Patents

Literature

37results about How to "Improve replacement rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Control water valve convenient to replace

InactiveCN107701750AEasy to replaceEasy to snap in and fixOperating means/releasing devices for valvesSlide valveEngineeringControl valves

The invention provides an easy-to-replace control water valve, which includes a valve seat. Both sides of the top of the valve seat are hinged with a first connecting rod through a rotating shaft. A hollow tube is fixedly installed on one side of the outer surface of the first connecting rod. The inner wall of the hollow tube One side of the valve is fixedly installed with a connecting spring, one end of the connecting spring is fixedly connected with a limit block, one side of the limit block is fixedly installed with a fixed rod, the upper and lower sides of the fixed rod are welded with pull rods, and the two sides of the outer surface of the valve seat Both are fixedly installed with L-shaped rods, and one side of the outer surface of the L-shaped rods is fixedly installed with a concave plate, and one side of the concave plate is clamped with one end of the fixed rod through the opening slot. The easy-to-replace control water valve facilitates the clamping and fixing of the fixed rod and the concave plate on the L-shaped rod by setting the connecting spring, thereby facilitating the disassembly of the support rod and the first connecting rod, making the disassembly method simpler , Only one person can complete the disassembly operation, thus saving the use of manpower.

Owner:JOHNSTON FLOW TECH WUXI CO LTD

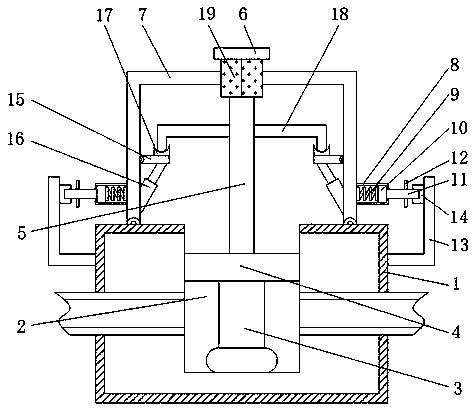

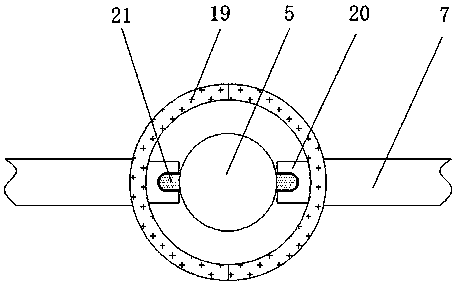

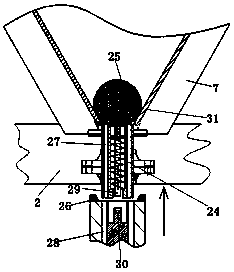

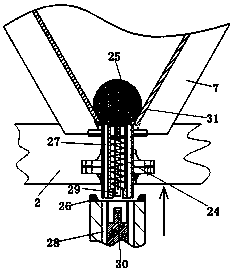

Dust-reduction spraying device for tunnel construction

InactiveCN108561174AImprove applicabilityAvoid blockageDust removalFire preventionLocking mechanismWater source

The invention provides a dust-reduction spraying device for tunnel construction. The dust-reduction spraying device comprises a base and is characterized in that a water tank is fixedly mounted on oneside of the top of the base, connecting blocks are welded to two sides of the inner cavity of the water tank, a first filter screen is arranged between the two connecting blocks, the bottom of the first filter screen contacts with the tops of the connecting blocks, clamp blocks are welded to two sides of the bottom of the first filter screen, one sides of the clamp blocks are clamped with the slots of the connecting blocks, a second filter screen is fixedly mounted at the top of the first filter screen, a sealing plate is hinged to one side of the top of the water tank through hinges, one side of the sealing plate is provided with a locking mechanism, a water outlet in one side of the water tank is fixedly connected with a water pump through a pipeline, and an atomizing mechanism is fixedly mounted on one side of the water pump through a pipeline. The dust-reduction spraying device has the advantages that impurities in water can be filtered through the first filter screen and the second filter screen, so that the device can use water from rivers nearly without causing blocking, and the adaptability of the spraying device is increased.

Owner:向朝婉

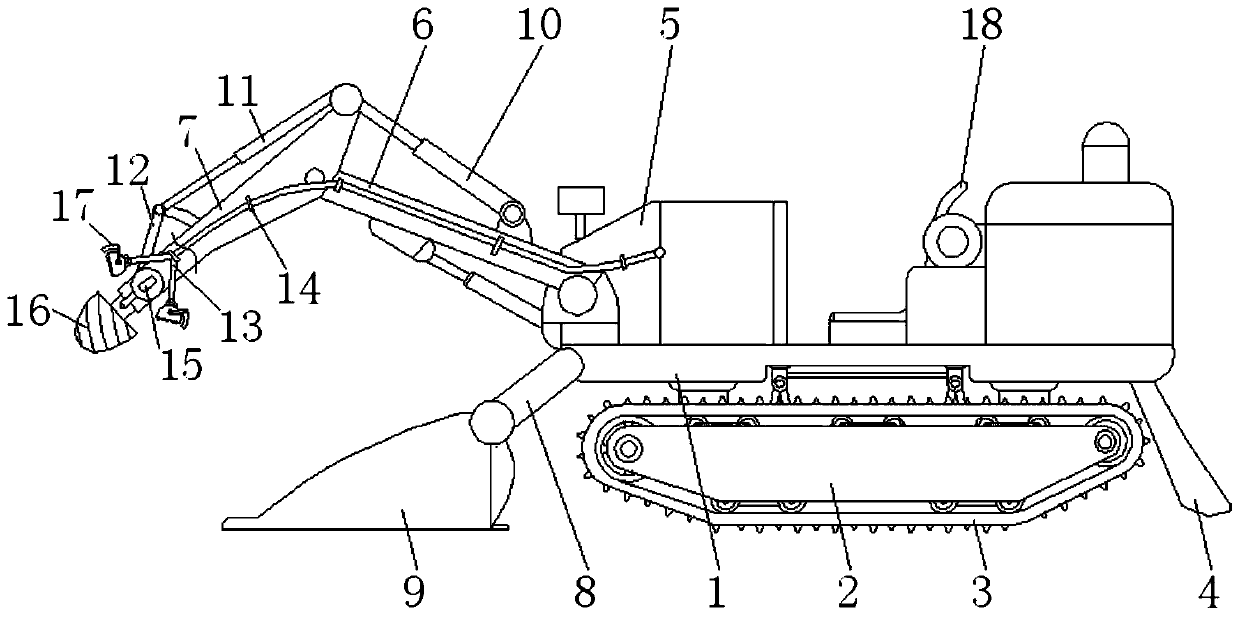

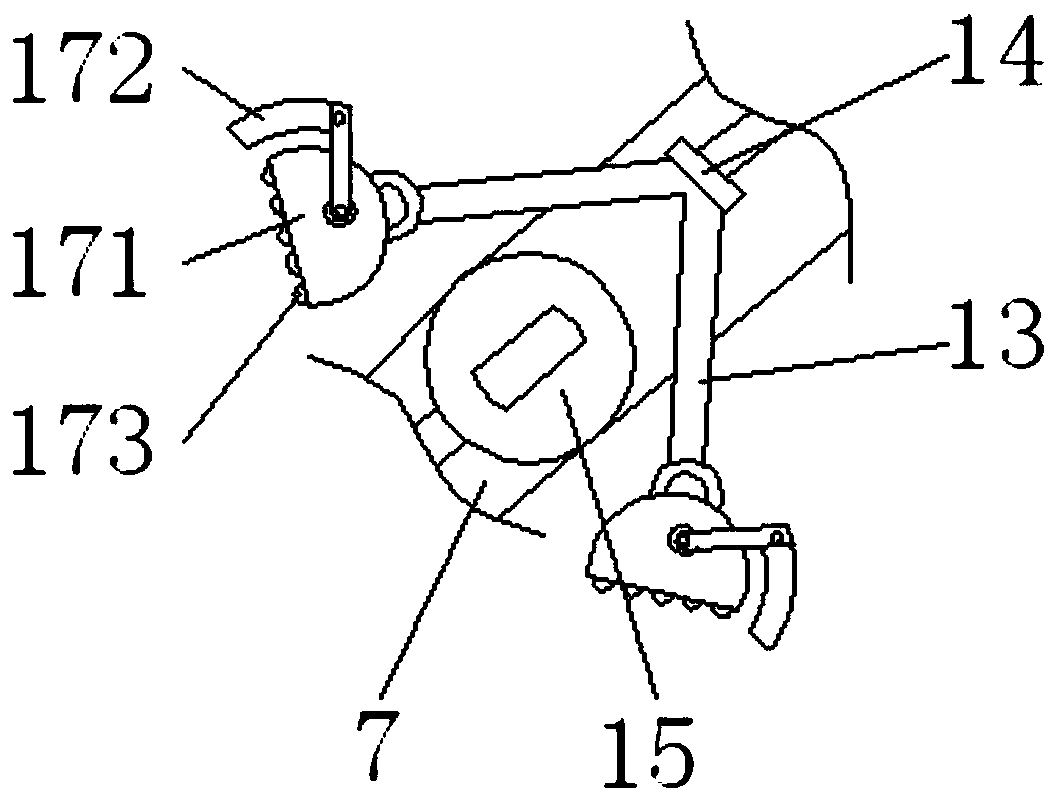

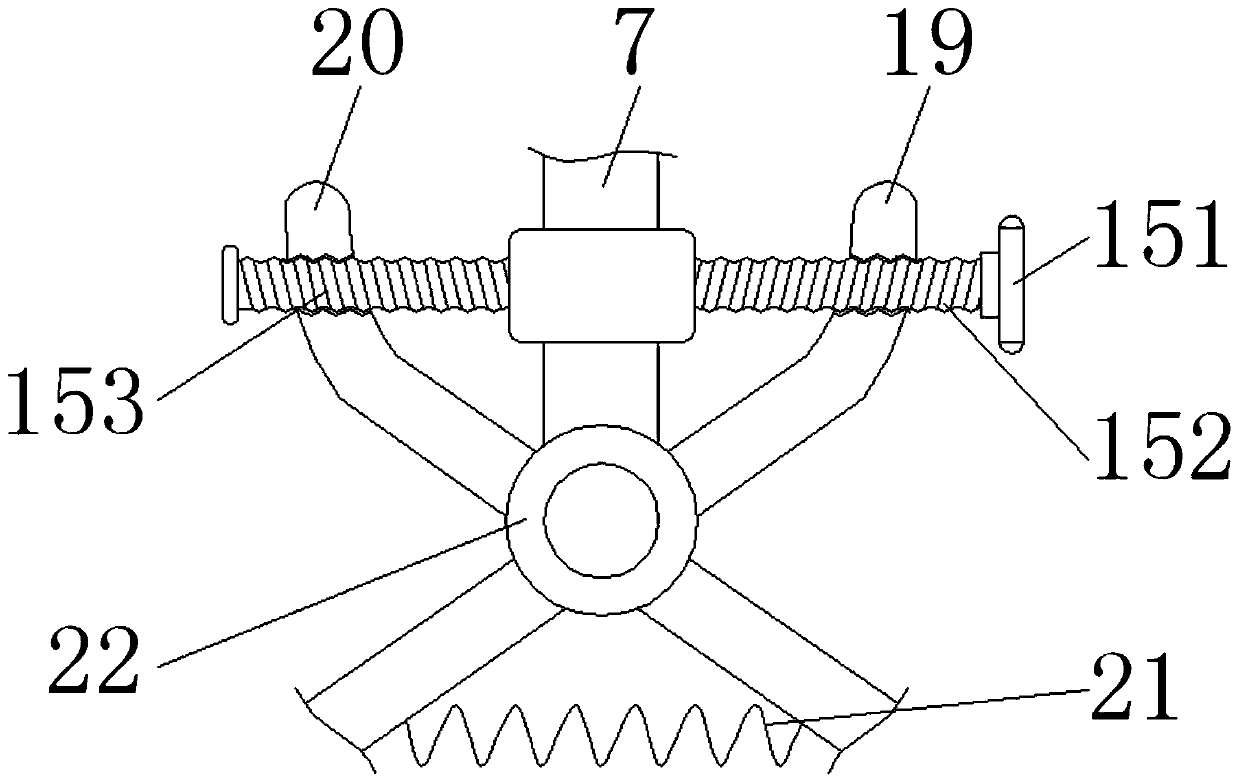

Cantilever type heading machine for tunnel excavation

The invention relates to the technical field of heading machines and discloses a cantilever type heading machine for tunnel excavation. The heading machine comprises a heading machine body, the left side of the upper surface of the heading machine body is fixedly connected with a box, the bottom of the heading machine body is fixedly connected with a driving supporting device, the outer surface ofthe driving supporting device is in transmission connection with a crawler belt, the left side of the box is movably connected with a supporting arm, the left end of the supporting arm is movably sleeved with a transmission arm, and the left end of the transmission arm is clamped with a heading head through a fastening device. According to the cantilever type heading machine for tunnel excavation, an included angle of 90 degrees is formed between two dust removal devices and a conveying tube, so that a proper amount of dustproof foam is conveniently sprayed on the position of a heading end for exploitation, the dustproof foam plays a role in solidifying dust, the spraying coverage rate is high, the flying degree of dust in a tunnel is reduced, the definition of the visual field of a useris improved, meanwhile, the dustproof foam cannot melt geology which is melted immediately when meeting water and is extremely easy to disintegrate, and the user can conveniently excavate.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

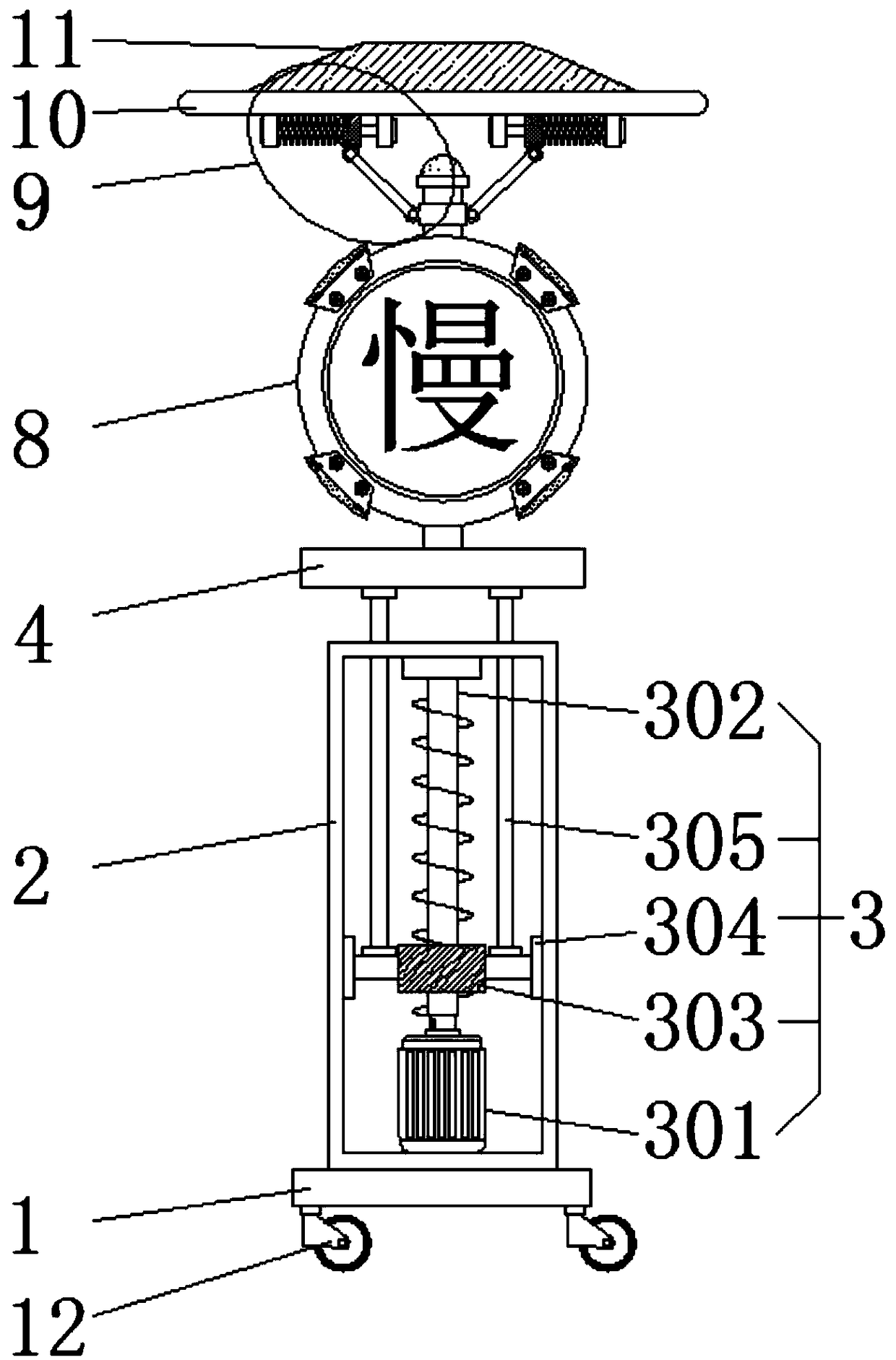

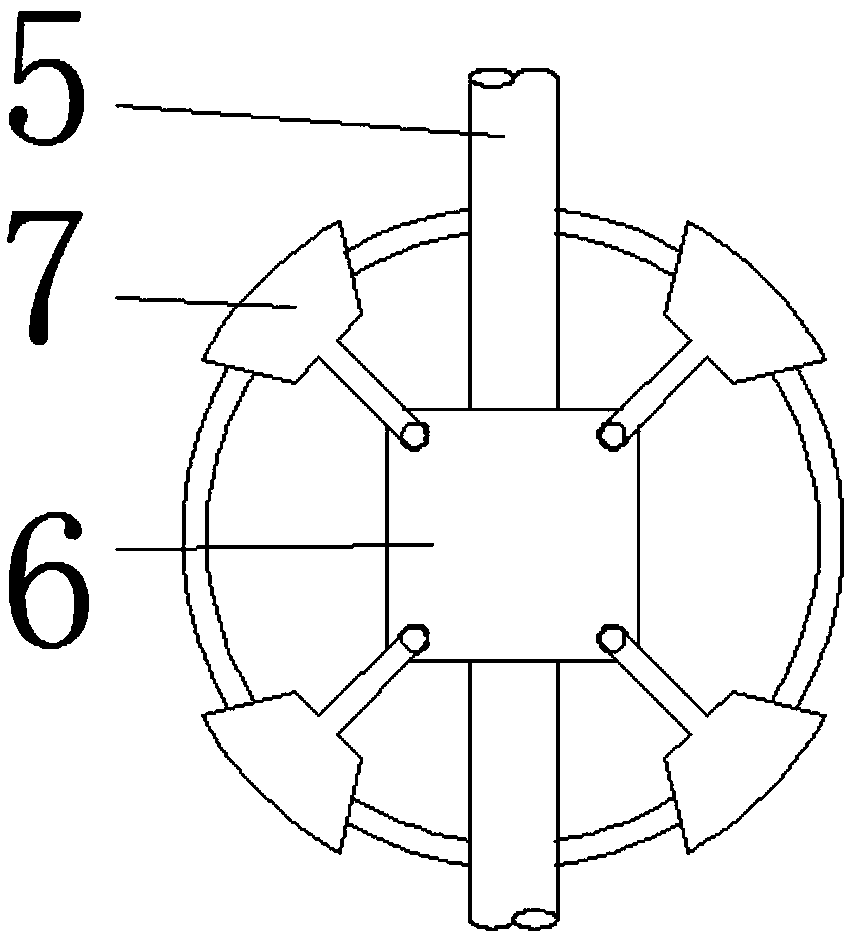

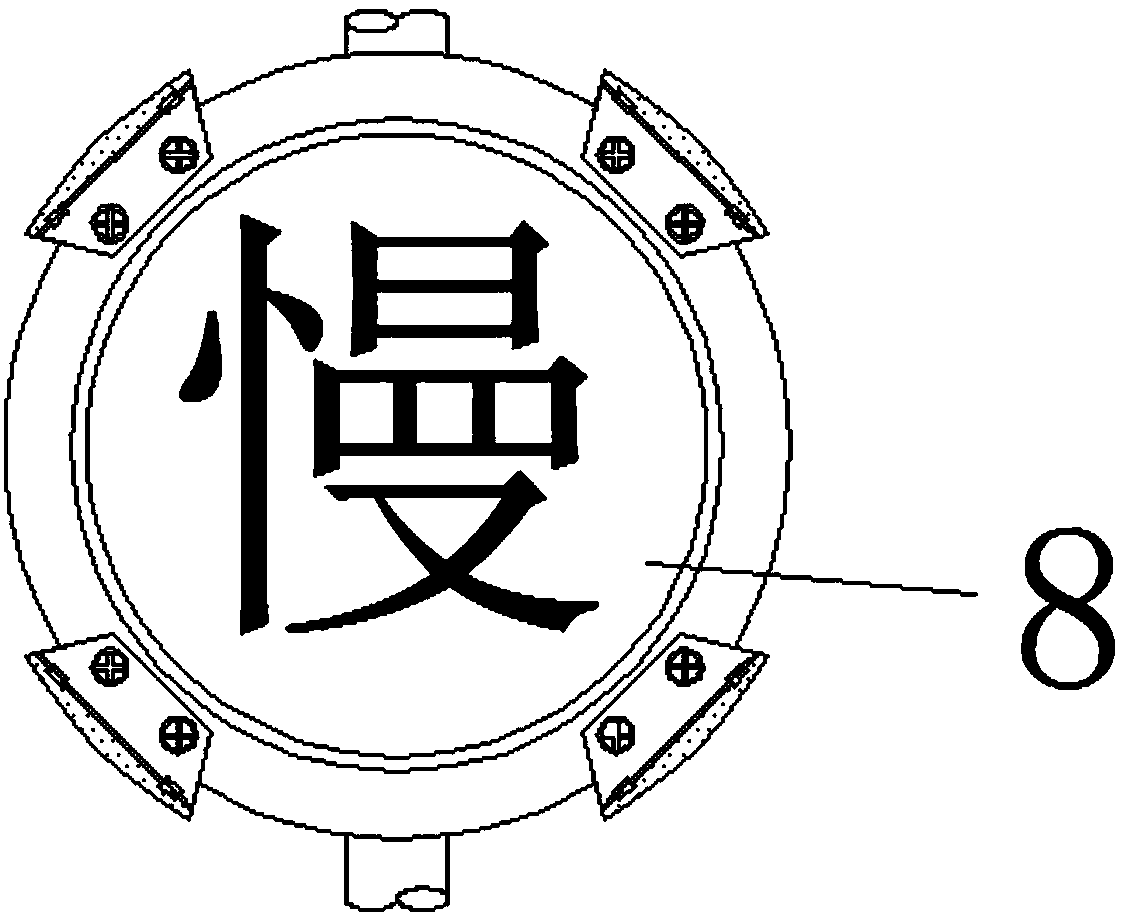

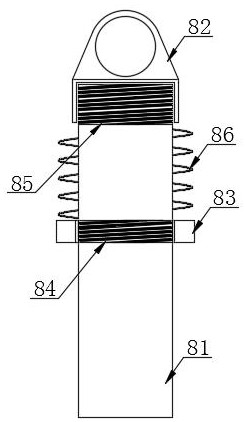

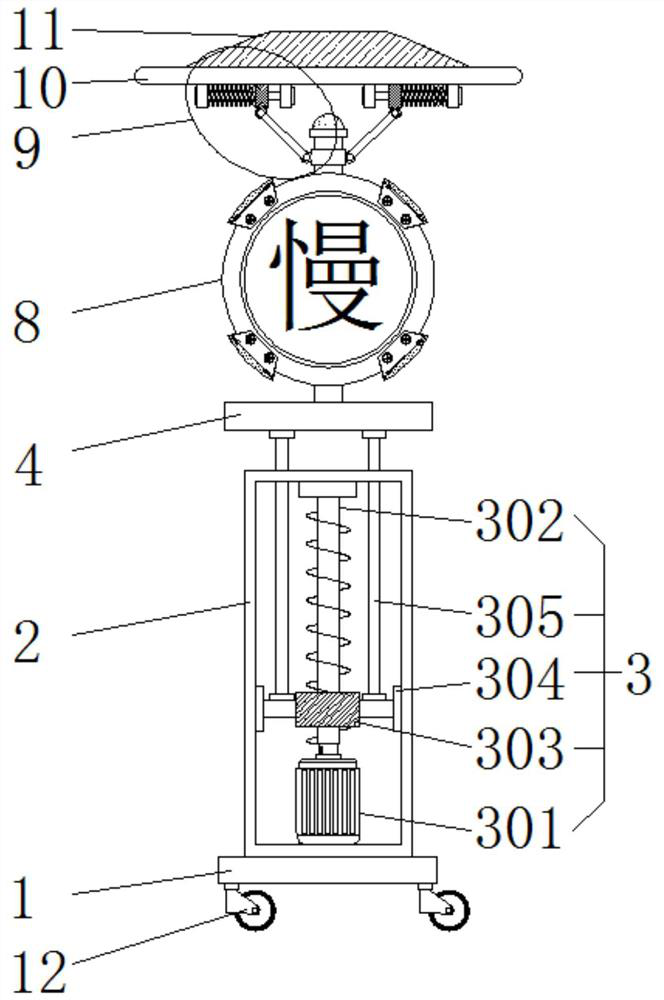

Reminder device convenient for replacing warning signs for power supply construction

The invention discloses a reminder device convenient for replacing warning signs for power supply construction, including the base, a vertical lifting column is fixedly installed on the upper surfaceof the base, and a lifting device is installed in the lifting column, a threaded rod is driven to rotate by opening a driving motor, so that the threaded connecting block moves linearly along the threaded rod, as such, the push rod push and adjusts the height of the connecting plate, the range of warning signs on the connection board is increased, to facilitate the replacement of damaged or otherwarning signs by staff, Increased rate of replacement, the buffer device can improve the protection of the arc cover and the shielding plate in rainy and snowy weather, as the arc cover and the shieldplate are impacted by the rain and snow, the shield plate is moved downward so that the distance between the shield plate and the fixing plate is reduced, and the two slide blocks are separated alongthe slide rail under the push of the rotating lever, and the springs on the slide rail are compressed at the same time, thereby cushioning, damping and protecting the arc cover and the shield plate.

Owner:国网河南省电力公司嵩县供电公司 +2

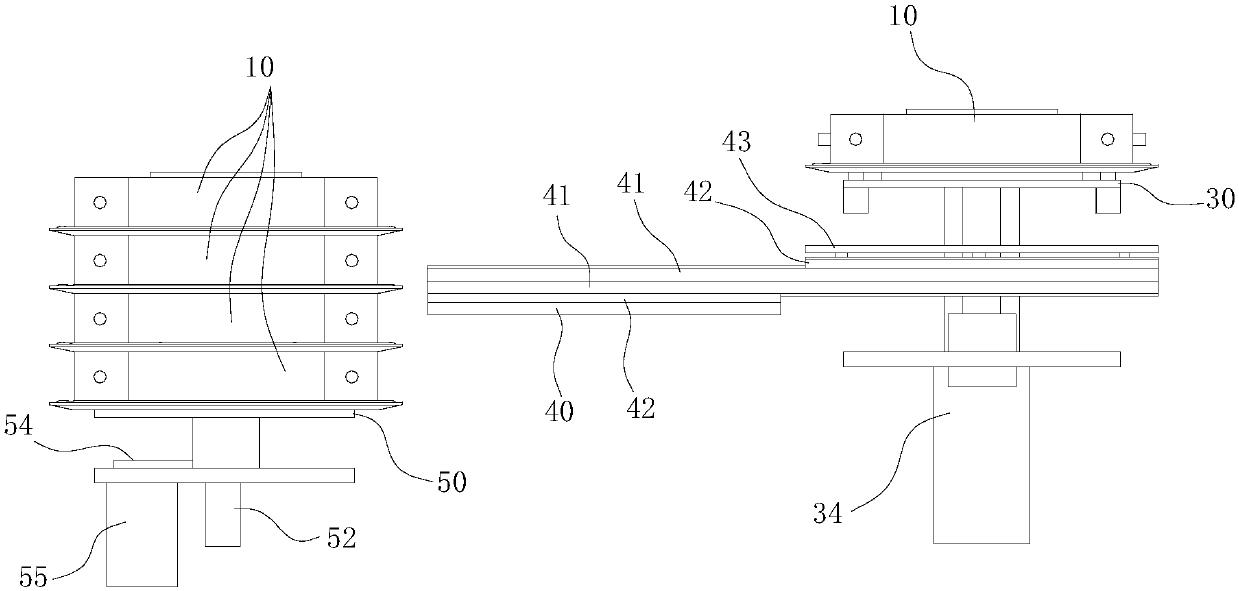

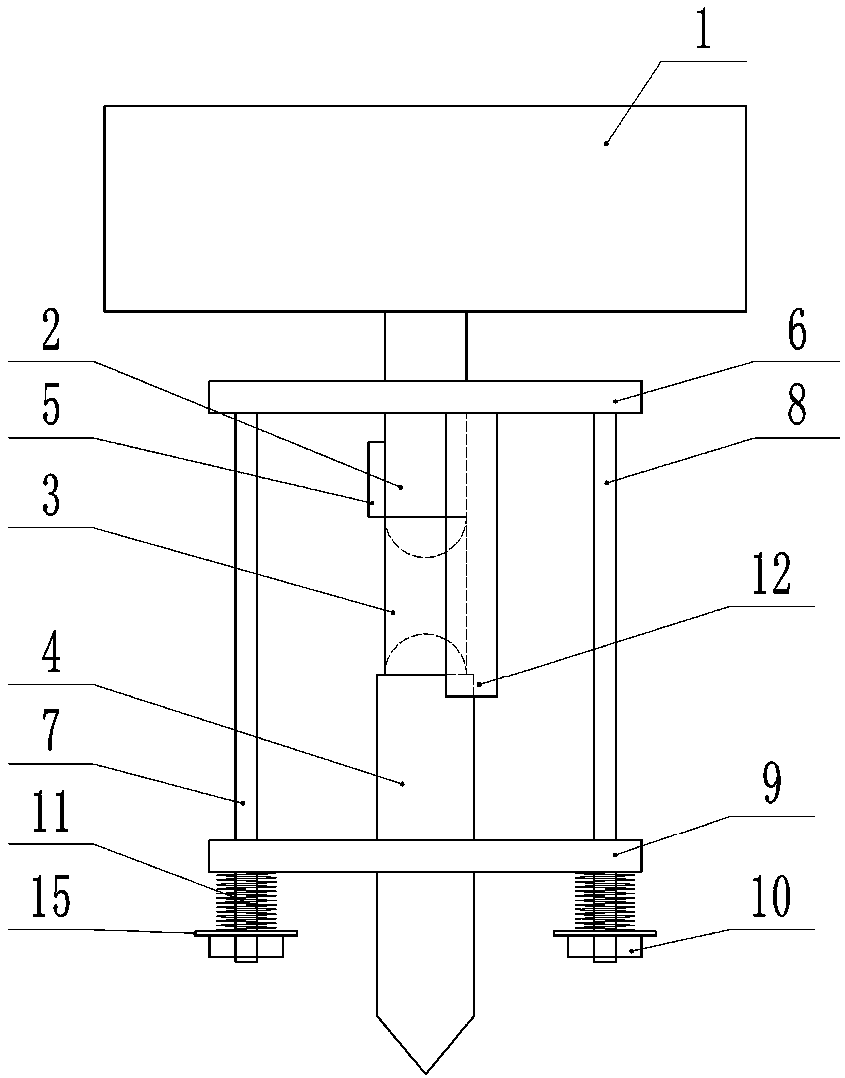

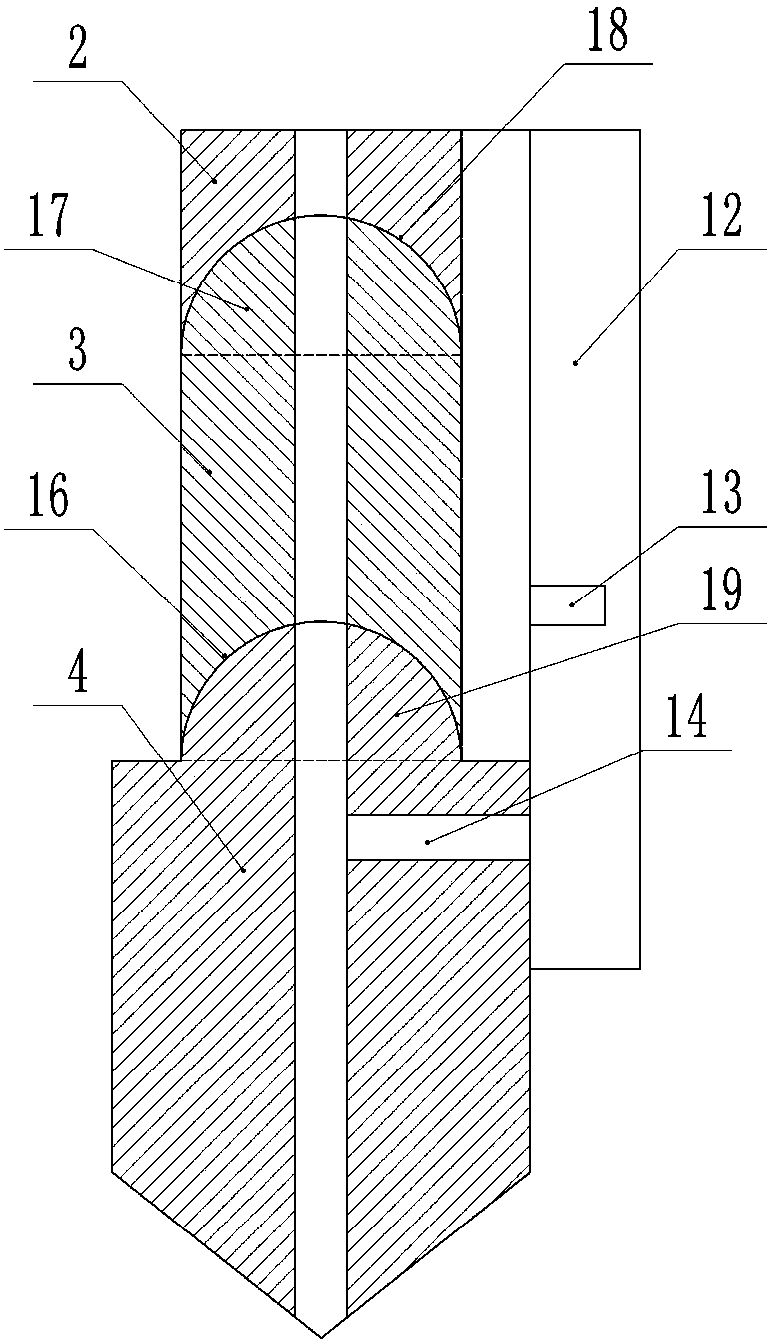

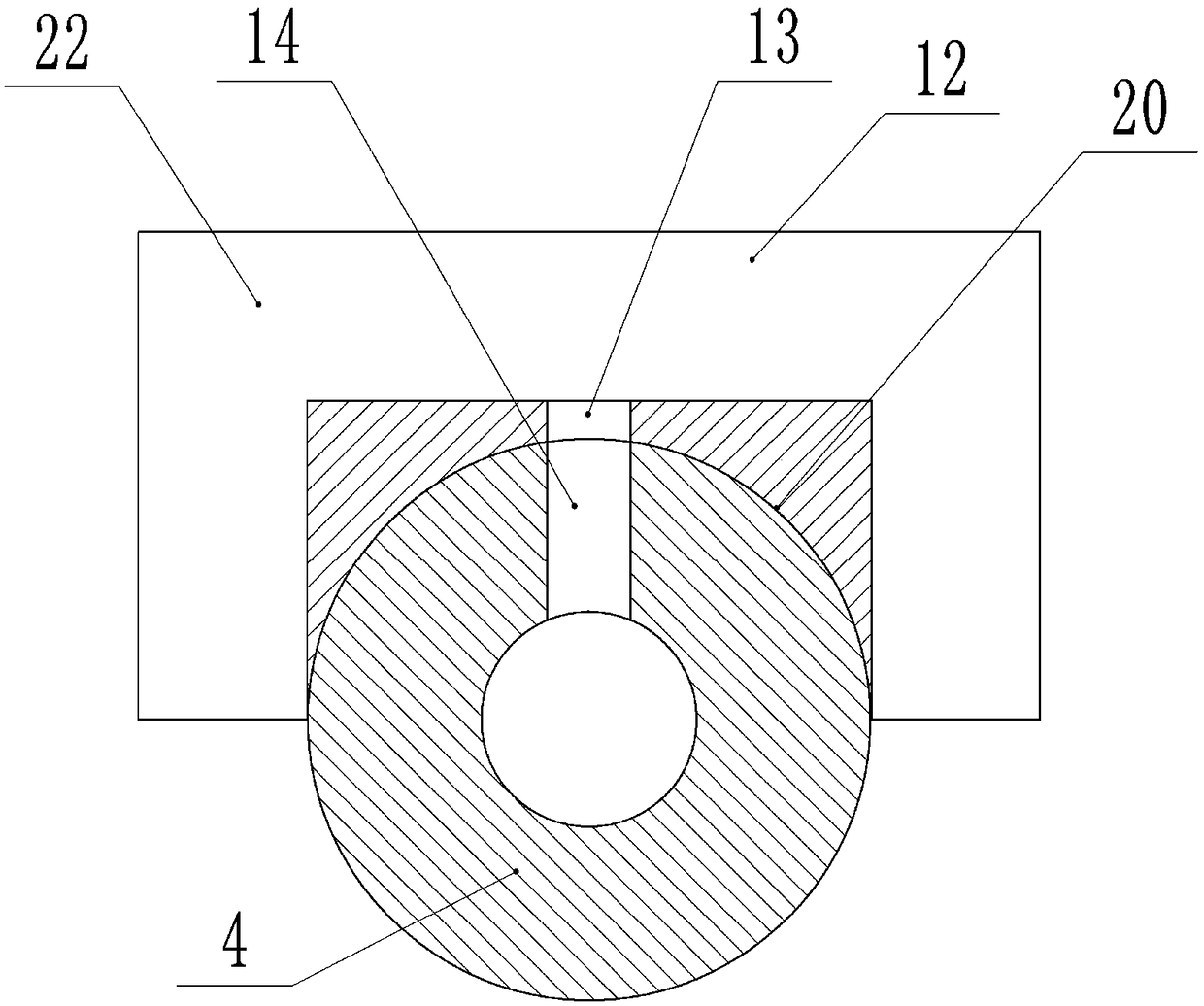

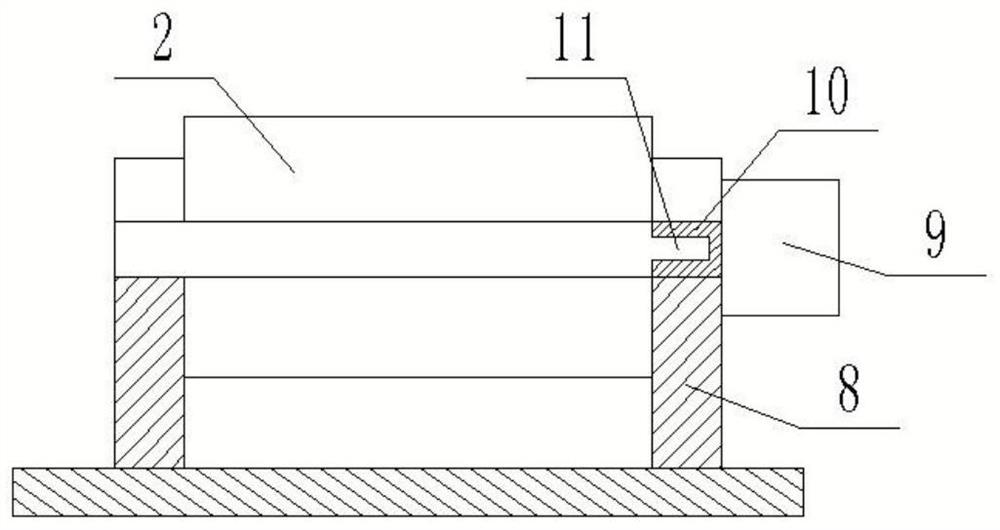

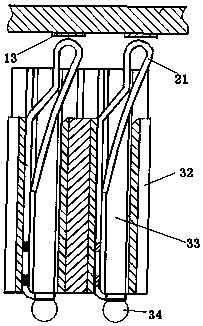

Device for disassembling battery of electric car

InactiveCN107650881AQuick releaseImprove replacement rateElectric propulsion mountingElectric vehicle charging technologyNew energyAutomotive battery

The invention belongs to the technical field of energy supply of new energy vehicles, and particularly relates to a device for disassembling a battery of an electric car. The device for disassemblingthe battery of the electric car comprises a lifting mechanism, a translation mechanism and a stacking mechanism. The lifting mechanism comprises a tray reciprocatingly arranged in a vertical direction. The tray is provided with a trigger actuating mechanism capable of triggering a triggering device. The translation mechanism includes two horizontally arranged cantilevers parallel to each other. The cantilevers reciprocate between the lifting mechanism and the stacking mechanism in the self length direction. The cantilevers are provided with lifting arms reciprocating in the vertical direction.When the cantilevers are located at the position of the lifting mechanism, the lifting arms are just located under the flange protruding outwards from the battery edge. The disassembling device can quickly disassemble the battery of the electric car so as to increase the battery replacement speed and provide technical support for the new energy supply mode of the electric car.

Owner:胡小玲

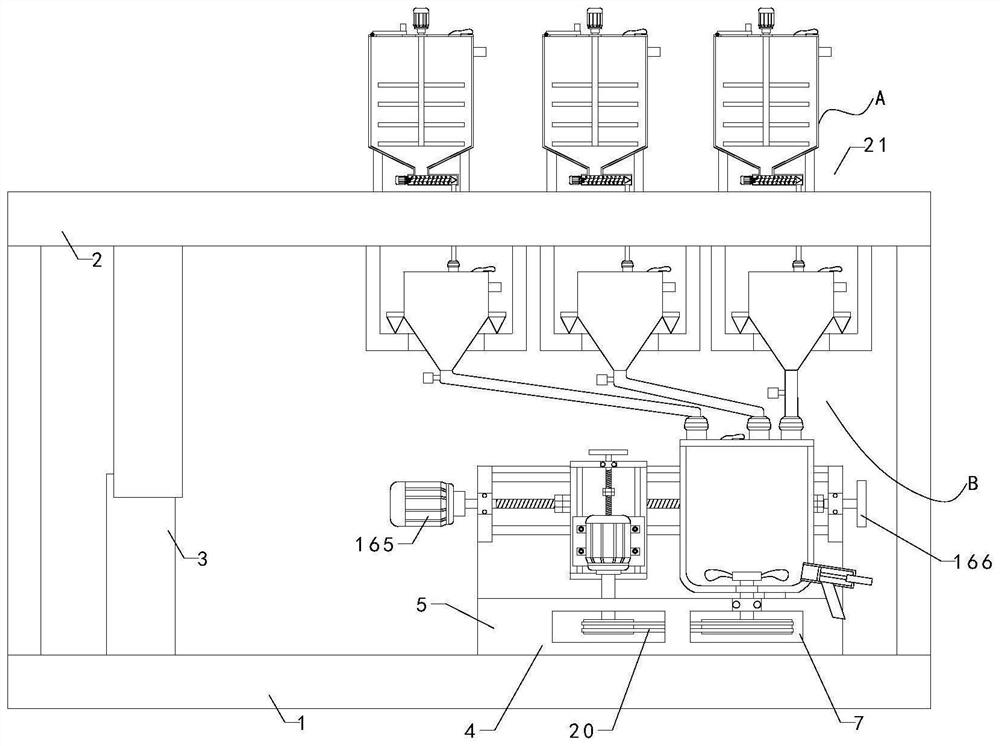

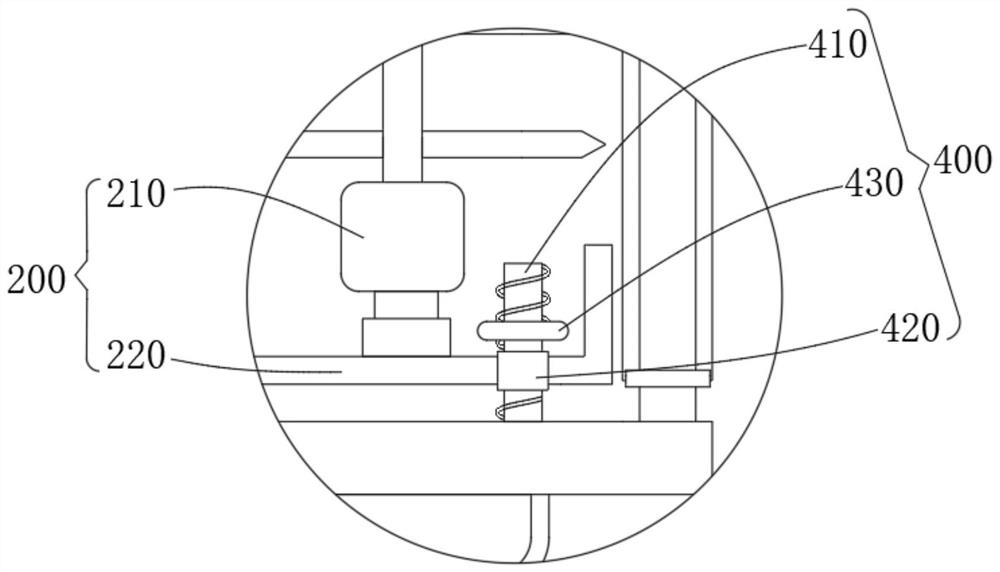

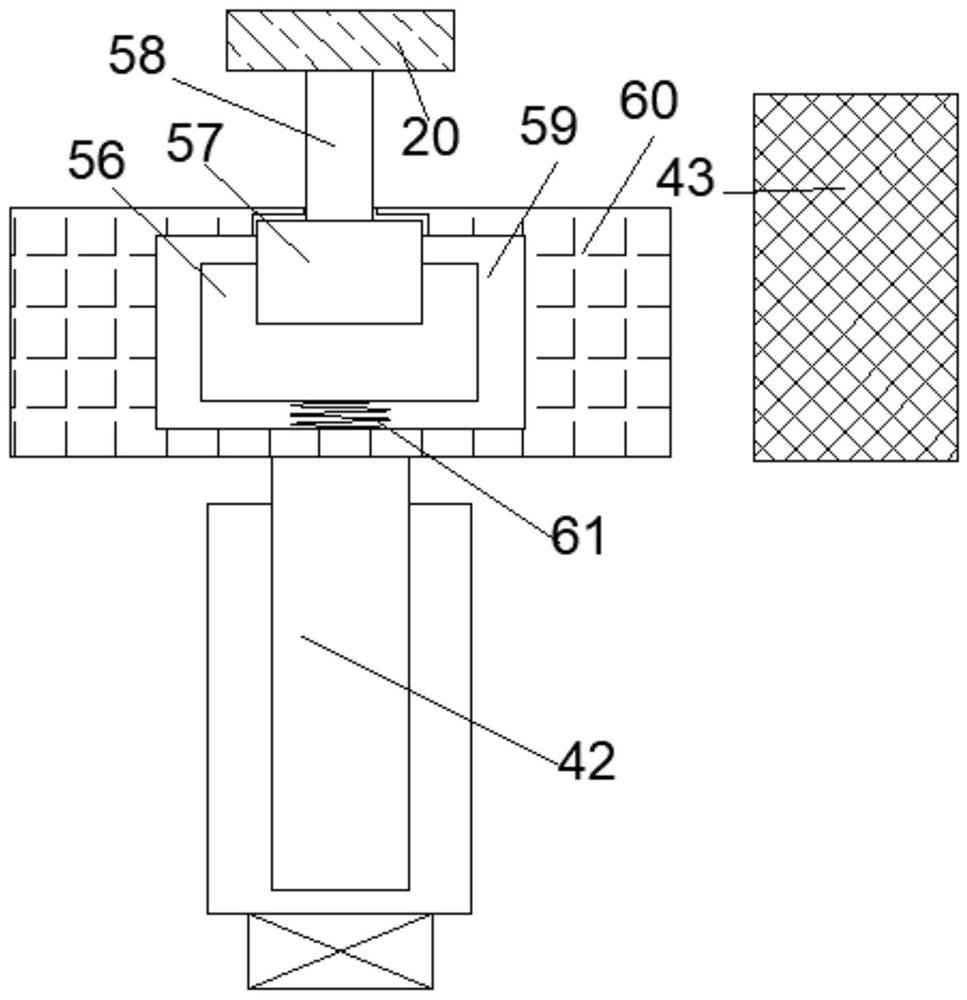

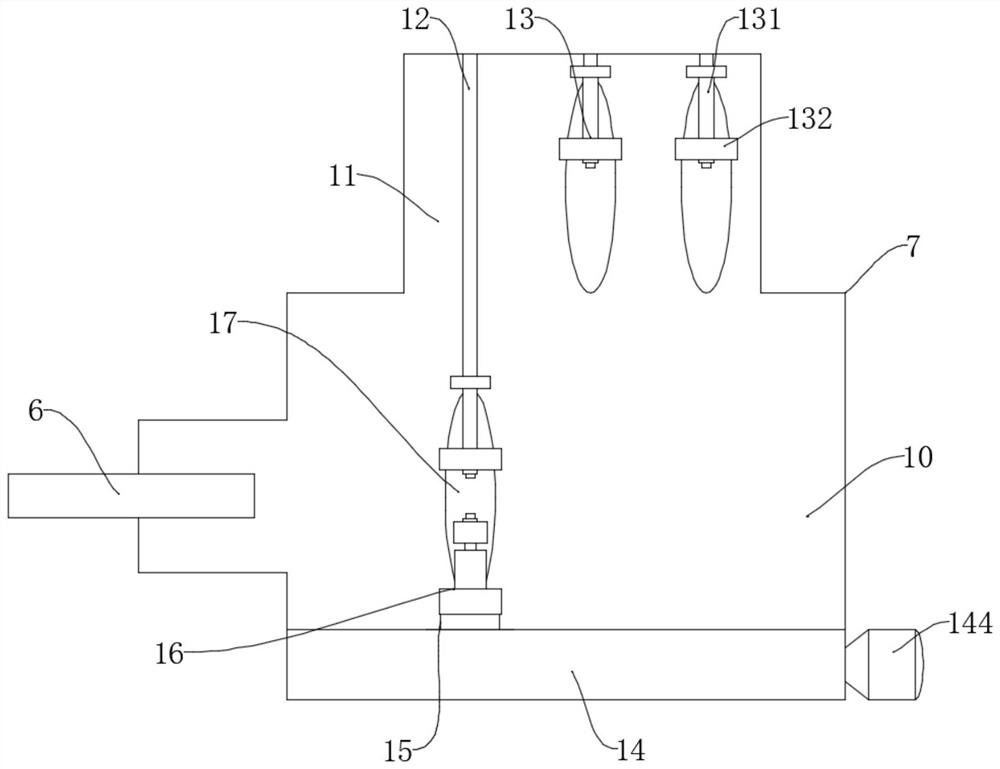

Medical biological 3D printing device

ActiveCN108032521AQuick changeQuick combinationManufacturing enclosures3D object support structuresTemperature controlShape change

The invention discloses a medical biological 3D printing device. During printing, a printing material can be quickly replaced; during replacement, quick connection can be achieved only by moving a print head assembly and then matching the feeding end of the print head assembly with a discharging head of a needed printing raw material tank; when replacement of the printing raw material is needed, rapid combination with the needed printing raw material can be achieved only by electrically connecting two contacting conductive control sheets with two fixed conductive sheets at the corresponding printing raw material tank for 2-3 seconds at the same time; the matching precision is high, the replacement rate of the printing material can be greatly increased, and the printing accuracy can be improved; and in addition, through constant temperature control of the printing material, shape change after printing is reduced and the printing accuracy is improved.

Owner:渭南职业技术学院

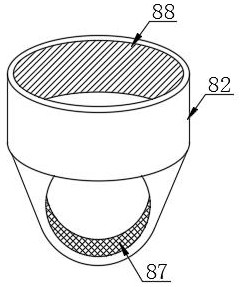

HID xenon type automobile front combination lamp

InactiveCN112097216AImprove replacement rateEasy to assemble and disassembleVehicle headlampsOptical signallingEngineeringElectrical and Electronics engineering

The invention discloses an HID xenon type automobile front combination lamp, and particularly relates to the technical field of automobile lamps. The HID xenon type automobile front combination lamp comprises a lamp shell; a frame plate is fixedly arranged at the edge of one end of the lamp shell, and a lining plate is fixedly embedded in the other end of the lamp shell; a lampshade is arranged onthe side, away from the lamp shell, of the frame plate; an inserting groove is formed in the side, facing the lampshade, of the frame plate; an inserting plate is correspondingly arranged on the side, facing the frame plate, of the lampshade; the inserting plate is matched with the inserting groove; a clamping mechanism is arranged at the joint of the inserting plate and the inserting groove; theclamping mechanism comprises an inserting rod; a handle is arranged at the top end of the inserting rod; and the middle of the inserting rod is sleeved with a limiting plate. According to the automobile front combination lamp, the handle is lifted upwards to compress a first spring through a limiting plate, so that the bottom end of the inserting rod is completely separated from the inserting groove and the inserting plate; and the lampshade is separated from the frame plate through a second anti-skid strip on the surface of the lampshade, so that the replacement rate of a bulb in the automobile front combination lamp can be greatly increased, and disassembly and assembly are convenient and fast.

Owner:JIANGSU QINLONG VEHICLE LAMP

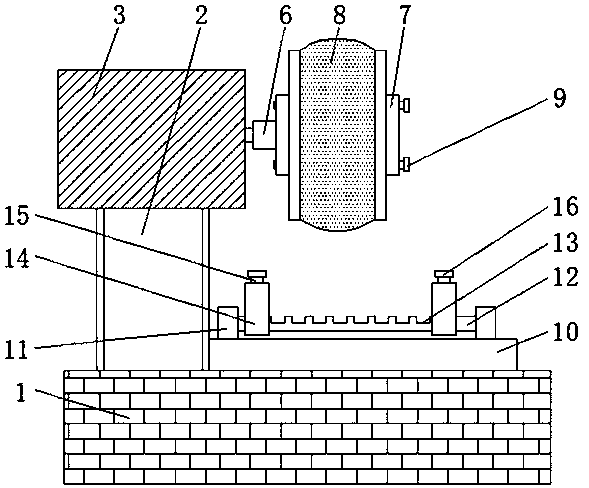

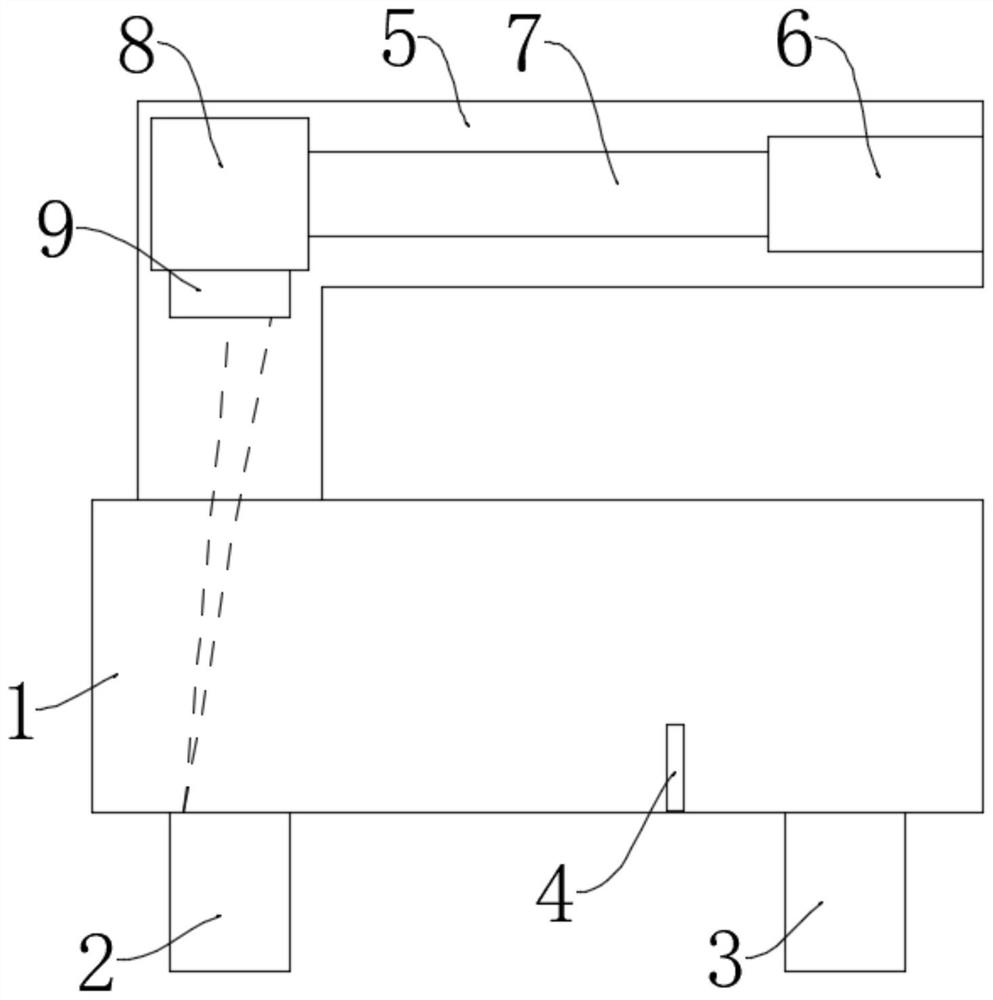

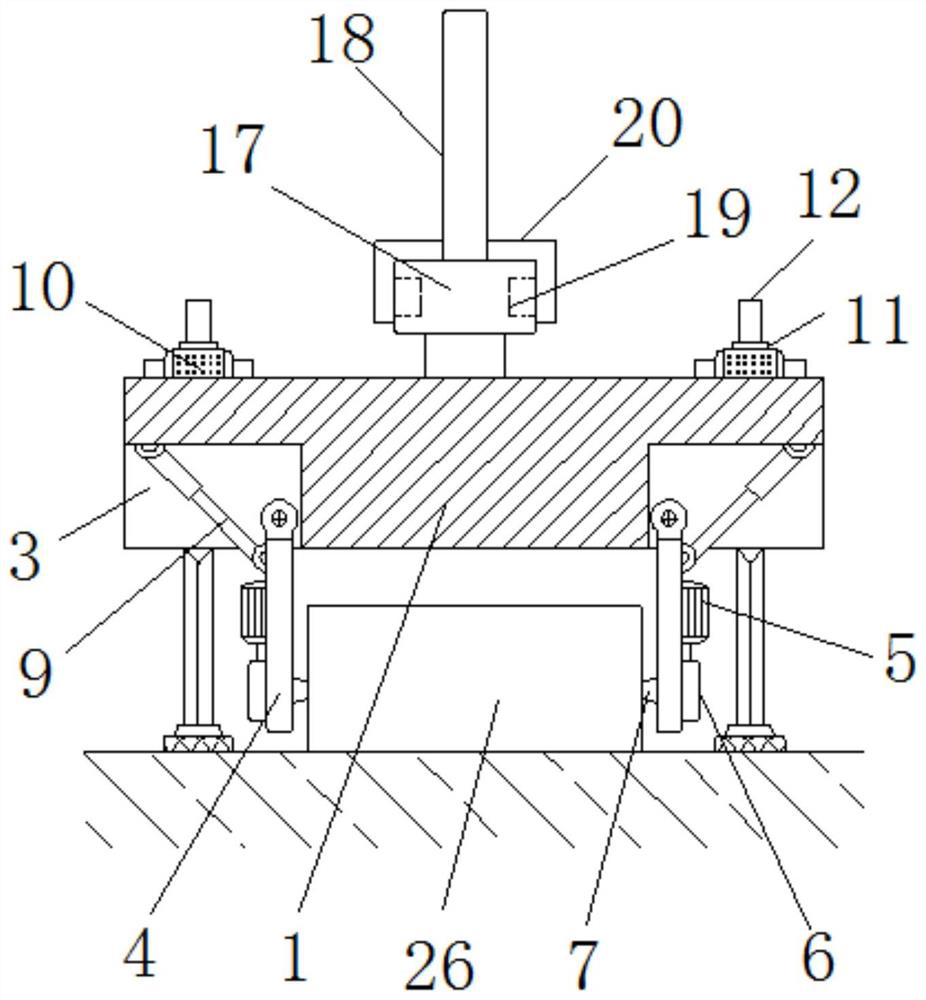

Precise part efficient machining grinding tool

PendingCN108214301AEfficient machining of abrasive toolsEasy to replaceGrinding wheel securing apparatusGrinding work supportsElectric machineryEngineering

The invention relates to the technical field of accessory machining equipment, and discloses a precise part efficient machining grinding tool. The precise part efficient machining grinding tool comprises a base, wherein supporting columns are fixedly arranged on the left side of the top of the base, a motor box is fixedly arranged at the tops of the supporting columns, a bottom plate is fixedly arranged at the bottom of the inner cavity of the motor box, the top of the bottom plate is fixedly provided with a servo motor located in an inner cavity of the motor box, one end of an output shaft ofthe servo motor penetrates through and extends to the outside of the right side of the motor box, the right end of the servo motor is fixedly sleeved with a fixing casing pipe, and the right side ofthe fixing casing pipe is provided with fixing plates. According to the precise part efficient machining grinding tool, the two fixing plates, a grinding wheel and bolts are cooperatively used, so that the grinding wheel can be replaced conveniently, the replacement speed is increased, an old grinding machine is prevented from being used; the grinding wheel for grinding is an integrated design, sothat the grinding wheel is not easy to replace, and the production efficiency is severely reduced; and due to the action of an adjusting box, the parts can be conveniently fixed, and the stability during grinding is improved.

Owner:FORTURE TOOLS CO LTD

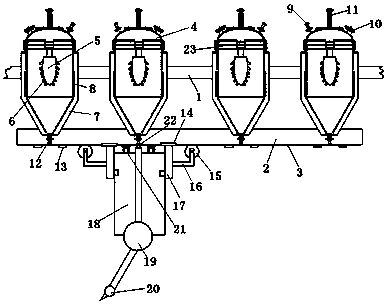

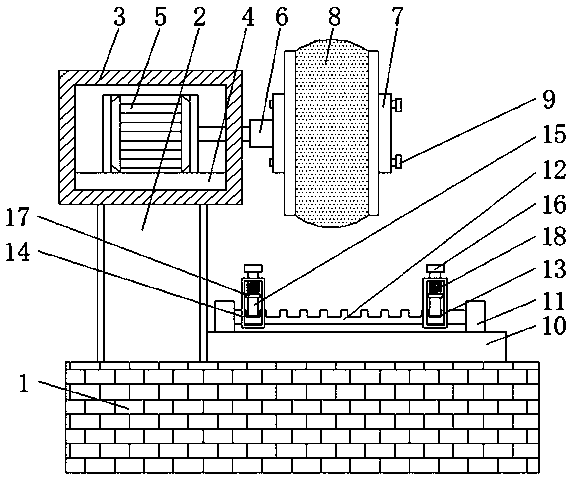

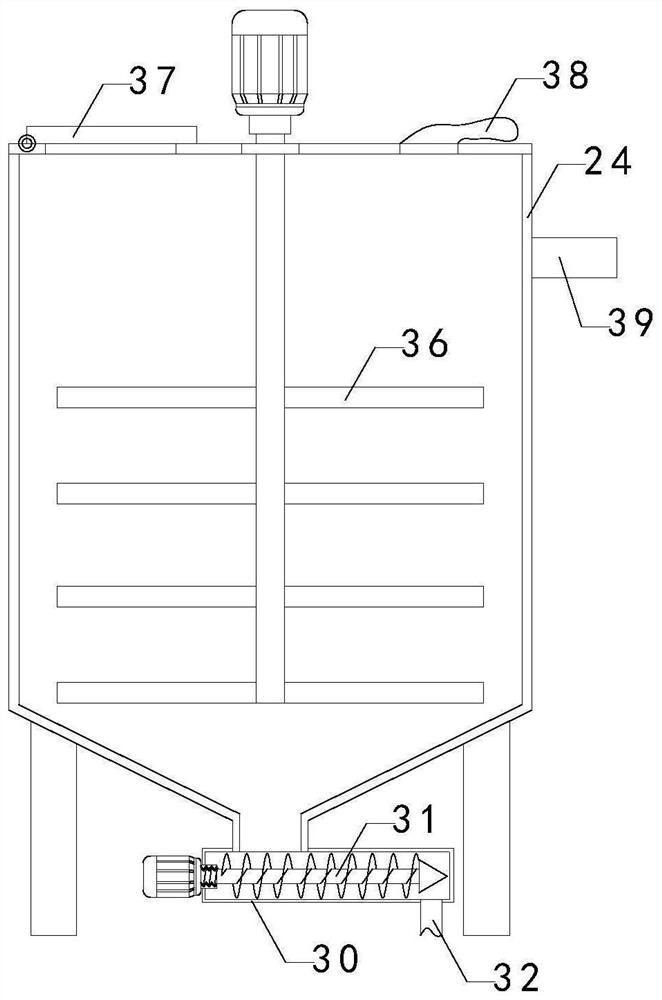

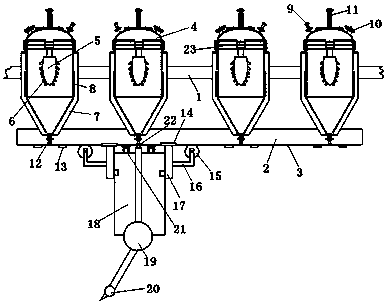

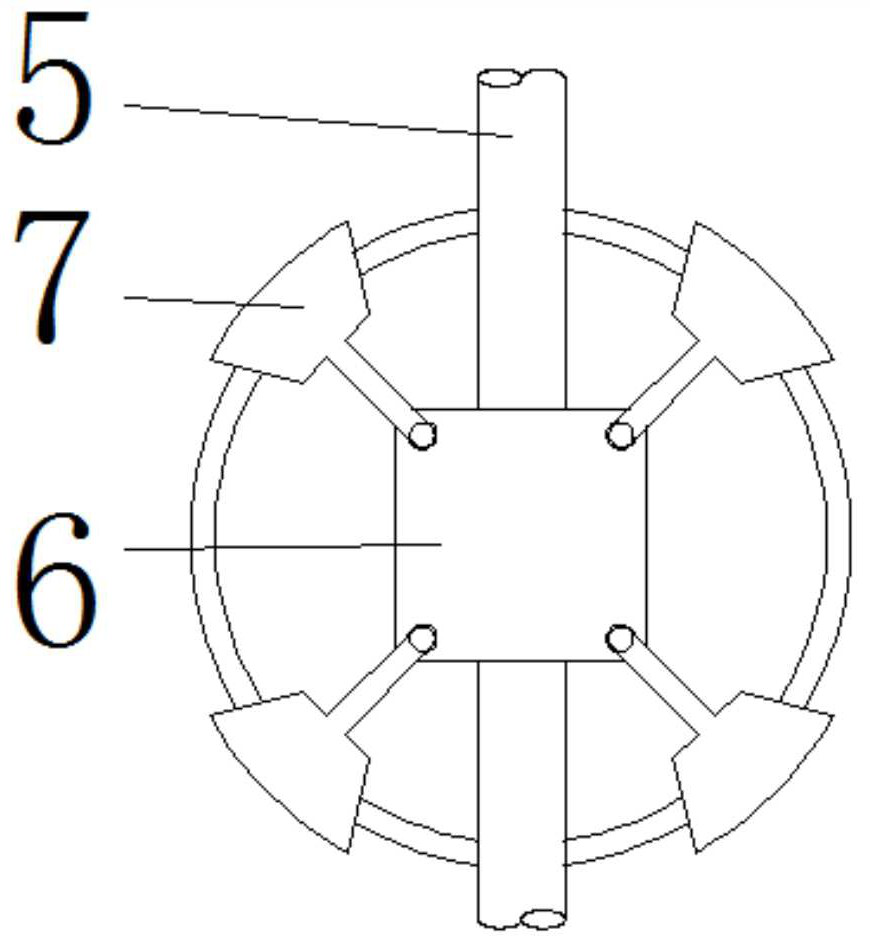

Flavored green juice powder quantitative batching device with seasoning function

InactiveCN111729605AStable deliveryImprove replacement rateTransportation and packagingRotary stirring mixersElectric machineryEngineering

The invention relates to the technical field of green juice powder processing accessory devices, and in particular, relates to a flavored green juice powder quantitative batching device with a seasoning function, wherein the device is simple in structure, can perform full-automatic quantitative blanking on various raw materials of the green juice powder, is convenient to replace and maintain a driving motor of a high-speed mixer, and improves the working efficiency. The device comprises a first platform and a second platform which are connected with each other. Stairs are arranged between thefirst platform and the second platform; a high-speed mixer body is arranged at the top of the first platform; the high-speed mixer body comprises a shell and a mixing bin mounted at the top of the shell; cavities are formed in the machine shell, the left rear side and the right front side of the machine shell communicate with a first opening and a second opening correspondingly, a rotating shaft is rotatably mounted at the second opening through a bearing, the top end of the rotating shaft extends into the mixing bin, a plurality of stirring blades are arranged at the top end of the rotating shaft, the bottom end of the outer side wall of the mixing bin communicates with a discharging pipe, and a discharging plate is slidably arranged in the discharging pipe through an air cylinder.

Owner:合肥膳之纤生物科技有限公司

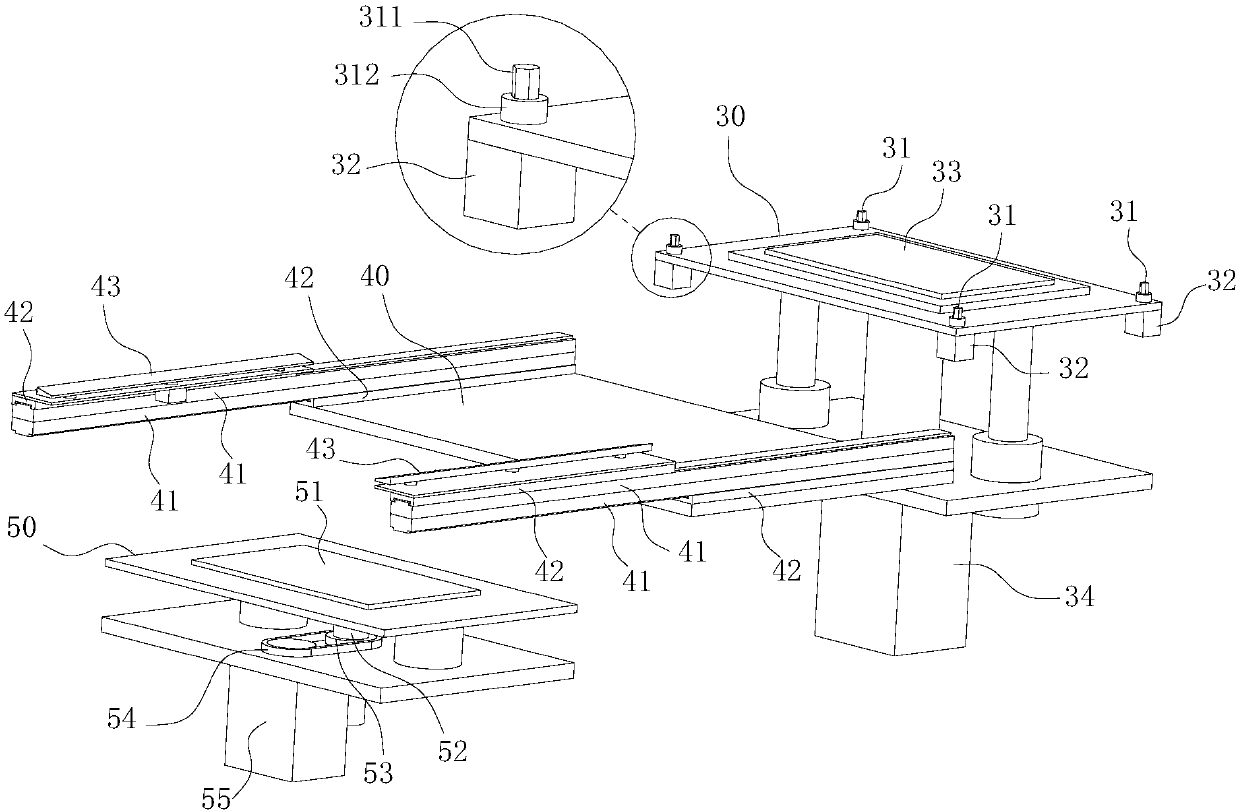

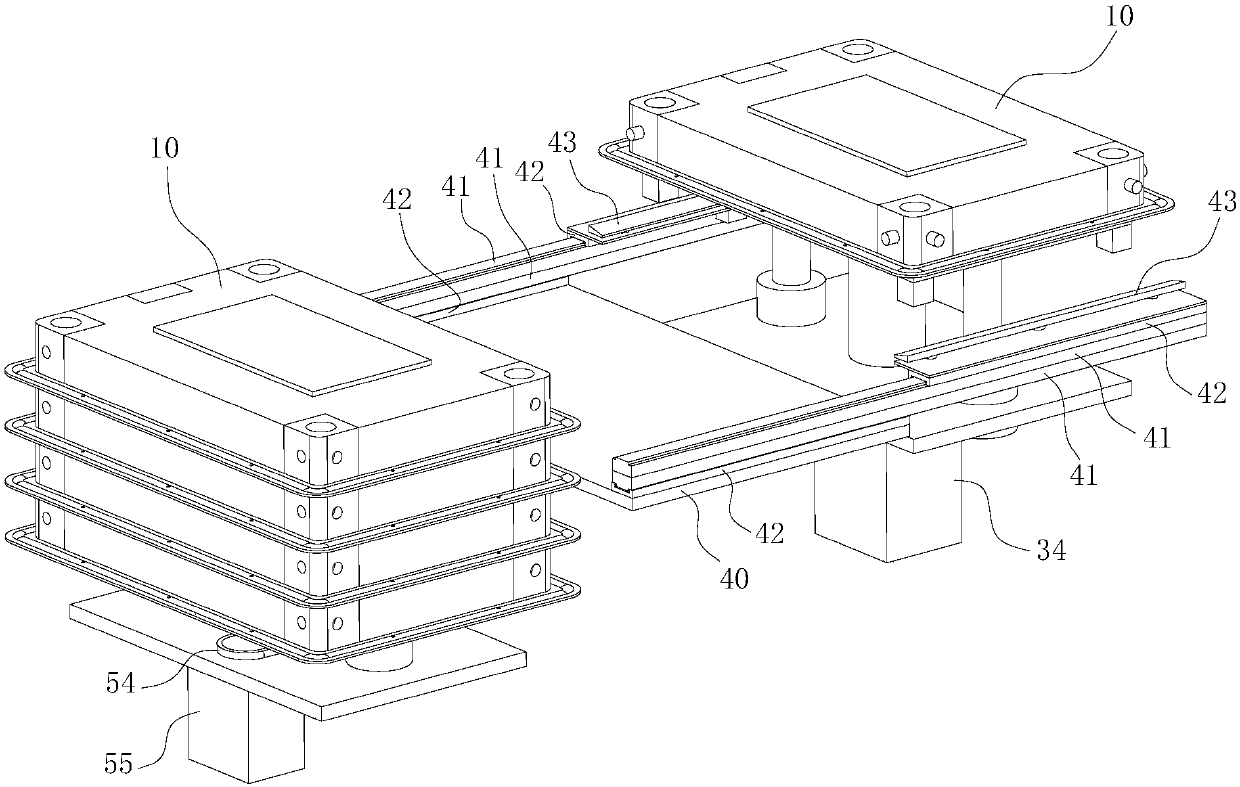

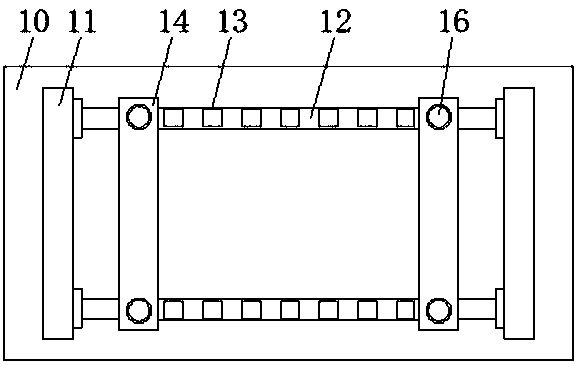

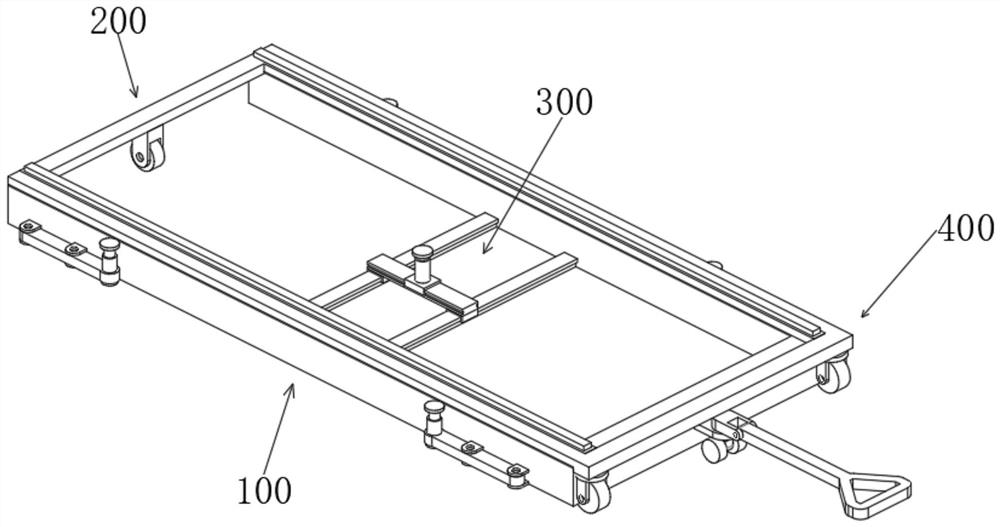

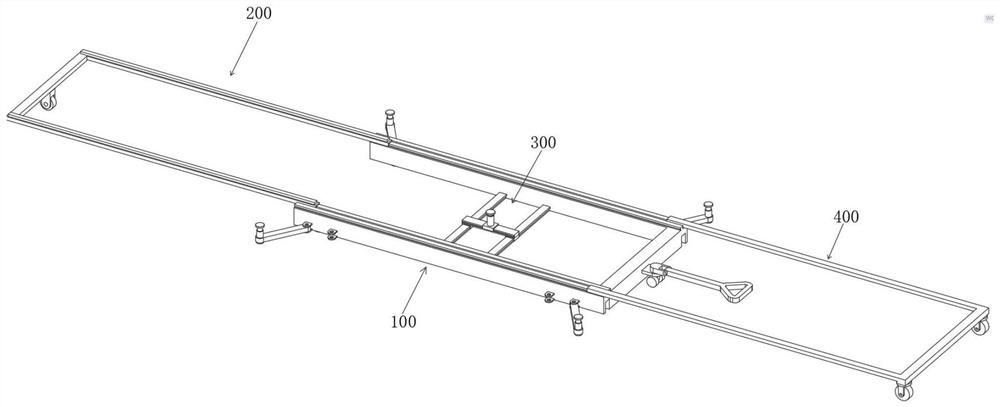

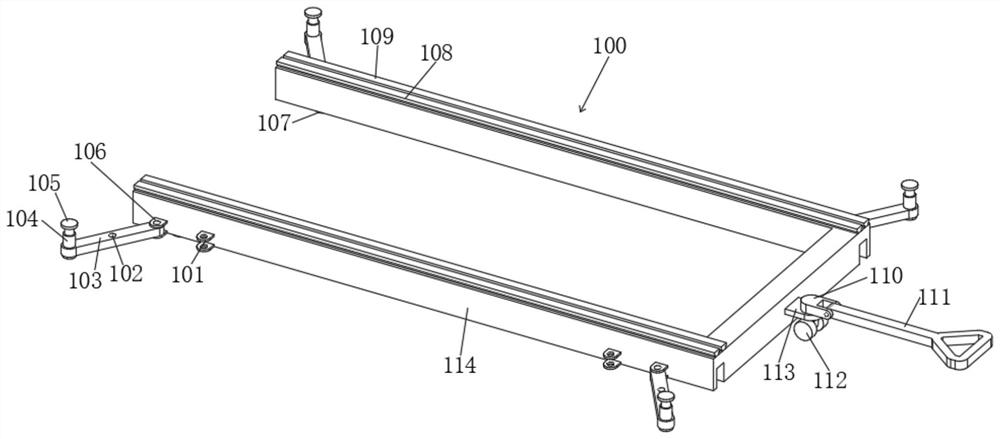

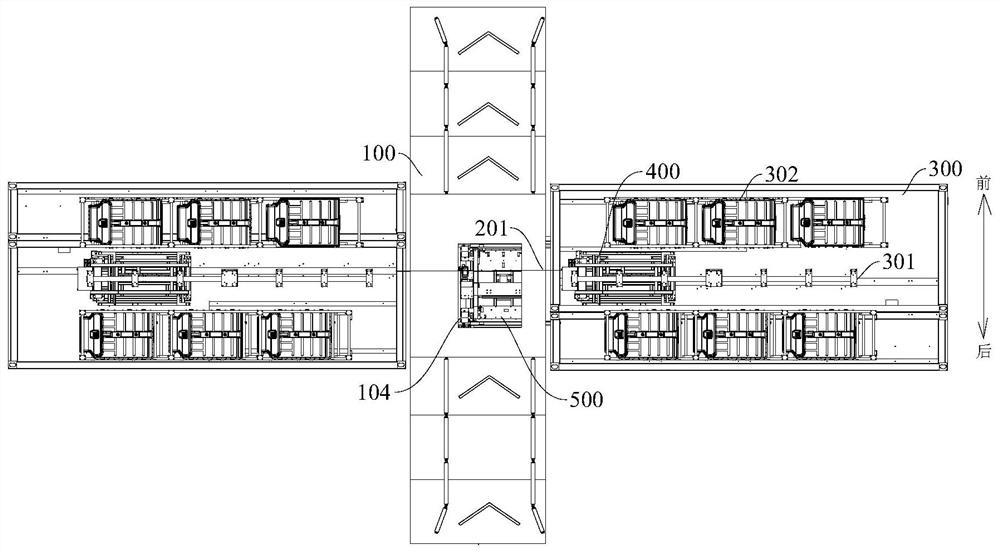

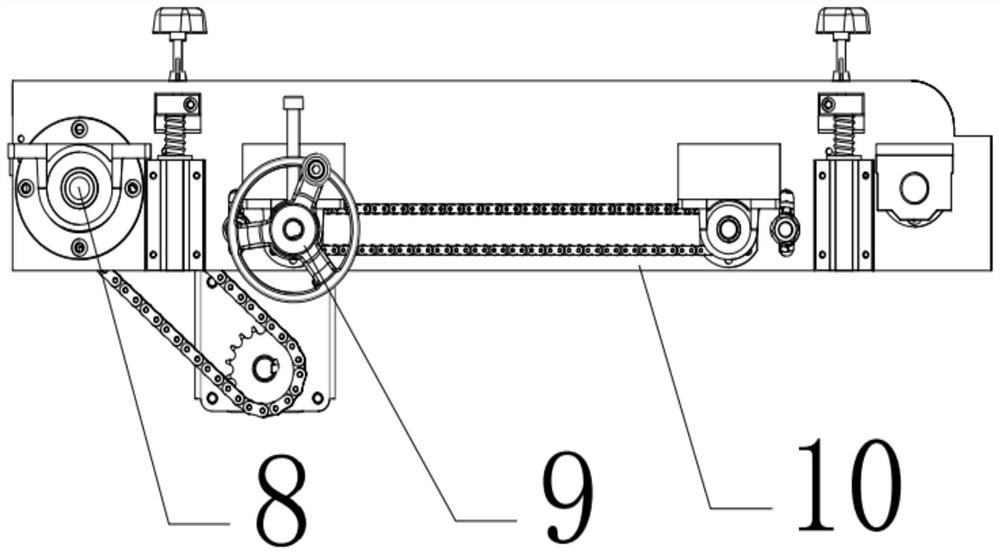

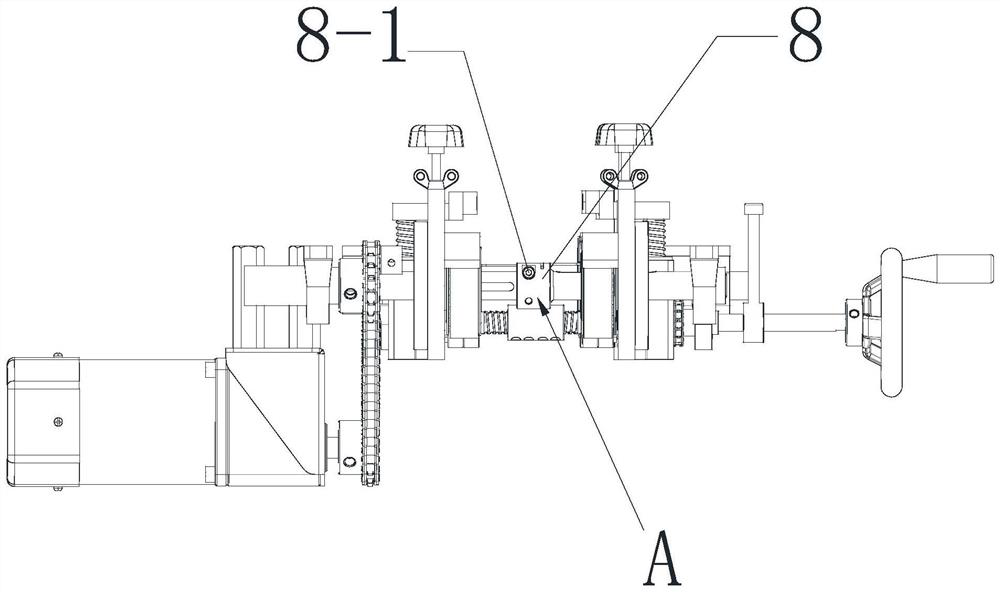

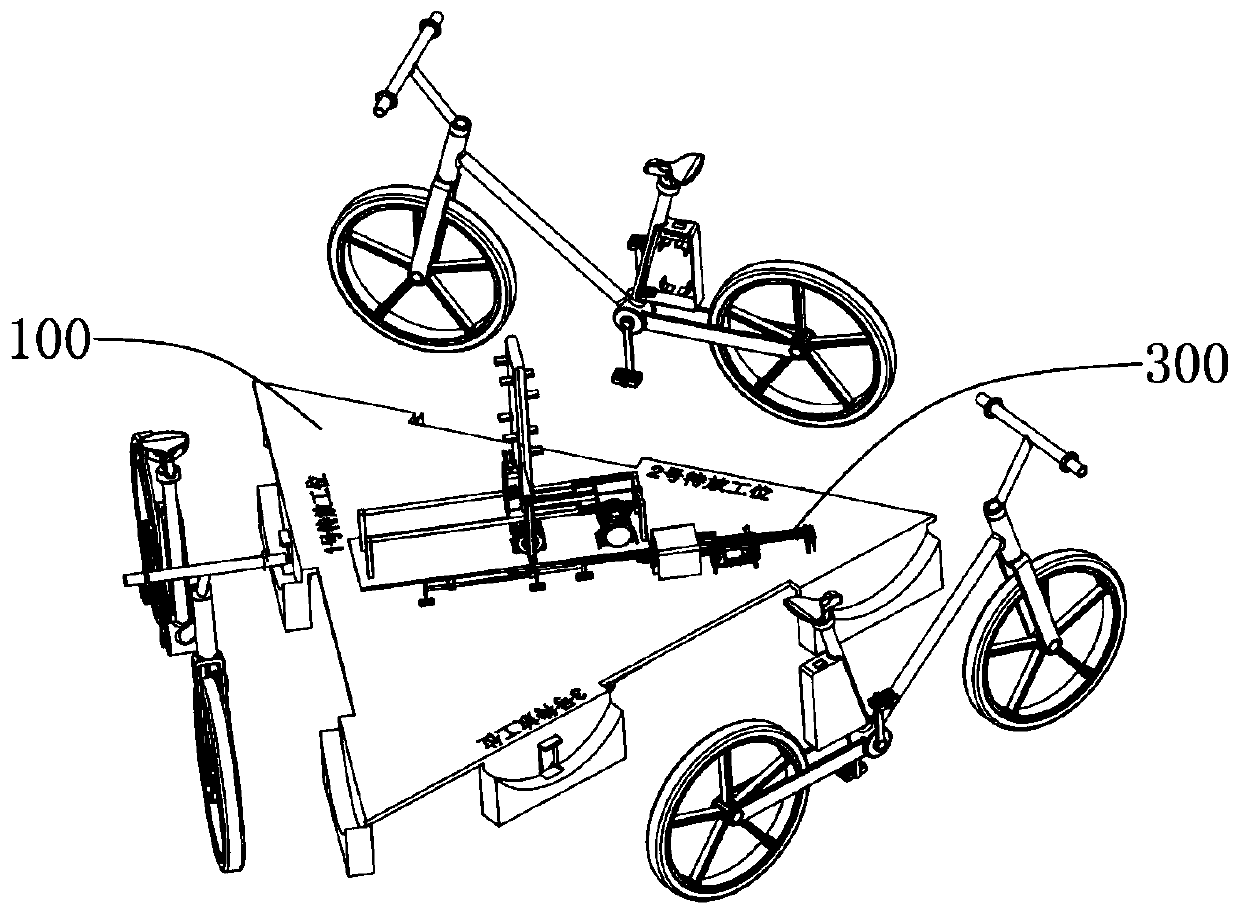

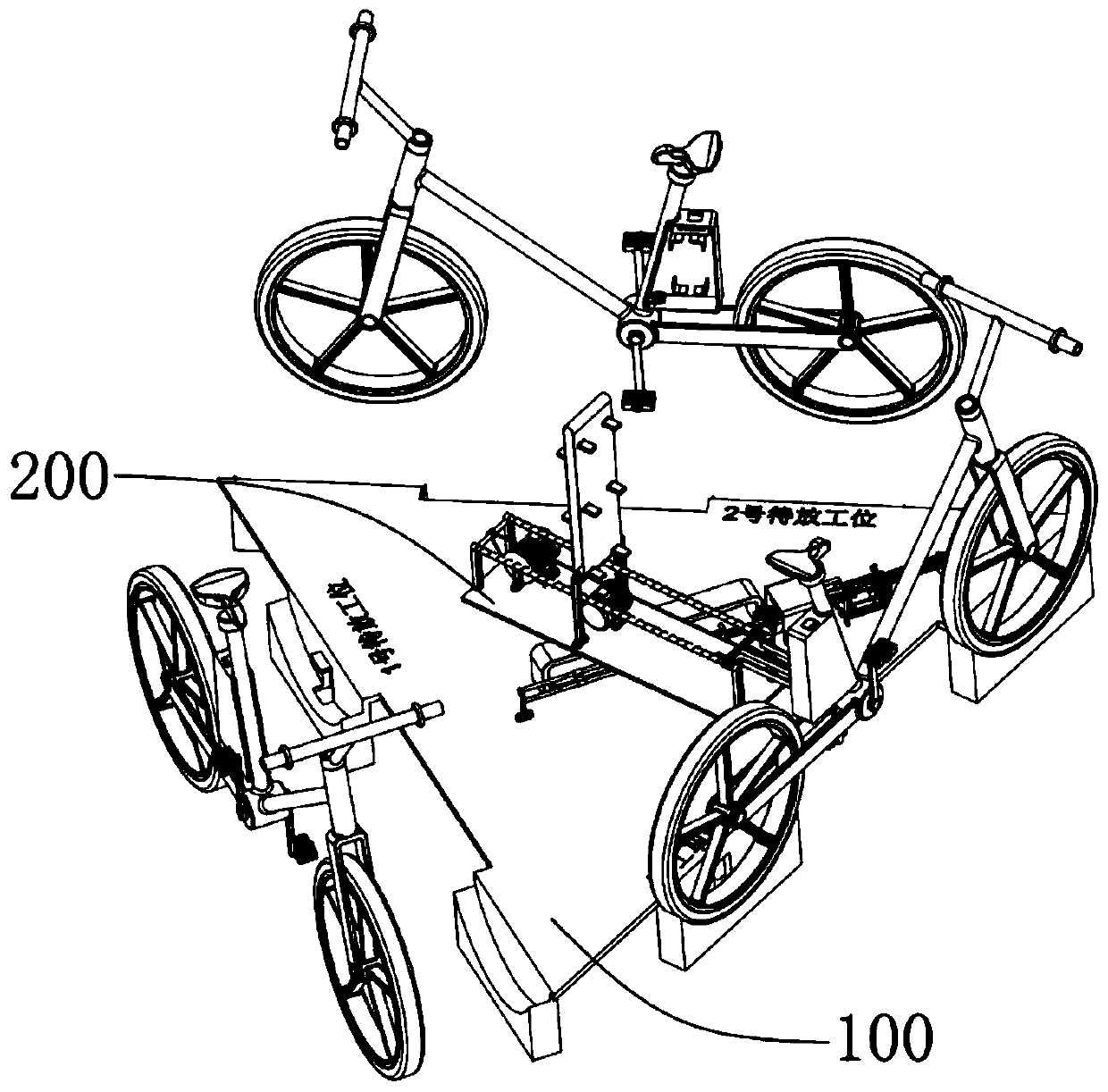

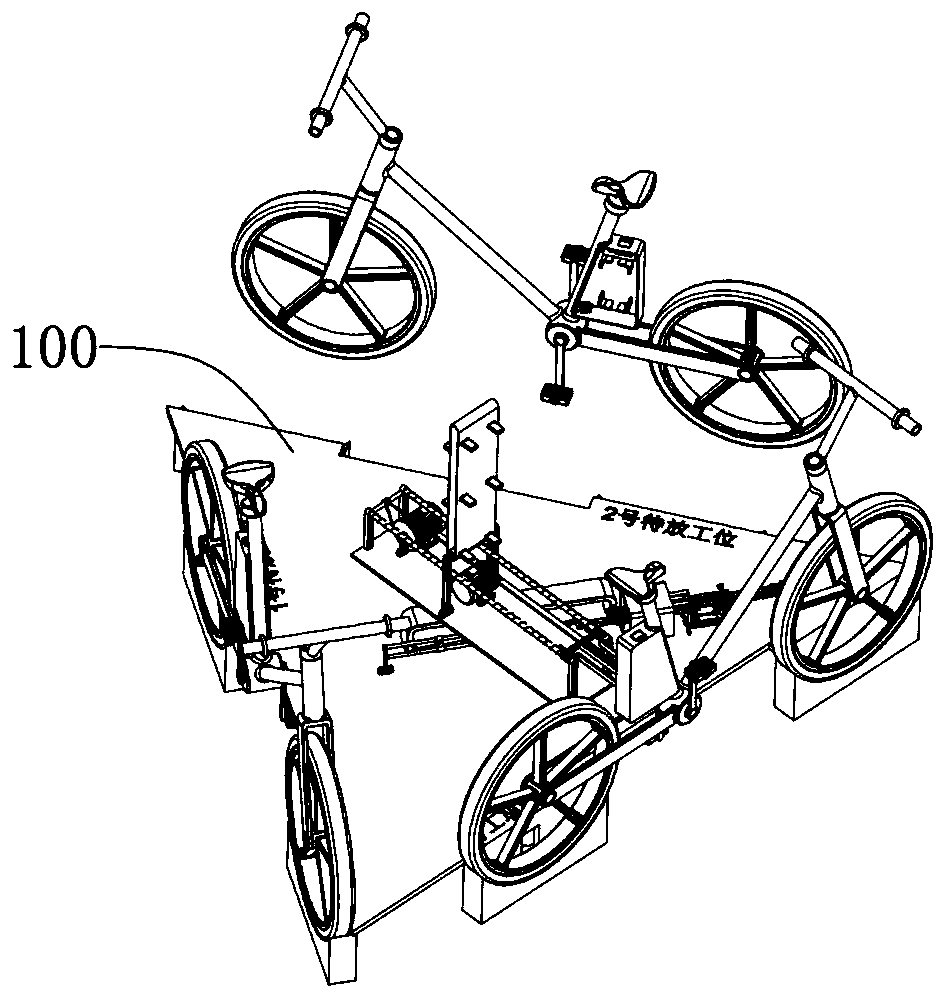

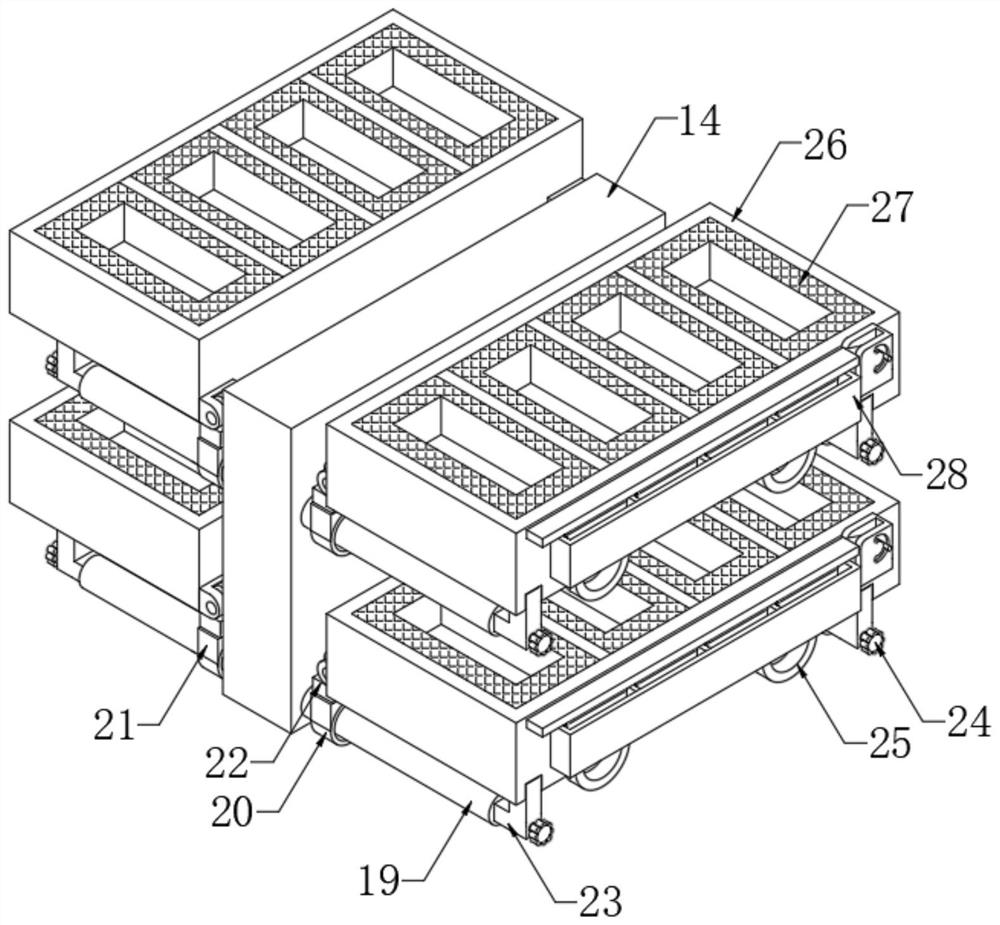

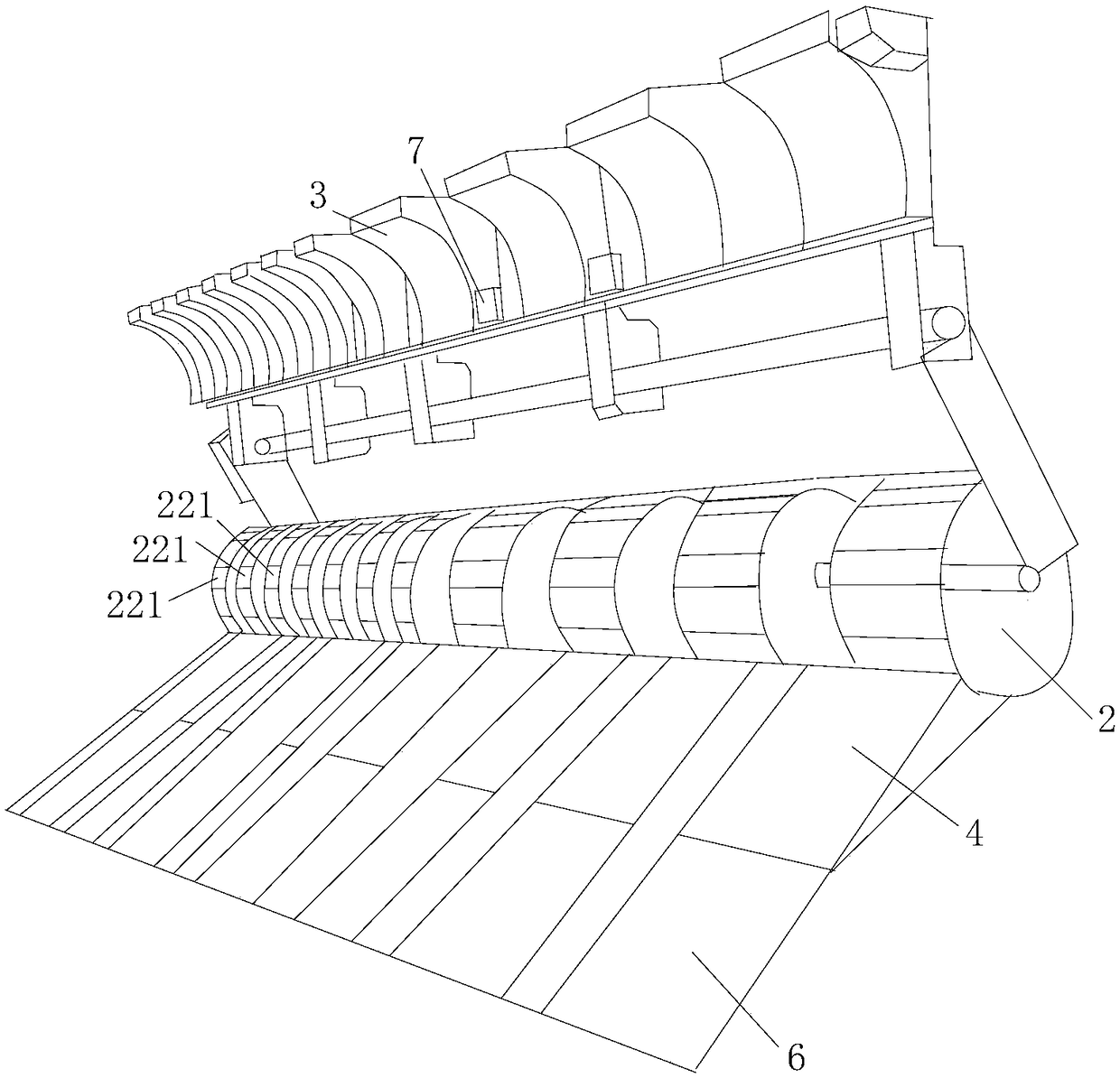

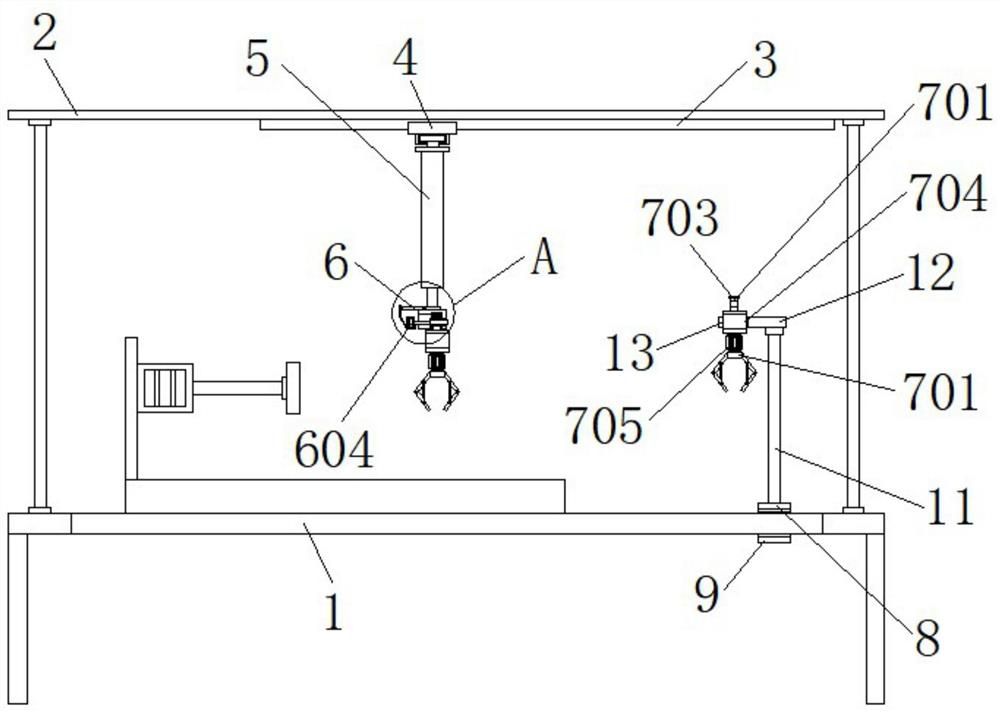

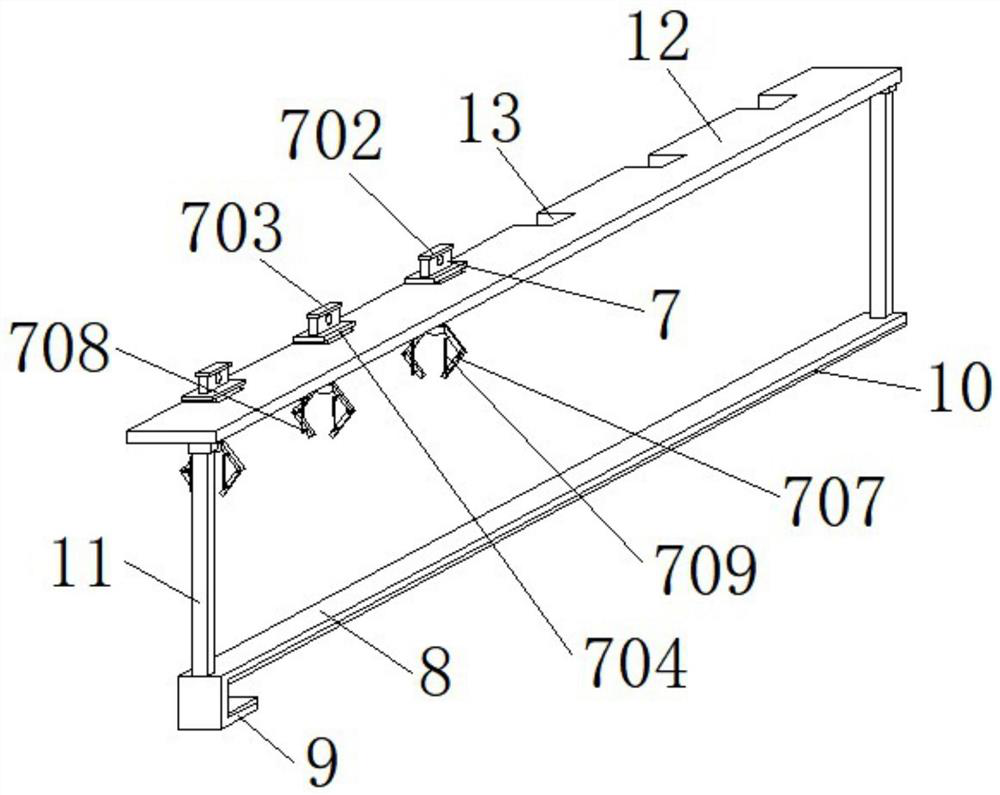

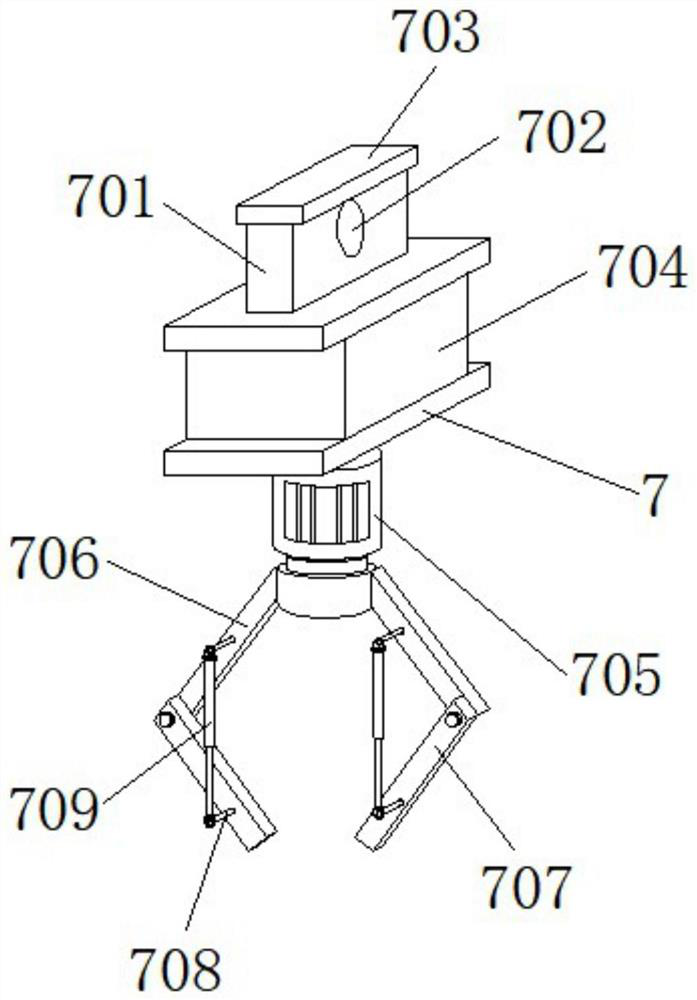

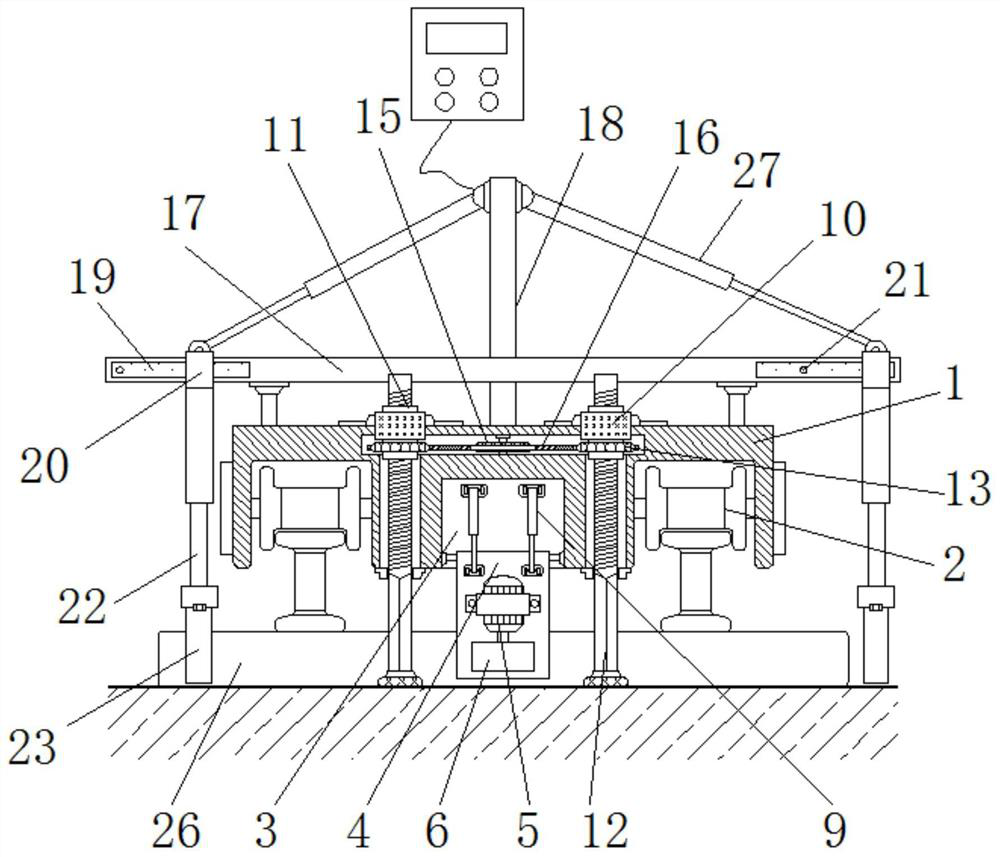

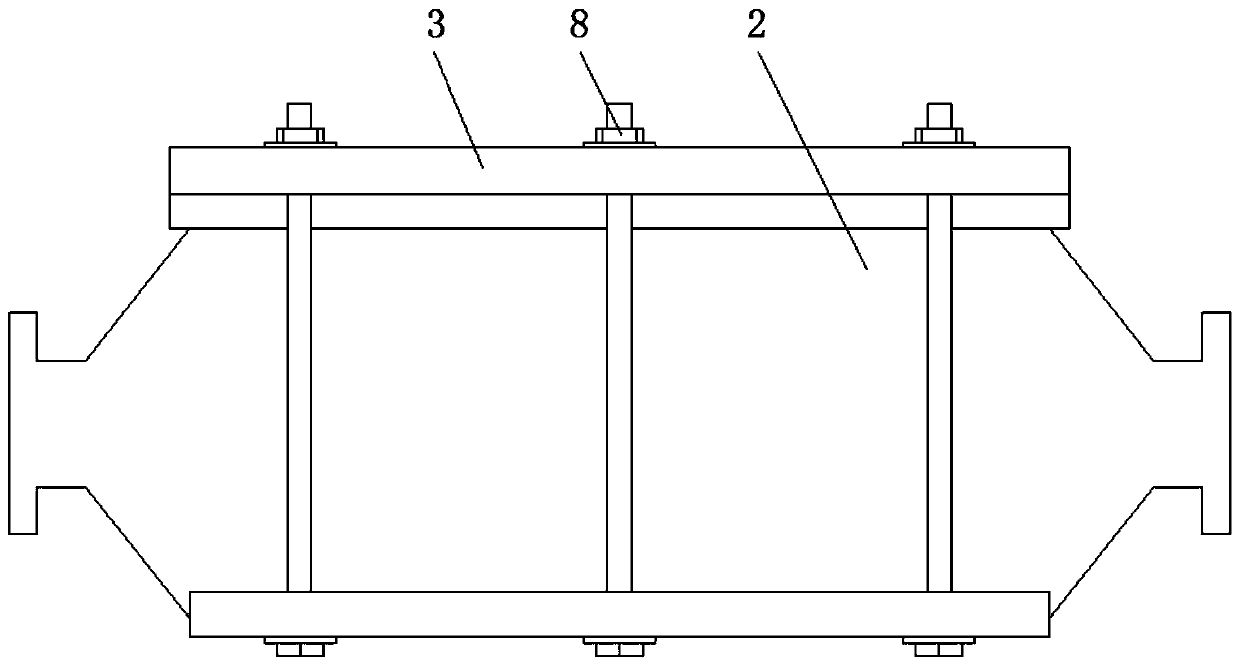

A new energy vehicle battery replacement transfer device

ActiveCN110450761BSimple replacement processImprove replacement rateCharging stationsVehicle servicing/repairingAutomotive batteryNew energy

The invention discloses a new energy vehicle battery changing and transferring device. The new energy vehicle battery changing and transferring device comprises a mobile base, a first bearing frame, an adjusting jacking mechanism and a second bearing frame; the mobile base comprises a U-shaped frame; and the U-shaped frame is a combined structure which is obtained by welding two parallel cross rods and a longitudinal rod at one ends of the cross rods. According to the new energy vehicle battery changing and transferring device, as the movable mobile base is arranged, the first bearing frame and the second bearing frame which are reverse to the moving direction are slidingly connected to the upper part of the mobile base, and arranging the adjusting jacking mechanism in the U-shaped frame,a fully-charged vehicle battery panel is borne by the first bearing frame, the low-capacity vehicle battery panel is placed on the second bearing frame through the adjusting jacking mechanism after being detached, the fully-charged vehicle battery panel is mounted by using the adjusting jacking mechanism during changing a battery of a new energy vehicle; and therefore, the new energy vehicle battery changing and transferring device can finish detaching and transferring of the battery panel when the mobile base moves to the battery panel so that the battery panel changing process is simplified,and the battery panel changing speed is increased.

Owner:江苏亚龙汽车有限公司

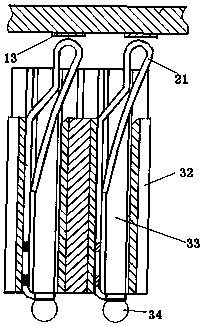

Injection molding machine

ActiveCN108437351AAvoid affecting productionQuick disassembly and replacementSpray nozzleTransverse plane

The application belongs to the technical field of injection molding equipment and particularly discloses an injection molding machine. The injection molding machine comprises a materiel storage box and a spray nozzle communicating with the materiel storage box is arranged on the materiel storage box; the spray nozzle comprises a first pipe head, a second pipe head and a third pipe head, wherein the first pipe head, the second pipe head and the third pipe head communicate in sequence; a rubber sleeve connected with the first pipe head in a sealing and sleeving manner is arranged on the second pipe head; a first transverse plate is arranged on the first pipe head, a first vertical rod is arranged at one side of the first transverse plate and a second vertical rod is arranged at the other side of the first transverse plate; the third pipe head is fixedly connected with a second transverse plate and the second transverse plate is connected with the first vertical rod and the second vertical rod by nuts; first springs are connected between the nuts and the second transverse plate and a fixing plate is arranged on the first transverse plate. The injection molding machine is mainly used for injection molding and the problem is solved that the inspection time after the spray nozzle of the injection molding machine is blocked is long and therefore the machining efficiency is lowered.

Owner:宁波鑫神泽汽车零部件有限公司

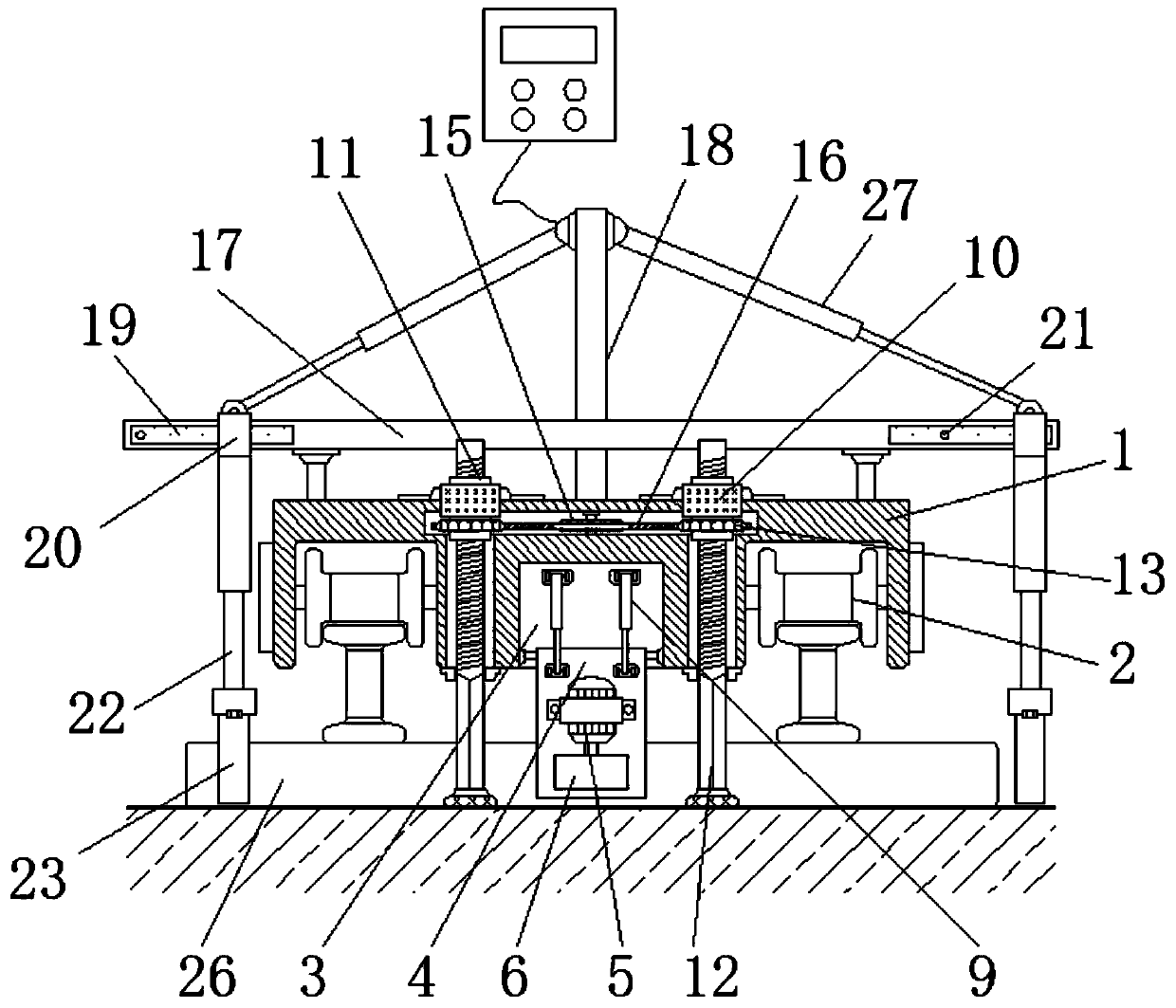

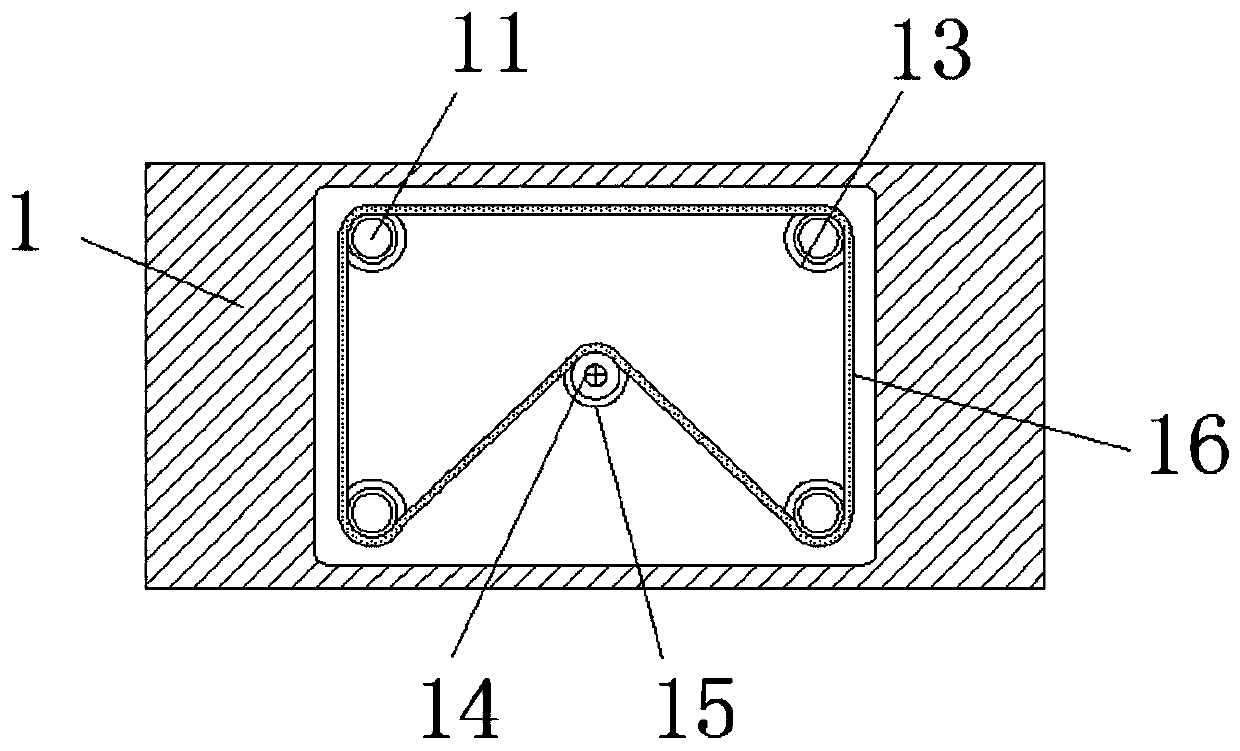

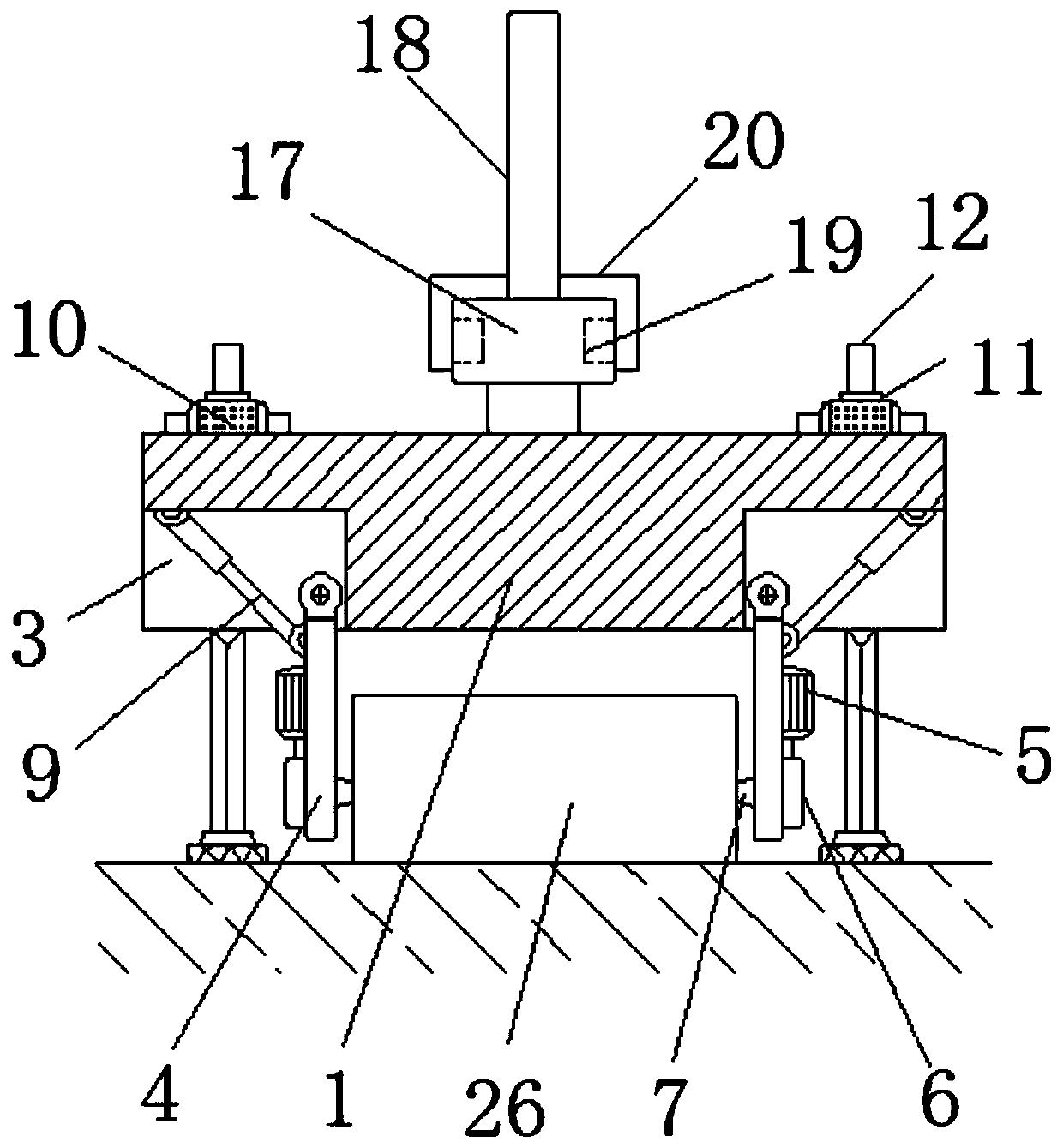

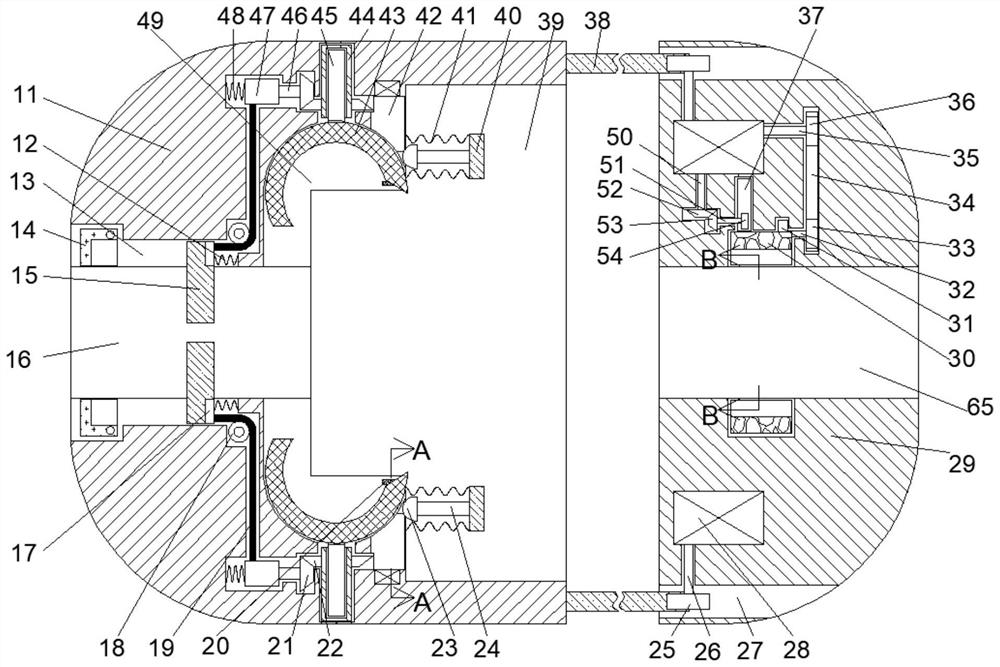

Auxiliary replacement equipment for disassembling, assembling and replacing railway traffic sleepers

ActiveCN110939029AQuick disassembly and replacementImprove replacement rateRailway track constructionGear wheelElectric machinery

The invention discloses auxiliary replacement equipment for disassembling, assembling and replacing railway traffic sleepers. The equipment comprises a shell, a first motor, a first hydraulic rod, a second motor, a photoelectric sensor, a second hydraulic rod and a third hydraulic rod, moving wheel assemblies are fixedly installed on the edge of the bottom of the shell. The first motor and a positioning cylinder are mounted on the outer wall of the side plate in an embedded manner; a guide gear is mounted in the positioning cylinder through a rotating shaft; a bearing support is fixed to the top of the shell, a guide frame and a fixing rod are fixedly installed at the top of the shell, a sliding groove is reserved in the outer wall of the end of the fixing rod, a connecting rod is perpendicularly fixed to the bottom of the sleeve, and a third hydraulic rod is installed between the top of the sleeve and the outer wall of the top of the fixing rod in a hinged mode. According to the auxiliary replacement equipment for railway traffic sleeper dismounting and replacing, rapid dismounting and replacing of the sleeper are facilitated, labor consumption of manual assistance is reduced, operation is convenient and rapid, the sleeper replacement rate is increased, positioning is accurate, and use is convenient.

Owner:新昌县知贝机械有限公司

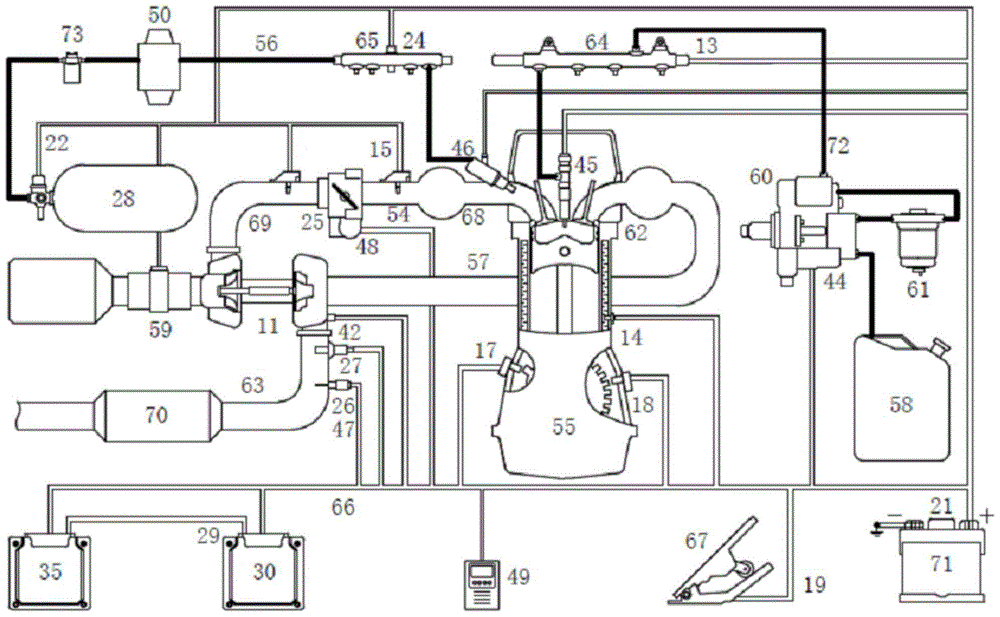

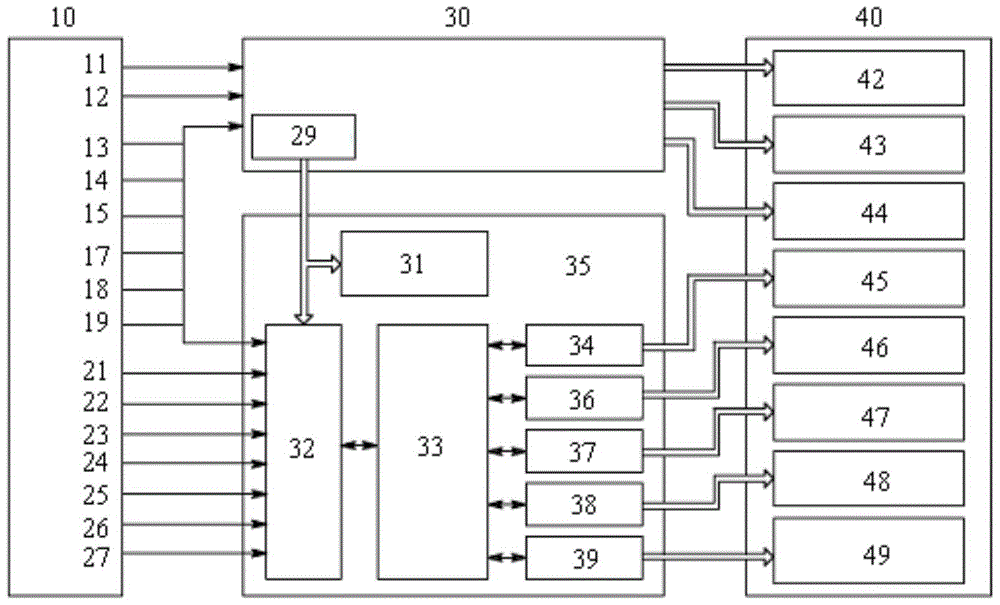

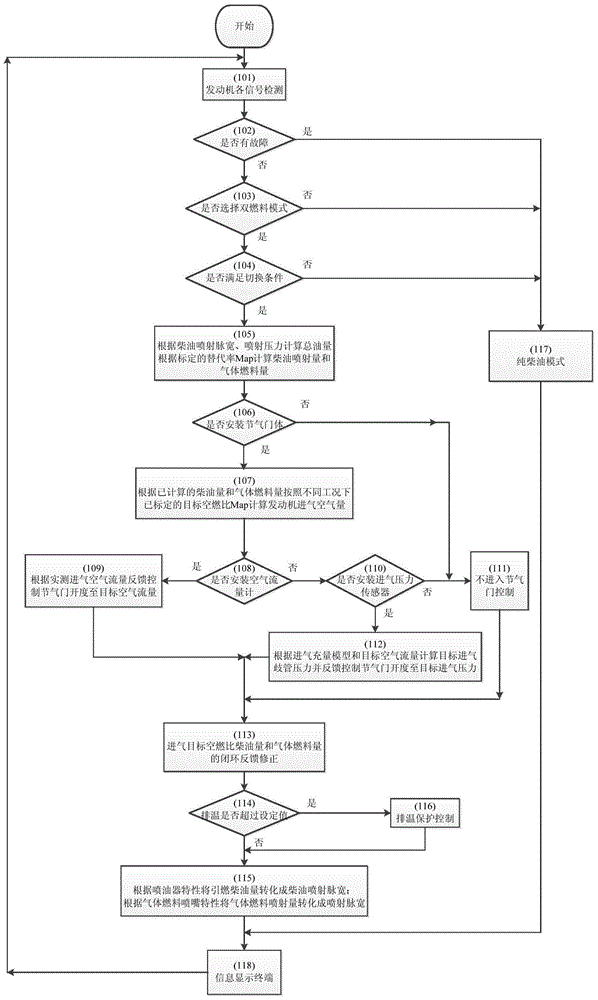

Control system and control method of oil-air dual-fuel engine with electronically controlled fuel supply

ActiveCN103982308BImprove reliabilitySafe and stable operationElectrical controlInternal combustion piston enginesClosed loop feedbackExhaust gas emissions

The invention discloses a control system and a control method of an oil / gas dual-fuel engine in electronic control oil supply. The control system comprises a high-pressure common-rail injection system, a fuel gas injection system and an oil / gas dual-fuel electronic control system, wherein the oil / gas dual-fuel electronic control system comprises a sensor part, an actuator, a dual-fuel ECU (Electronic Control Unit) and a fuel oil ECU, the oil / gas dual-fuel electronic control system controls the diesel oil amount through an oil injector, the fuel gas amount through a fuel gas control injection nozzle and the air inlet amount through an electronic throttling valve body, and an air-fuel ratio when the oil / gas dual-fuel engine works can be detected and controlled in a closed loop feedback way through a wide-domain oxygen sensor. According to the control method disclosed by the invention, the oil / gas dual-fuel engine can be switched under a pure fuel oil working mode and a fuel oil / fuel gas dual-fuel working mode, the good running of the oil / gas dual-fuel engine can be controlled, the diesel injection amount can be accurately controlled according to different working states of a diesel engine, the injection time, the injection duration, the air inlet amount and the air-fuel ratio of gas fuel can also be controlled, thus the safe and stable running of the dual-fuel engine can be ensured, the fuel consumption can be reduced, and the exhaust gas emission can be reduced.

Owner:NANJING GAICHI POWER TECH +1

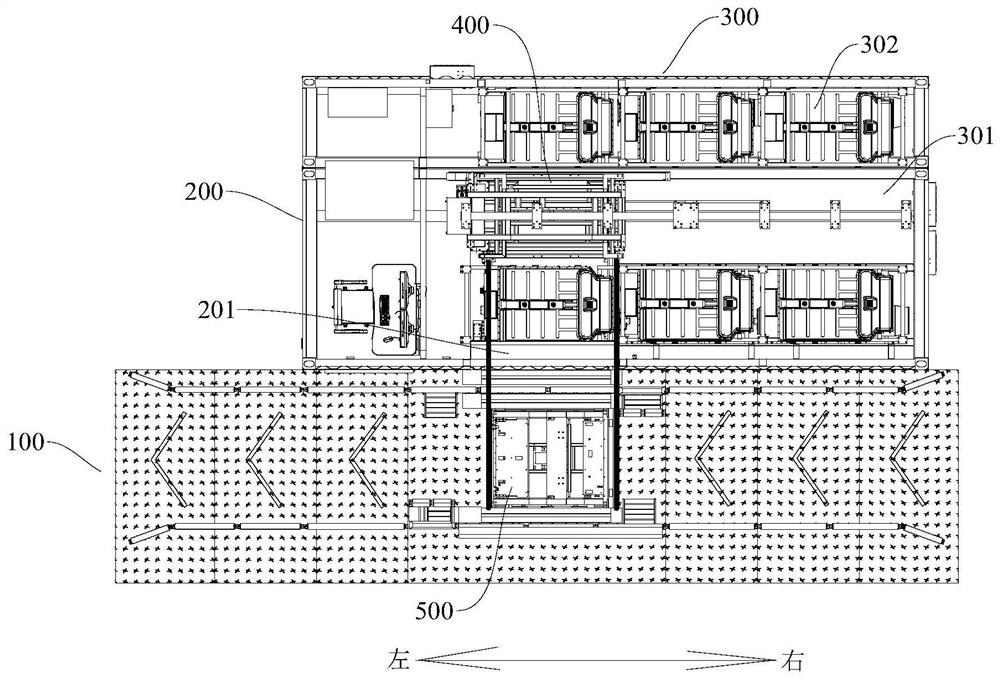

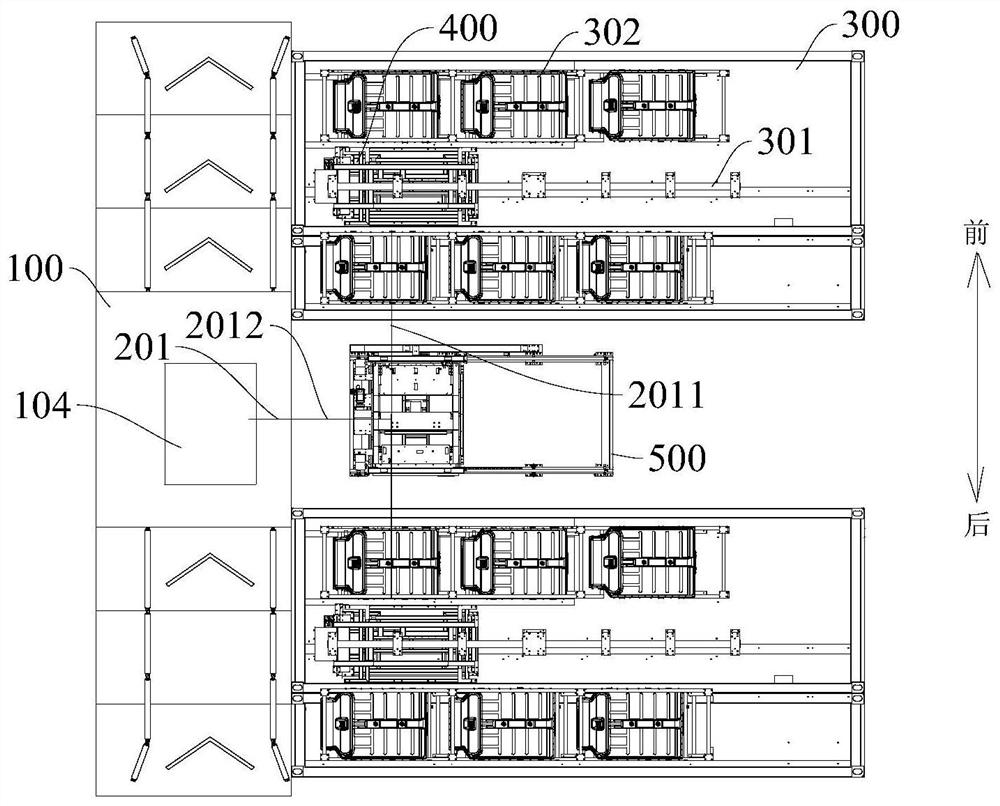

Battery replacing station and power battery replacing method

PendingCN112389264AImprove the speed of battery replacementImprove replacement rateCharging stationsVehicle servicing/repairingPower batteryElectrical battery

The invention discloses a battery replacing station and a power battery replacing method. The battery replacing station comprises a battery replacing cabin, wherein an electric vehicle can drive intothe battery replacing cabin so as to replace the power battery of the electric vehicle; a charging bin, wherein a battery transfer channel is arranged in the charging bin, and a battery replacing channel is arranged between the battery replacing bin and the charging bin; a battery transfer device which moves in the battery transfer channel so as to take and place the power battery; and a battery replacing moving device which moves in the battery replacing channel so as to realize replacement and transfer of the power battery; the battery replacing moving device is in butt joint with the battery transfer device in a direct butt joint or indirect butt joint mode, and thus power battery replacement is achieved. Therefore, through cooperation of the battery replacing bin, the charging bin, thebattery transferr device and the battery replacing moving device, the speed of replacing the power battery of the electric vehicle can be increased, the time for replacing the power battery can be saved, and thus the replacement rate of the power battery can be increased.

Owner:BEIJING ELECTRIC VEHICLE +1

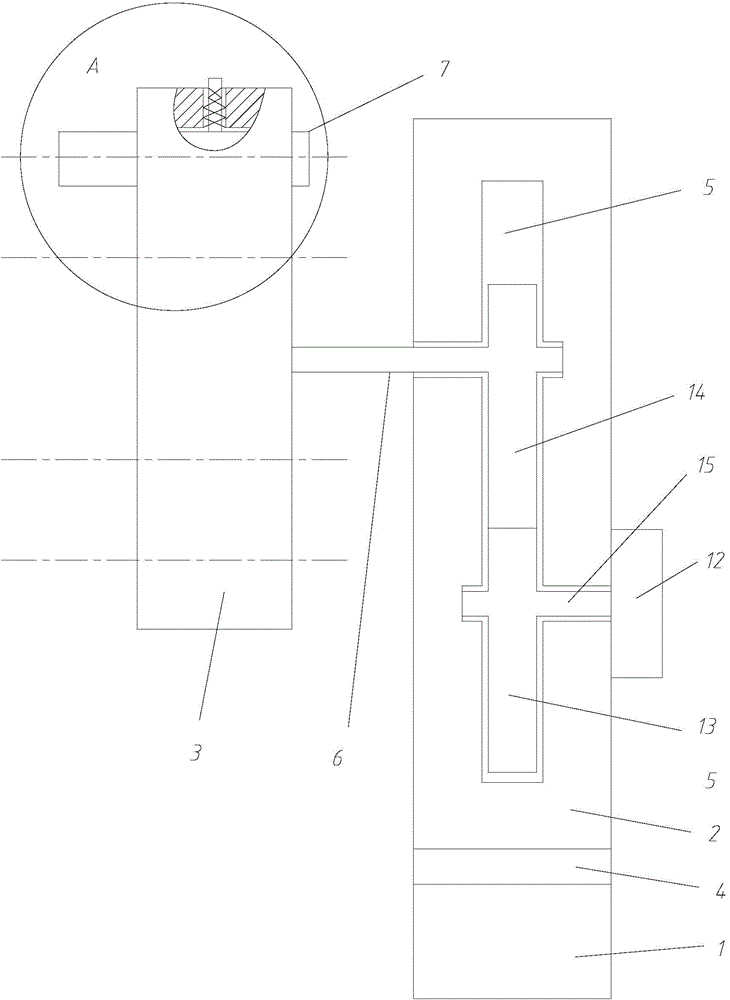

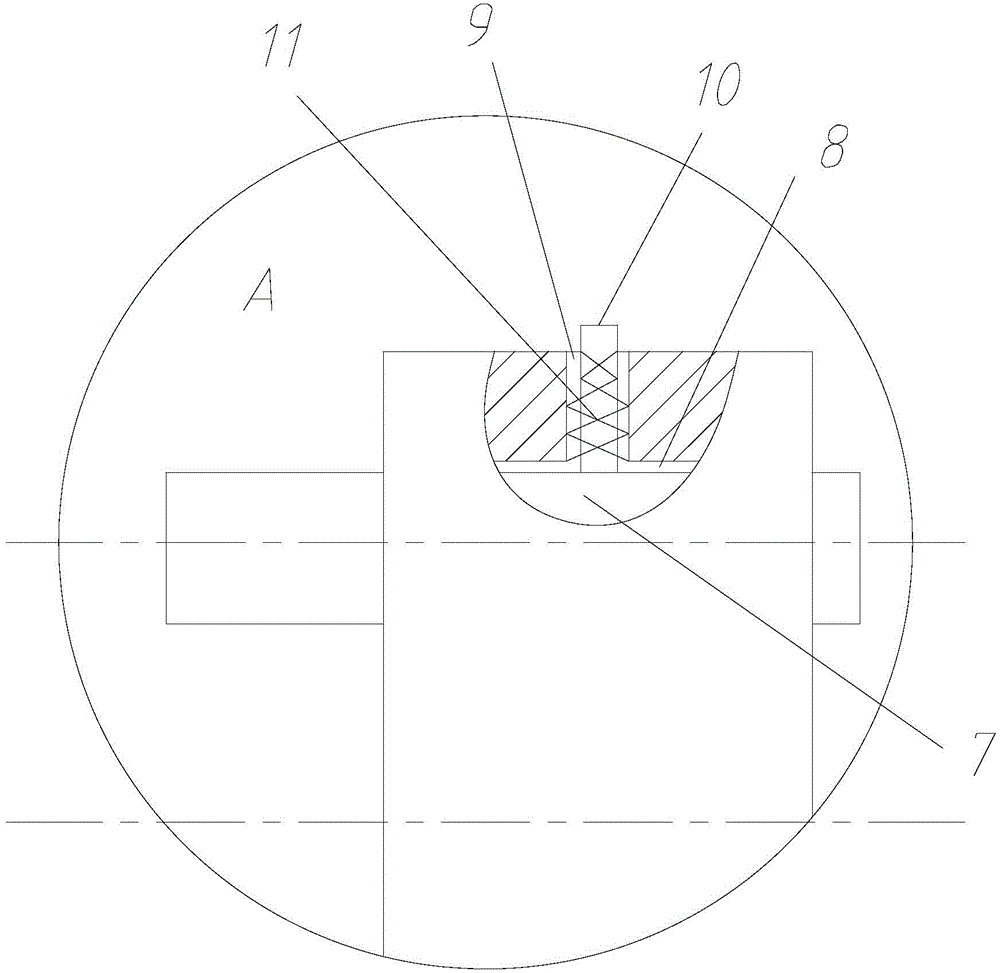

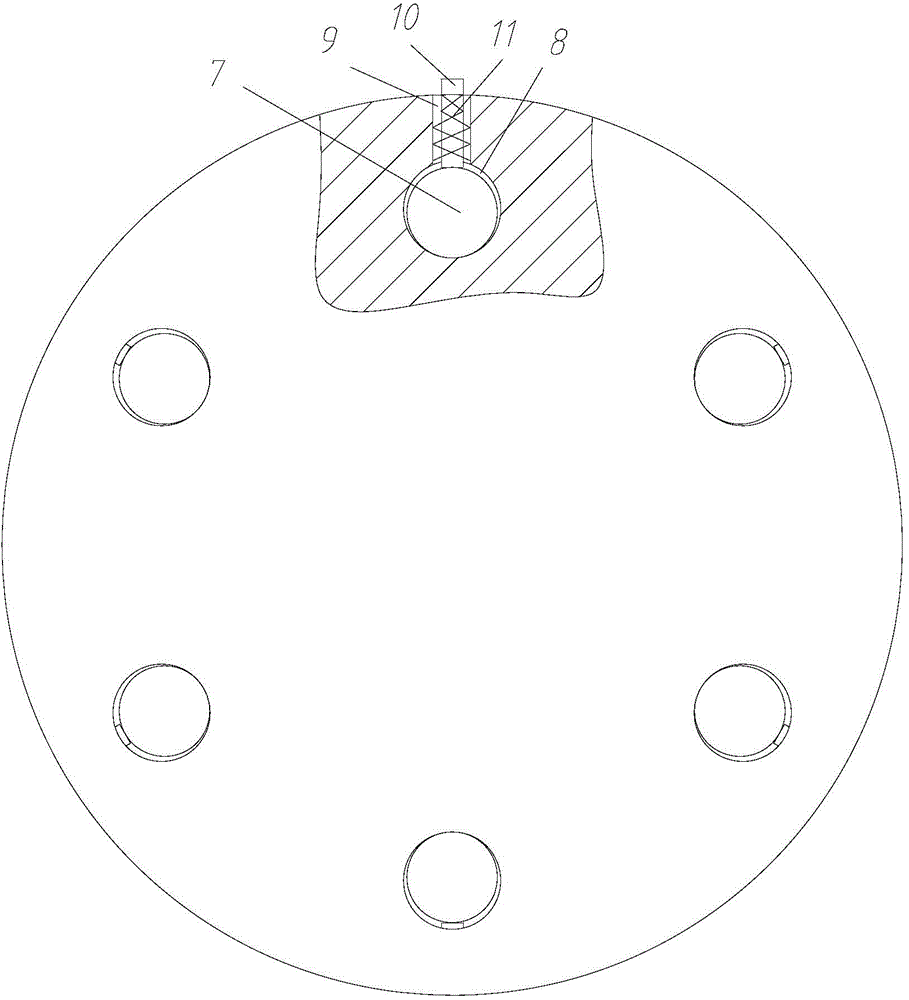

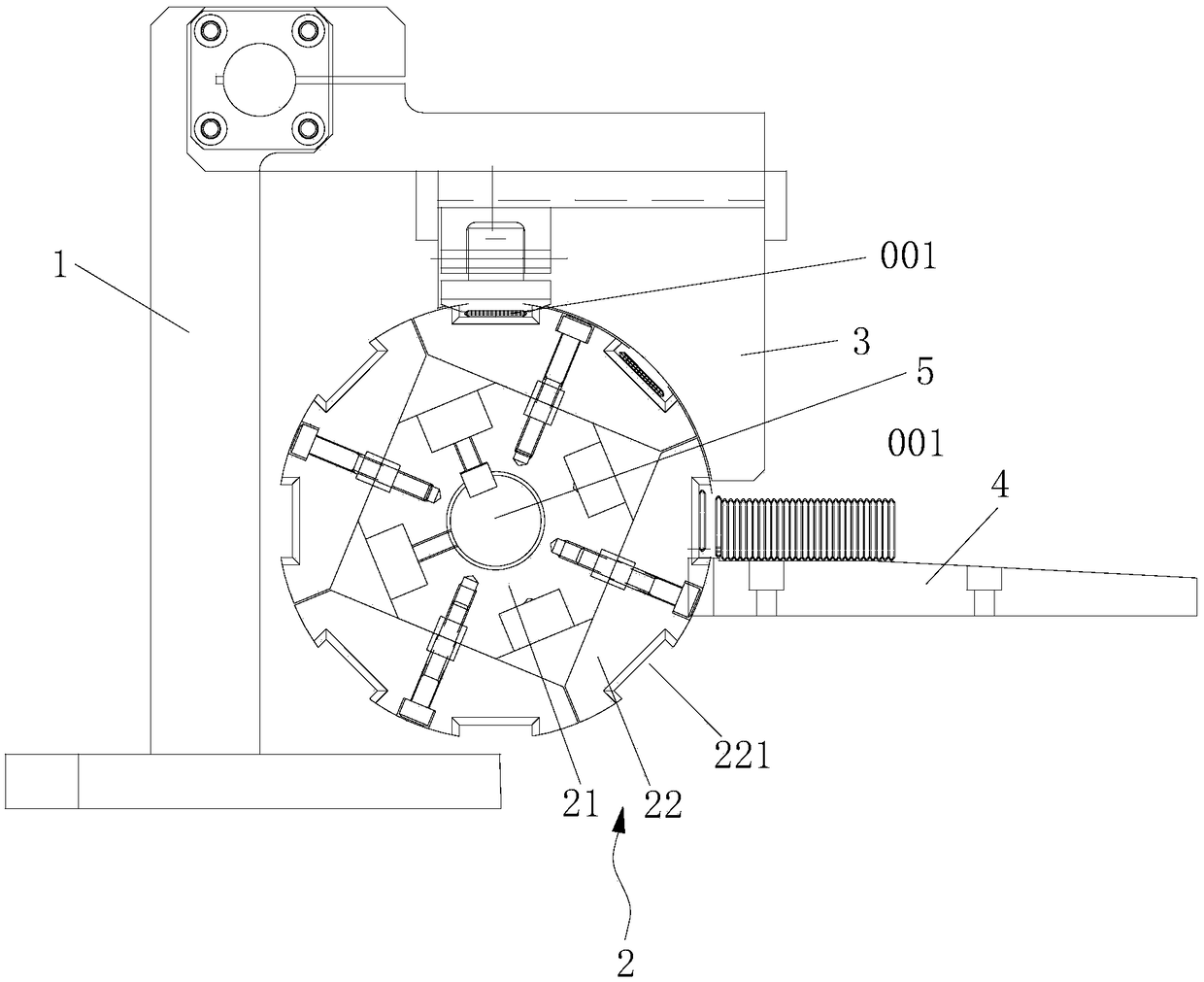

Tool changing post

InactiveCN104400528AShorten the timeImprove replacement ratePositioning apparatusMetal-working holdersLocking mechanismDrive shaft

The invention relates to a tool changing post. The tool changing post comprises a base capable of moving back and forth, and left and right, a fixture seat arranged on the base and capable of moving up and down, a rotatable fixture arranged on one side of the fixture seat; a lifting mechanism is connected between the base and the fixture seat; a receiving cavity for receiving a transmission mechanism is arranged inside the fixture seat; a transmission shaft connected with the transmission mechanism is arranged on the sidewall of one side of the fixture seat; the fixture is cylindrical; a plurality of through holes for holding cutting tools are formed in the fixture in the axial direction; the through hole are distributed evenly around the axis of the fixture; a locking mechanism for locking the cutting tools is arranged on the sidewall of the fixture; the fixture is connected with the fixture seat by use of a transmission shaft; the transmission shaft is coaxial with the fixture, and the transmission shaft is perpendicular to the sidewalls of the fixture seat. The tool changing post has the advantages that the coaxality of hole machining after tool changing is guaranteed, and meanwhile, the trouble of tool re-setting after tool changing is avoided, the time taken by tool changing is shortened and the tool changing rate is greatly increased.

Owner:CHANGZHOU ZHUJIANG TOOL

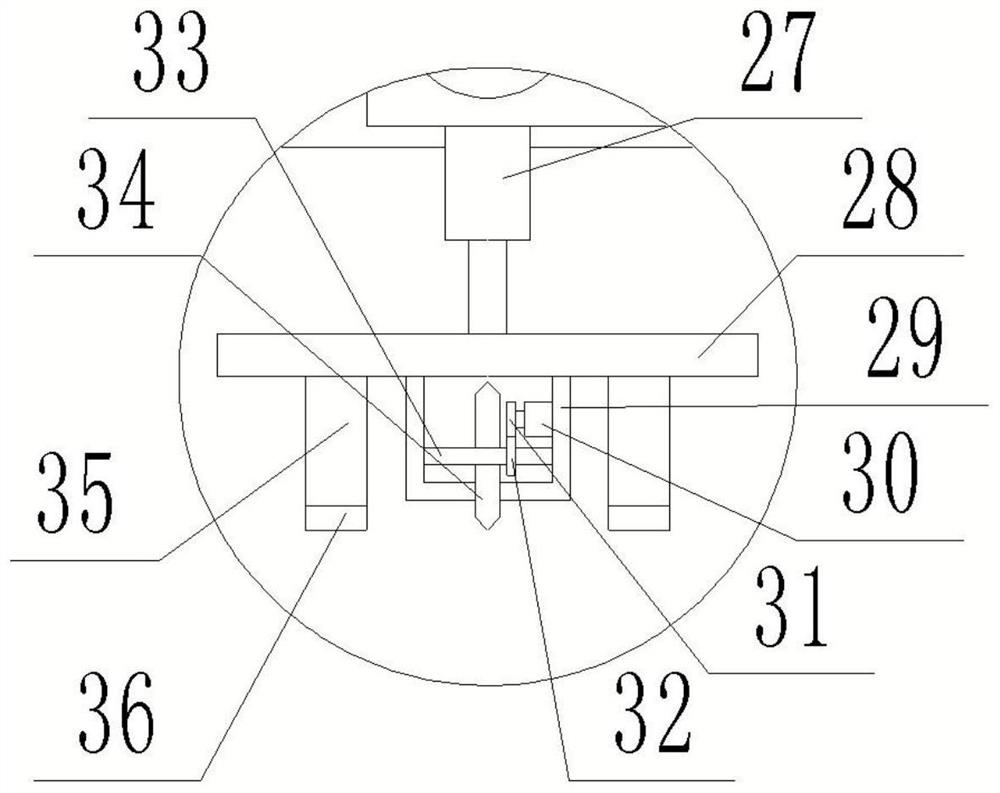

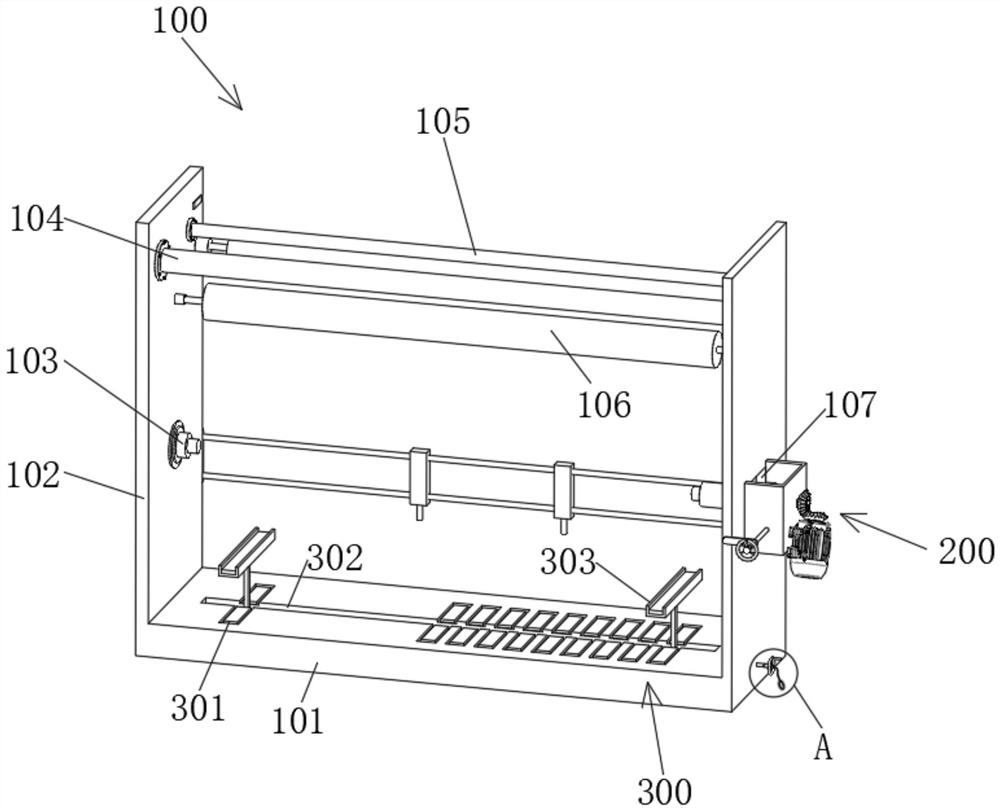

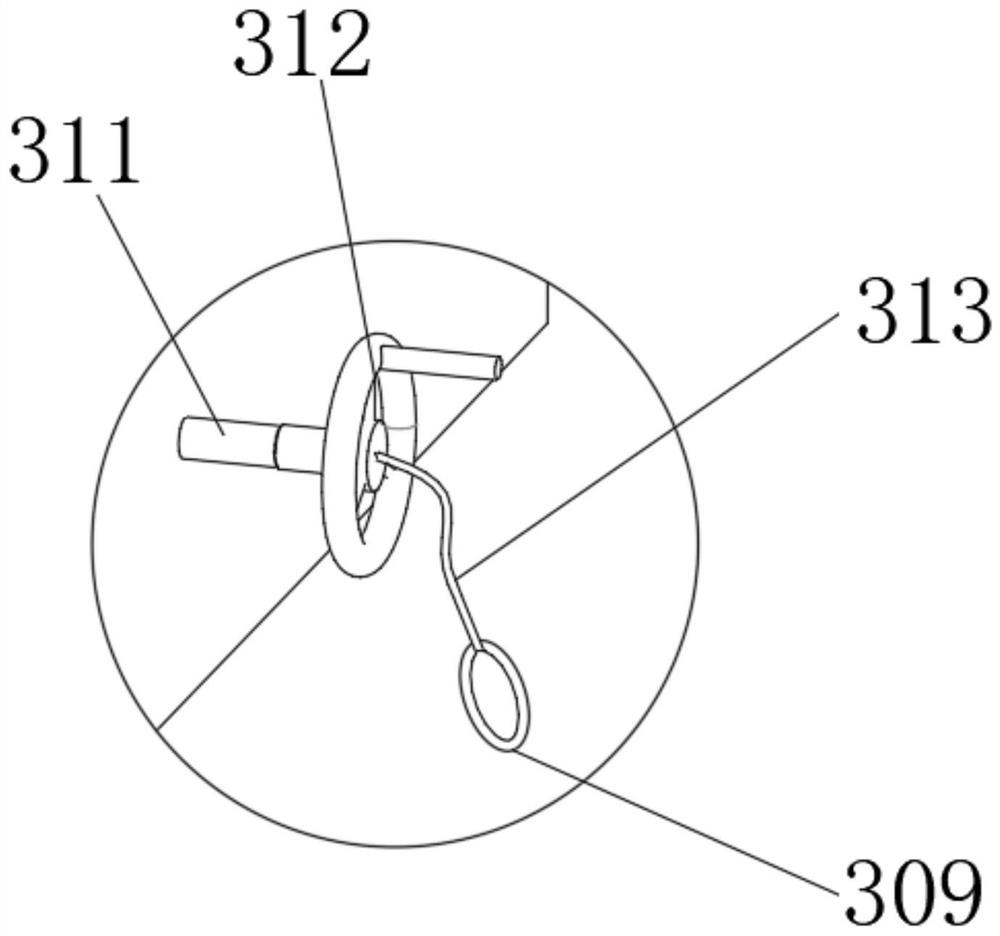

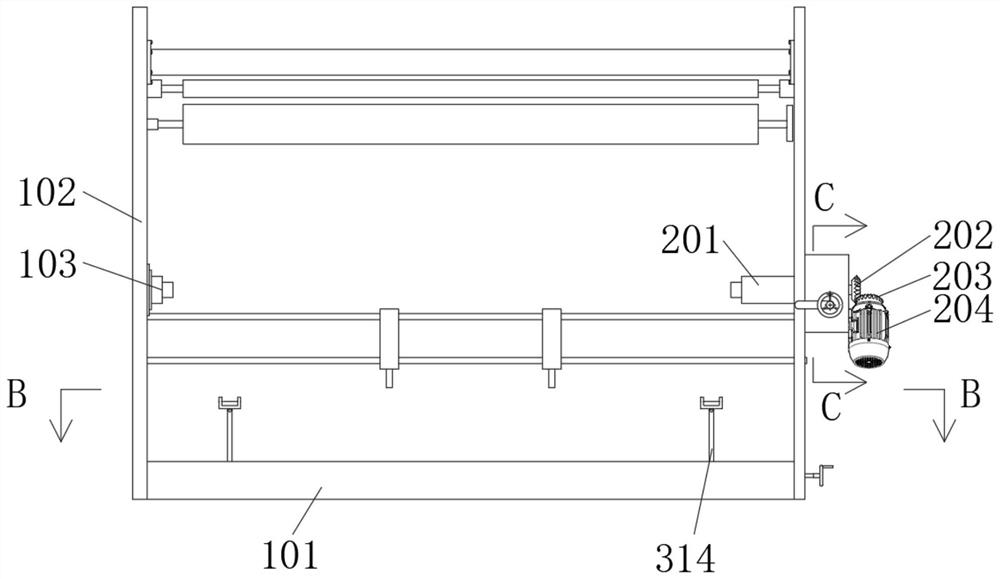

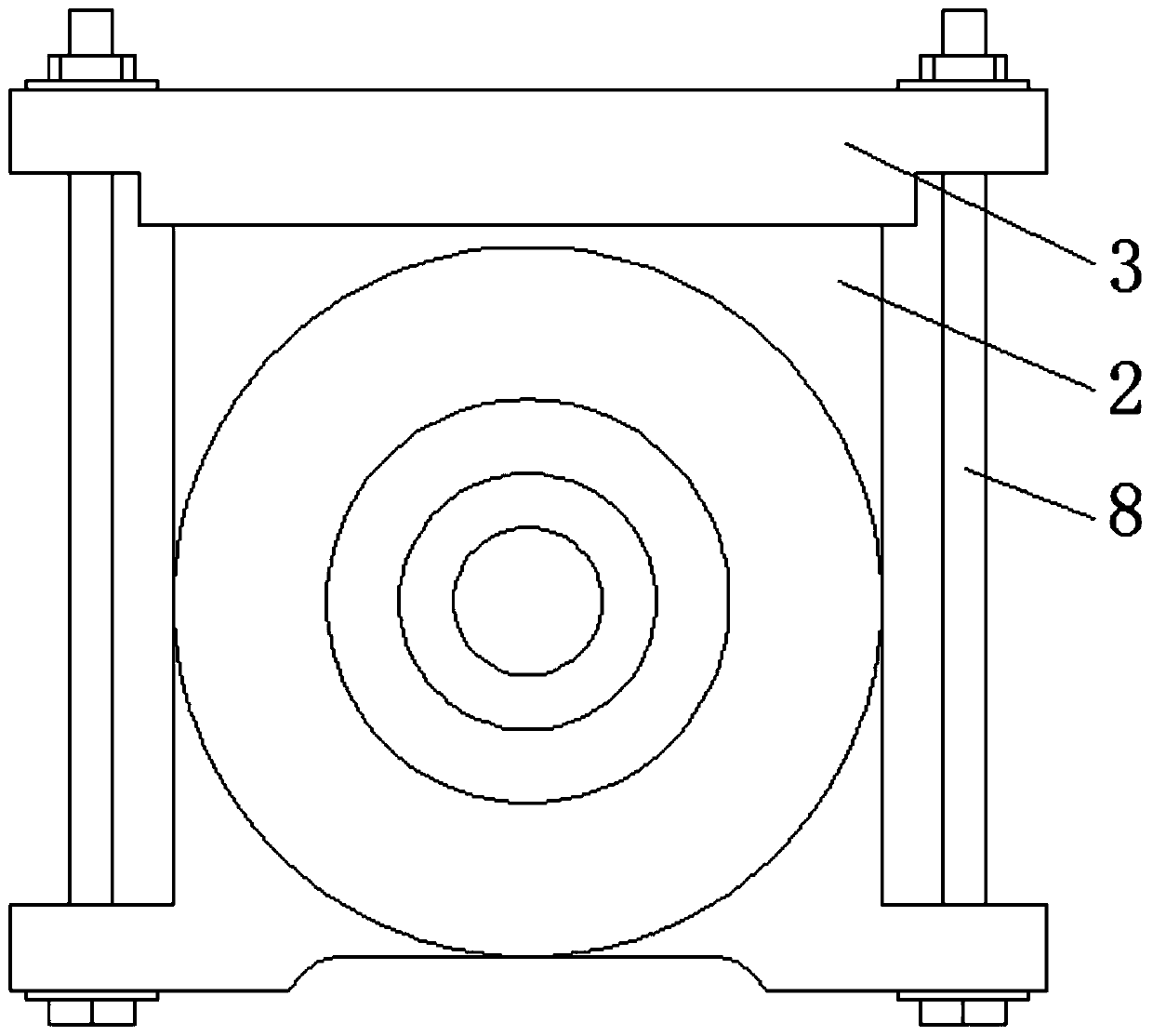

Copper foil cutting device

PendingCN114559479AHave a tense effectGuaranteed stabilityMetal working apparatusWebs handlingStructural engineeringCopper foil

The invention discloses a copper foil cutting device which comprises a bottom plate, a discharging mechanism is arranged on one side of the top face of the bottom plate, a discharging roller is detachably connected to the top of the discharging mechanism, electrolytic copper foil is wound on the outer wall of the discharging roller, a tensioning mechanism is arranged on the side, located on the discharging mechanism, of the top face of the bottom plate, and supporting plates are fixedly connected to the two sides of the middle of the top face of the bottom plate correspondingly. A paving mechanism and a transmission mechanism are arranged between the two supporting plates, a moving mechanism is arranged between the two cross beams, a cutting mechanism is arranged at the bottom of the moving mechanism, a conveying shell is arranged below the cutting mechanism, the bottom face of the conveying shell is fixedly connected with the top face of the bottom plate, and conveying mechanisms are arranged on the two sides of the top face of the conveying shell correspondingly. A dust collection mechanism is arranged between the two conveying mechanisms, a material taking mechanism is arranged on the other side of the top face of the bottom plate, a material collecting box is arranged below the material taking mechanism, and the electrolytic copper foil wound on the discharging roller sequentially penetrates through the tensioning mechanism, the paving mechanism, the transmission mechanism and the cutting mechanism to be cut together with the dust collection mechanism.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

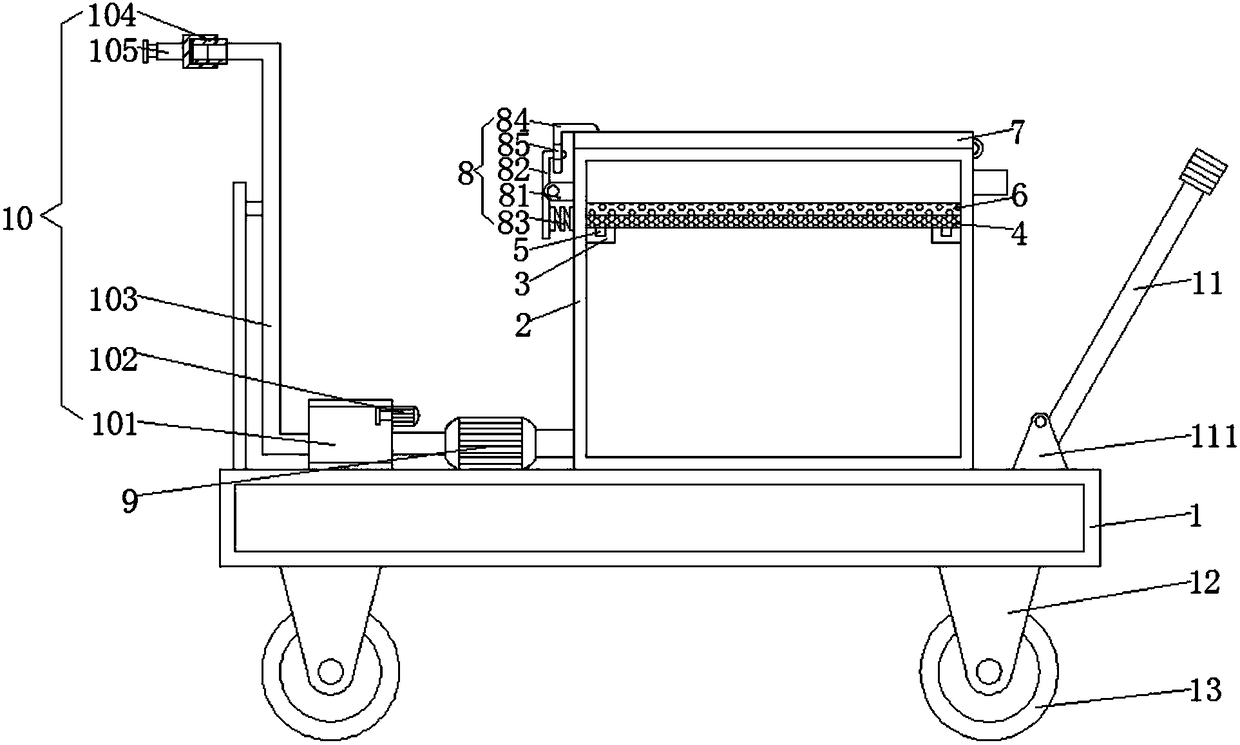

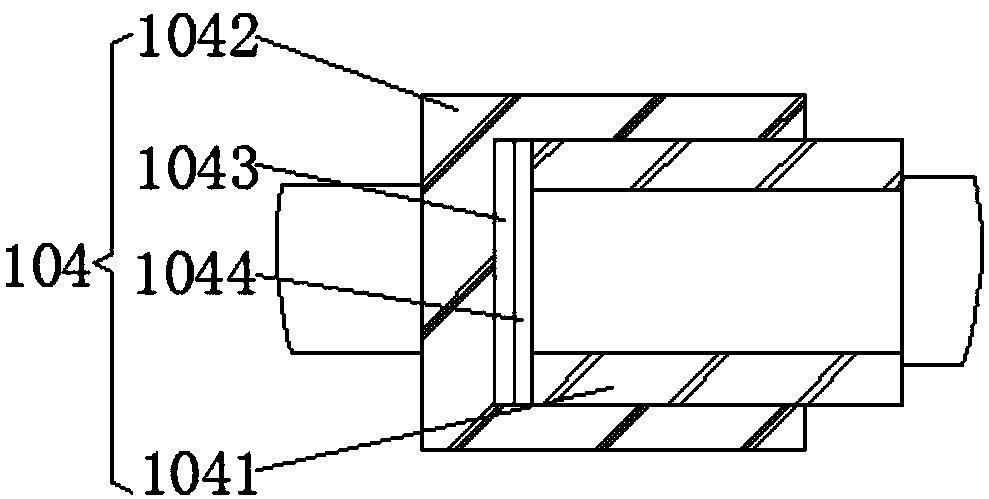

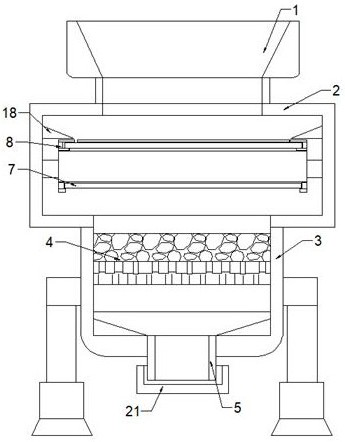

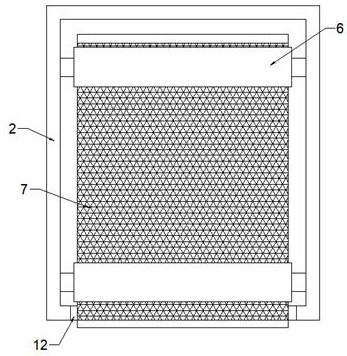

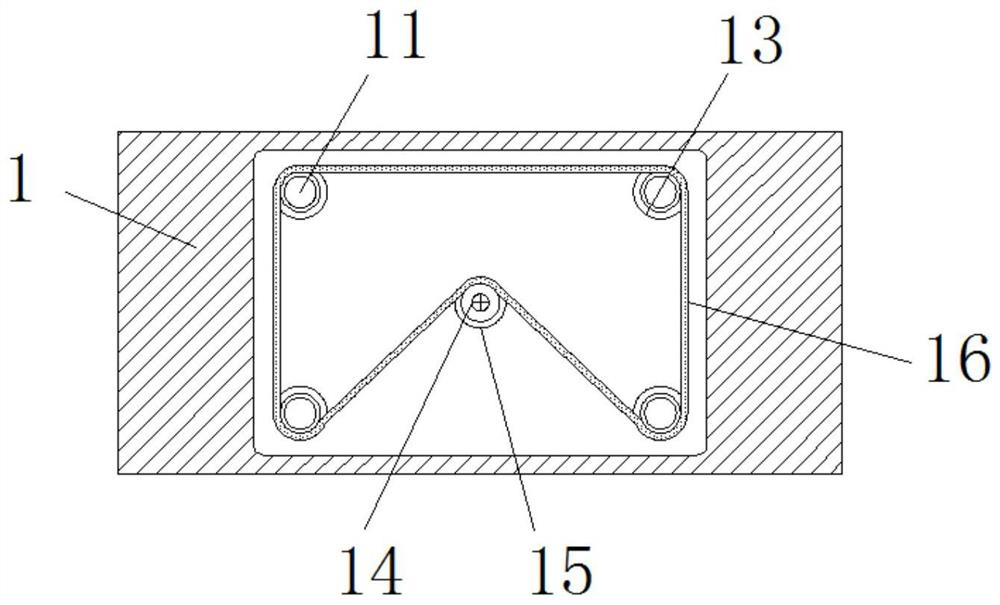

Quick synchronous belt replacing mechanism

PendingCN114229341ASimple structureImprove replacement rateConveyorsControl engineeringControl theory

Owner:瑞安市杰峰智能科技有限公司

Food crusher capable of effectively guaranteeing edible safety and use method thereof

The invention discloses a food crusher capable of effectively guaranteeing edible safety. The food crusher capable of effectively guaranteeing edible safety comprises a crusher assembly, a driving assembly, a detaching assembly and a connecting assembly, wherein the crusher assembly comprises a crushing treatment frame, a charging port formed in the top surface of the crushing treatment frame, as well as a first rotating shaft and a second rotating shaft which are arranged in the crushing treatment frame; and the driving assembly comprises a driving motor connected with the second rotating shaft, and a concave storage frame connected with the driving motor. A use method of the food crusher capable of effectively guaranteeing edible safety comprises the following steps of S1, S2 and S3. According to the invention, through mutual cooperation of a detaching structure and a connecting structure, the effect of quickly moving crushing blades and the motor out of the treatment frame integrally is achieved, so that no cleaning dead angle is ensured during cleaning, the cleaning speed is increased, the cleanliness is improved, and the food crushing quality and the food safety are ensured; and moreover, all the blades can be integrally detached, washed and replaced quickly through the connecting structure, so that the replacement speed is increased.

Owner:姜棋桐

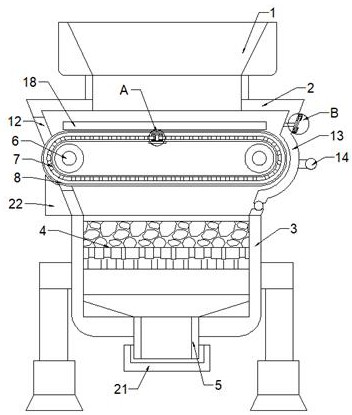

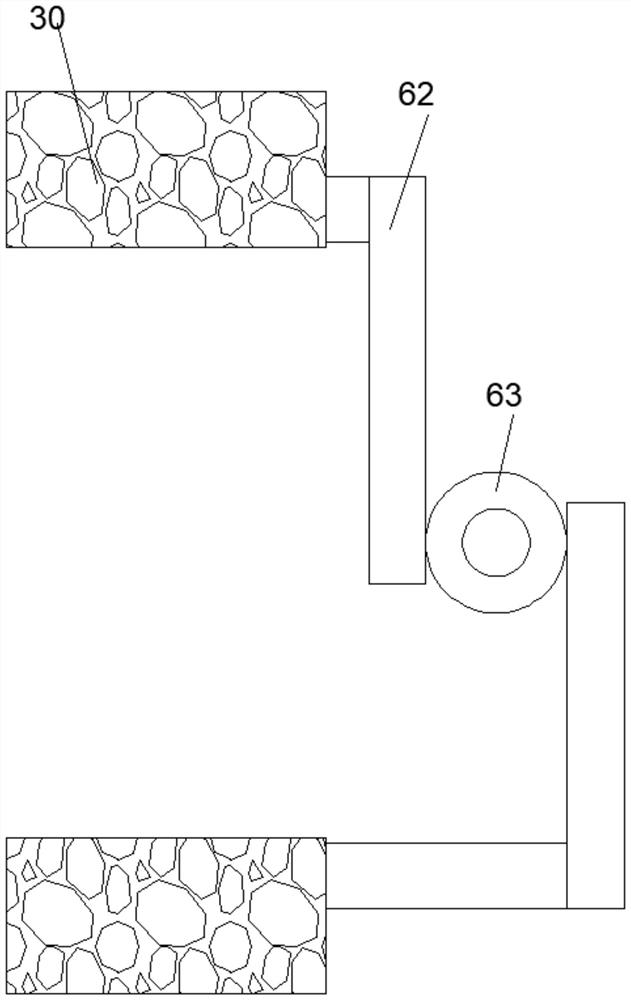

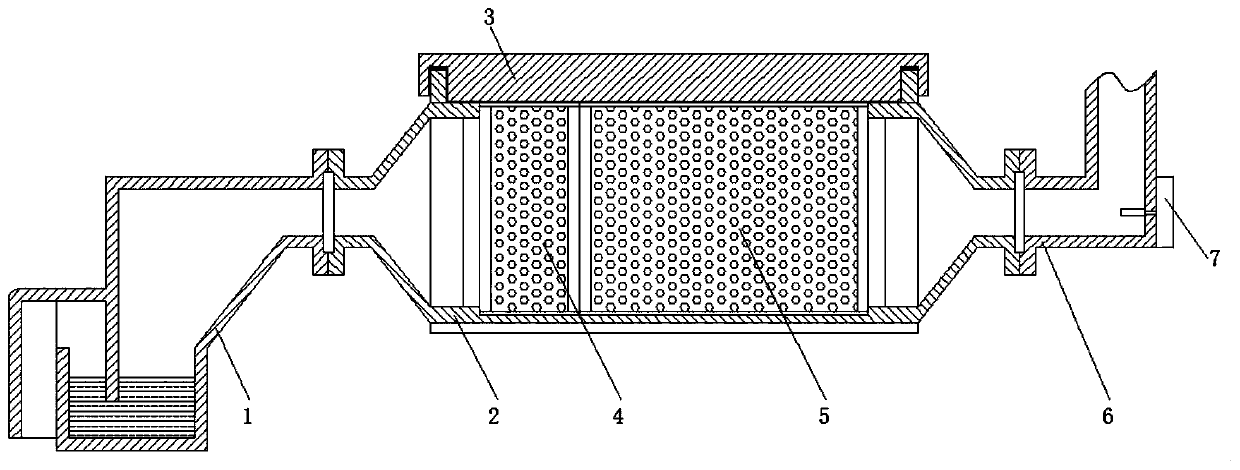

A kind of sewage treatment equipment that is convenient to replace the filter screen

ActiveCN112742097BExtended service lifeEasy to replaceMembrane filtersMoving filtering element filtersEngineeringSewage treatment

The invention discloses a kind of sewage treatment equipment which is convenient to replace the filter screen. The sewage treatment equipment comprises; The water pipe is fixedly connected to the top of the filter box, and the multi-effect filter layer is fixedly installed inside the tank body; the garbage filter mechanism, the garbage filter mechanism includes a guide wheel, a filter screen and a limit strip, and the two ends of the guide wheels rotate Installed on the side wall of the filter box, two limit bars are symmetrically sleeved between the two guide wheels; the replacement assembly includes a connecting bar, a block and a moving rod, and the two ends of the connecting bar are fixedly connected Between the two limiting bars, a plurality of moving bars are equidistantly threaded on the upper end of the connecting bar, and the resisting block is fixedly connected to the bottom of the moving bars. The speed of filtering and cleaning is improved, and the service life of the device is extended at the same time. At the same time, the replacement method is simple and quick, and the replacement rate of the filter screen is improved.

Owner:山东利金新材料科技有限公司

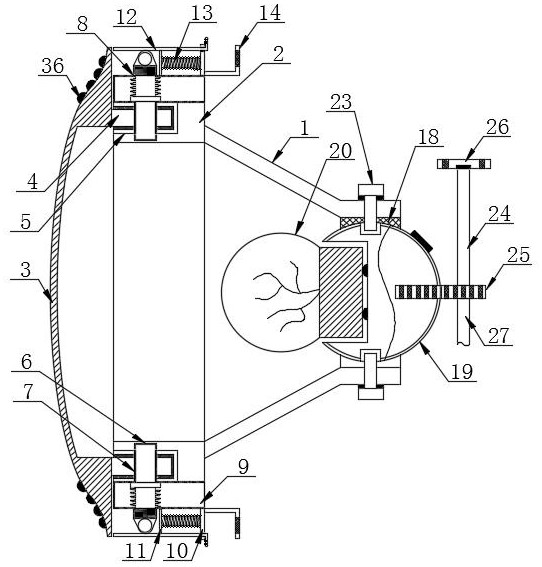

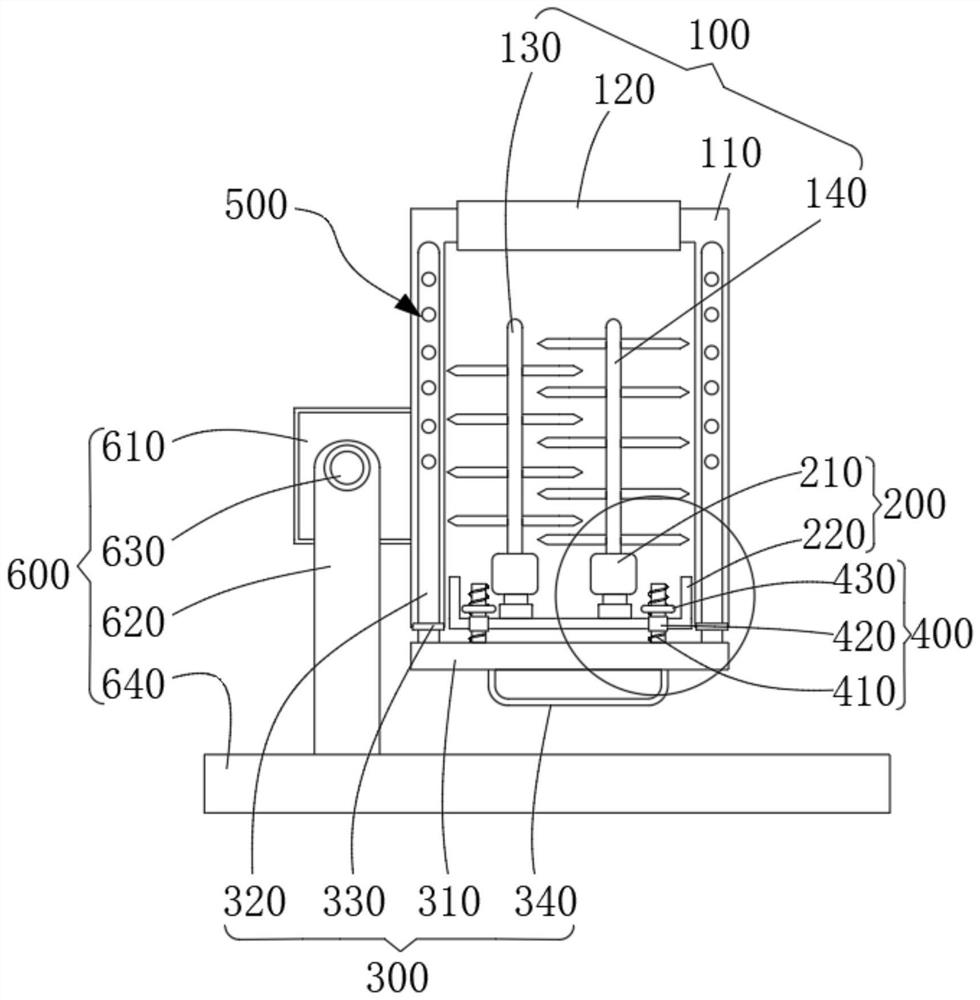

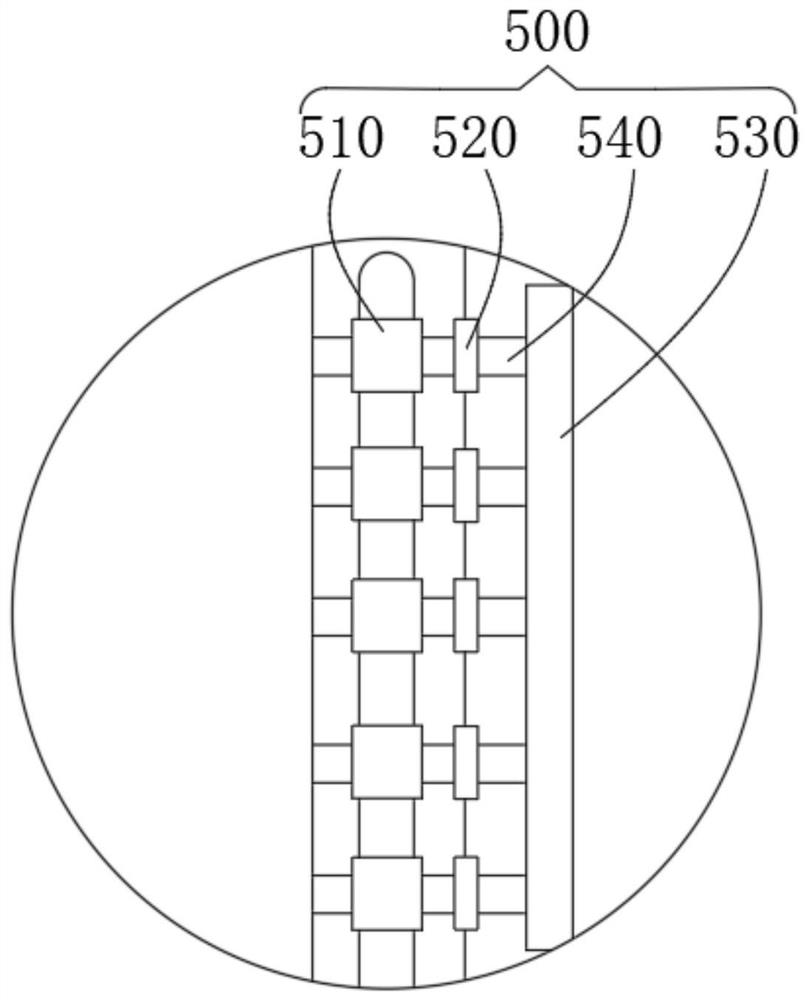

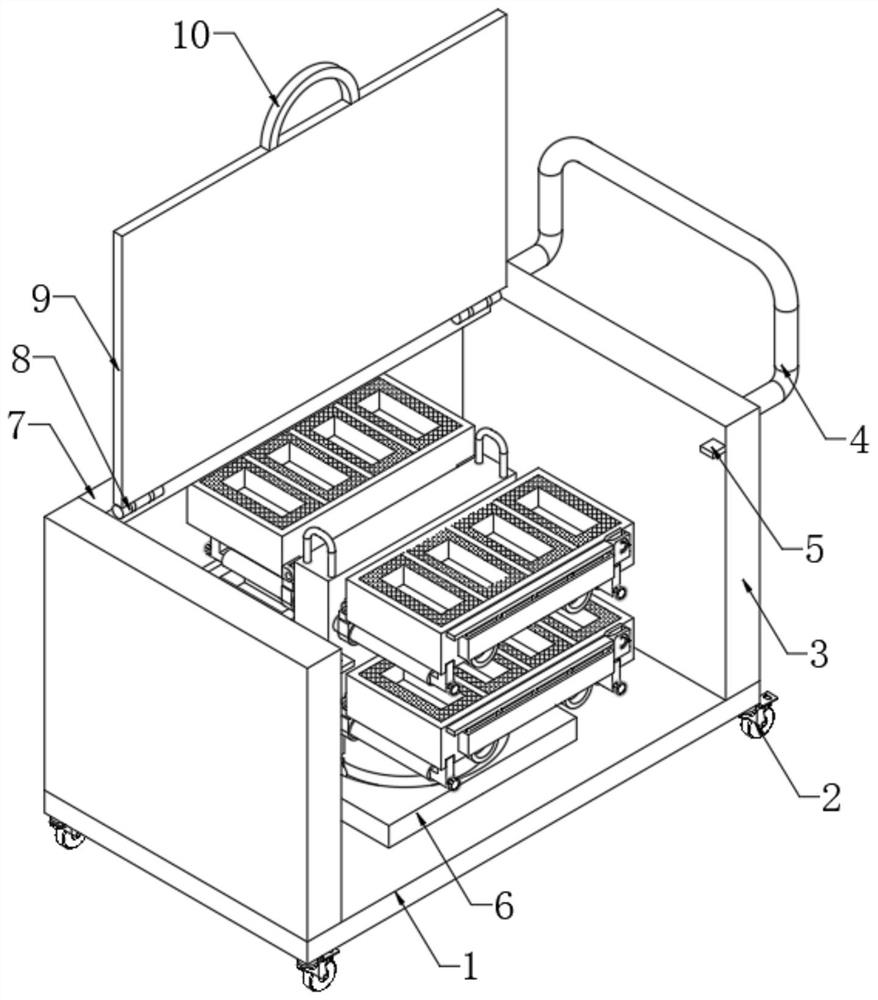

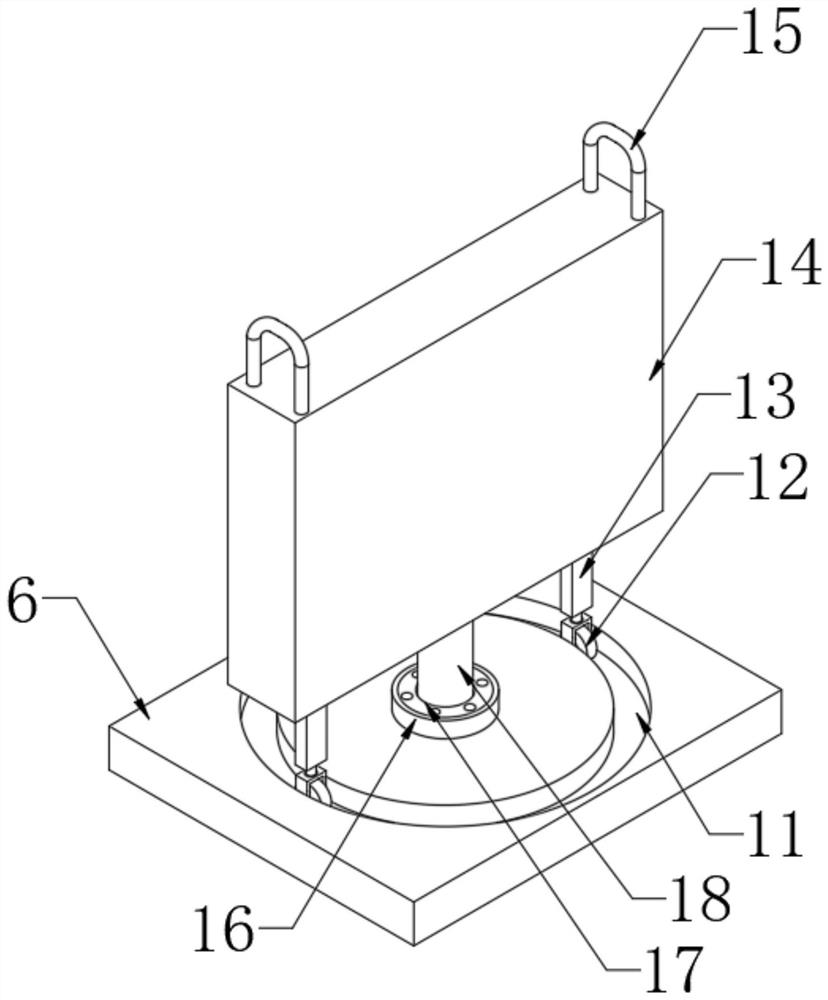

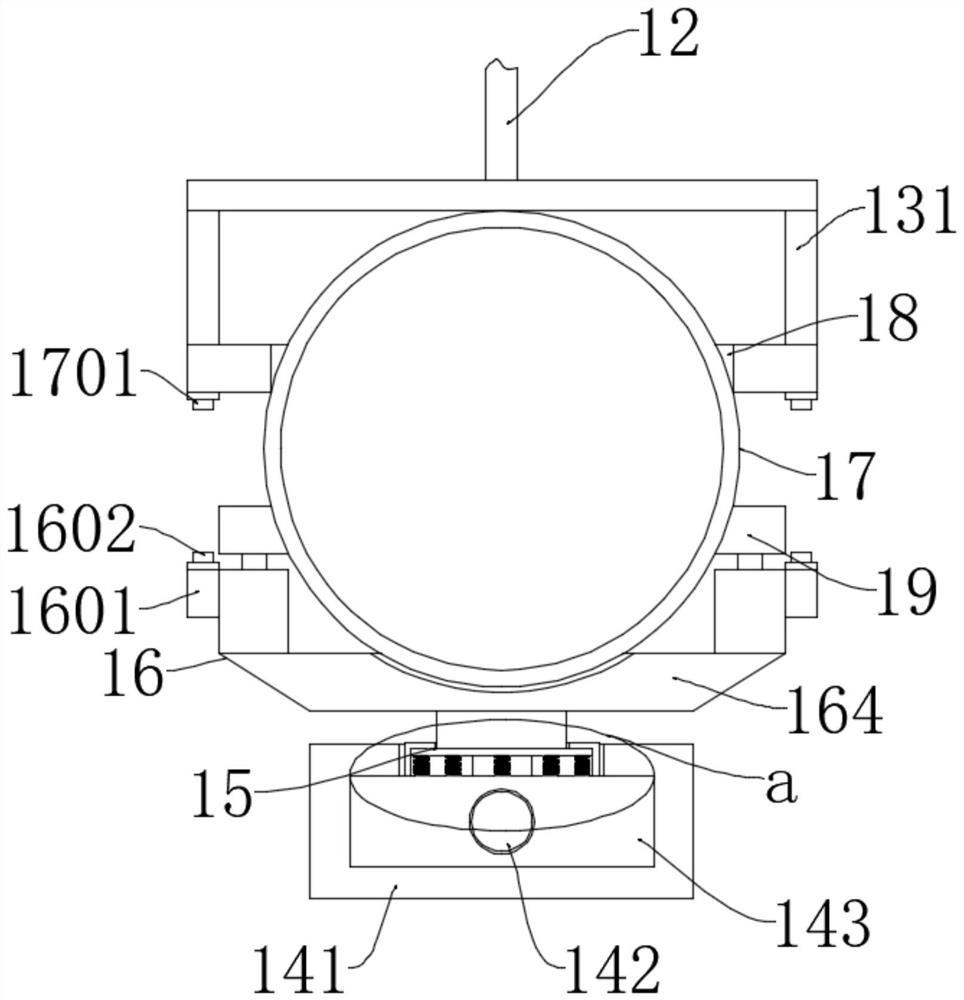

Separating battery replacement equipment capable of autonomously resetting

InactiveCN110745111ARealize rational utilizationEasy to operateCharging stationsElectric propulsion mountingElectrical and Electronics engineeringControl engineering

The invention provides separating battery replacement equipment capable of autonomously resetting. The separating battery replacement equipment capable of autonomously resetting includes a horizontally-arranged triangular-shaped mounting plate, and a steering mechanism is arranged between the mounting plate and a steering plate. The steering plate is further provided with a battery replacement device for mounting a battery into a battery mounting box, and the mounting plate is provided with a power driving device for driving the steering mechanism to rotate. The power driving device includes adirectly-pushing mechanism for driving the steering mechanism, a transmission mechanism for driving the directly-pushing mechanism, a trigger sequencing mechanism for controlling the power transmission of the transmission mechanism, a power source for powering the transmission mechanism and a retention reset mechanism for controlling the reset of the transmission mechanism. Through the automaticreplacement of a battery of a shared mini-motorcycle, reasonable use of human resources is achieved, multiple stations can be sequenced in sequence at the same time for battery replacement, and the replacement rate is greatly improved.

Owner:陆海燕

Tool placing frame for machining lathe and using method of tool placing frame

InactiveCN113043067ASmooth rotationEasy accessProtection and storage accessoriesPillow block bearingEngineering

The invention discloses a tool placing frame for a machining lathe and a using method of the tool placing frame. The tool placing frame comprises a bottom plate, wherein movable trundles are fixedly arranged at the four corners of the bottom end of the bottom plate, side plates are fixedly arranged on the two sides of the top end of the bottom plate, a connecting plate is fixedly arranged in the middle of the top end of the bottom plate, and a bearing seat is fixedly arranged in the middle of the top end of the connecting plate; and a rotating bearing is fixedly mounted on the inner wall of the bearing seat, the inner wall of the rotating bearing is rotationally connected with the bottom of the outer wall of a rotating shaft, the top end of the rotating shaft is fixedly connected with the middle of the bottom end of a supporting plate, and pulling handles are fixedly arranged on the two sides of the top end of the supporting plate correspondingly. The rotating bearing is arranged in the bearing seat connected through the connecting plate, the rotating bearing is rotationally connected with the rotating shaft connected with the supporting plate, a supporting rod connected with the supporting plate is connected with a limiting universal wheel, and the limiting universal wheel is connected with a limiting circular groove formed in a connecting plate in a penetrating and inserting mode, so that the placing frame can be rotated more conveniently, personnel can rotate the placing frame by rotating the supporting plate, and the personnel is guaranteed to take and use cutters on the two sides of the placing frame.

Owner:聂旭旗

Equipment for disassembling bearing on rotating shaft

InactiveCN112975840AAchieve disassemblyAvoid damageMetal-working hand toolsClassical mechanicsStructural engineering

Owner:南京卓菲诗纸业有限公司

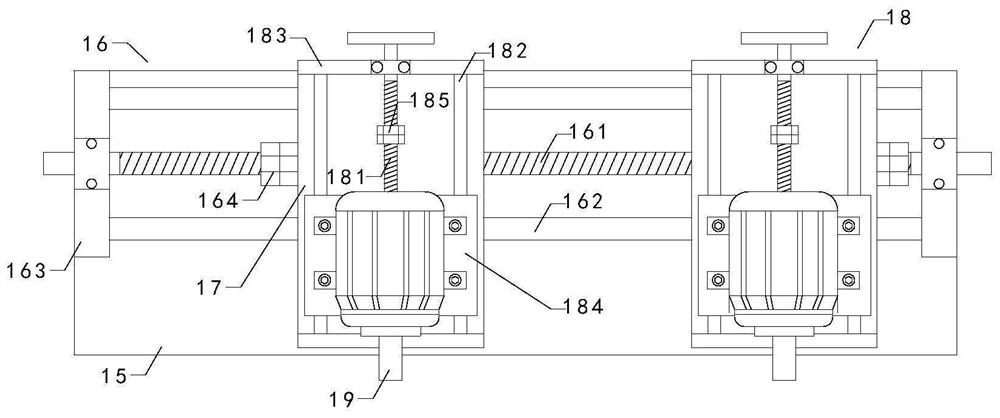

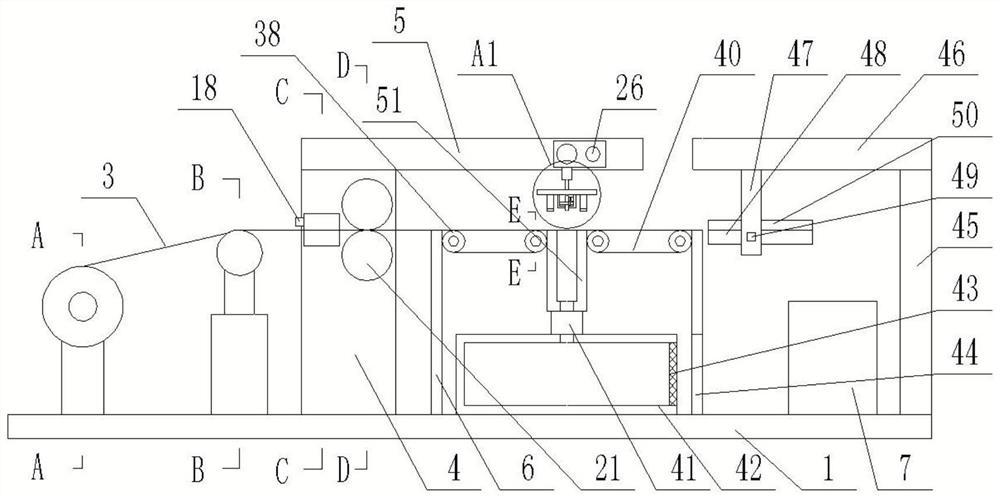

Flat pipe arrangement device

PendingCN108927696ASolve labor intensitySolve efficiency problemsMetal working apparatusAgricultural engineering

The invention discloses a flat pipe arrangement device, and belongs to the technical field of flat pipe arrangement. The flat pipe arrangement device comprises a drum wheel and an output platform; thedrum wheel is connected with a rotating shaft on a working bracket; a groove for placing flat pipes is formed in the peripheral surface of the drum wheel; the groove is axially arranged; the axial end of the groove is a flat pipe inlet end; the flat pipes can enter the groove from the flat pipe inlet end; the output platform is arranged on one side of the drum wheel; and when the groove is rotated to the output platform, the flat pipes are discharged from the groove to the output platform. The flat pipe arrangement device realizes overturning arrangement of horizontal-discharged flat pipes ina pipe cutting machine through the drum wheel and the output platform, and solves the problems of high labor intensity and low efficiency due to main manual operation in traditional flat pipe arrangement work.

Owner:SHANGHAI HEKE EQUIP MFG

Robot polishing device capable of replacing clamp according to needs

ActiveCN112792706AImprove replacement rateIncrease the lengthGrinding carriagesPolishing machinesSuction forceButt joint

The invention discloses a robot polishing device capable of replacing a clamp according to needs, and belongs to the technical field of polishing. The robot polishing device comprises a device body, a supporting frame is arranged at the top of the device body, a first electromagnetic sliding rail is mounted at the top end of the inner side of the supporting frame, and a second electromagnetic sliding rail is slidably connected to the bottom of the first electromagnetic sliding rail; and a hydraulic push rod is mounted at the bottom of the second electromagnetic sliding rail. The first electromagnetic sliding rail and the second electromagnetic sliding rail generate a surrounding type magnetic field under the action of electric power, the hydraulic push rod is driven to move to the position over a containing groove containing a suitable clamp, then the length of the output end of the hydraulic push rod is increased, a support is moved to the outer side of a protruding block, and then under the action of a magnetic block and an iron block, the protruding block is directly attracted to the magnetic block under magnetic attraction, then the hydraulic push rod moves leftwards under the action of the first electromagnetic sliding rail, a limiting block is slowly moved out of the containing groove, and therefore rapid butt joint and fixing are achieved.

Owner:日禺光学科技(苏州)有限公司

A medical biological 3D printing device

ActiveCN108032521BQuick changeQuick combinationManufacturing enclosures3D object support structuresTemperature controlShape change

Owner:渭南职业技术学院

Laser collimator for 3D printer

ActiveCN114536765AQuick fixFast and accurate fixationAdditive manufacturing apparatusIncreasing energy efficiencyComputer printingGalvanometer

The invention provides a laser collimator for a 3D printer, and belongs to the technical field of equipment for the 3D printer, the laser collimator comprises a forming chamber, a forming cylinder and a powder cylinder are arranged in the forming chamber, a focusing field lens is arranged below a laser scanning galvanometer system, and a laser collimation assembly comprises a working chamber and a lens standby chamber. An upper fixing frame is installed at the output end of the telescopic rod, a buffering assembly is installed on the pushing assembly, a lower locking piece is installed on the buffering assembly, and an upper fixing block and a lower fixing block are arranged on the side edges of the upper end and the lower end of the lens. The laser collimator solves the problems that a lens in an existing laser collimator for the 3D printer needs to be aligned when being put down, alignment of the lens can be achieved only through repeated adjustment when alignment operation is conducted on the lens, time consumption is long, and meanwhile after the lens is put down, the lens needs to be moved back and forth to adjust the position of the lens, so that the alignment efficiency is high. And vibration is generated in the adjusting process, so that deviation is easily generated in the adjusting process of the lens.

Owner:NANJING CHAMLION LASER TECH CO LTD

Auxiliary replacement equipment for railway traffic sleeper disassembly and replacement

ActiveCN110939029BQuick disassembly and replacementImprove replacement rateRailway track constructionGear wheelElectric machinery

The invention discloses an auxiliary replacement device for railway traffic sleeper disassembly and replacement, which comprises a housing, a first motor, a first hydraulic rod, a second motor, a photoelectric sensor, a second hydraulic rod and a third hydraulic rod. The bottom of the housing is A moving wheel assembly is fixedly installed on the edge, a first motor and a positioning cylinder are embedded on the outer wall of the side plate, and a guide gear is installed on the inner shaft of the positioning cylinder, and a bearing support is fixed on the top of the housing. The top of the shell is fixedly installed with a guide frame and a fixed rod, and a chute is reserved on the outer wall of the end of the fixed rod, and a connecting rod is vertically fixed on the bottom of the sleeve, and the top of the sleeve and the top outer wall of the fixed rod A third hydraulic rod is hingedly installed between the upper parts. The railway traffic sleeper disassembly and replacement auxiliary replacement equipment facilitates fast disassembly and replacement of sleepers, reduces labor consumption of manual assistance, is convenient and quick to operate, speeds up the replacement rate of sleepers, and is accurate in positioning and easy to use.

Owner:新昌县知贝机械有限公司

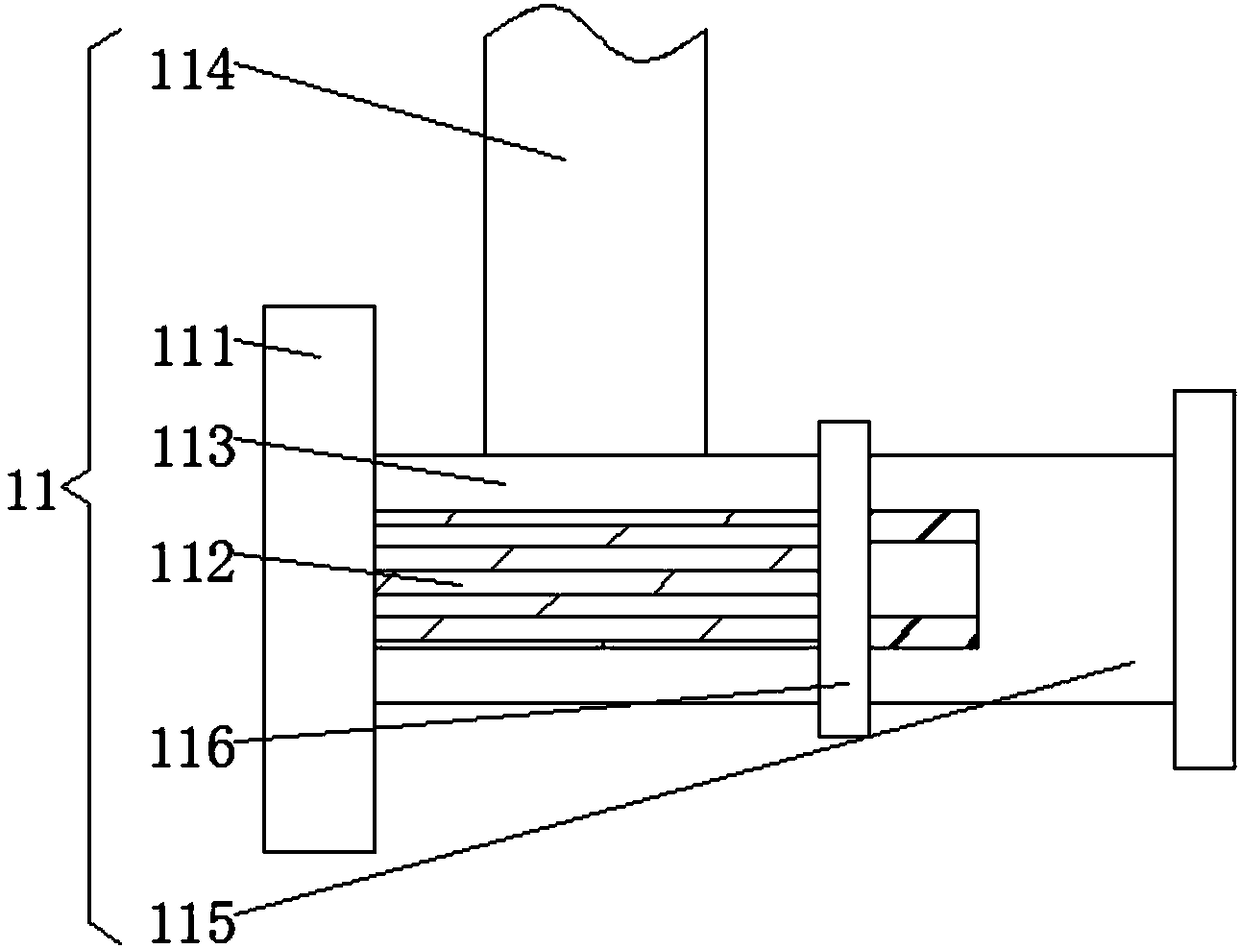

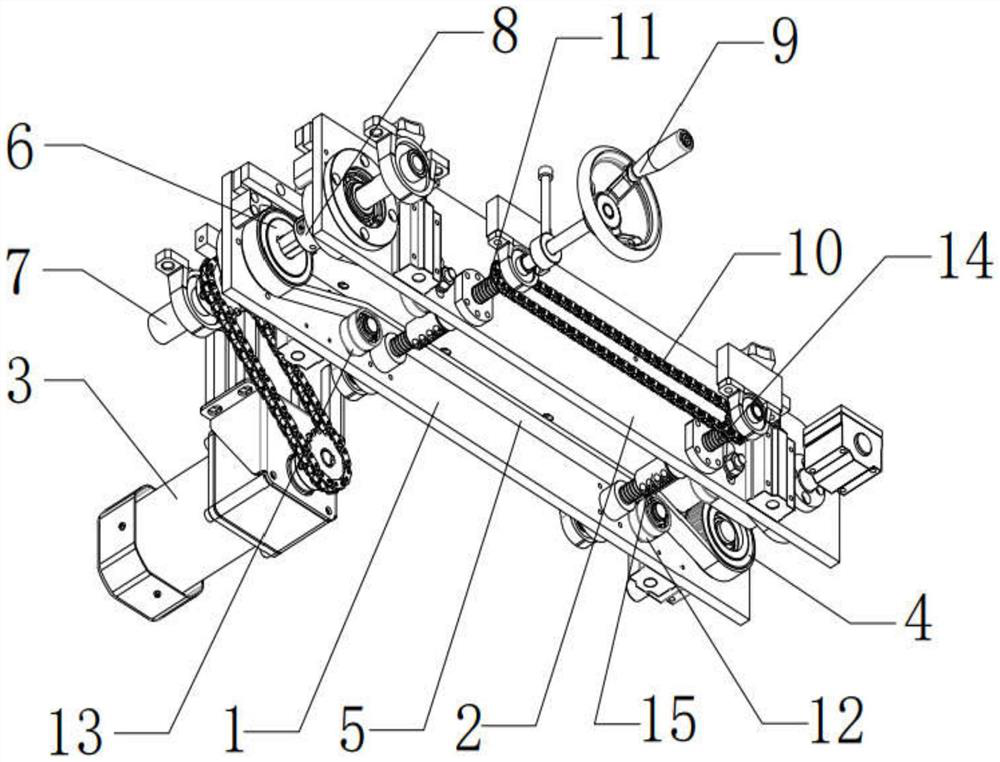

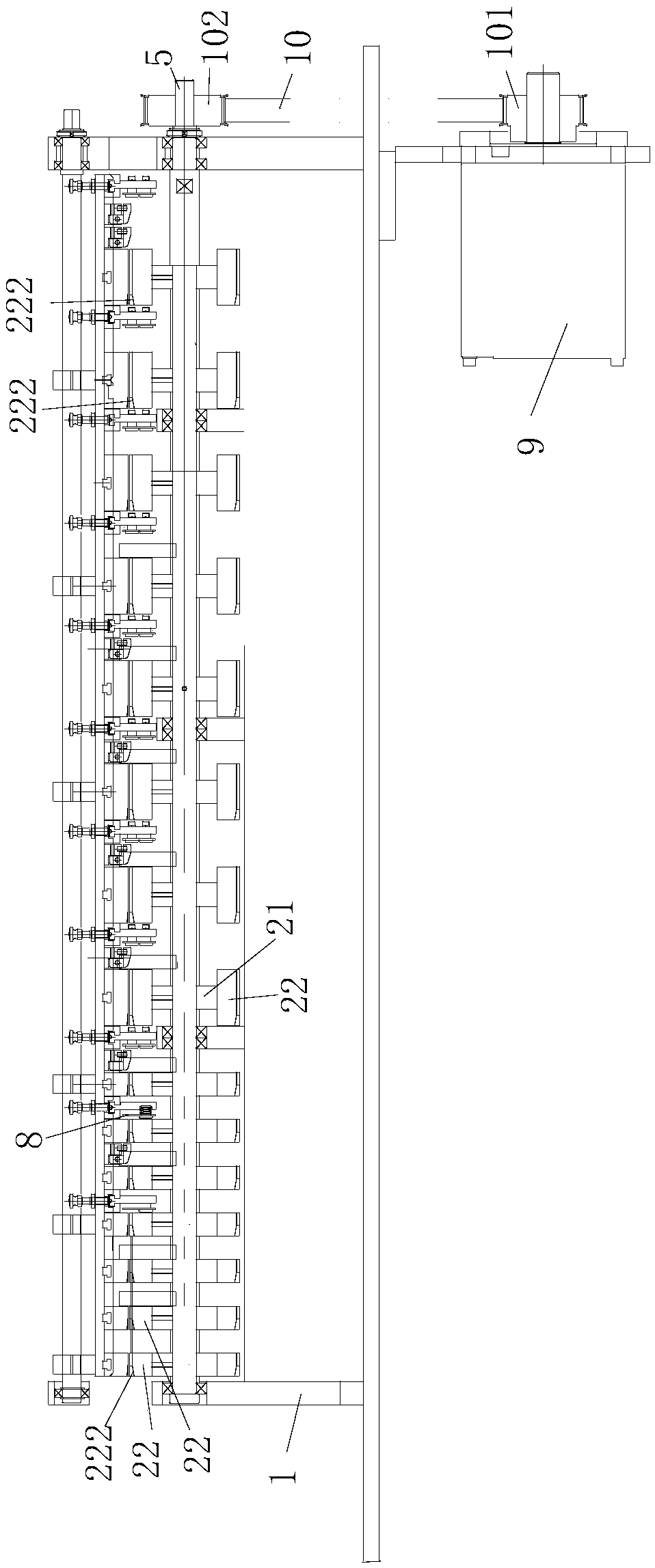

Web-fed material printing equipment with adjustable width of plate with shaft

ActiveCN112537118AImprove rotational stabilityImprove firm performanceRotary intaglio printing pressEngineeringPrinting press

The invention relates to the technical field of printing equipment, and particularly relates to web-fed material printing equipment with the adjustable width of a plate with a shaft. The equipment comprises a printing rack, the printing rack comprises a bottom plate, vertical plates are fixed on two sides of the top surface of the bottom plate, the middle part of one vertical plate is rotatably connected with a driven ejector shaft, the middle part of the other vertical plate is provided with a square hole, a main transverse rod and an auxiliary transverse rod are fixed between the upper portions of the inner side walls of the two vertical plates, conveying rollers are rotatably connected to the positions, located on the lower portion of the main transverse rod, of the inner side walls ofthe two vertical plates, and an ink fountain fixing mechanism used for bearing an ink fountain is arranged on the top face of the bottom plate. According to the web-fed material printing equipment, after a first nut block moves relatively, a driving rod can be driven to push an ejector shaft fixing frame to move along a sliding rail, and compared with the mode that the driven ejector shaft is changed to fix plate cylinders, the structure is higher in plate cylinder rotating stability, therefore, the fixing firmness of the printing equipment on the plate cylinders with different plate widths isimproved, and the investment cost of the equipment of enterprises is reduced.

Owner:黄山枘淼机电科技有限公司

Moisture absorber for transformer

ActiveCN110797163AImprove securityImprove efficiencyTransformers/inductances coolingTransformers/inductances casingsTransformerProcess engineering

The invention relates to the technical field of conventional electric power manufacturing, and discloses a moisture absorber for a transformer. The moisture absorber comprises a side box, a main box body, a sealing cover, a silica gel moisture absorption device I, a silica gel moisture absorption device II, a connecting pipe, an air humidity detector and a bolt, wherein the right end of the side box is connected with the left end of the main box body through a flange plate, and the sealing cover is located on the upper surface of the main box body. Real-time humidity detection is carried out on air entering the transformer through the arrangement of an air humidity detector, so that the safety of the transformer is effectively improved; the moisture absorption effect of the moisture absorber is strictly monitored by adopting a modern technology; and manual observation and a glass silica gel cylindrical container are omitted, the labor cost is reduced, the structural strength of the moisture absorber is improved, the safety of the moisture absorber is improved, and the loss caused by damage of the silica gel container is reduced. Meanwhile, the use efficiency of silica gel can be effectively improved, the use time of the silica gel is prolonged, the replacement frequency of the silica gel is reduced, and the maintenance cost is reduced.

Owner:国网吉林省电力有限公司延边供电公司

A reminder device for easy replacement of warning signs for power supply construction

The invention discloses a reminder device convenient for replacing warning signs for power supply construction, including the base, a vertical lifting column is fixedly installed on the upper surfaceof the base, and a lifting device is installed in the lifting column, a threaded rod is driven to rotate by opening a driving motor, so that the threaded connecting block moves linearly along the threaded rod, as such, the push rod push and adjusts the height of the connecting plate, the range of warning signs on the connection board is increased, to facilitate the replacement of damaged or otherwarning signs by staff, Increased rate of replacement, the buffer device can improve the protection of the arc cover and the shielding plate in rainy and snowy weather, as the arc cover and the shieldplate are impacted by the rain and snow, the shield plate is moved downward so that the distance between the shield plate and the fixing plate is reduced, and the two slide blocks are separated alongthe slide rail under the push of the rotating lever, and the springs on the slide rail are compressed at the same time, thereby cushioning, damping and protecting the arc cover and the shield plate.

Owner:国网河南省电力公司嵩县供电公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com