Current collector electrode structure, secondary battery and preparation method thereof

A technology of electrode structure and secondary battery, which is applied in the direction of secondary battery manufacturing, secondary battery, electrode carrier/collector, etc., can solve problems such as damage, and achieve the effect of ensuring safety performance, integrity, and connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

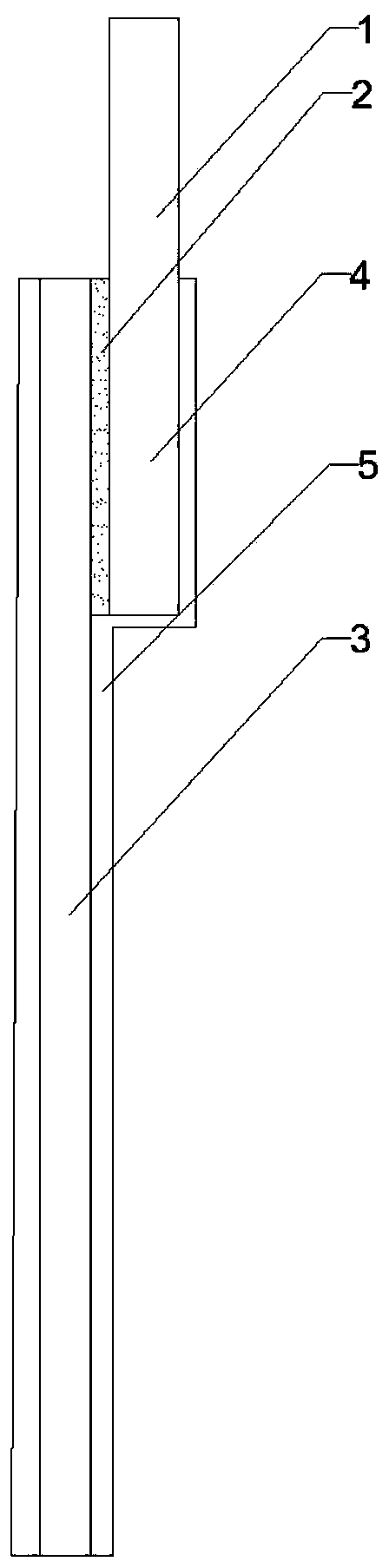

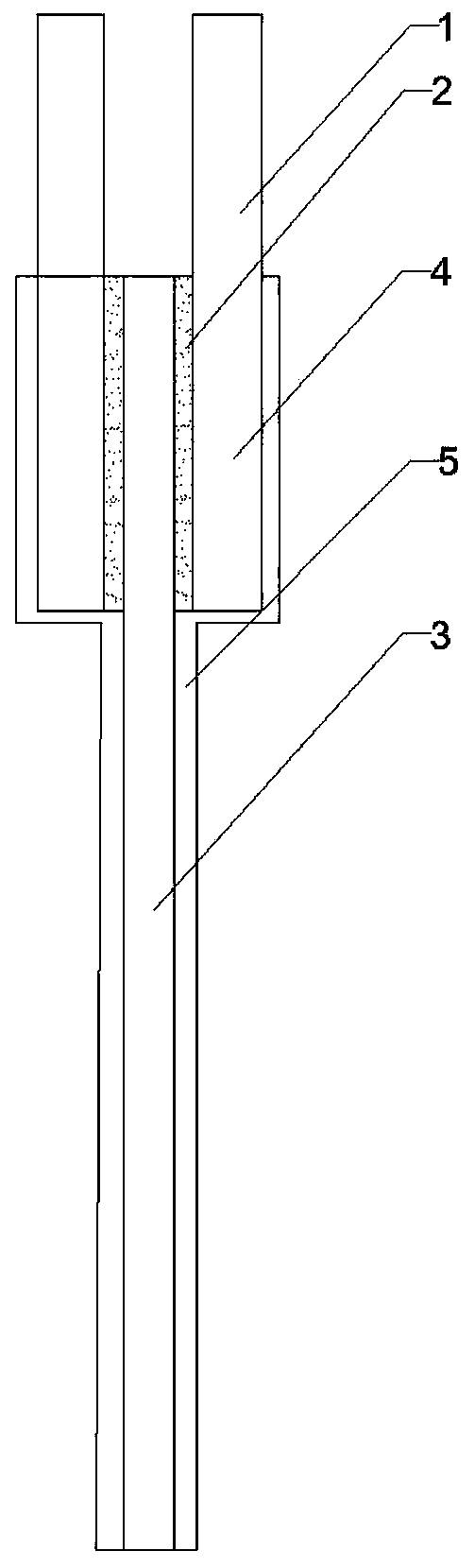

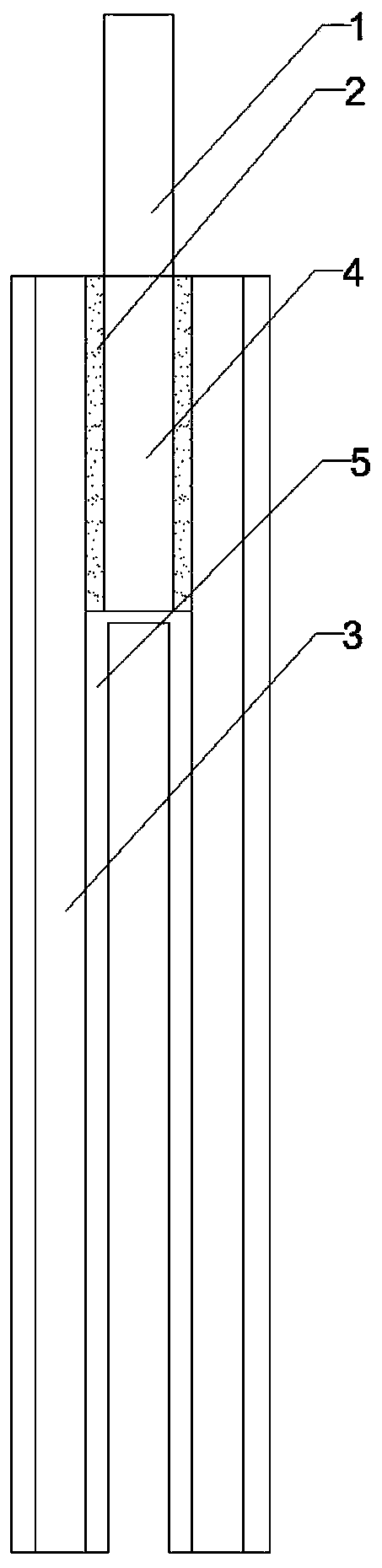

Image

Examples

preparation example Construction

[0096] The present application also provides a method for preparing a secondary battery, comprising the following steps: preparing a current collector electrode, coating the positive or negative active material on the current collector electrode, rolling die-cutting, lamination or winding assembly, liquid injection , into content.

[0097] When preparing the current collector, according to a specific embodiment of the present application, the tabs are first adhered to the insulating layer through an adhesive, and the compounding method can be dry compounding or thermal compounding; A conductive layer forms on the surface of the ear.

[0098] Among them, the formation process of the conductive layer can be selected from physical vapor deposition (PVD), vacuum evaporation, chemical vapor deposition (CVD), atomic layer deposition (ALD), magnetron sputtering, high-power electron beam, molecular beam epitaxy, printing, Coating one or a combination of conductive pastes. In this em...

Embodiment 1

[0103] Take a polypropylene film with a thickness of 10um as the positive electrode insulating layer, take an aluminum foil with a thickness of 10um and a width of 20mm as the positive electrode tab, and adhere the positive electrode tab to the end of the surface of the positive electrode insulating layer. The adhesive is a polymethacrylate adhesive, the bonding strength is 7N / cm, and the width of the composite area of the positive electrode tab and the positive electrode insulating layer is 10mm. Then, a conductive layer is formed on both sides of the adhered positive insulating layer by physical vapor deposition. The material of the conductive layer is aluminum, and the thickness of the conductive layer is 0.5um to form a positive current collector electrode structure.

[0104] Take a polypropylene film with a thickness of 10um as the negative electrode insulation layer, take a copper foil with a thickness of 10um and a width of 20mm as the negative electrode tab, and adher...

Embodiment 2

[0107] A secondary battery was produced by the same method as in Example 1 except that the adhesive used was an epoxy resin adhesive and the adhesive strength was 10 N / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com