Parallel micro-positioning platform based on driving of piezoelectric ceramic driver and micro-positioning platform system

A technology of micro-positioning platform and piezoelectric ceramics, which is applied to the parts and instruments of the instrument, can solve the problems such as the inability to guarantee the output displacement straightness, the easy damage to the piezoelectric ceramic driver, and the asymmetry of the processing and assembly structure. The effect of suppressing narrow-band ground disturbance, improving displacement output straightness, and being easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

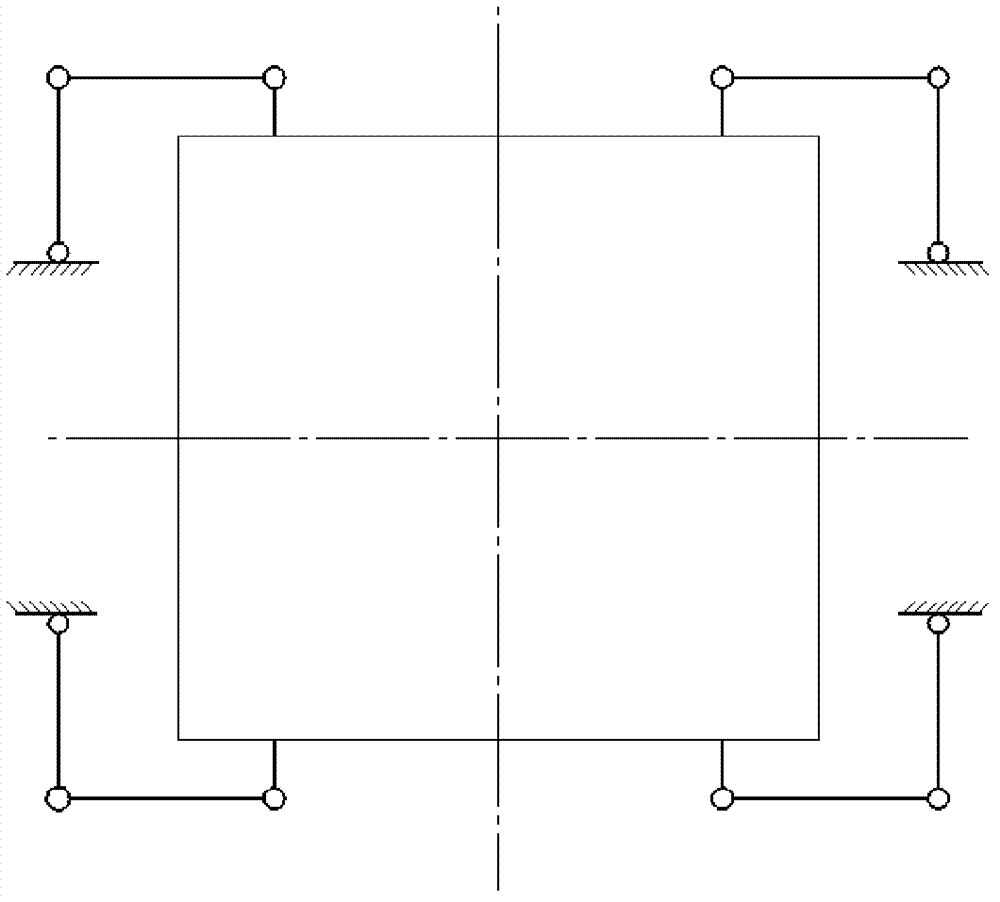

[0025] Since the present invention adopts a parallel structure, the three drivers act on the moving platform at the same time, and the influence of the structural asymmetry of the platform caused by processing and assembly errors on the straightness of the displacement output can be eliminated through closed-loop control; the uniquely designed piezoelectric ceramic driver The tight spring can make the driver always be pressed on the moving platform; the universal hinge can prevent the piezoelectric ceramic driver from breaking due to the bending moment.

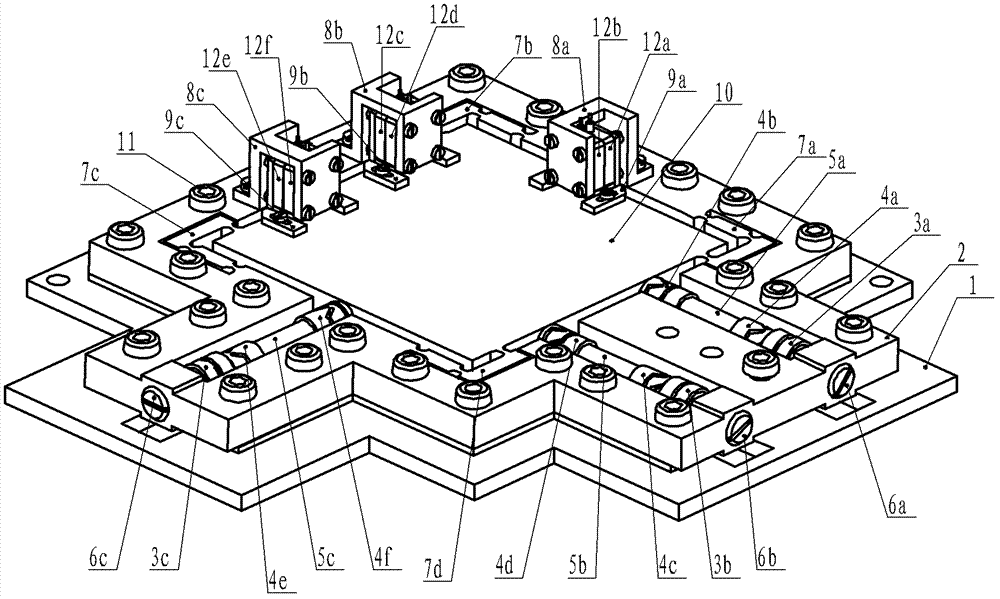

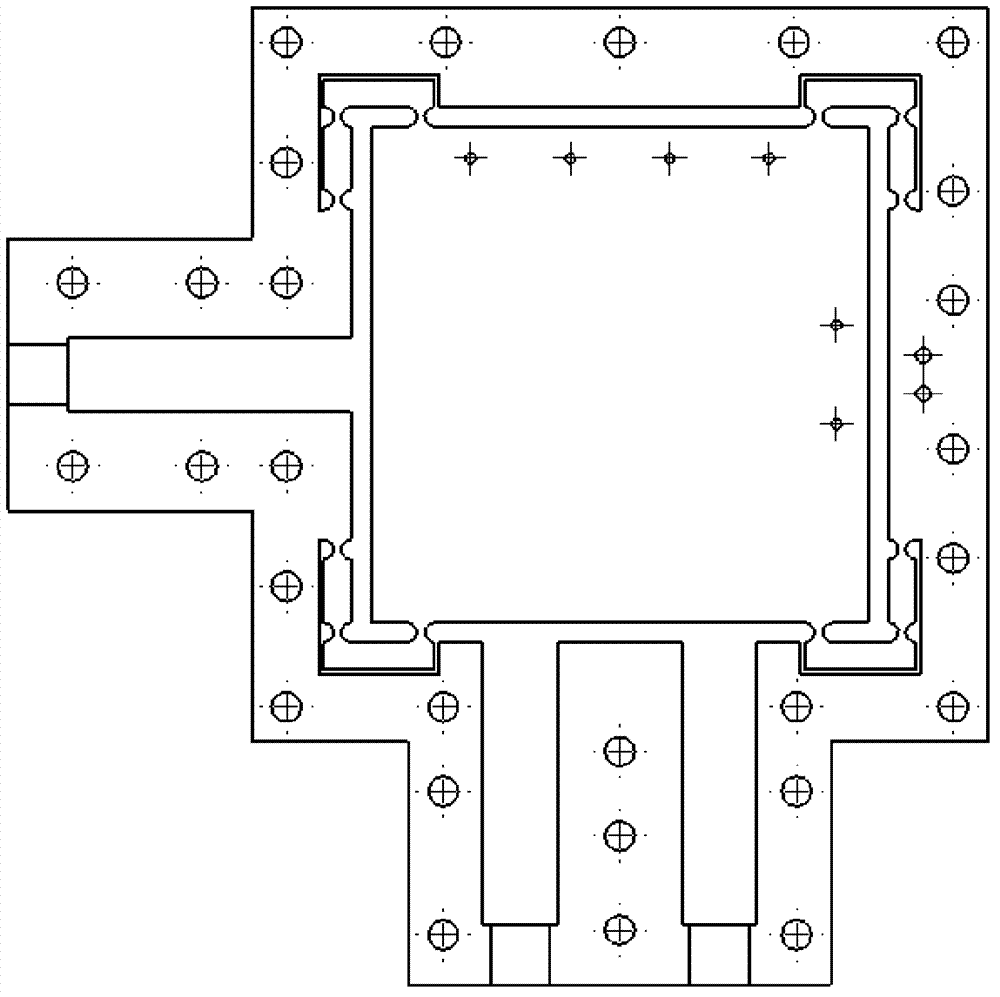

[0026] Such as figure 1 As shown, the parallel micro-positioning platform driven by a piezoelectric ceramic driver of the present invention is composed of a micro-motion stage 2 and a substrate 1 , and the micro-motion stage 2 is fixed on the substrate 1 by a plurality of set screws 11 . The micro-movement platform 2 includes a moving platform 10 in the middle and four flexible hinges 7a, 7b, 7c, 7d located at the four corner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com