Pressure-shear testing machine with side guide rail and vertical loading cylinder

A vertical loading and guiding rail technology, which is applied in the direction of applying stable shear force to test the strength of materials, testing of mechanical components, testing of machine/structural components, etc., can solve the problem of damage to linear guide rails, affect test accuracy, and waste money And time and other issues, to achieve the effect of saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

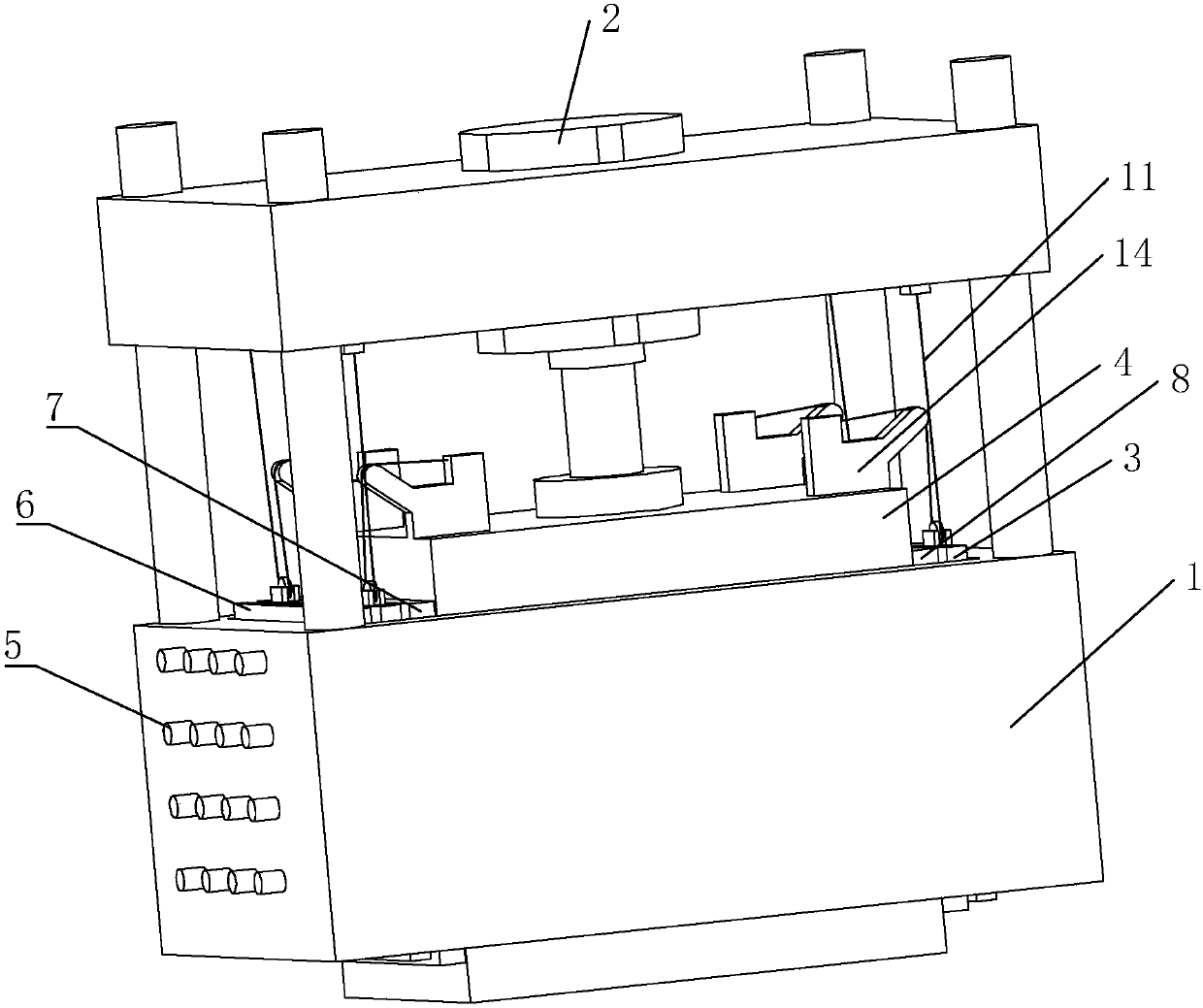

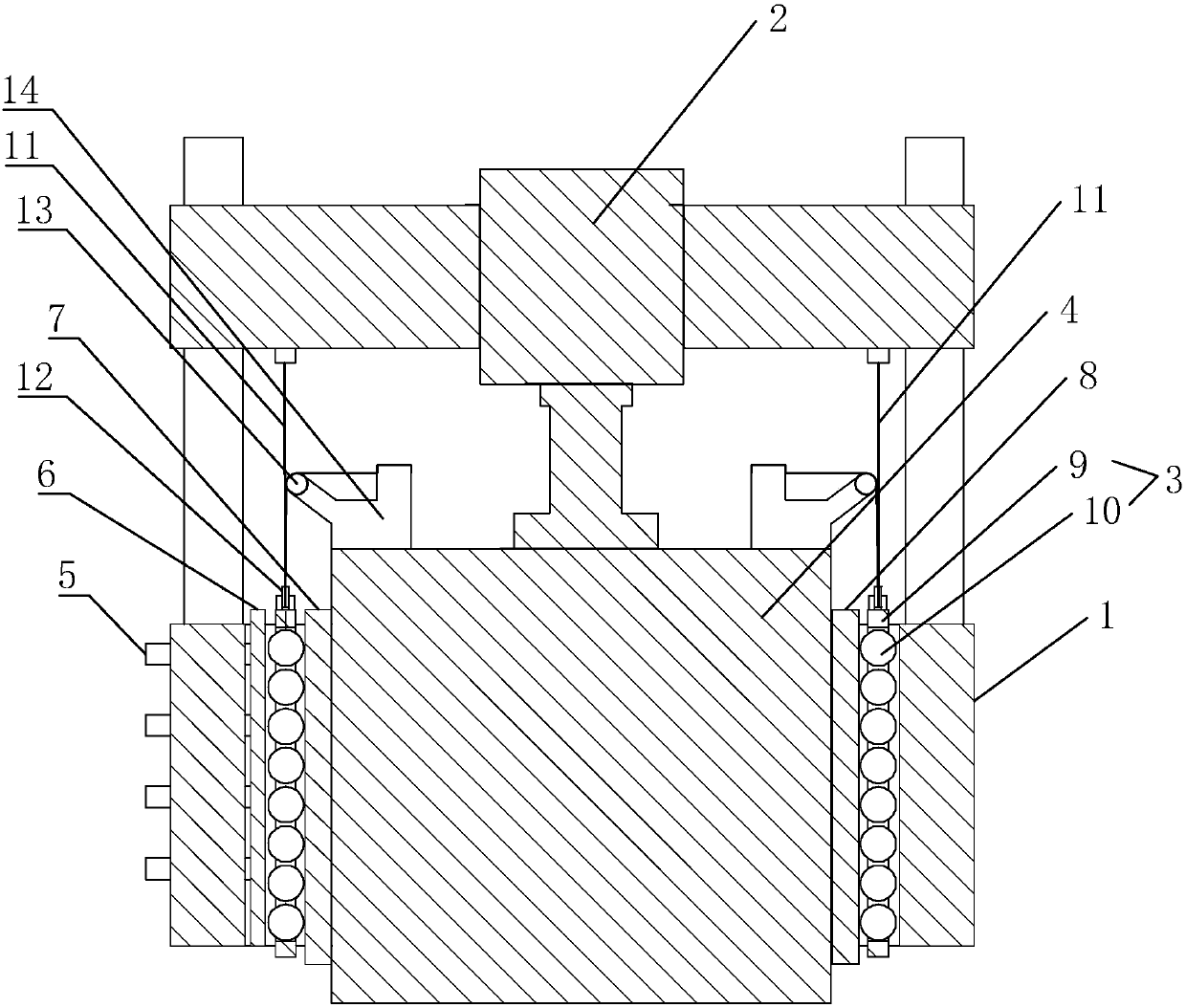

[0016] refer to Figures 1 to 2 As shown, a compression-shear testing machine of a side guide rail and a vertical loading cylinder of the present embodiment includes a frame 1, a vertical cylinder 2, a rolling guide rail 3, a load platform 4, a clamping mechanism and a pulley device. There are two rolling guide rails 3, the clamping mechanism includes a pre-tightening force bolt 5, a push plate 6, a first clamping plate 7 and a second clamping plate 8, and the pre-tightening force bolt 5 is installed on the frame 1 One side of the push plate 6 is connected to one end of the pre-tightening force bolt 5 inside the frame 1, the first clamping plate 7 is installed on the surface of the push plate 6, and the second clamping plate 8 is installed on the machine frame 1, and the second clamping plate 8 is set corresponding to the first clamping plate 7, the load platform 4 is arranged between the first clamping plate 7 and the second clamping plate 8, and the first clamping plate 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com