Self-adaptive electric sleeve for robot and robot

A robotic and self-adaptive technology, applied in manipulators, metal processing, metal processing equipment, etc., can solve problems affecting efficiency, cumbersome operation process, and high difficulty, so as to reduce operation difficulty, high alignment fault tolerance rate, and improve success rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

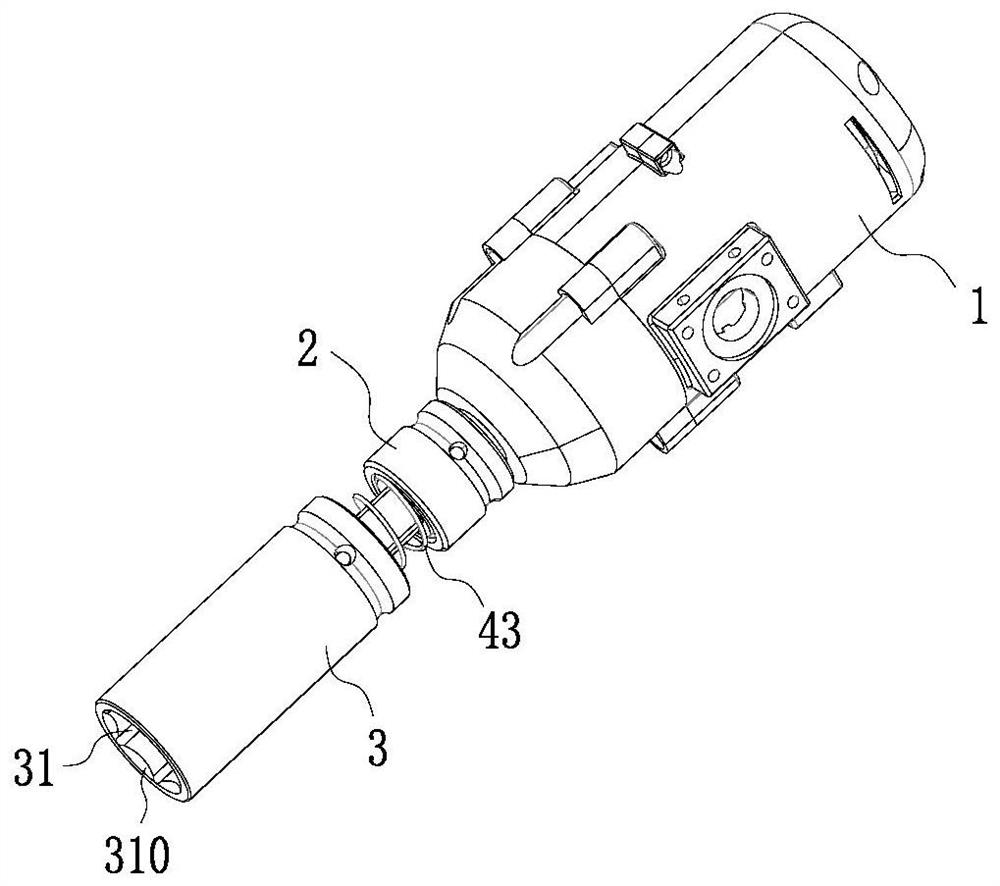

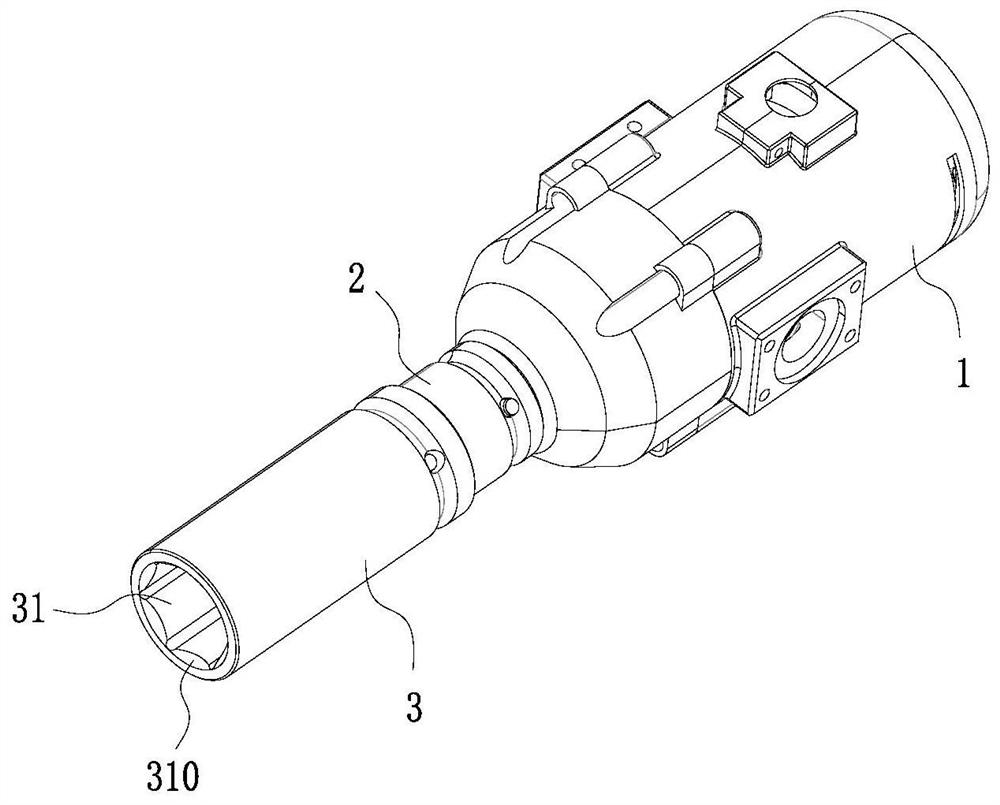

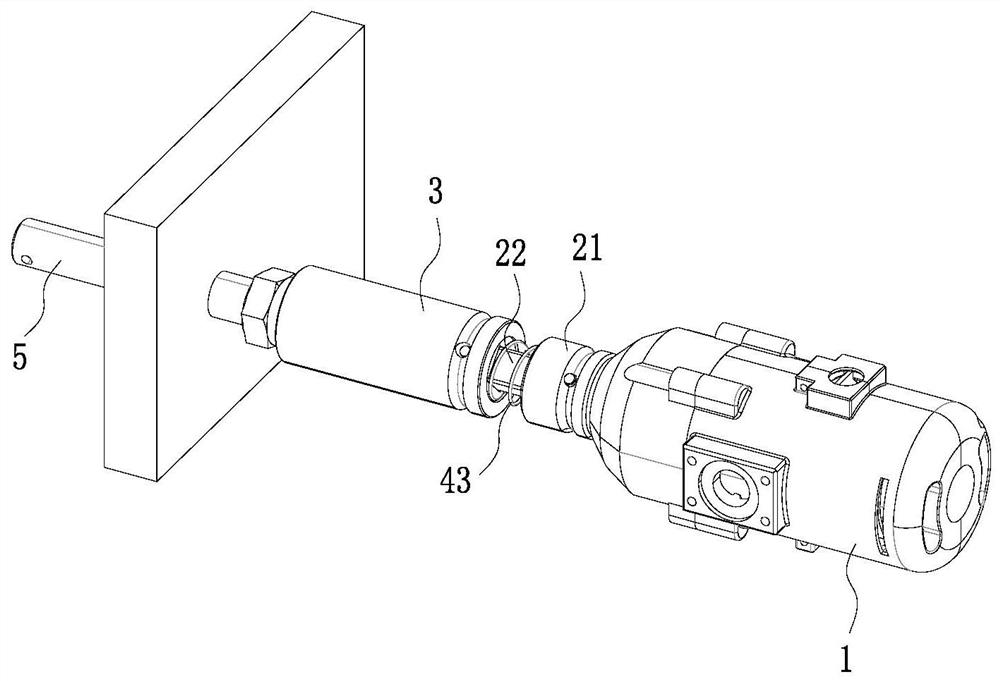

[0034] like Figure 1 to Figure 7 As shown, this embodiment shows an adaptive electric sleeve 3 for a robot, including a driver 1, a guide shaft 2 and a sleeve 3 for screwing a bolt head, and the guide shaft 2 includes a shaft body 22 and Shaft seat 21, the driver 1 is connected with the shaft seat 21, the sleeve 3 is sleeved on the shaft body 22, the driver 1 controls the rotation of the guide shaft 2, and the guide shaft 2 and the sleeve 3 rotate synchronously, the sleeve 3 is slidingly connected with the shaft body 22, the sleeve 3 moves along the length direction of the shaft body 22, and the shaft body 22 is sleeved with a The spring 43 is located between the shaft seat 21 and the sleeve 3 .

[0035] In this embodiment, the self-adaptive electric sleeve 3 includes a guide shaft 2 and a sleeve 3, the sleeve 3 is sleeved on the shaft body 22 of the guide shaft 2, and the sleeve 3 can 22 moves in the length direction, the shaft 22 is also sleeved with a spring 43, the spri...

Embodiment 2

[0047] This embodiment shows a robot, the robot includes an electric sleeve 3, the robot is used to eliminate power fittings, the electric sleeve 3 is as described in Embodiment 1 or other identical or similar embodiments electric socket 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com