Quick synchronous belt replacing mechanism

A synchronous belt and fast technology, which is applied in the field of quick-change synchronous belt mechanism, can solve the problems of troublesome disassembly, large equipment, and a relatively long time for replacement and maintenance, and achieve the effect of improving the replacement rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

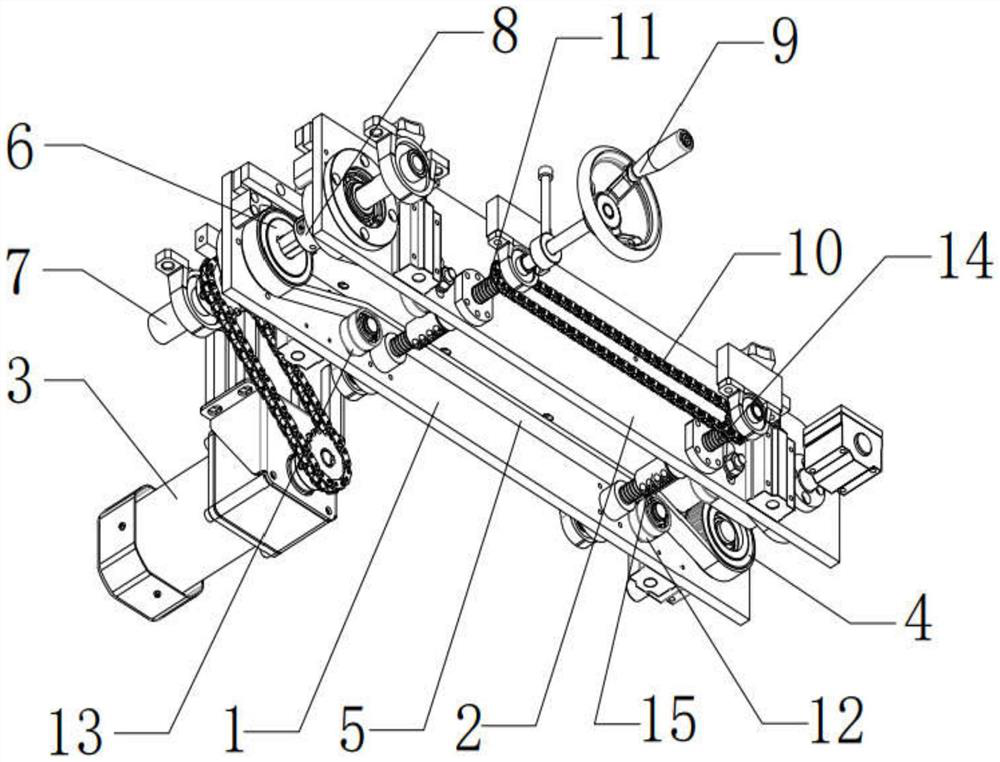

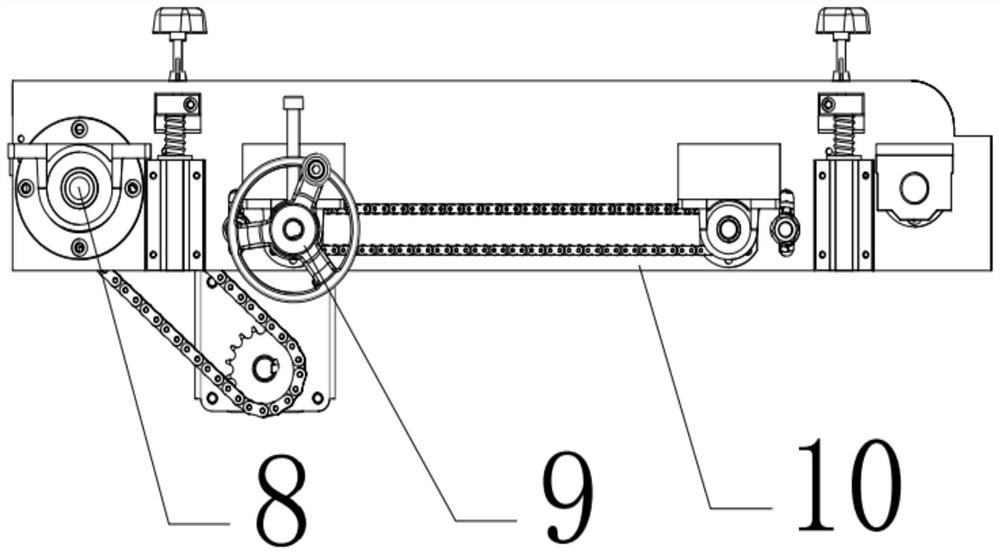

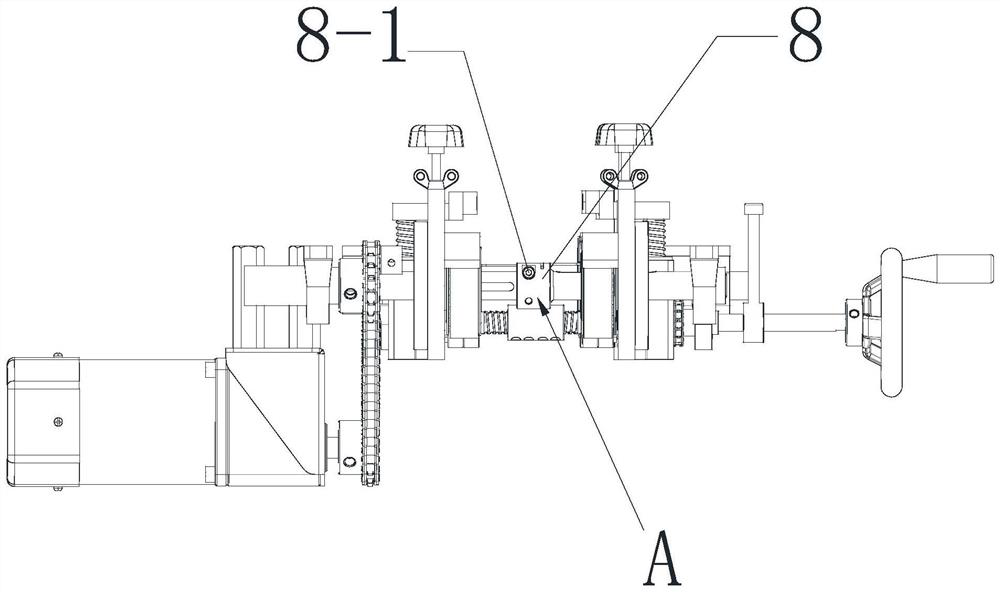

[0024] Such as Figure 1 to Figure 2 As shown, the present invention discloses a quick-change synchronous belt mechanism. Aiming at the difficulty of replacing the synchronous belt at present, this solution has been improved technically, as follows:

[0025] A fast follow-up synchronous belt mechanism includes a left side plate 1, a right side plate 2 and a synchronous belt mechanism, a space is formed between the left side plate 1 and the right side plate 2, and the synchronous belt mechanism is installed in the space, The left side plate 1 and the right side plate 2 are provided with an adjustment mechanism, which adjusts the relative distance between the left side plate 1 and the right side plate 2. The timing belt mechanism includes a drive motor, a main shaft 7, a main Pulley 6, synchronous belt 5, and slave pulley 4, main pulley 6, and main shaft connector 8 are installed in the front and rear of the space between the left side plate and the right side plate, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com