EMI resistant balanced touch sensor and method

A touch sensor, sensor technology, applied in the direction of electrical components, pulse technology, electronic switches, etc., can solve problems such as non-compliance with electromagnetic compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

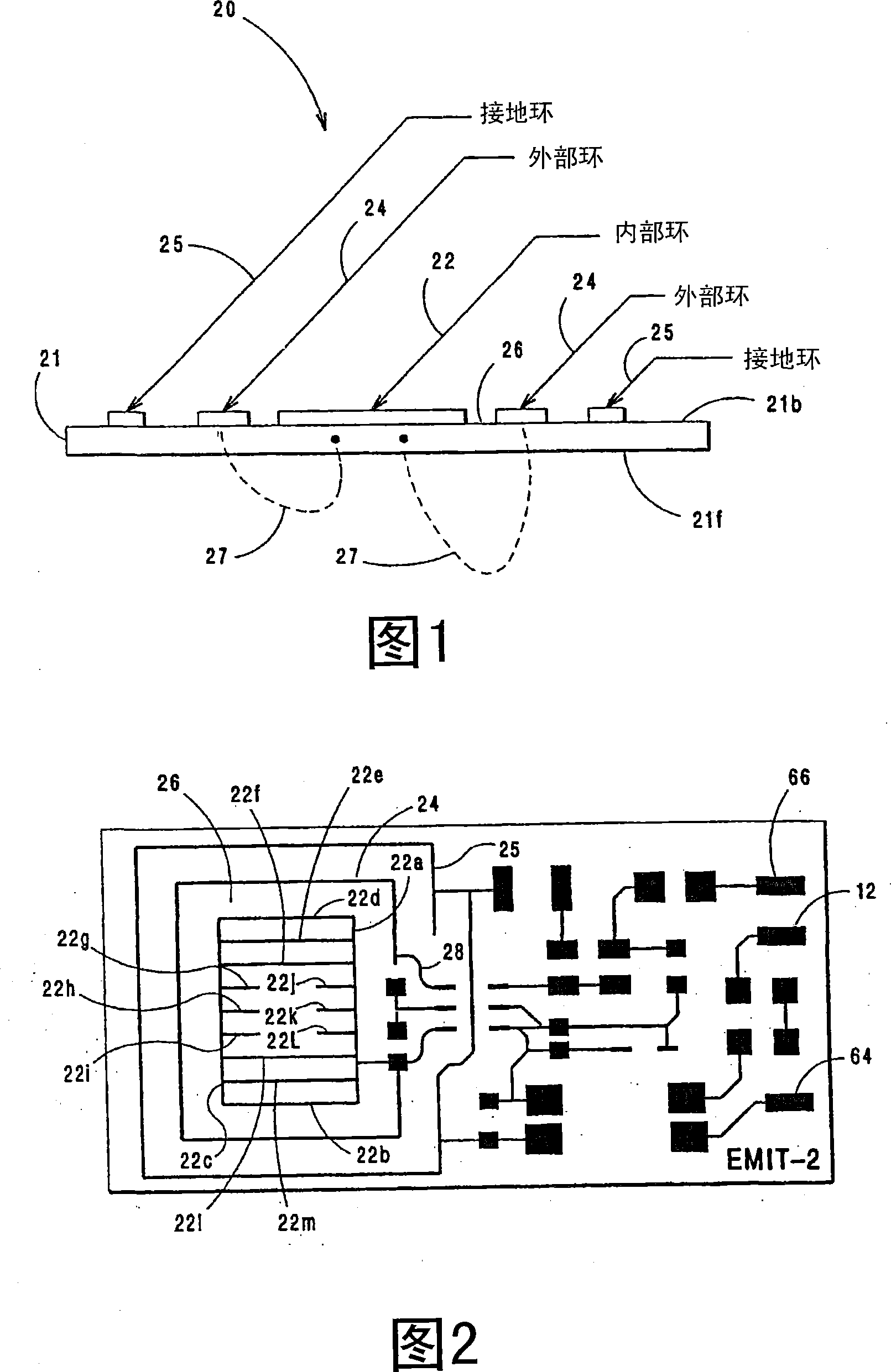

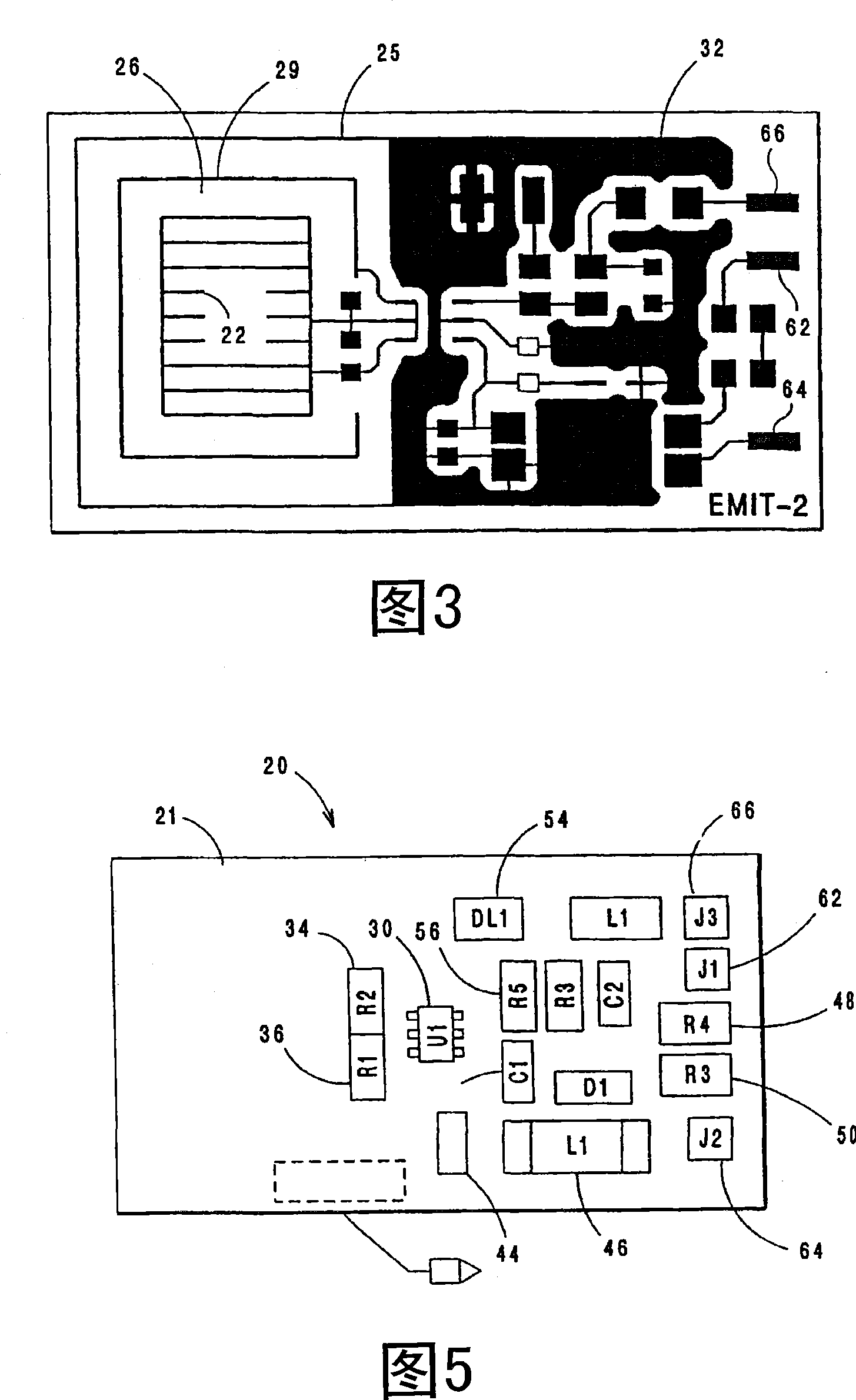

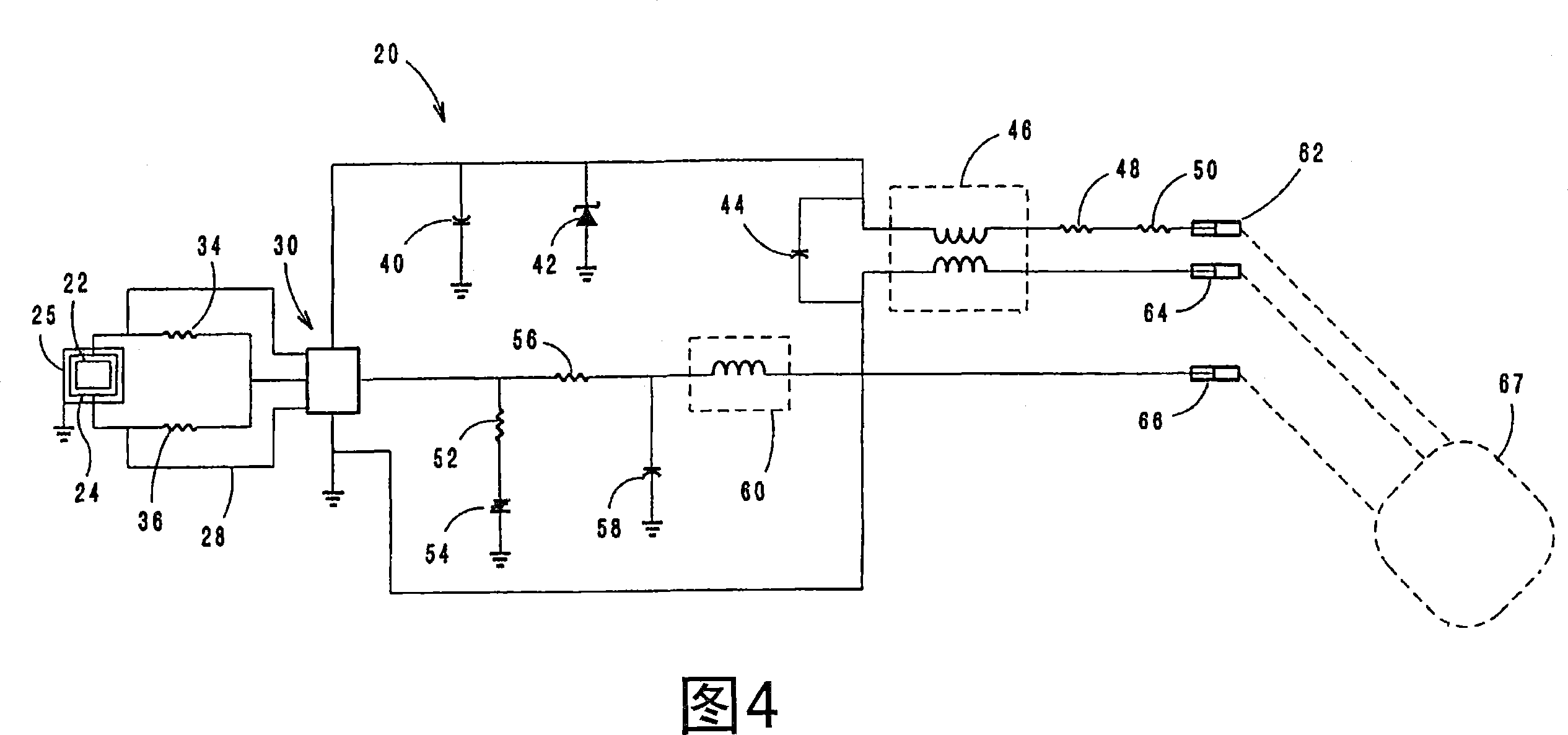

[0037] Referring to the exemplary embodiment shown in FIGS. 1-5, the EMI resistant balanced touch sensor 20 includes conductive traces on a printed circuit board or substrate 21 with a balanced board sensor electrode pattern, It has a first plate or inner electrode 22 within a second or outer electrode 24 . The second electrode 24 defines a conductive surface area substantially equal to the plate surface area of the first electrode 22 . An optional conductive ground ring 25 at least partially surrounds the second electrode 24 to isolate one plate electrode from the other plate electrode or the surrounding environment. As shown in FIG. 1 , the electric field lines 27 of the touch sensor sense the presence of a user's finger, a metal object, or a liquid / gas interface.

[0038] A single touchpad sensor 20 is attached to an insulating substrate 21 as shown in FIG. 1 . Substrate 21 preferably has a substantially uniform thickness and can be made of any type of structurally supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com