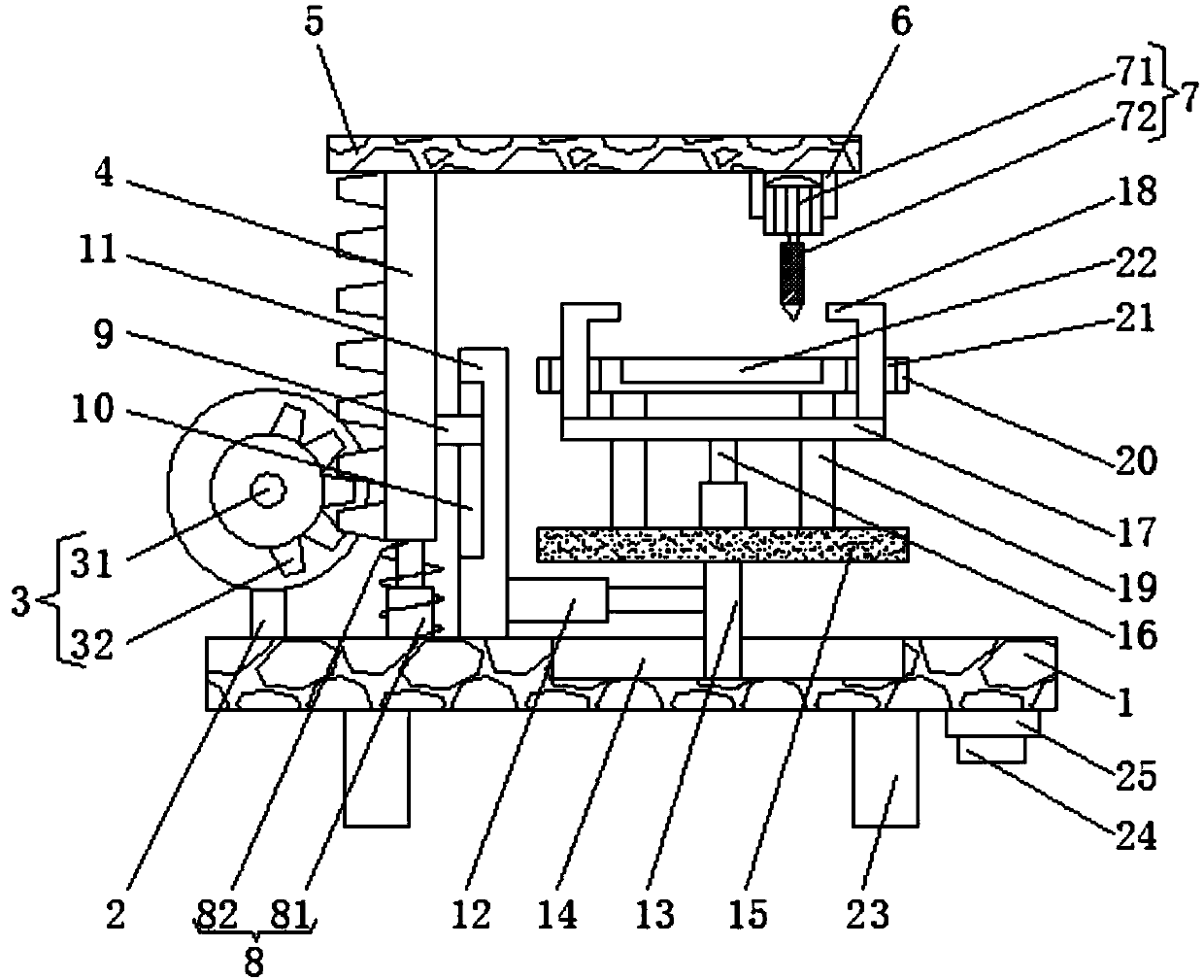

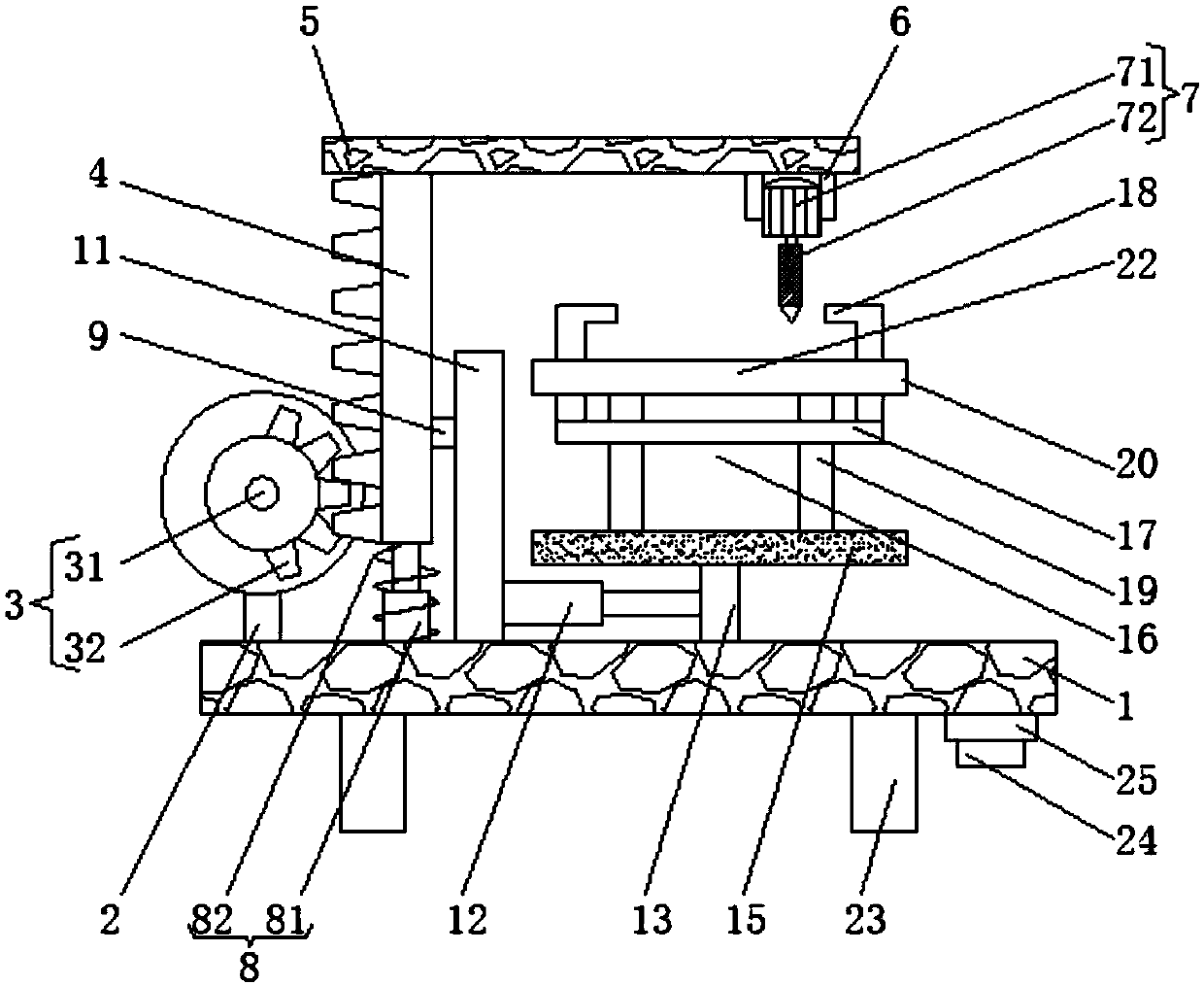

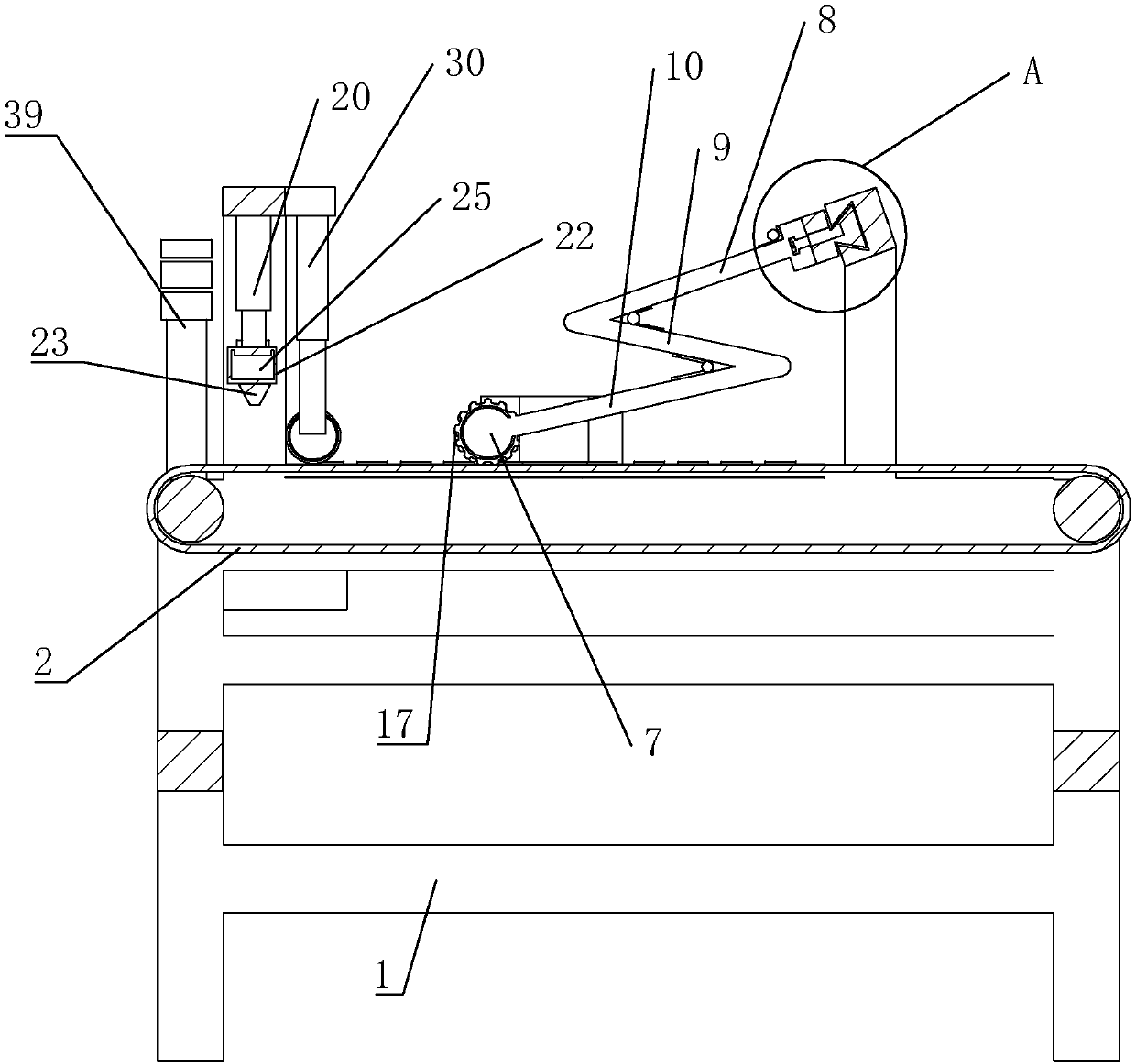

Artificial grass drilling device

InactiveCN109877908AConvenience to workTo achieve the purpose of continuous drillingMetal working apparatusArtificial turfEngineering

The invention discloses an artificial grass drilling device comprising a bottom board. The upper surface of the bottom board is fixedly connected with the lower surface of a first drive device througha first fixing rod; the first drive device is engaged with a toothed rod; the top end of the toothed rod is fixedly connected with a fixing board; the lower surface of the fixing board is fixedly connected with two second fixing rods; and the opposite faces of the two second fixing rods are fixedly connected with the left side face and the right side face of a second drive device separately. According to the artificial grass drilling device, through mutual cooperation of a first motor, a half gear, the toothed rod, the fixing board, the second fixing rods, a second motor, a drill bit, a telescopic rod, a spring, a first electric push rod, a second slide block, a second slide groove, a second electric push rod, a movable board, an L-shaped extrusion board and a load board, the drill bit vertically moves in a reciprocated mode to drill an artificial grass, and accordingly the continuous drilling purpose is achieved, and staff can work conveniently.

Owner:江门市新会区高航信息咨询有限公司

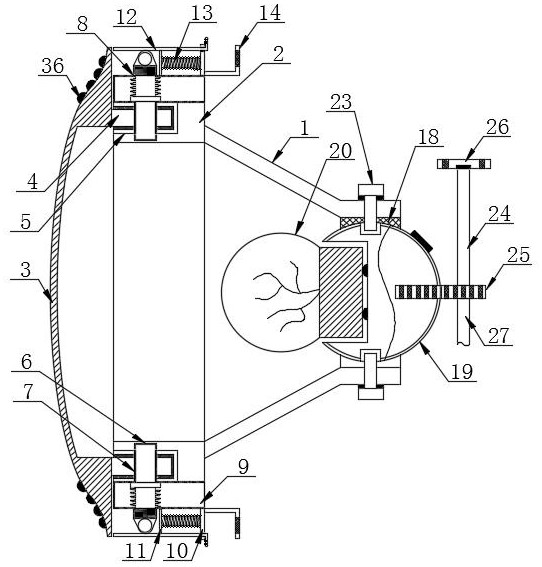

Heart mitra clip

The invention discloses a heart mitra clip. The heart mitra clip comprises a first mitra clip, a second mitra clip, a third mitra clip and a limiting mechanism, wherein the first mitra clip is provided with a first left mitra clip and a first right mitra clip which are symmetrical; the second mitra clip is provided with a second left mitra clip and a second right mitra clip which are symmetrical,and can be arranged on the first mitra clip in a sliding and sleeving manner; the third mitra clip can be arranged on the second mitra clip in a sliding and sleeving manner; and the limit mechanism isused for limiting the first mitra clip from leaving away from the second mitra clip in a sliding manner or limiting the combination of the first mitra clip and the second mitra clip from leaving awayfrom the third mitra clip in a sliding manner. The heart mitra clip can enter the heart through a duct, for the mitra which cannot be normally opened and closed, the first left mitra clip and the second left mitra clip can clamp the left valve leaflet, the first right mitra clip and the second right mitra clip can clamp the right valve leaflet, the combination of the first mitra clip and the second mitra clip is dragged into the third mitra clip, and blood regurgitation is avoided; and the limit mechanism enables movement control to be more accurate, and the situation that the first mitra clip is separated from the second mitra clip, or the combination of the first mitra clip and the second mitra clip is separated from the third mitra clip is avoided.

Owner:MALLOW MEDICAL SHANGHAICO LTD

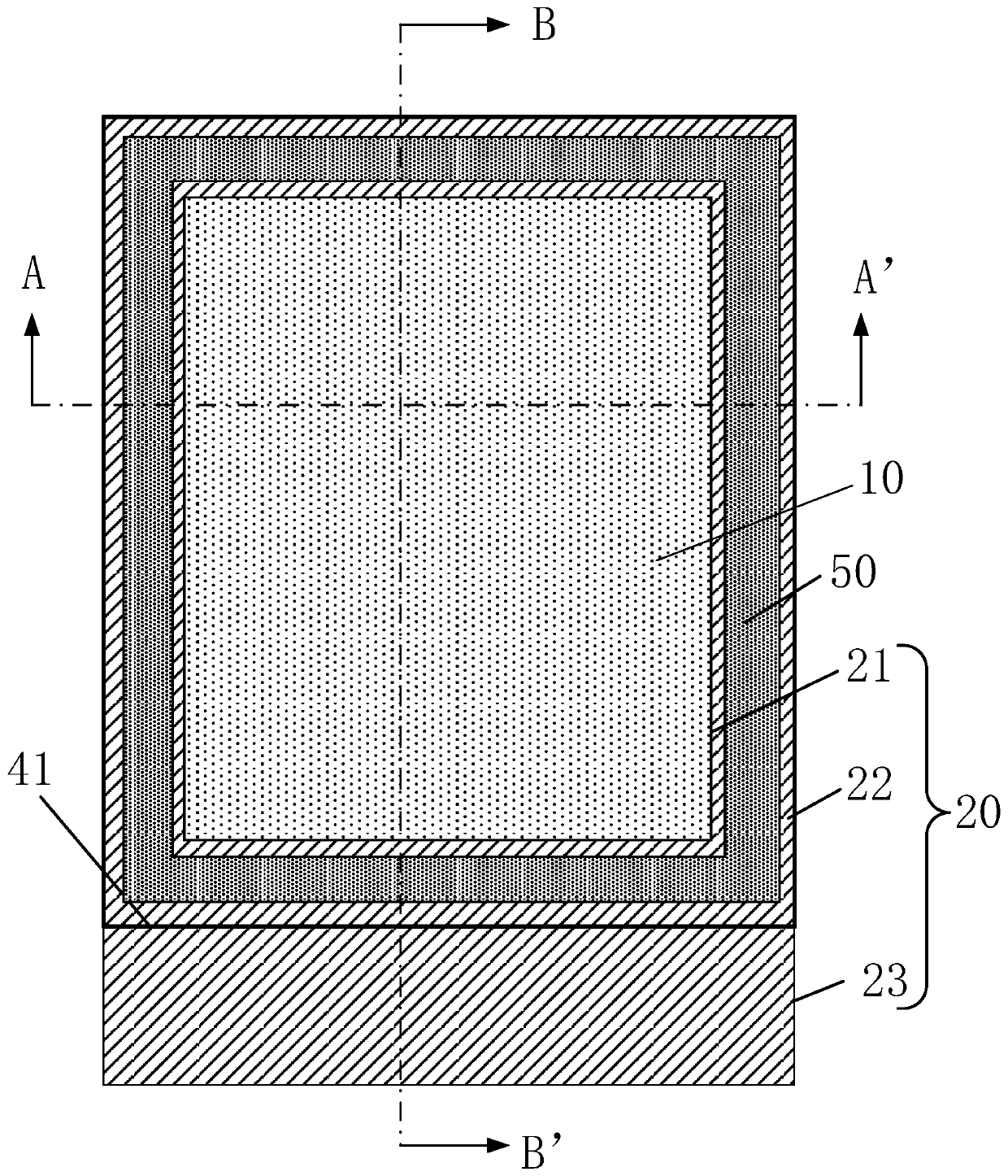

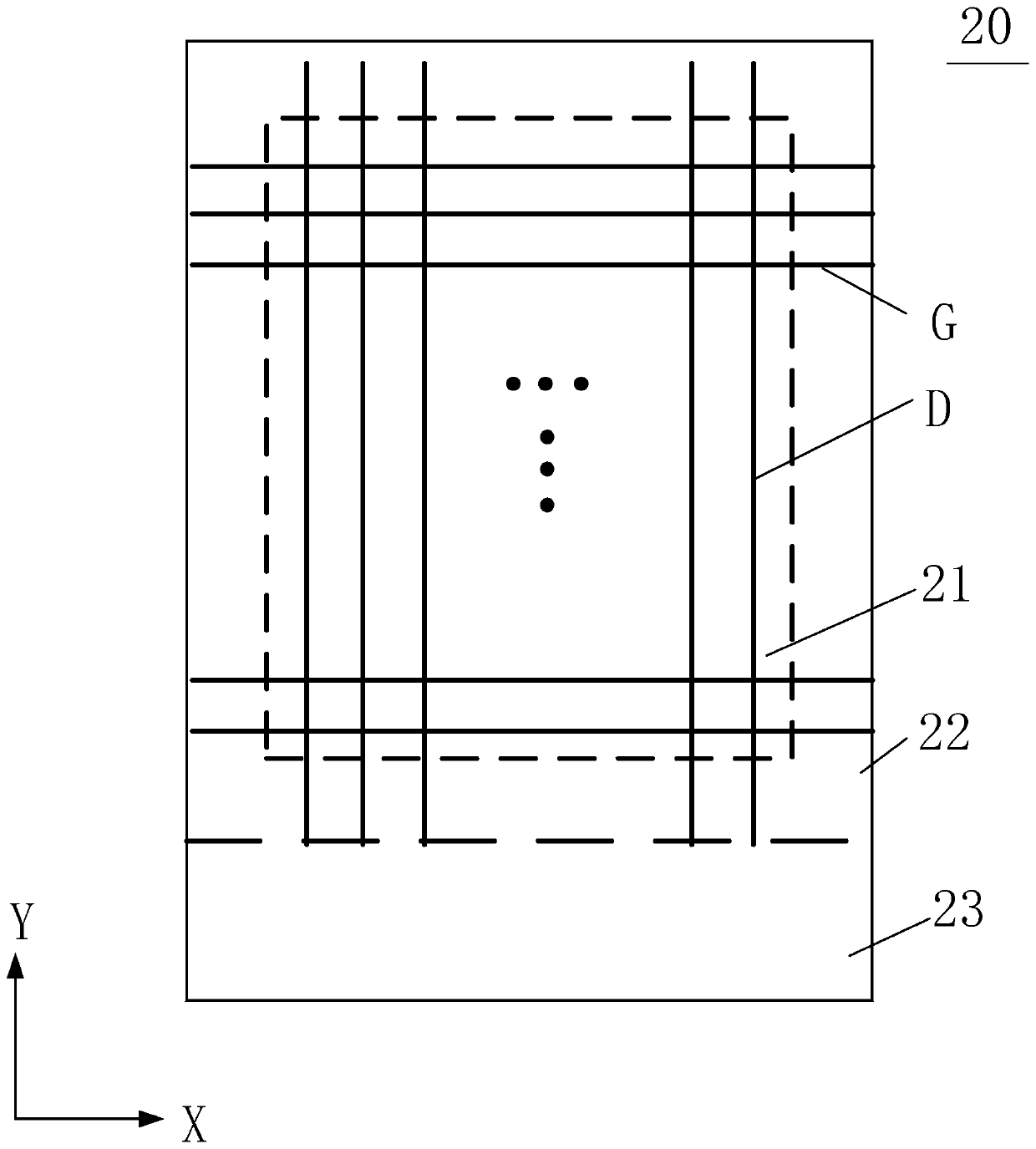

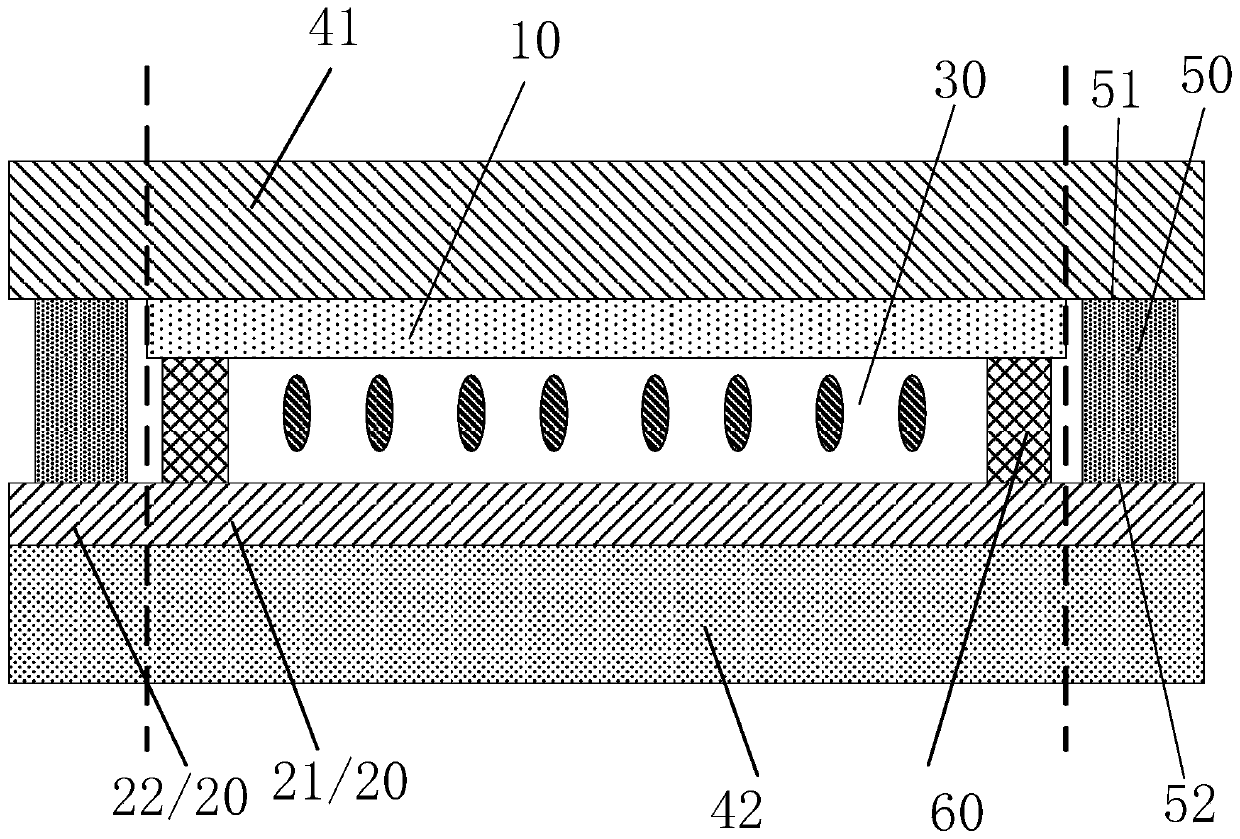

Flexible display panel, manufacturing method thereof and flexible display device

ActiveCN110335543AImprove performanceAvoid Separation SituationsIdentification meansLiquid-crystal displayEngineering

The invention discloses a flexible display panel, a manufacturing method thereof and a flexible display device. The flexible display panel comprises a first flexible substrate and a second flexible substrate which are oppositely arranged. The second flexible substrate comprises a main body part, a protruding part and a binding part. The orthographic projection of the first flexible substrate to the second flexible substrate coincides with the main body part. The protruding part surrounds the body part, and the binding part is located on the side, away from the body part, of the protruding part. The liquid crystal layer is arranged between the first flexible substrate and the second flexible substrate. A first polaroid is positioned on one side, far away from the second flexible substrate,of the first flexible substrate. A second polaroid is positioned on one side, far away from the first flexible substrate, of the second flexible substrate. A sealant is arranged between the first polaroid and the protruding part and surrounds the first flexible substrate. According to the flexible display panel, the problem that when the flexible display panel is bent, the first flexible substrateand the second flexible substrate which are attached to the edge of the flexible display panel are prone to separation is effectively solved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Backboard of folding display panel and preparation method thereof

InactiveCN112599006AImprove display qualityReduce distortionIdentification meansInterfacial adhesionStructural engineering

The invention provides a backboard of a folding display panel and a preparation method thereof. The backboard comprises a substrate, a bonding layer located on the substrate and an anti-bending metalplate located on the bonding layer, wherein the anti-bending metal plate is preferably SUS stainless steel, the thickness of the SUS stainless steel layer is preferably 0.3 mm to 1.5 mm, and a grooveis formed in the side, close to the bonding layer, of the anti-bending metal plate; the inner wall of the groove is bent or inclined towards the center of the groove, the groove is filled with the bonding layer, the contact area between the bonding layer and the anti-bending metal plate is effectively increased through the groove, the interface adhesive force can be effectively improved, the situation that the anti-bending metal plate is separated from the bonding layer is avoided, a part of the bonding layer is embedded in the groove, and the inner wall of the groove limits the bonding layerto extend outwards, so that deformation of the bonding layer is further reduced, and the phenomenon that the bonding layer extrudes the substrate is avoided; and stress distribution of the bending area is more coordinated, continuous and uniform, and therefore, the display quality of the folding display panel is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

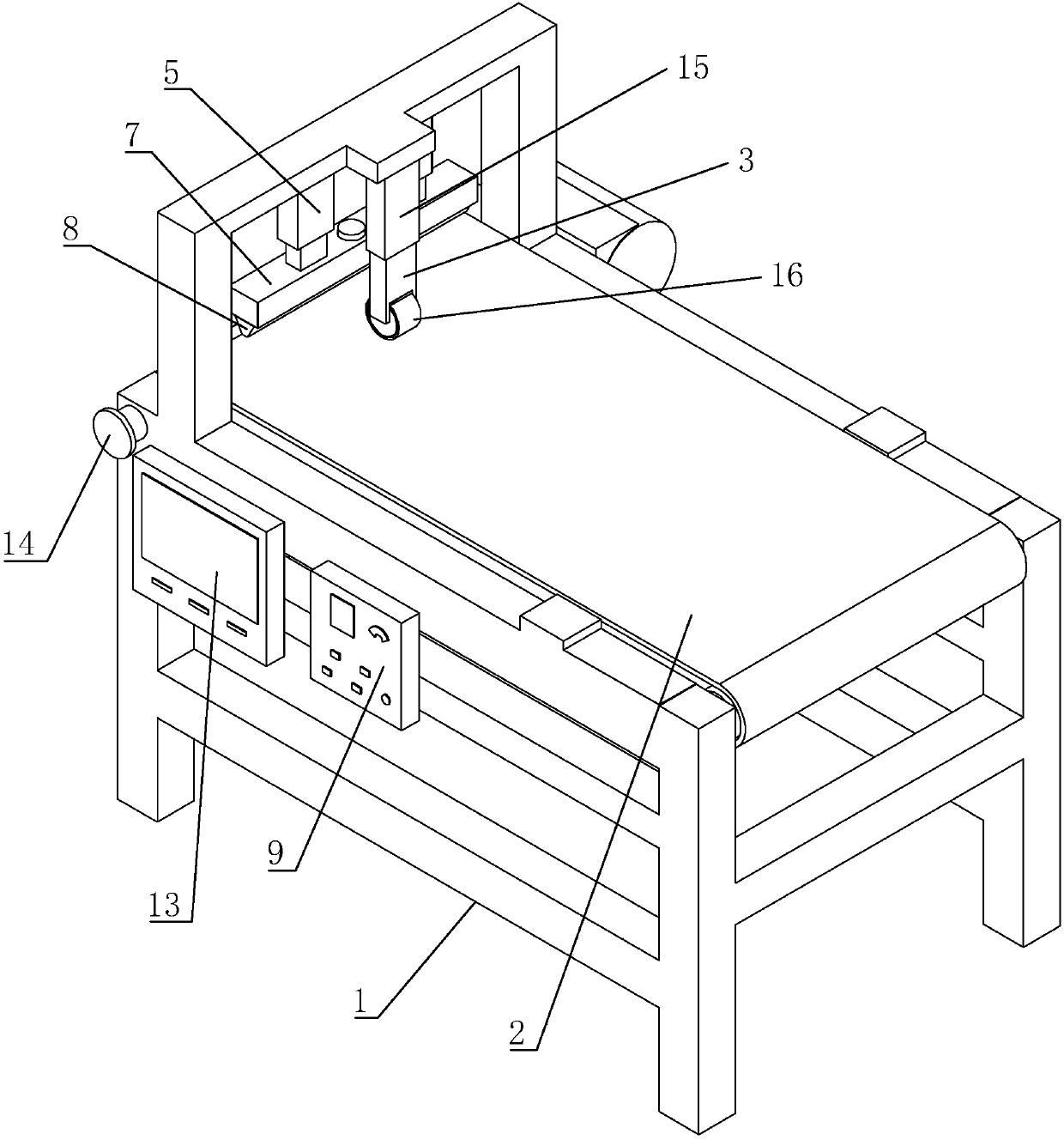

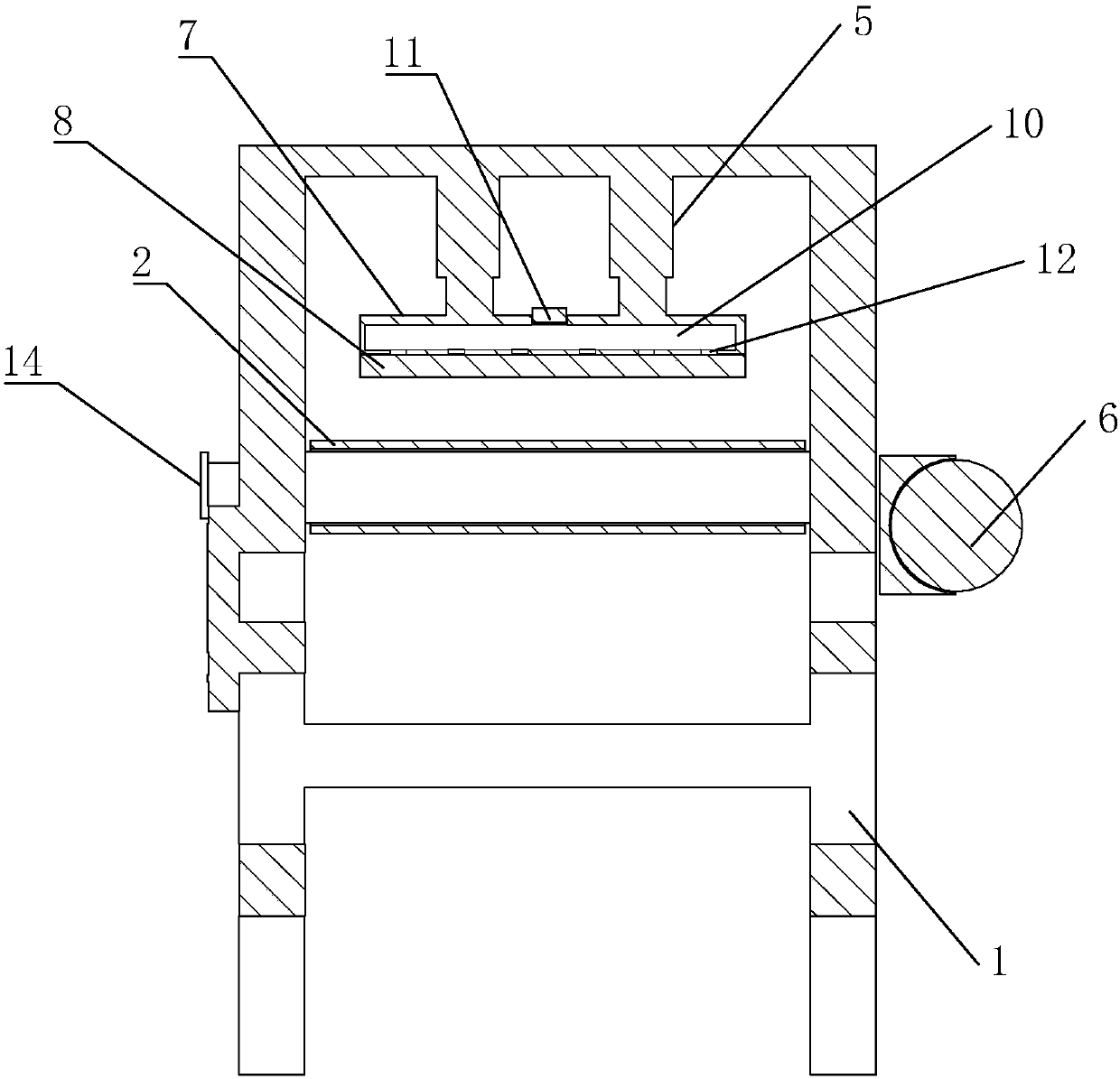

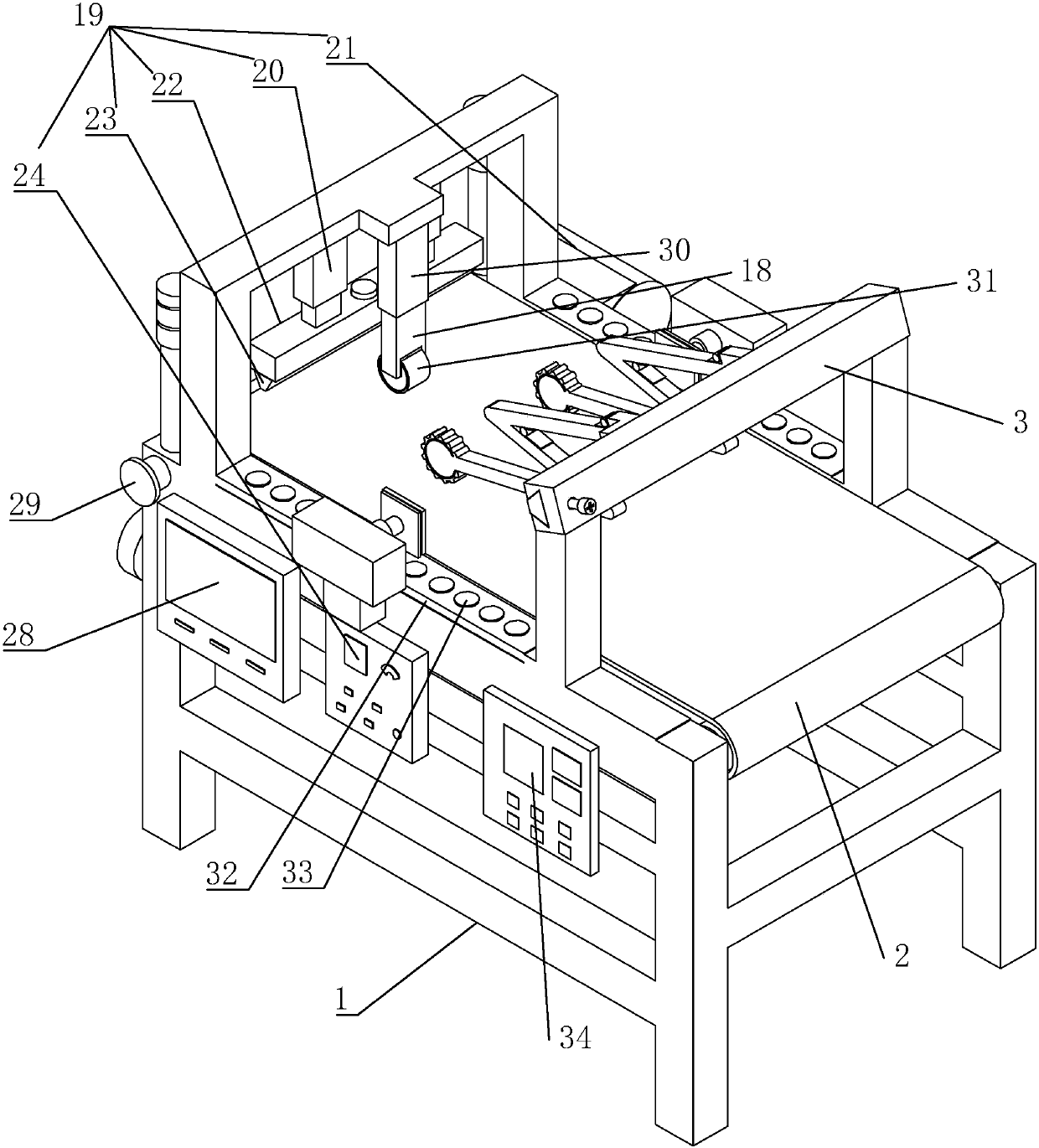

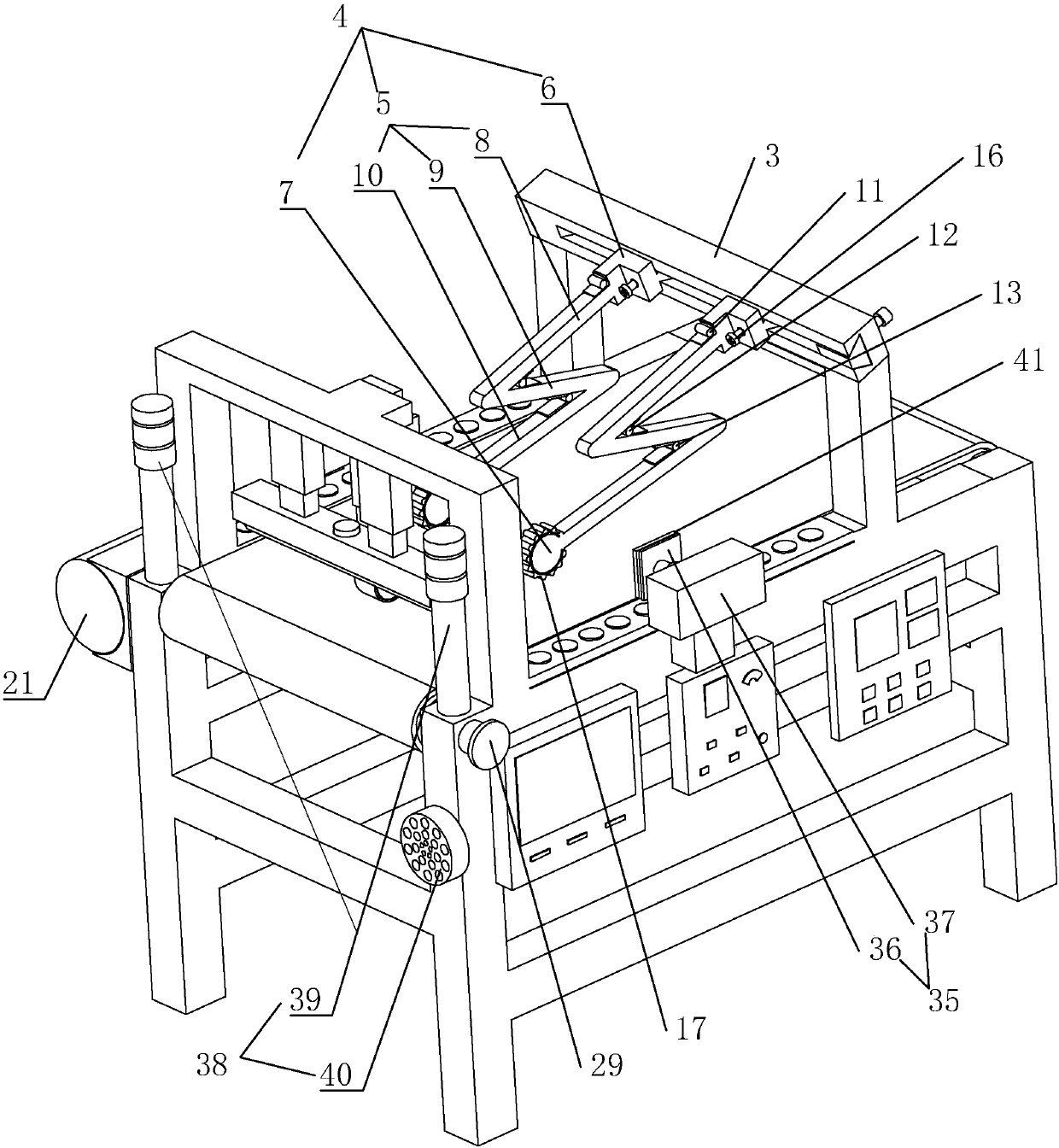

Paperboard production and conveying line and use method thereof

PendingCN107825758AConvenient length measurementEasy drift detectionConveyorsBox making operationsPaperboardDisplay device

The invention discloses a paperboard production and conveying line. According to the technical scheme, the paperboard production and conveying line is characterized in that the paperboard production and conveying line comprises a rack and a conveying belt arranged on the rack; a stroke detection device abutting against the surface of the conveying belt is arranged on the rack; a marking device isarranged on the rack; a roller of the stroke detection device abuts against the surface of the conveying belt; a display is arranged on the rack; the display is connected with the output end of a controller; bar guide plates are arranged on the rack; infrared detectors are arranged on the bar guide plates; a processor is arranged on the rack; and position correction devices for paperboard resetting are arranged on the parts, located on the two sides of the conveying belt, of the rack correspondingly. The paperboard production and conveying line can provide marked paperboard surfaces, so that workers can carry out bending operation on paperboards conveniently, shifting detection and position correction operation can be carried out on the paperboards on the conveying belt, and the situationthat the paperboards fall off the conveying belt is avoided.

Owner:安吉县格林纸箱厂

HID xenon type automobile front combination lamp

InactiveCN112097216AImprove replacement rateEasy to assemble and disassembleVehicle headlampsOptical signallingEngineeringElectrical and Electronics engineering

The invention discloses an HID xenon type automobile front combination lamp, and particularly relates to the technical field of automobile lamps. The HID xenon type automobile front combination lamp comprises a lamp shell; a frame plate is fixedly arranged at the edge of one end of the lamp shell, and a lining plate is fixedly embedded in the other end of the lamp shell; a lampshade is arranged onthe side, away from the lamp shell, of the frame plate; an inserting groove is formed in the side, facing the lampshade, of the frame plate; an inserting plate is correspondingly arranged on the side, facing the frame plate, of the lampshade; the inserting plate is matched with the inserting groove; a clamping mechanism is arranged at the joint of the inserting plate and the inserting groove; theclamping mechanism comprises an inserting rod; a handle is arranged at the top end of the inserting rod; and the middle of the inserting rod is sleeved with a limiting plate. According to the automobile front combination lamp, the handle is lifted upwards to compress a first spring through a limiting plate, so that the bottom end of the inserting rod is completely separated from the inserting groove and the inserting plate; and the lampshade is separated from the frame plate through a second anti-skid strip on the surface of the lampshade, so that the replacement rate of a bulb in the automobile front combination lamp can be greatly increased, and disassembly and assembly are convenient and fast.

Owner:JIANGSU QINLONG VEHICLE LAMP

Safety traction rope

InactiveCN111802864AAvoid safety accidentsCause safety accidentChildren furnitureTraction cordEngineering

The invention discloses a safety type traction rope, which comprises an adult bracelet and a child bracelet, wherein a driving assembly is movably arranged on the surface of the adult bracelet, a connecting pipe is fixedly arranged at one end of the driving assembly, a disengaging assembly is arranged at the end, away from the driving assembly, of the connecting pipe, and is fixedly arranged on the surface of the child bracelet, the driving assembly comprises a storage pipe, and the storage pipe is movably connected to the surface of the adult bracelet. According to the invention, a corrugatedpipe is beaten by family members, a liquid in the corrugated pipe enters a connecting pipe, the liquid in the connecting pipe drives a driving rod to move through a piston and a piston rod, the driving rod drives a fixed arm to rotate through the driving block until the fixed arm completely enters a fixed frame, and the fixed frame can pop up from the inner wall of a mounting groove at the moment, so that the connecting pipe does not pull a child bracelet any more, safety accidents caused by the fact that a child cannot struggle out of a traction rope are avoided, and the safety performance of the device is high.

Owner:韩莹莹

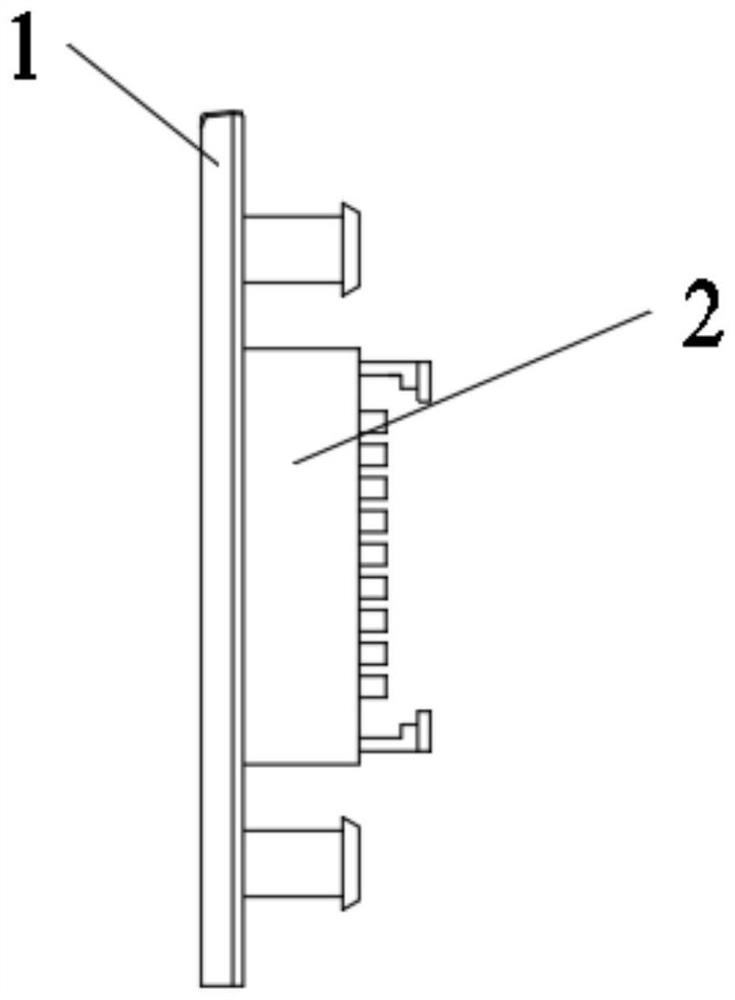

Double-source same-screen display liquid crystal display device

ActiveCN113377319AAvoid Separation SituationsAvoid disconnectionHousing of computer displaysDigital output to display deviceLiquid-crystal displayEngineering

The invention belongs to the technical field of display equipment, and particularly relates to a double-source same-screen display liquid crystal display device which comprises a display assembly, a connecting assembly and a fixing assembly. According to the liquid crystal display device, the display component can be fixedly clamped in the fixing component without a fastener, so that the liquid crystal display device is convenient to mount, the condition that the display screen is separated from the fixing component due to accidental touch is avoided, the condition that the exposed circuit is disconnected with the female plug of the connector when encountering external force is better avoided, and the use is safer.

Owner:深圳市宏铨煋科技有限公司

Parallel micro-positioning platform based on driving of piezoelectric ceramic driver and micro-positioning platform system

ActiveCN102324253BHigh positioning accuracyImproved straightness of motionInstrumental componentsElectricityLoop control

The invention relates to a parallel micro-positioning platform based on the driving of piezoelectric ceramic drivers and a system, which comprises a micropositioner, a baseplate and a control system, wherein the micropositioner comprises a movable platform and four flexible hinges, a single piezoelectric ceramic driver and a pair of side-by-side piezoelectric ceramic drivers are respectively arranged at the two adjacent sides of the movable platform, one end of each piezoelectric ceramic driver and the movable platform are connected through a universal hinge, the other end of each piezoelectric ceramic driver is connected with a pre-tightening spring through the other universal hinge, and the pre-tightening spring is pre-tightened through a bolt; a capacitance sensor is respectively arranged on the upper surface of the movable platform along the axis direction of each piezoelectric ceramic driver; and one capacitance sensor is positioned on a sensor bracket fixed at the outer side of the micropositioner, the other capacitance sensor is positioned on the other sensor bracket fixed on the upper surface of the movable platform, and computer closed-loop control is adopted. Through theparallel micro-positioning platform and system, the displacement straightness accuracy and the positioning precision are effectively improved, coupling is eliminated, driver separation is avoided, and piezoelectric drivers are protected. By adopting an LQG (Linear Quadratic Gaussian) algorithm of an augmented noise model, narrowband foundation disturbance is effectively inhibited, and the positioning precision is improved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

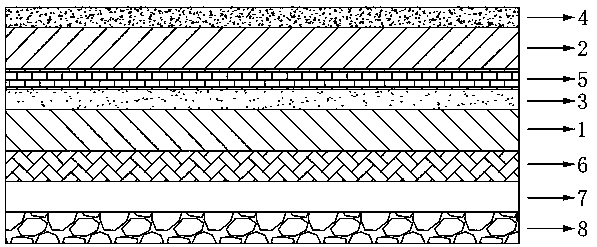

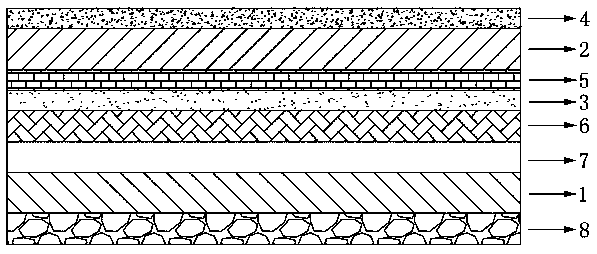

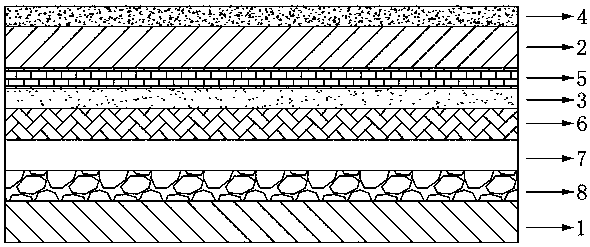

Aluminum foil mylar adhesive tape and preparation method thereof

InactiveCN110819251AImprove performanceExtended service lifeEster polymer adhesivesPressure sensitive film/foil adhesivesPolyesterPolymer science

The invention relates to the technical field of aluminum foil mylar adhesive tapes, particularly to an aluminum foil mylar adhesive tape and a preparation method thereof, wherein the prepared aluminumfoil mylar adhesive tape is good in weather resistance, cannot be denatured and broken under the condition of temperature change and humidity change, can avoid the separation of an aluminum foil froma polyester tape in a use process, and comprises a polyester film layer, an adhesion layer, an aluminum foil layer, an adhesion layer and an isolation layer, wherein the polyester film layer, the adhesion layer, the aluminum foil layer, the adhesion layer and the isolation layer are arranged from top to bottom, the adhesion layer comprises 5-15 parts of aqueous acrylic acid and 15-20 parts of cross-linked polyacrylic acid, and during the use, the aqueous acrylic acid and the cross-linked polyacrylic acid are mixed and added into a hot melting machine and are melted and stirred and mixed uniformly. The preparation method comprises: S1, base material preparing; S2, adhesive preparing; S3, polyester film layer treatment; S4, coating with an adhesive solution; Ss5, drying treatment; S6, laminating treatment; S7, curing treatment; S8, irradiation cross-linking modification treatment; S9, winding; and S10, slitting.

Owner:昆山恒永昌电子科技有限公司

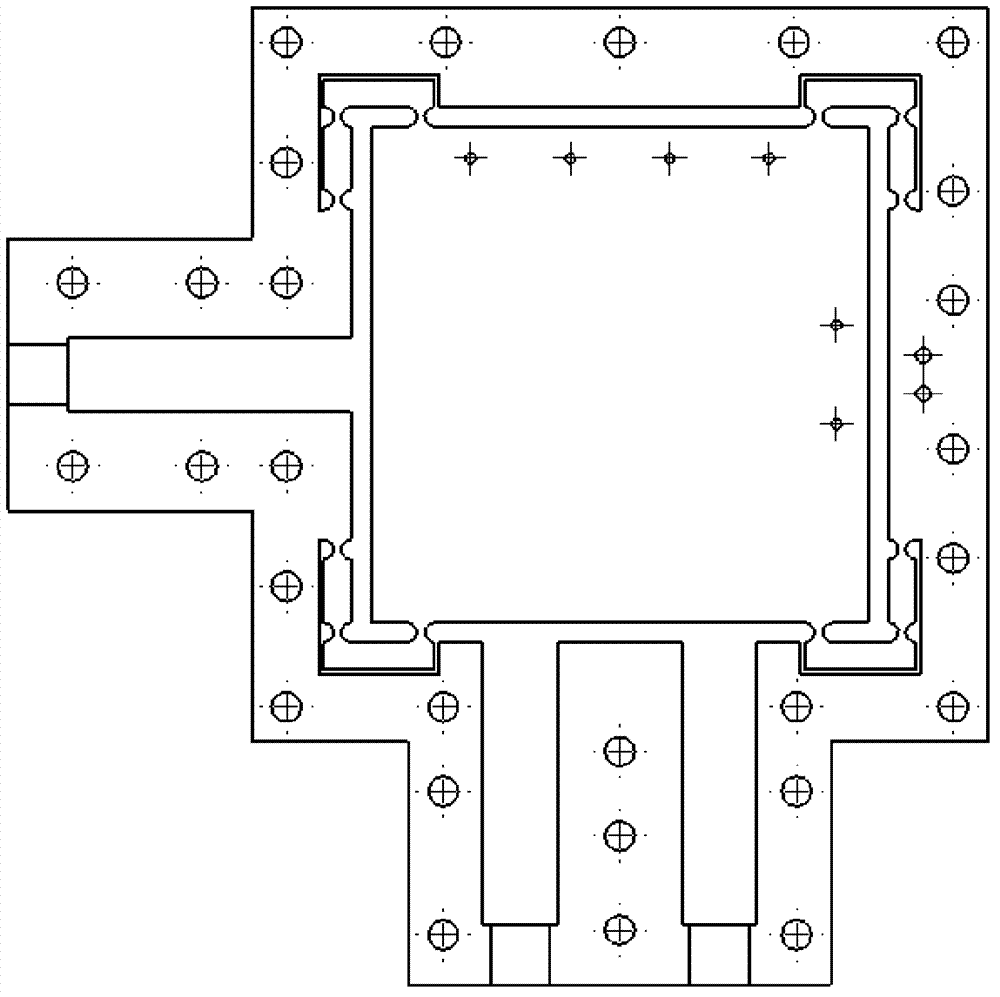

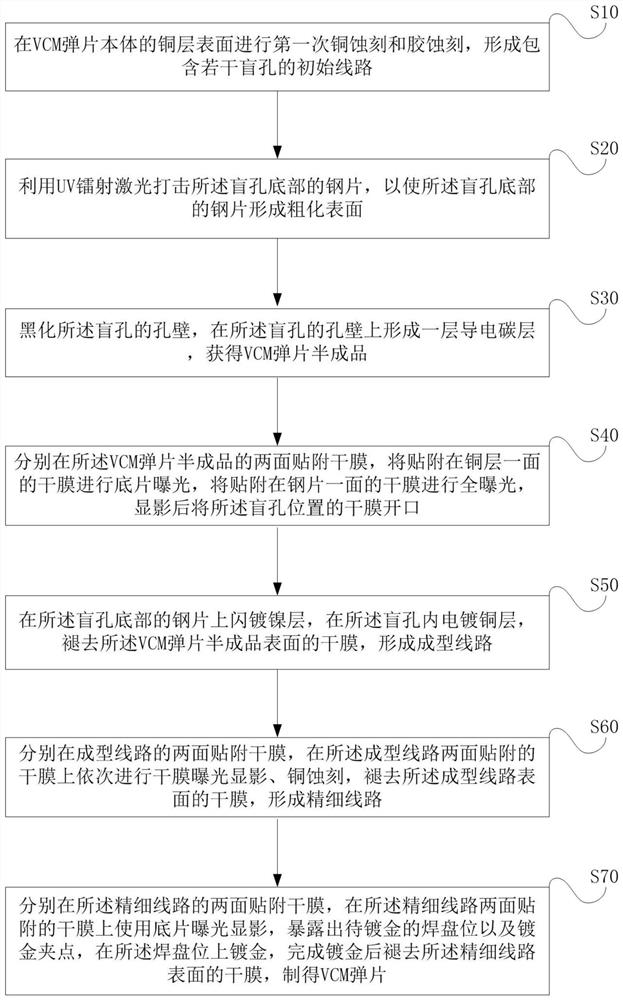

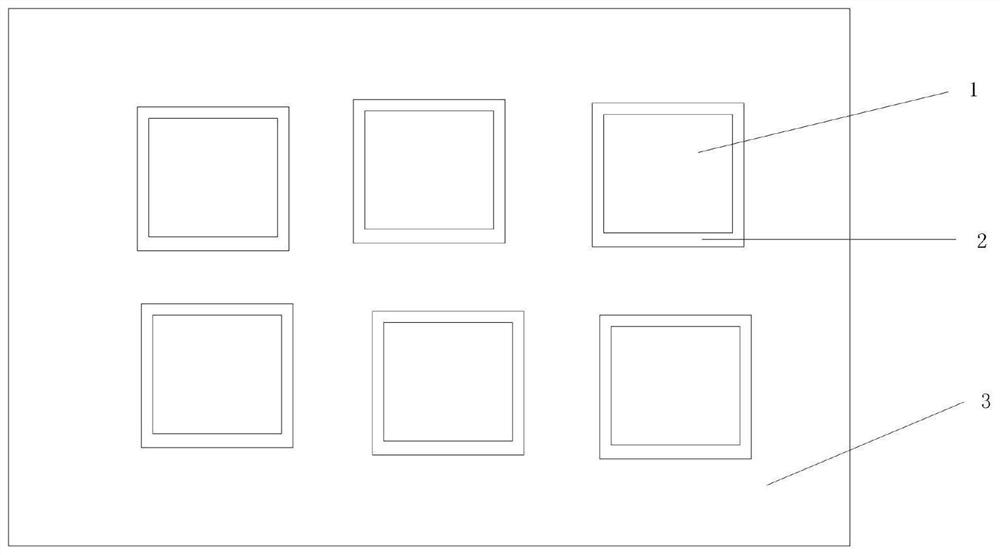

VCM elastic sheet and processing method thereof

ActiveCN111712056AImprove surface roughnessIncrease roughnessManufacturing dynamo-electric machinesConductive material chemical/electrolytical removalEtchingElectronic component

The invention provides a VCM elastic sheet and a processing method thereof. The method comprises the steps of carrying out the first copper etching and glue etching on the surface of a copper layer ofa VCM elastic sheet body, and forming a plurality of blind holes; attaching dry films to the two sides of the VCM elastic sheet body, and opening the dry films at the blind holes after exposure and development; attaching dry films to the two faces of the blind hole for the second time after copper electroplating is conducted in the blind hole, and then carrying out second-time dry film exposure development, copper etching and film stripping; and carrying out exposure and development after dry films are attached to the two sides for the third time, exposing a bonding pad position to be platedwith gold and gold-plated clamping points, and removing the dry films on the surface after gold is plated on the bonding pad position to obtain the VCM elastic sheet. According to the invention, copper etching is carried out on the surface of the copper layer, an initial circuit comprising the plurality of blind holes is formed, and then a copper layer and a steel sheet are conducted in a manner of electroplating copper in the blind holes, and the bonding pad position to be plated with gold and the gold-plated clamping points are exposed on the surface of the copper layer in a manner of exposing and developing a negative film, so that more electronic elements can be mounted on the bonding pad position to realize more functions.

Owner:MFS TECH HUNAN

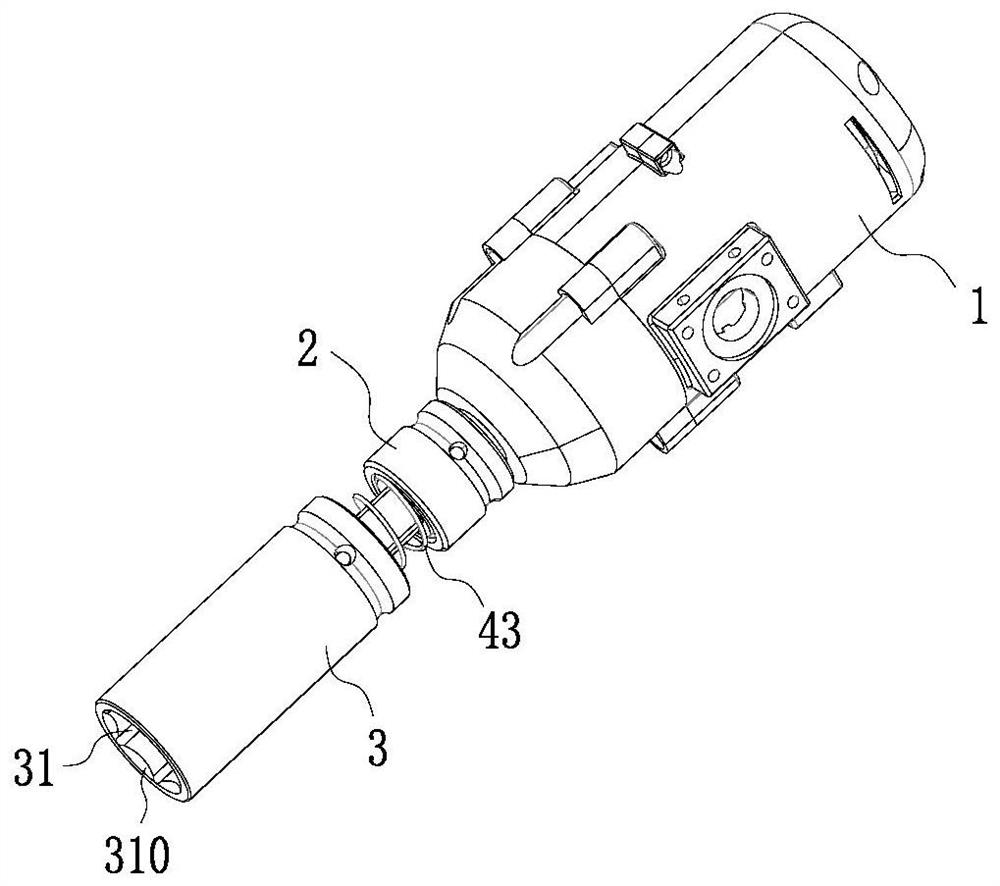

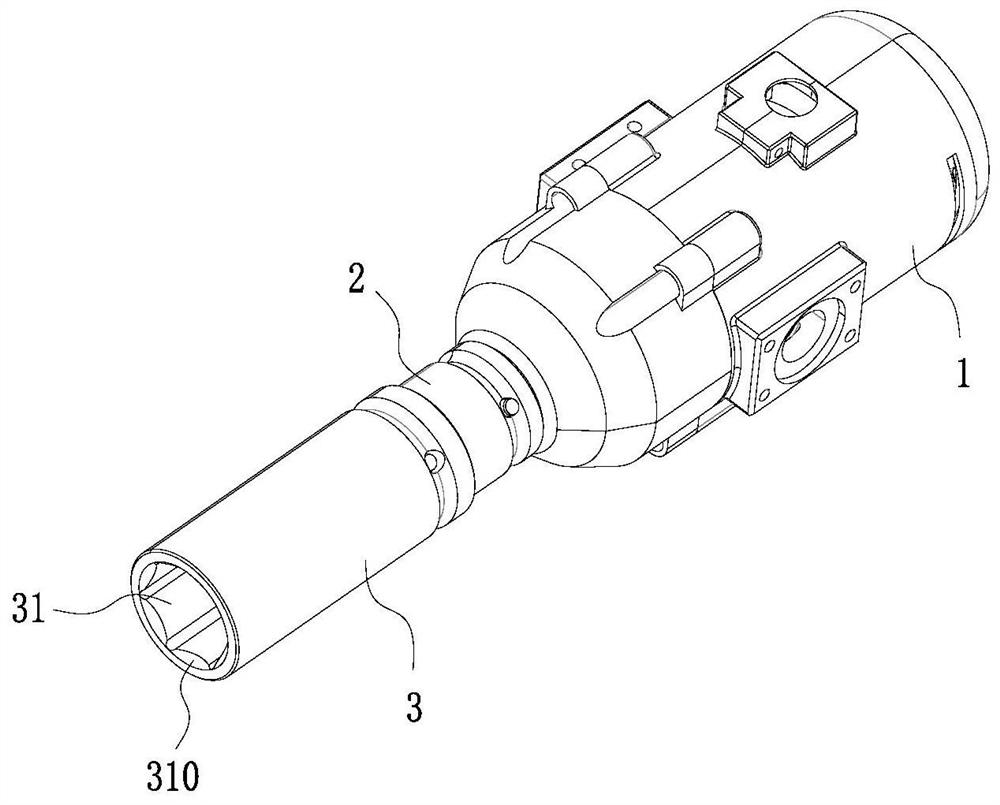

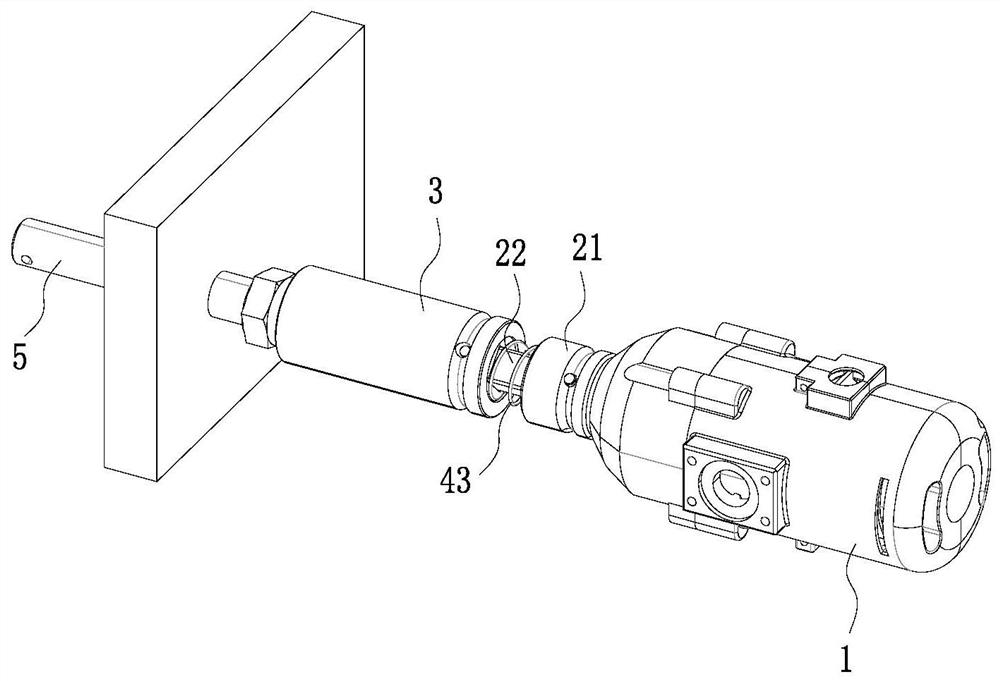

Self-adaptive electric sleeve for robot and robot

InactiveCN112658665AAvoid not fully tighteningPrevent disengagementGripping headsMetal working apparatusControl engineeringControl theory

The invention displays a self-adaptive electric sleeve for a robot. The self-adaptive electric sleeve comprises a driver, a guide shaft and a sleeve body used for screwing a bolt head; the guide shaft comprises a shaft body and a shaft base, the driver is connected with the shaft base, the sleeve body is arranged on the shaft body in a sleeving mode, and the driver controls the guide shaft to rotate; and the guide shaft and the sleeve body rotate synchronously, the sleeve body is connected with the shaft body in a sliding mode, the sleeve body moves in the length direction of the shaft body, the shaft body is sleeved with a spring used for enabling the sleeve body to be away from the shaft base, and the spring is located between the shaft base and the sleeve body. The self-adaptive electric sleeve has the advantage that the electric sleeve can be prevented from being disengaged or jacked. The invention further provides the robot.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JINHUA POWER SUPPLY CO +1

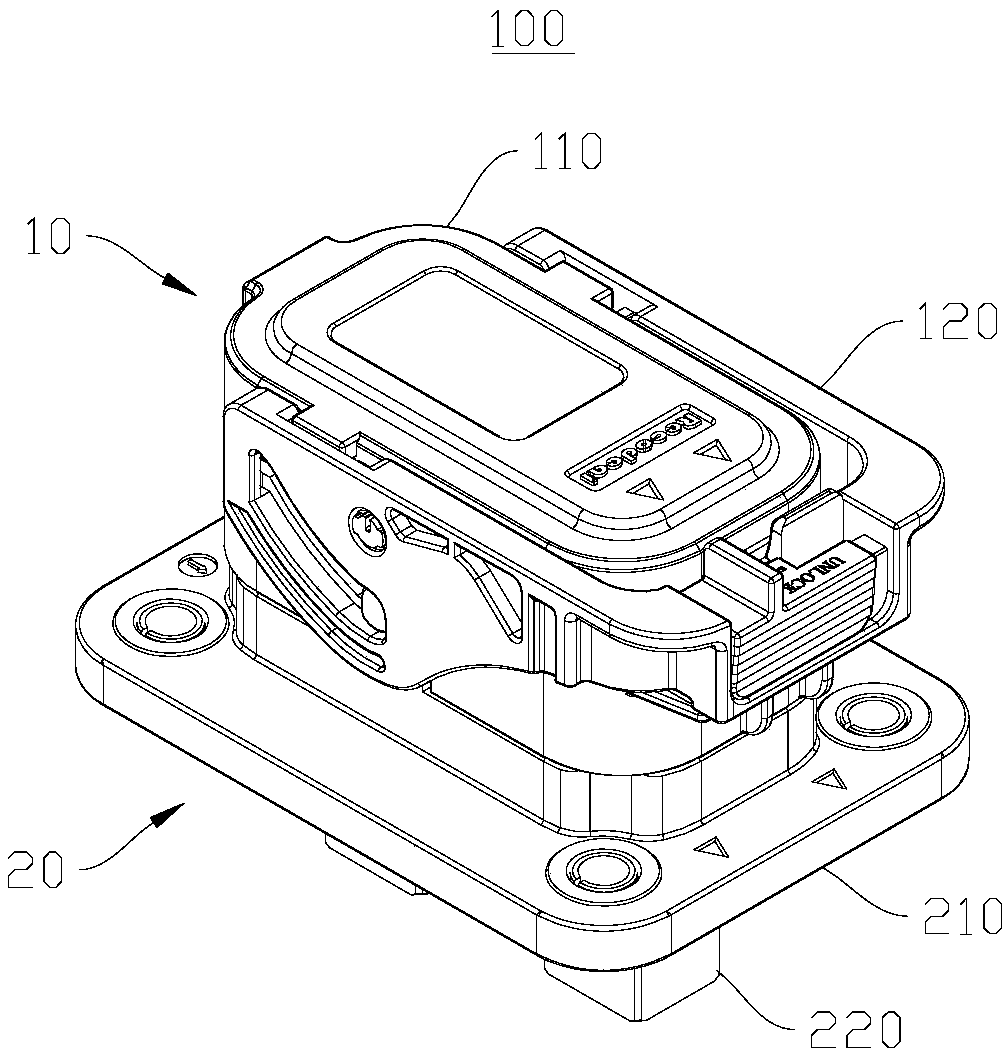

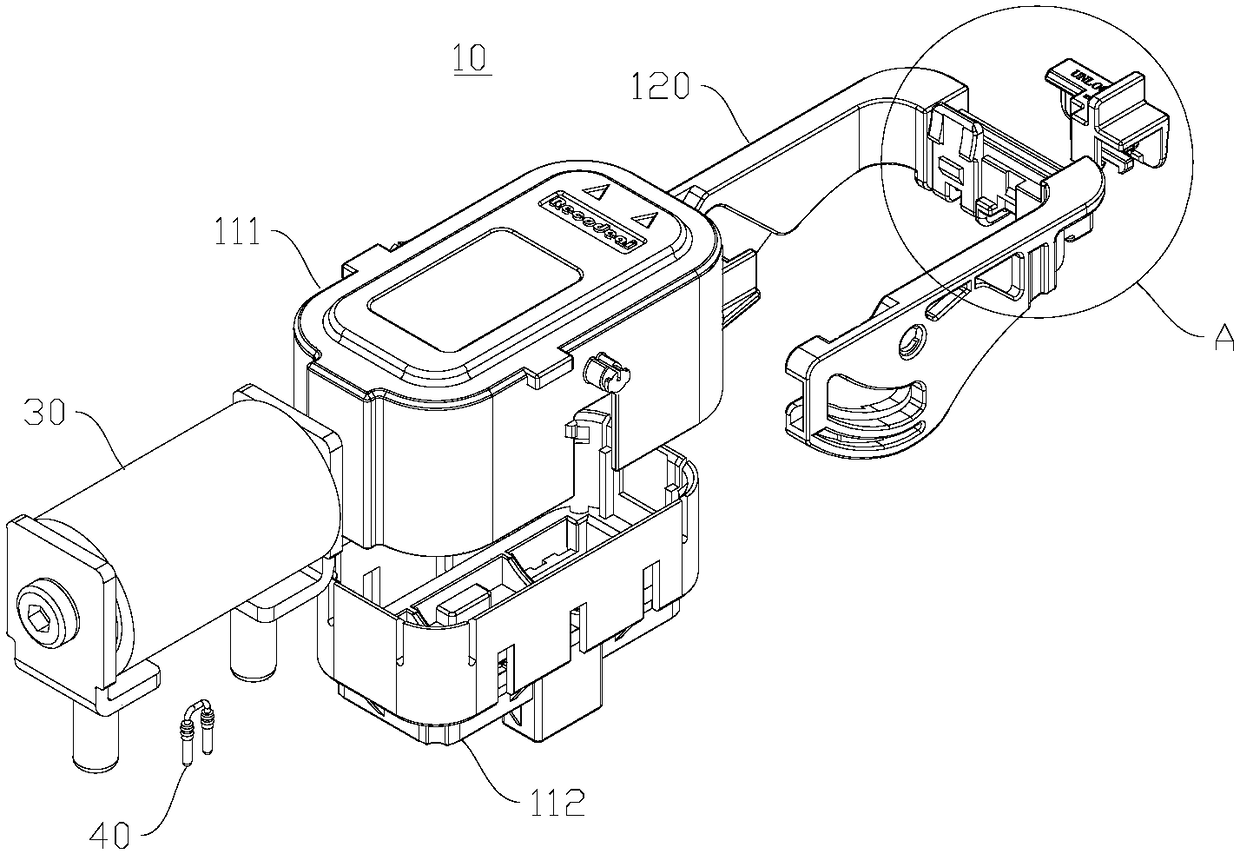

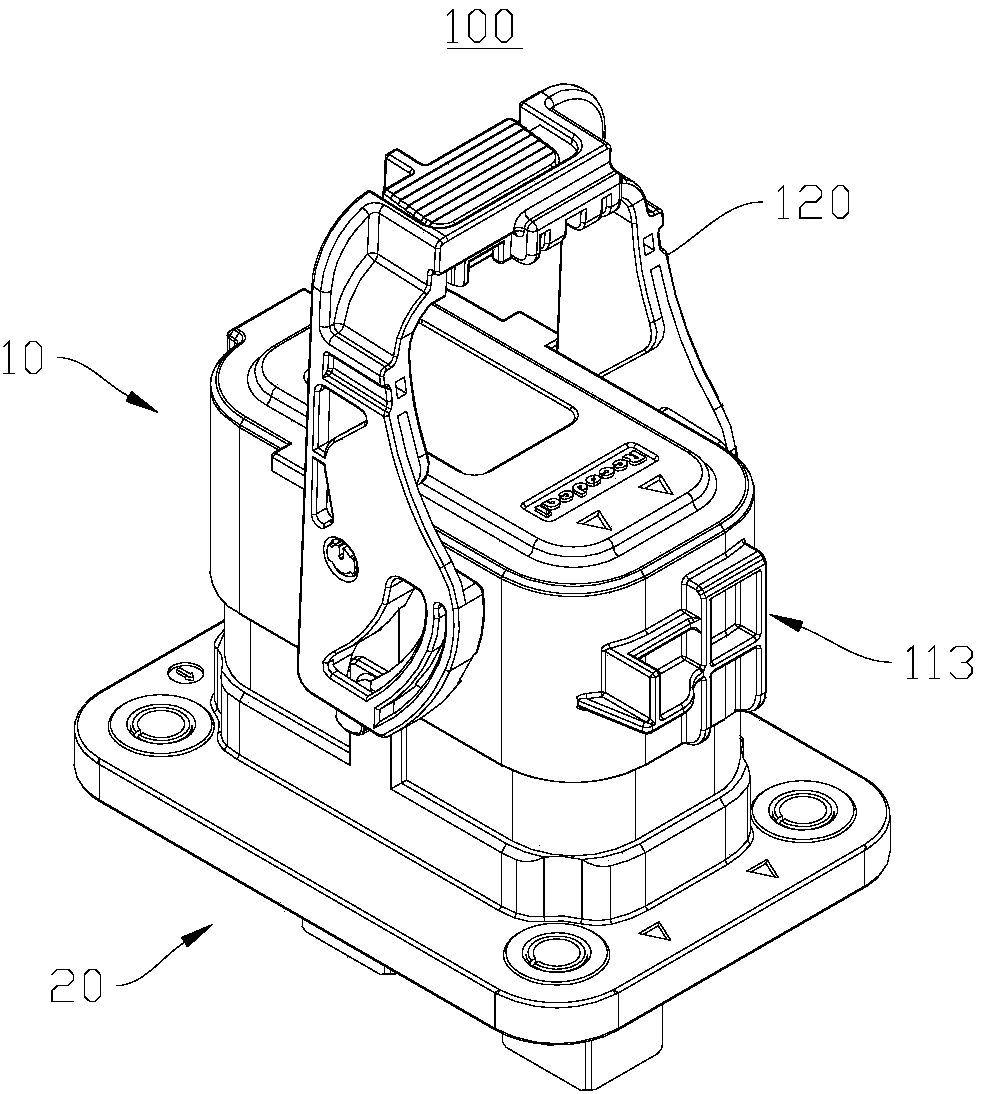

Manual maintenance switch

PendingCN108155514AReliable locking functionReliable lockingVehicle connectorsCoupling device detailsLocking mechanismEngineering

The invention discloses a manual maintenance switch and belongs to the technical field of electric passenger vehicles. The manual maintenance switch comprises a socket and a plug detachably connectedwith the socket. The plug comprises a first shell and a handle. One end of the handle is movably connected to the outer side wall of the first shell and the other end of the handle is respectively provided with a primary locking piece used for locking the handle to the first shell and a secondary locking piece used for locking the primary locking piece. The first locking piece is arranged on the inner side of the handle and is matched with a first locking groove arranged on the outer side wall of the first shell. The secondary locking piece is slidingly arranged on the handle The secondary locking piece comprises a spring bolt located on the inner side of the handle and a limiting plate connected with the spring bolt. The spring bolt is matched with a second locking groove arranged at theside of the primary locking piece. The limiting plate is in sliding connection with the primary locking piece. The manual maintenance switch is provided with a reliable locking mechanism and can be connected with the outside in three directions. The unlocking operation direction of the product is convenient to operate in a narrow space in the length direction of the product.

Owner:SICHUAN RECODEAL INTERCONNECT SYST CO LTD

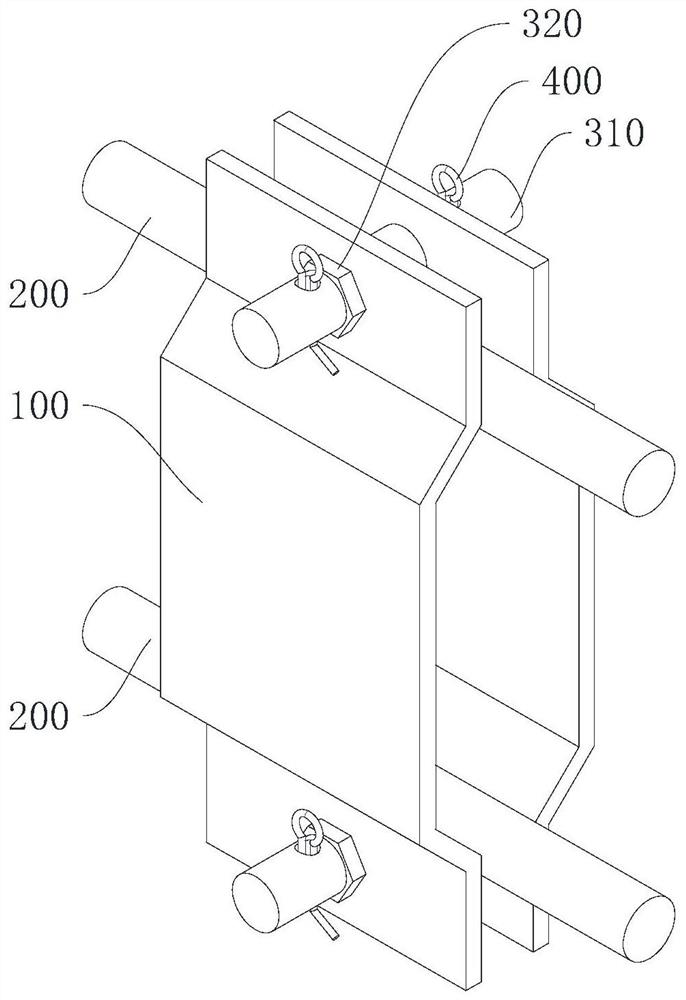

Vertical arrangement type double-suspension-clamp temporary protection device and pin repairing pretreatment method

ActiveCN112165030AAvoid Separation SituationsHigh degree of automationSuspension arrangements for electric cablesApparatus for overhead lines/cablesPretreatment methodSplit pin

The invention provides a vertical arrangement type double-suspension-clamp temporary protection device and a pin repairing pretreatment method. The vertical arrangement type double-suspension-clamp temporary protection device comprises a supporting frame, a self-walking assembly, a clamping assembly and a control unit. An insulating rod is arranged on the supporting frame, the self-walking assembly and the clamping assembly are arranged on the supporting frame, and the clamping assembly comprises two clamping plates. The control unit is electrically connected with the self-walking assembly andthe clamping assembly. The invention provides a pin repairing pretreatment method. The method comprises the steps that A, a supporting frame is moved to a wire through an insulating rod; B, the insulating rod is separated from the support frame; D, the self-walking assembly is started until the clamping assembly is in contact with the wire clamp; and D, the control unit controls the self-walkingassembly to stop, the clamping assembly is started, and the clamping plate is made to conduct clamping. Compared with the prior art, after the cotter pin is separated, the clamps can be clamped, and separation of the clamps is avoided.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

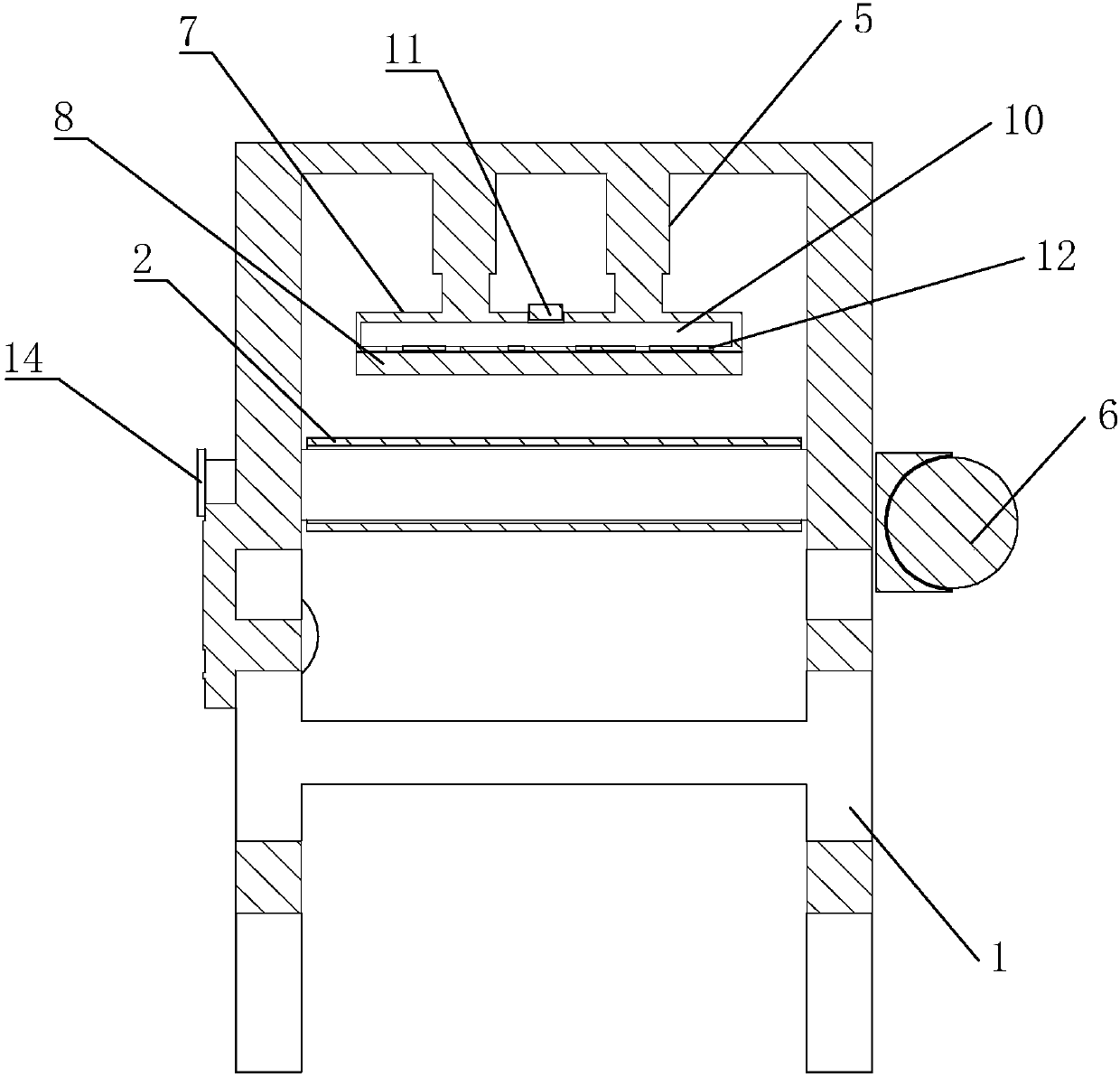

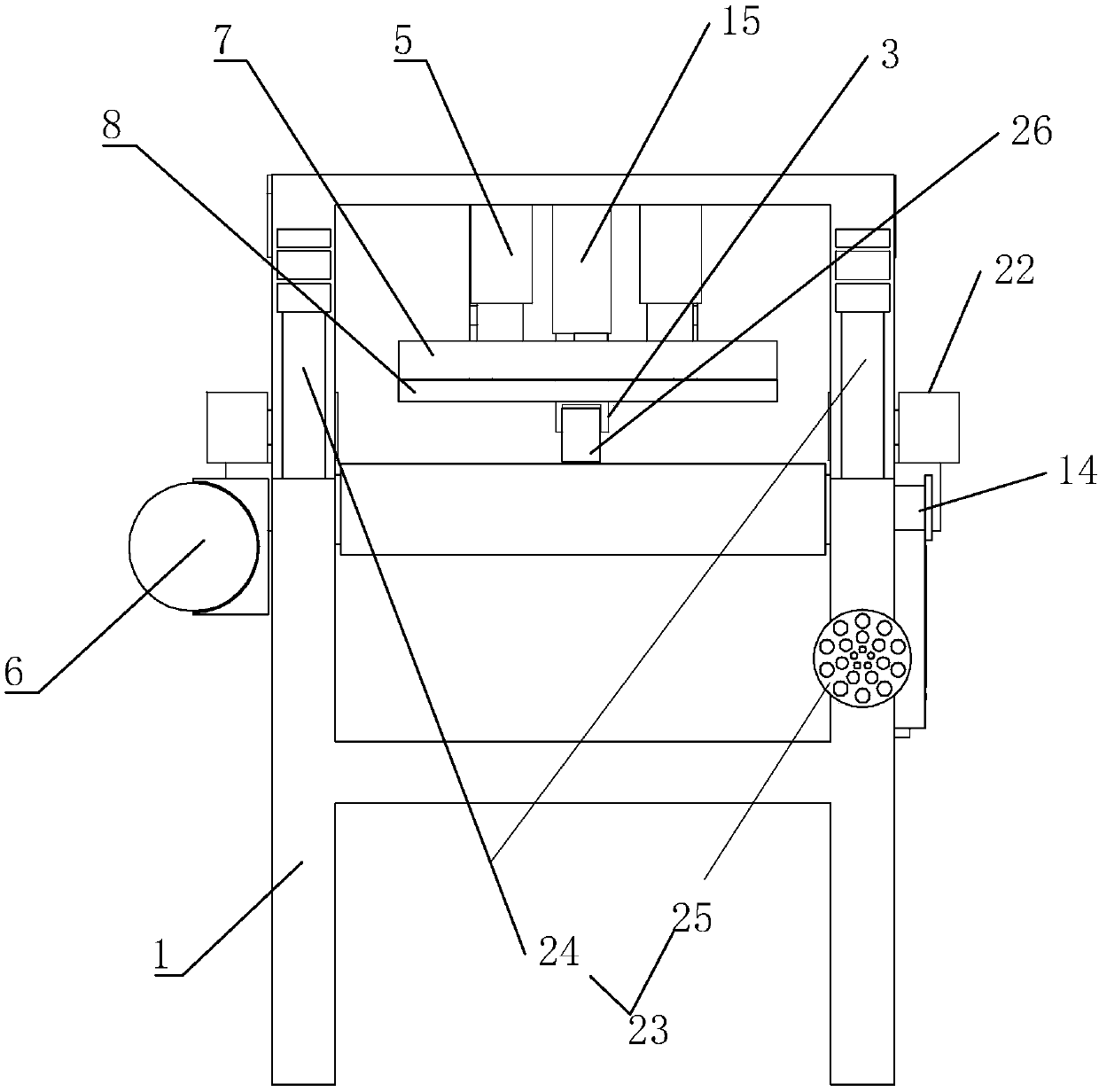

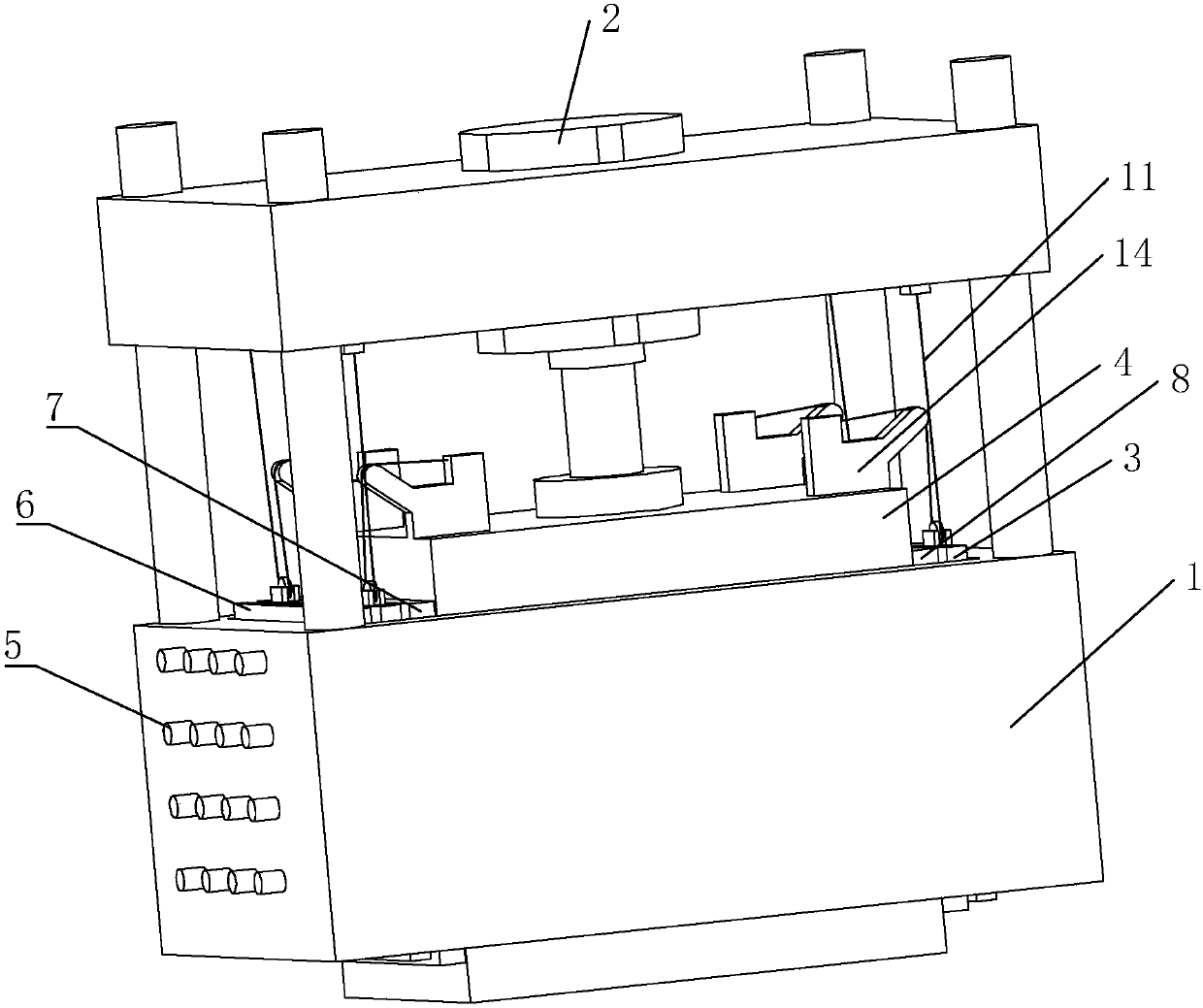

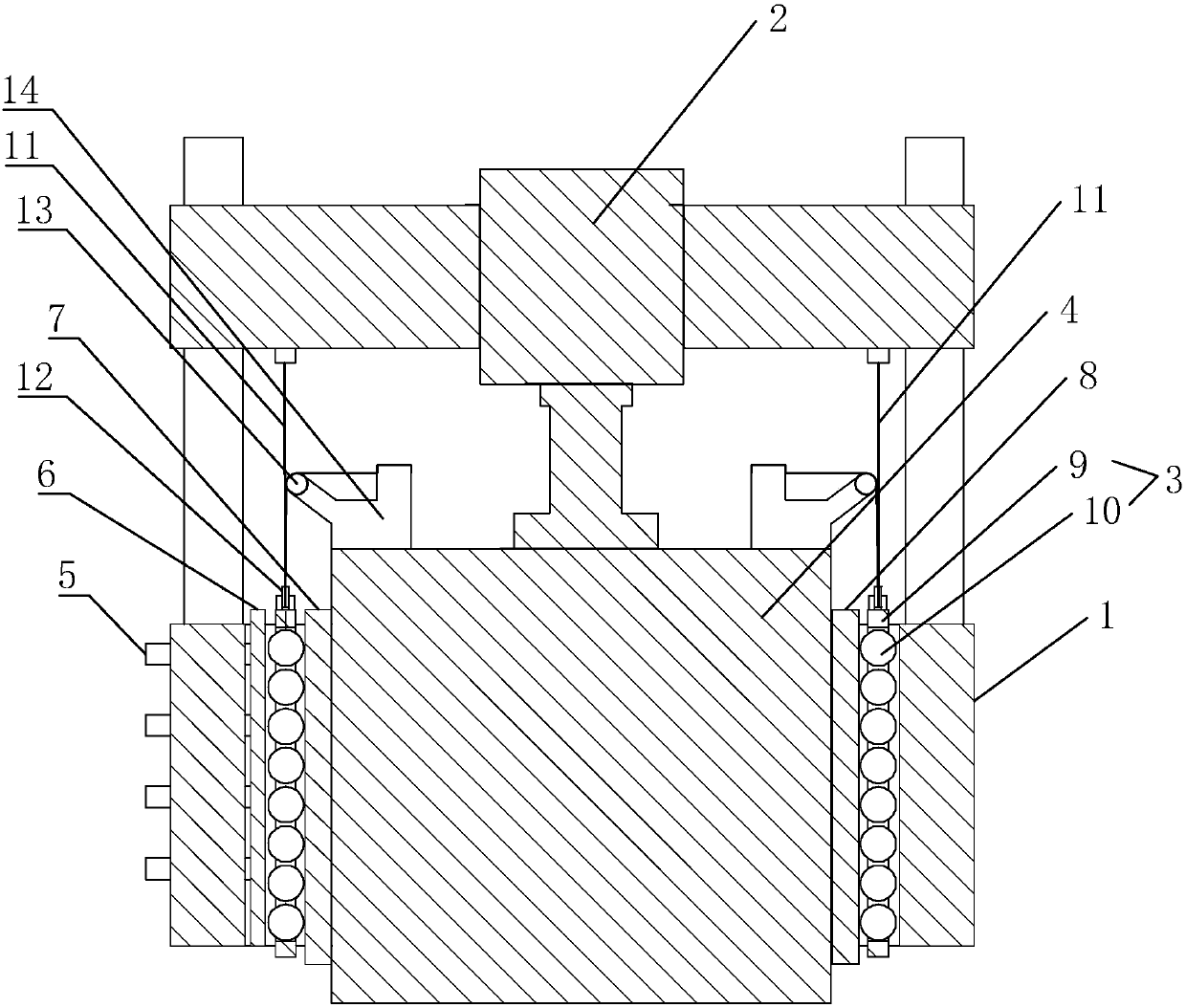

Pressure-shear testing machine with side guide rail and vertical loading cylinder

PendingCN107621421ASolve design problemsFix production issuesMachine part testingMaterial strength using steady shearing forcesCylinder blockVertical cylinder

The invention discloses a pressure-shear testing machine with a side guide rail and a vertical loading cylinder. The pressure-shear testing machine is characterized by including a machine frame, a vertical cylinder, a rolling guide rail, a load platform, a clamping mechanism and a pulley device; the clamping mechanism comprises a pretension bolt, a pushing plate, a first clamping plate and a second clamping plate, wherein the pretension bolt is mounted on one side of the machine frame, the pushing plate is connected with one end, located at the inner side of the machine frame, of the pretension bolt, the first clamping plate is installed on the surface of the pushing plate, the second clamping plate is installed on the machine frame, the load platform is arranged between the first clampingplate and the second clamping plate, a cylinder body of the vertical cylinder is installed above the machine frame, a piston rod of the vertical cylinder is arranged facing the load platform and fixed on the upper surface of the load platform, the pulley device is arranged on the machine frame and connected with the rolling guide rail. The pressure-shear testing machine with the side guide rail and the vertical loading cylinder provided by the invention can effectively solve the problems of design and manufacturing of large-load shearing force guide devices.

Owner:北京富力通达科技有限公司

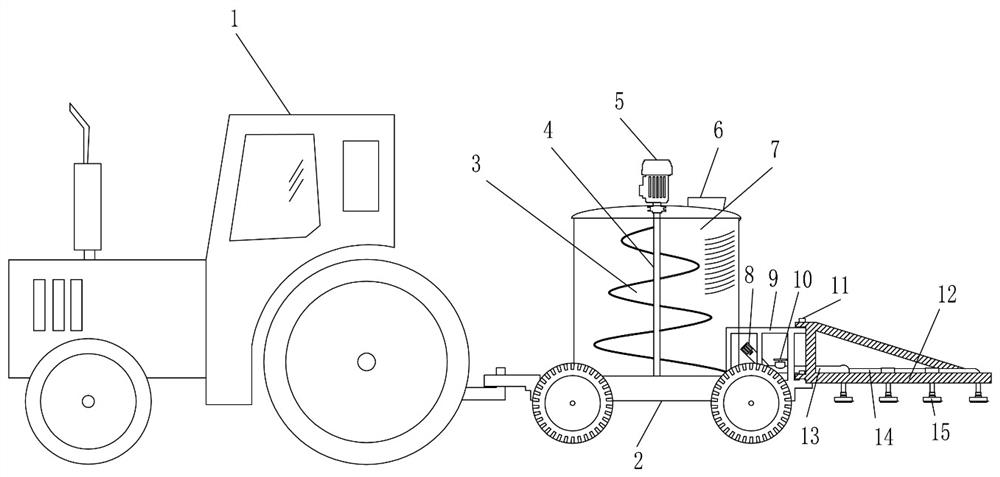

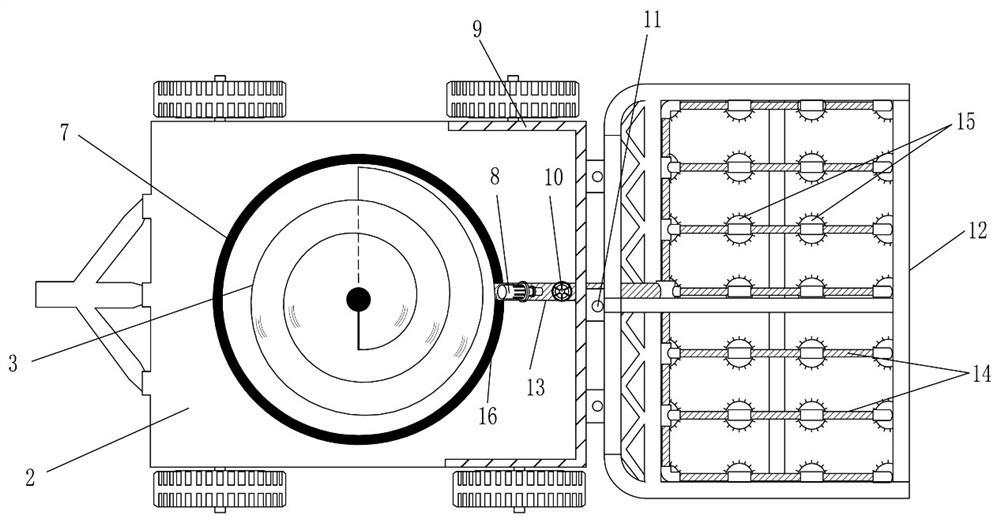

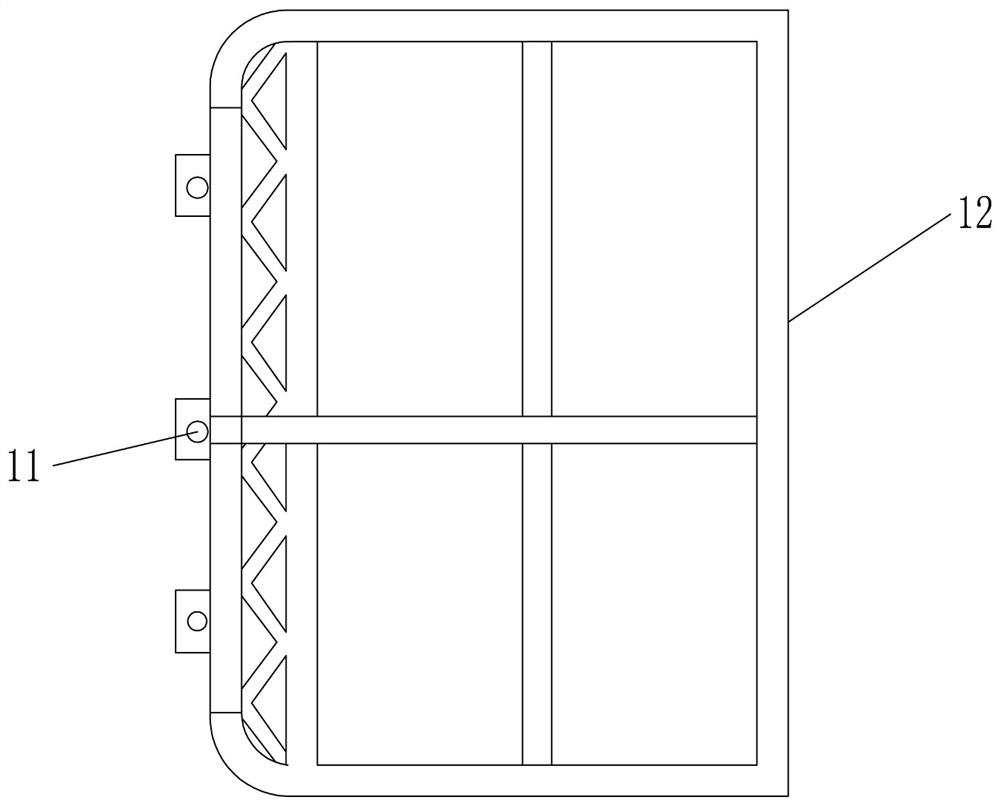

Slurry stirring and spraying machine for cemented sand and gravel dam

InactiveCN111906940AGuaranteed uniformityConditions affecting normal useFoundation engineeringCement mixing apparatusEngineeringSlurry

The invention relates to the technical field of slurry spraying, in particular to a slurry stirring and spraying machine for a cemented sand gravel dam. The slurry stirring and spraying machine is characterized in that a traction mechanism is connected and fixed to a supporting traveling mechanism, a slurry stirring system is arranged above the supporting traveling mechanism, a supporting frame isconnected to the tail end of the supporting traveling mechanism, a spray head system is arranged on the supporting frame, and the spray head system is connected with the slurry stirring system. According to the slurry stirring and spraying machine for the cemented sand gravel dam, a cementing material can be uniformly sprayed on an aggregate, so that uniform slurry spraying on the sand and gravelworking face is realized, the penetration degree of sprayed slurry adapts to the laying thickness of the aggregate, the slurry spraying amount per unit area can be accurately controlled, a water-cement mixture of the cementing material can be continuously stirred, and the phenomenon of water-cement separation is avoided.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Carton paperboard production conveying line capable of being marked and use method thereof

PendingCN107791581AConvenient length measurementAvoid Separation SituationsConveyorsPaper-makingCartonPaperboard

The invention discloses a carton paperboard production conveying line capable of being marked. According to the technical scheme, the production conveying line comprises a rack, and a conveying belt arranged on the rack, a stroke detecting device colliding with the surface of the conveying belt is arranged on the rack, a marking device is arranged on the rack, a roller of the stroke detecting device collides with the surface of the conveying belt, and a displayer is arranged on the rack, and is connected with the output end of a controller. According to the carton paperboard production conveying line capable of being marked, the paperboard surface can be marked, and a worker can conveniently carry out bending operation on the paperboard.

Owner:安吉县格林纸箱厂

Paperboard conveying line facilitating carton production and use method thereof

PendingCN107792693AReduce labor intensityIncrease productivityPaper-makingBox making operationsCardboardEngineering

The invention discloses a paperboard conveying line facilitating carton production. According to the technical scheme, the paperboard conveying line is characterized by comprising a rack and a conveying belt arranged on the rack; a support located on the upper side of the conveying belt is arranged on the rack, an abutting pressing device is arranged on the support, a stoke detection device abutting against the surface of the conveying belt is arranged on the rack, a marking device is arranged on the rack, guide strip plates are arranged on the rack, infrared detectors are arranged on the guide strip plates, a processor is arranged on the rack, and resetting devices which are used for resetting paperboards are arranged at the positions, on the two sides of the conveying belt, of the rack correspondingly. By the adoption of the paperboard conveying line facilitating carton production, the carton paperboards can abut against the surface of the conveying belt in a pressed manner, the situations that the carton paperboards drift on the conveying belt and fall off from the conveying belt are avoided, the drifting detection and the reset operation can be conducted on the paperboards on the conveying belt, the surfaces of the paperboards can be marked, and the paperboards can be bent by workers conveniently.

Owner:安吉多美家具厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com