Slurry stirring and spraying machine for cemented sand and gravel dam

A cemented sand gravel dam and slurry spraying technology, which is applied to cement mixing devices, infrastructure engineering, clay preparation devices, etc., can solve the problems of uneven mixing of cementitious materials and aggregates and less consumption, and reduce the Construction cost, ensure uniformity, ensure quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1. At present, when the cemented sand and gravel dam is being constructed, there is no special mixing and spraying link. The existing construction method is to add a small amount of cementitious material and water to the sand and gravel and then turn it over with a mixer or a material pit. Due to the small amount of cementitious material, the use of mixer or pit turning method will cause uneven mixing of cementitious material and aggregate, and in the process of loading and unloading, transportation and warehousing, etc. , all have varying degrees of separation of aggregate and cementitious material.

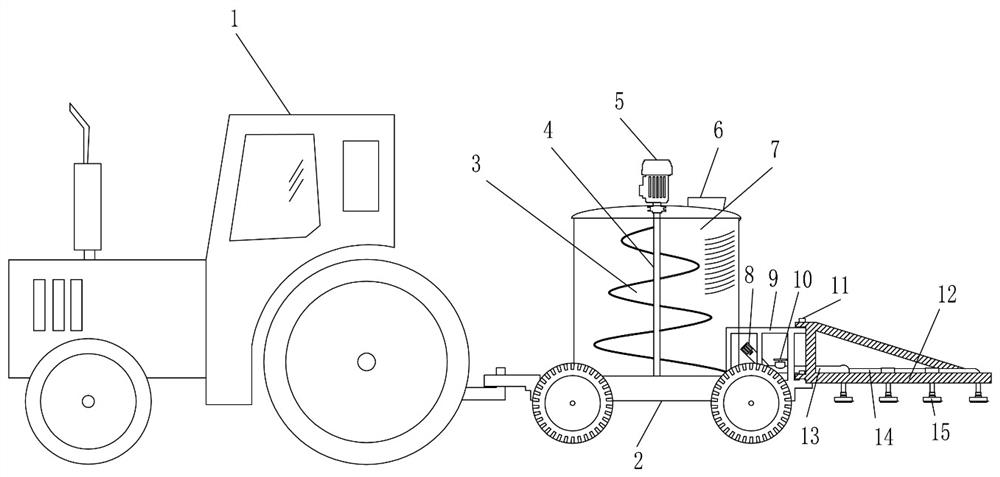

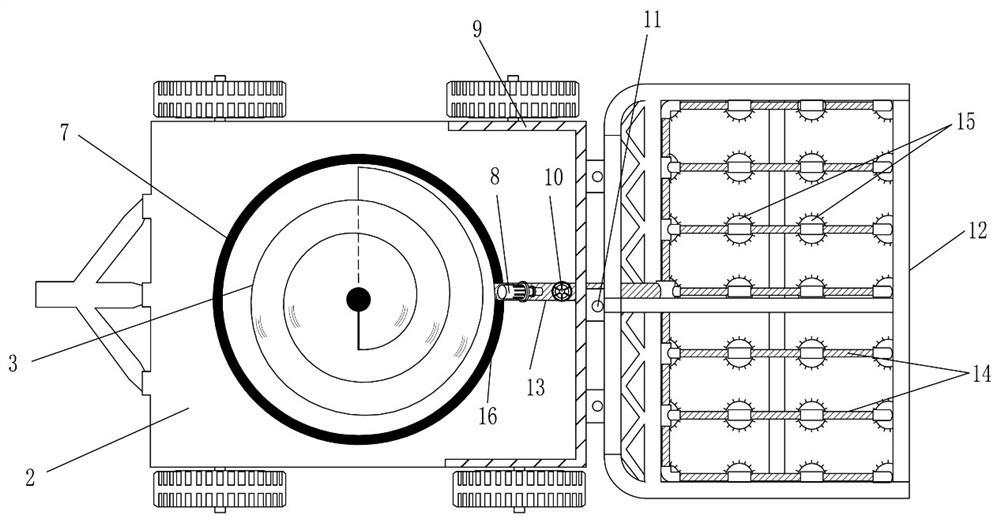

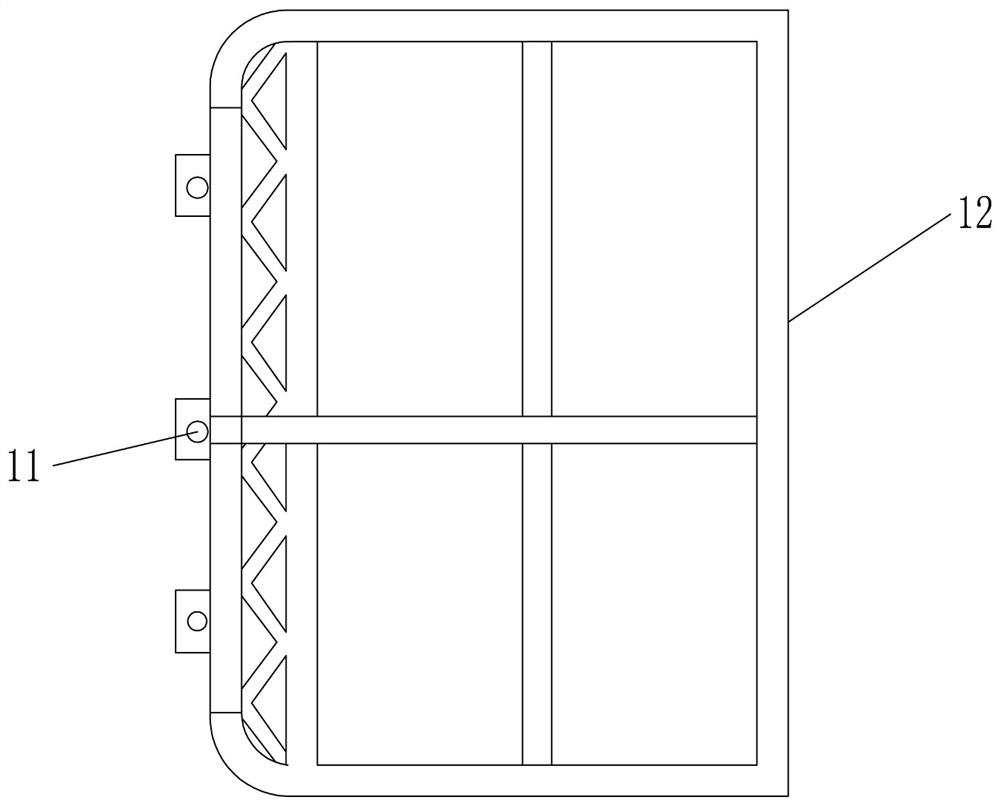

[0025] In view of the above problems, this embodiment provides a cemented sand and gravel dam slurry spraying machine, such as figure 1 Shown, comprise four-wheeled cart 2, the head end of four-wheeled cart 2 is fixedly connected together with the tail end of tractor 1, and tractor 1 drives four-wheeled cart 2 as traction power, and tractor 1 is a high-horsepower ...

Embodiment 2

[0027] Embodiment 2, a grouting and spraying machine for cemented sand and gravel dam in this implementation will be described centering on the differences from Embodiment 1.

[0028] In the present embodiment, the stirring blade 3 is a stirring spiral blade, and the outer diameter of the stirring blade 3 gradually decreases from the bottom to the top, and the outer diameter of the bottom of the stirring blade 3 is larger, so that the glue on the bottom of the stirring tank 7 can be more comprehensively adjusted. Stirring the cementitious material improves the stirring efficiency of the cementitious material, makes the mixing more uniform, and improves the grouting effect.

Embodiment 3

[0029] Embodiment 3, a cemented sand and gravel dam mixing and spraying machine in this implementation will be described centering on the differences from Embodiment 1.

[0030] In this embodiment, a guardrail is fixedly installed above the rear half of the four-wheeled cart 2. The added guardrail can better ensure the personal safety of the operator and prevent the operator from falling when feeding through the feed port 6. Condition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com