Separating battery replacement equipment capable of autonomously resetting

A battery replacement and separation technology, applied to charging stations, electric vehicles, electric power devices, etc., can solve the problems of slow replacement, chaotic battery replacement, disorder, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

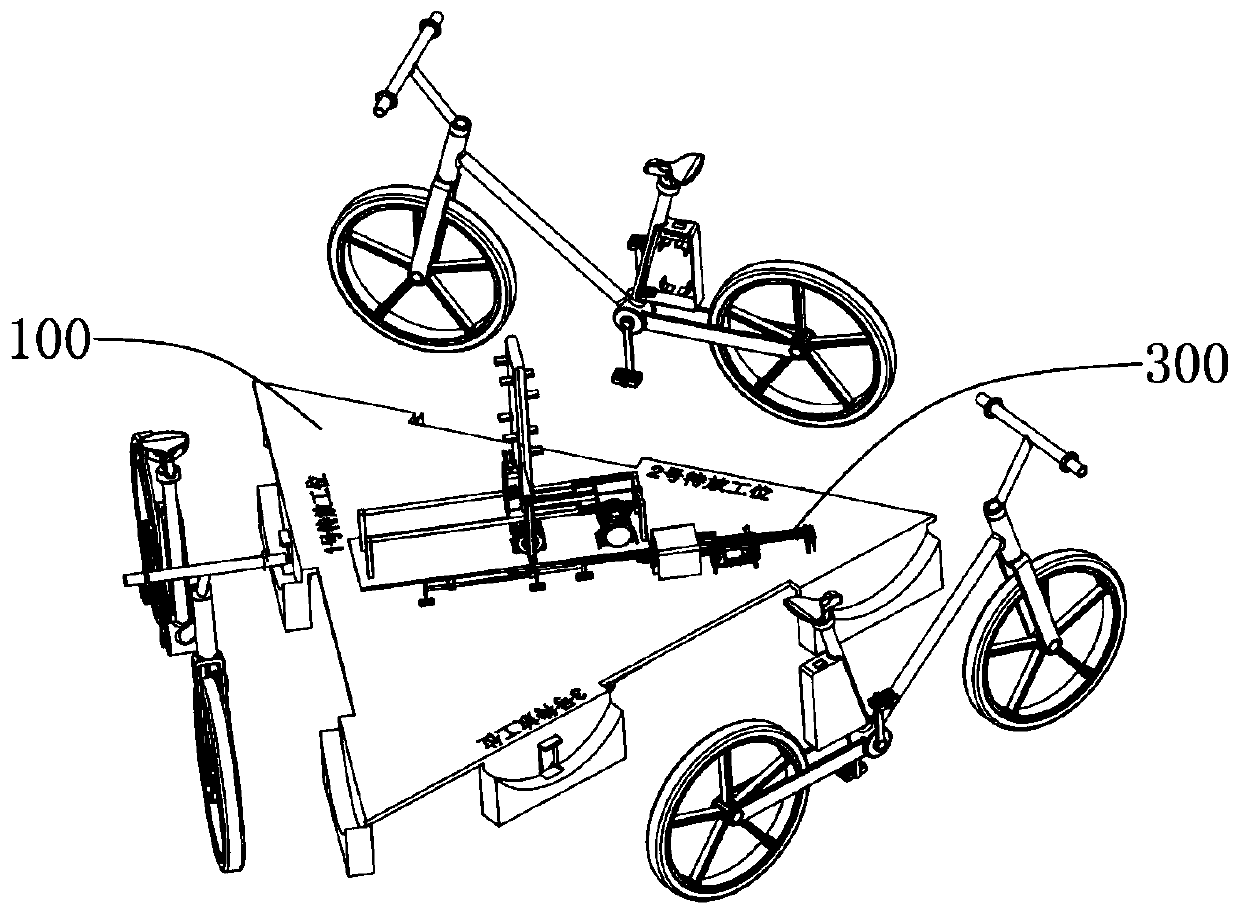

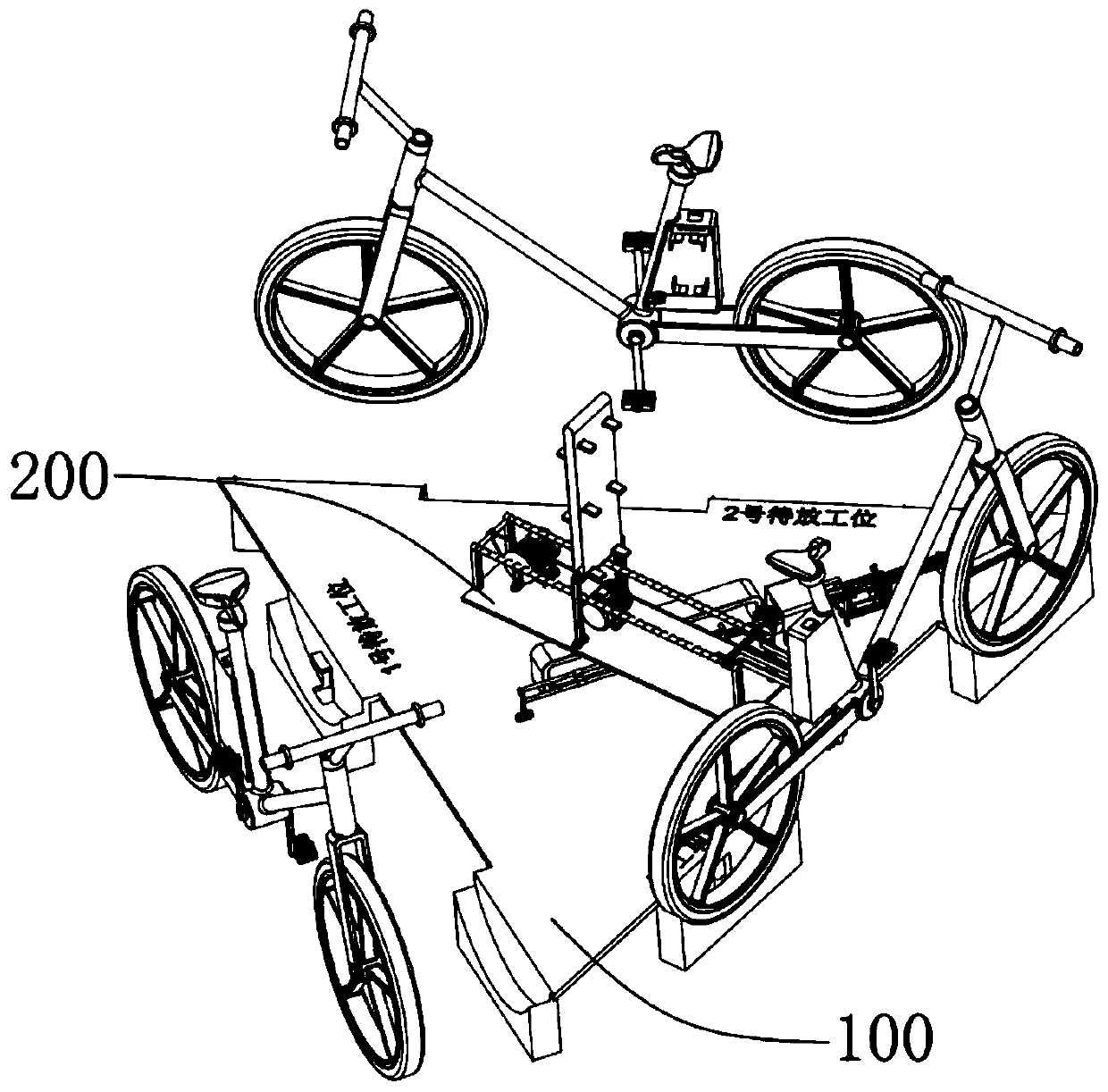

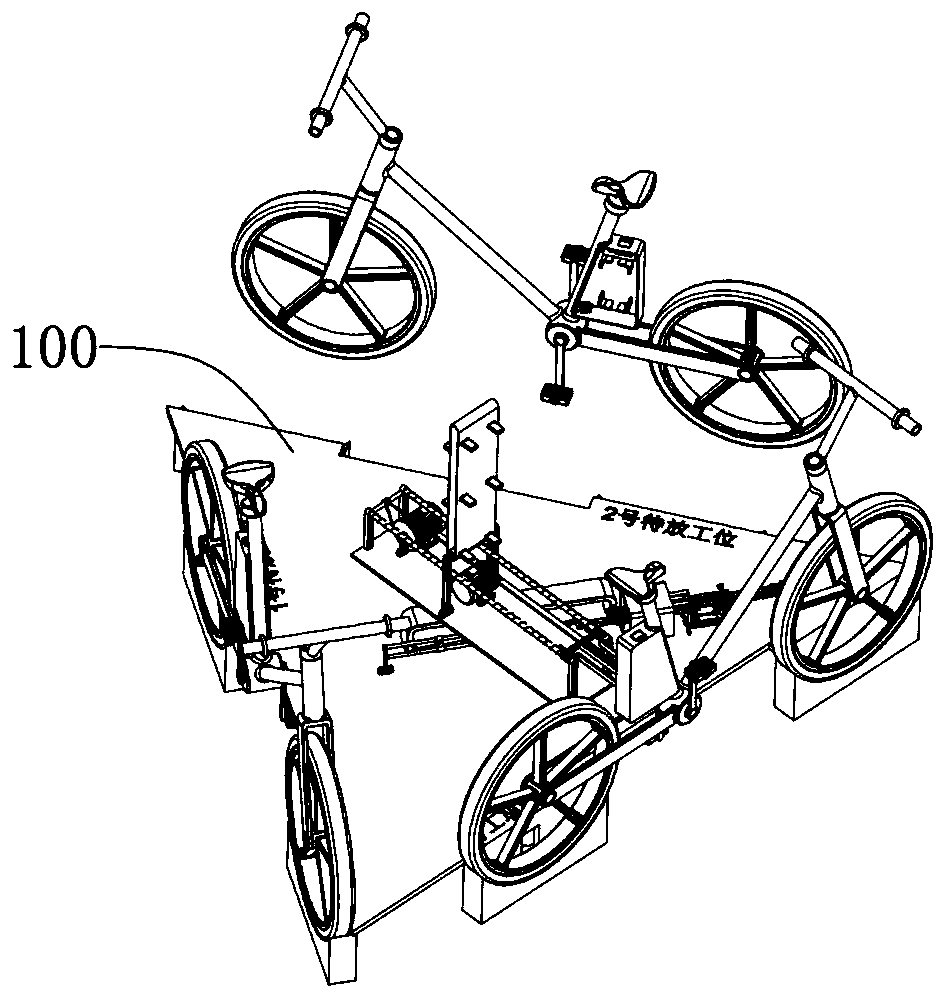

[0070] Such as Figure 1-48 As shown, an automatic docking and self-pedal sorting battery replacement machine includes a horizontally arranged and triangular mounting plate 100, and the three sides of the mounting plate 100 are vertically provided with front wheel fixing for placing the front wheels of the shared moped. Plate 102 and the rear wheel fixing plate 103 for placing the rear wheels, the front wheel fixing plate 102 and the rear wheel fixing plate 103 are arranged in parallel with the corresponding straight sides of the mounting plate 100 and are distributed at intervals, and the battery installation box 101 is arranged on the shared moped. The installation box 101 is a trapezoidal box with an opening on the end surface facing the center of the installation plate 100 and is provided with clamping lugs 106 for fixing the battery inside. Seat 104, the longitudinal direction of fixed seat 104 is vertically arranged with any one side of mounting plate 100 and the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com