Hydraulic system for tunnel loading test platform

A loading test, hydraulic system technology, applied in the direction of fluid pressure actuation device, servo motor, mechanical equipment, etc., can solve problems such as single means, and achieve the effect of reducing control components, rational design and application, and reliable and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

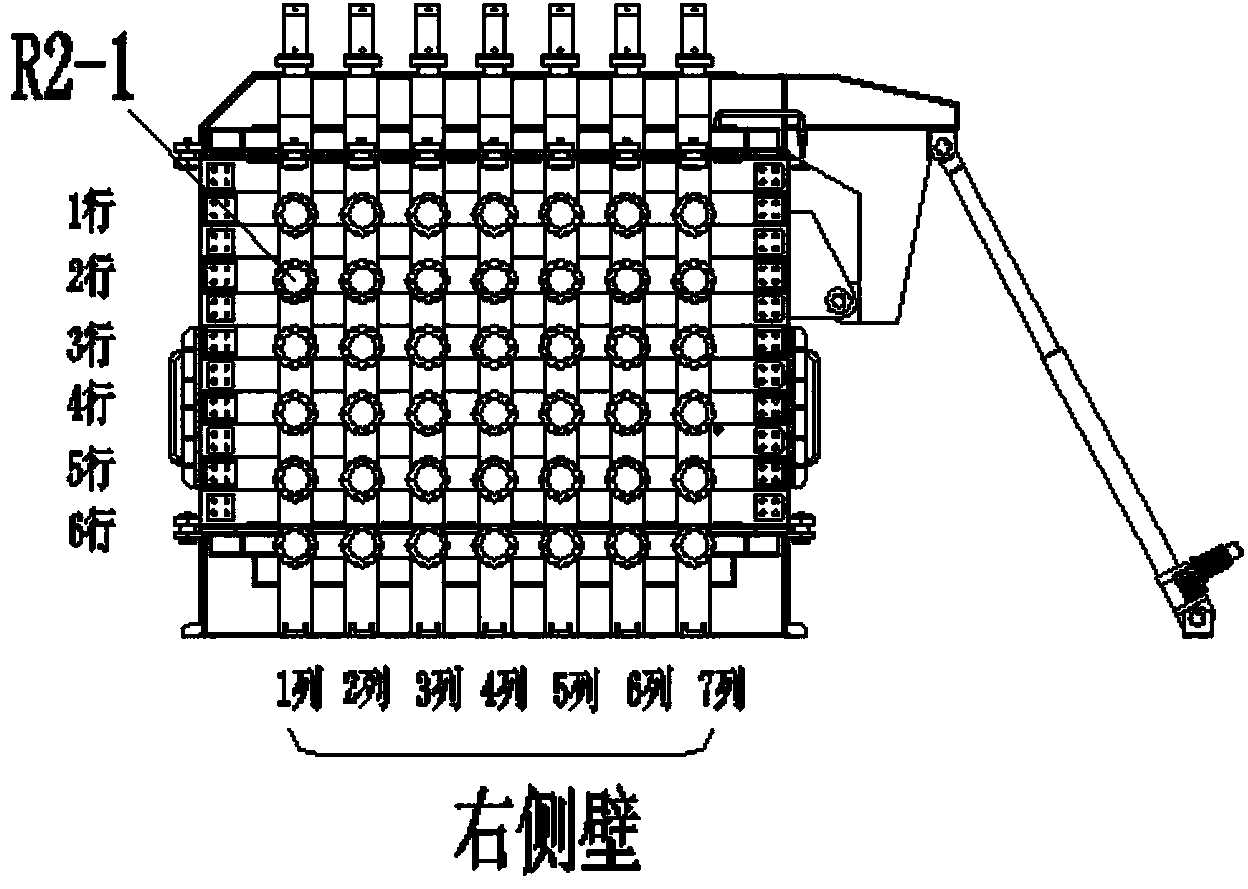

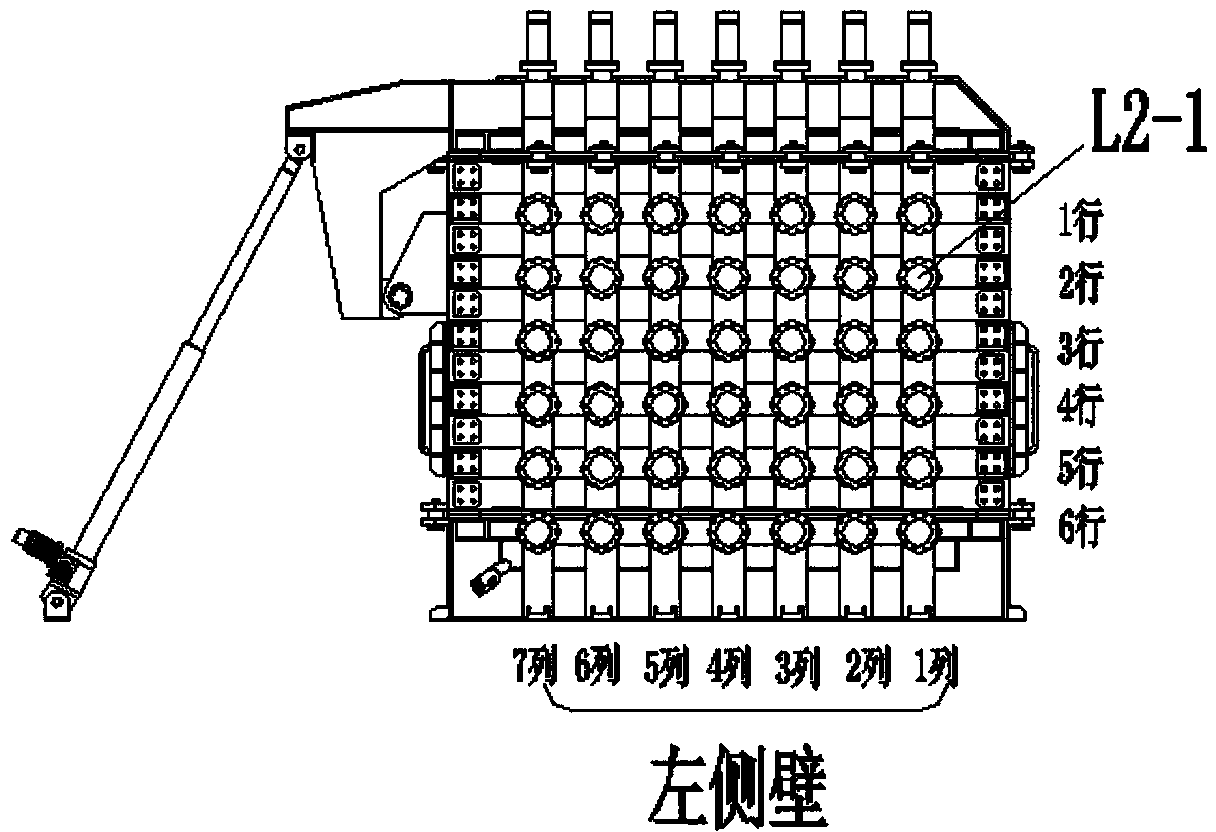

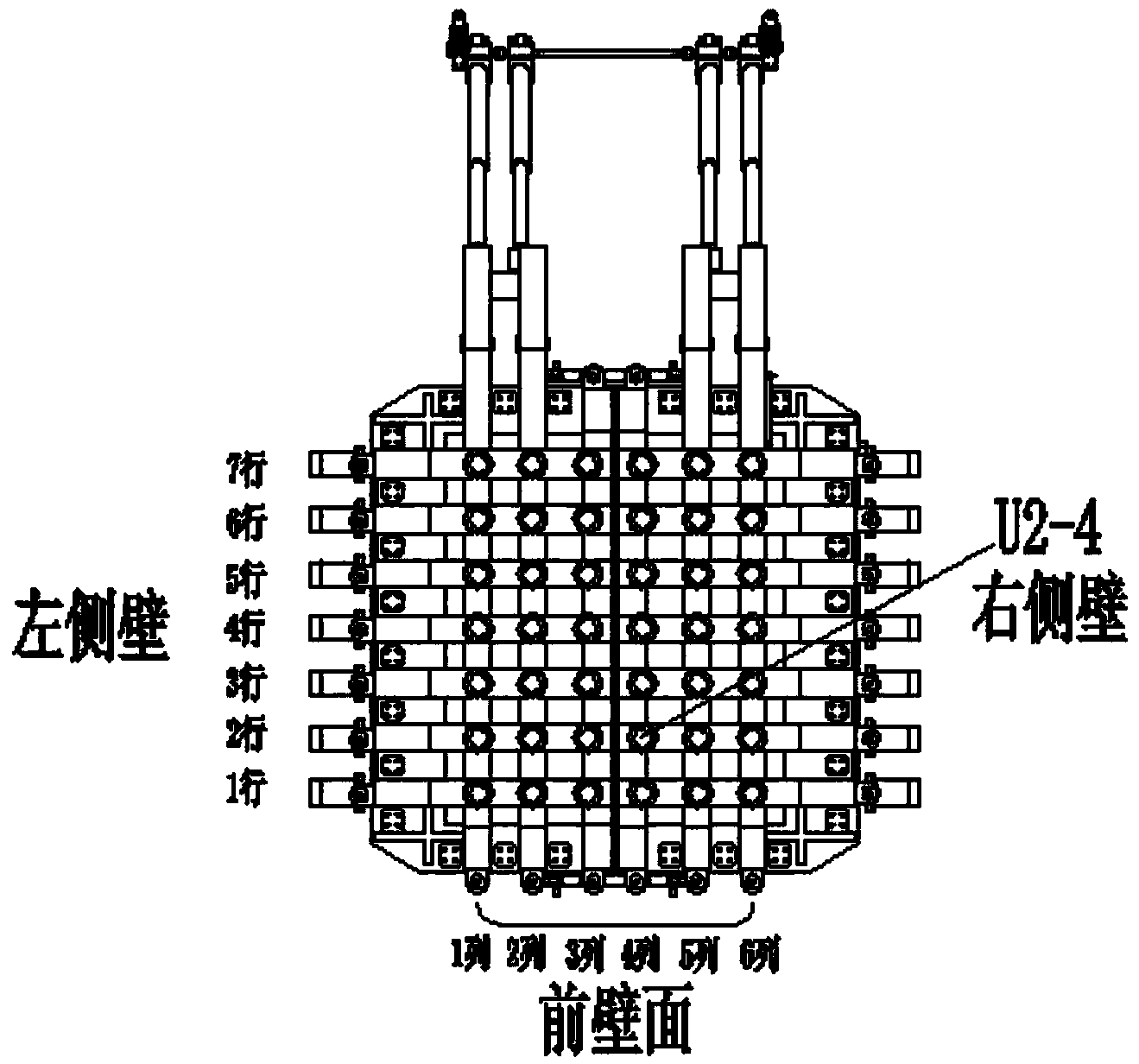

[0024] The present invention is further elaborated below in conjunction with accompanying drawing.

[0025] A hydraulic system for a tunnel simulation loading test platform of the present invention includes a hydraulic station, an actuator, a control system,

[0026] Such as Figure 8 As shown, the hydraulic station includes a constant pressure variable pump 11, a motor 12, a display element 13 and auxiliary devices. The variable pump and motor realize the oil supply function of the system. The maximum working pressure of the constant pressure variable pump in the system is 25Mpa, the working pressure is 20Mpa, the maximum flow rate is 80L / min, and the displacement is 63Ml / r. The rated power of the motor used is 37KW, and the speed is 1440r / min. The display components include digital pressure gauge, oil filter clogging alarm, oil temperature alarm, etc., which realize the conversion of hydraulic signal to electrical signal, and are convenient to cooperate with the electronic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com