Method and apparatus for manufacturing hollow fiber membrane module

A fiber membrane and fiber membrane bundle technology, which is applied in the field of hollow fiber membrane module production, can solve the problems of uneven end membrane wires and uneven arrangement of membrane wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

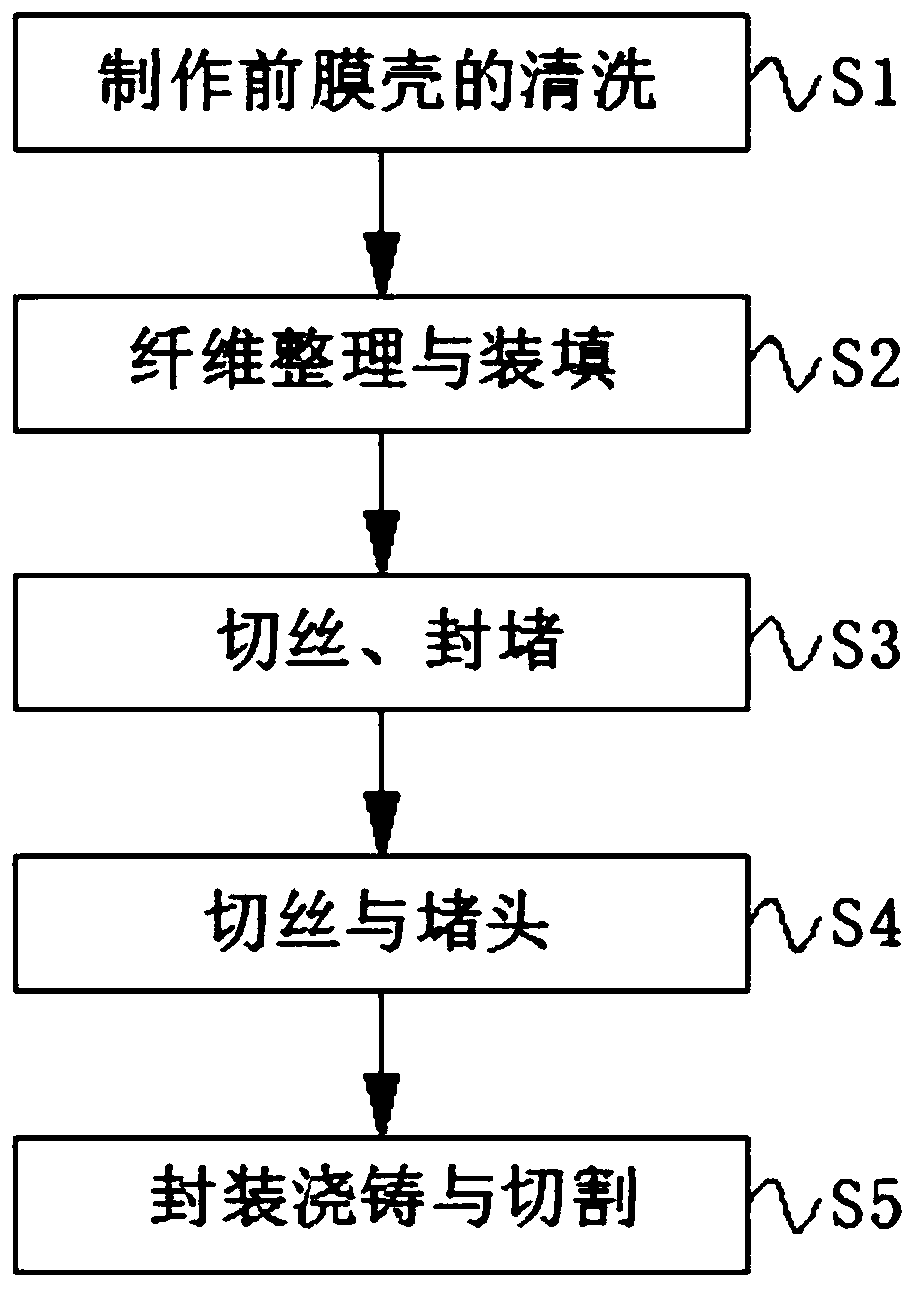

[0031] S1. Cleaning of the membrane shell before making: add tap water and a certain amount of cleaning agent to the first cleaning tank of the ultrasonic cleaning equipment to make a cleaning solution of a certain concentration, add pure water to the second cleaning tank, and clean the inner shell of the component, Put the shell and end cap into the first cleaning pool for ultrasonic cleaning, drain off excess cleaning liquid, put the cleaned component inner shell, shell and end cap into the second cleaning pool for ultrasonic cleaning, take them out, and dry them;

[0032] S2. Fiber finishing and filling: Hang a group of 200 hollow fiber membrane bundles on a fiber drying rack, visually inspect the hollow fiber membrane bundles on the drying rack, remove damaged and creased hollow fiber membranes, straighten out 1. After ensuring that the end faces are basically flat, re-bundle them. According to the filling quantity of a single module, hang a small bundle of hollow fiber mem...

Embodiment 2

[0037]S1. Cleaning of the membrane shell before making: add tap water and a certain amount of cleaning agent to the first cleaning tank of the ultrasonic cleaning equipment to make a cleaning solution of a certain concentration, add pure water to the second cleaning tank, and clean the inner shell of the component, Put the shell and end cap into the first cleaning pool for ultrasonic cleaning, drain off excess cleaning liquid, put the cleaned component inner shell, shell and end cap into the second cleaning pool for ultrasonic cleaning, take them out, and dry them;

[0038] S2. Fiber finishing and filling: Hang a group of 350 hollow fiber membrane bundles on a fiber drying rack, visually inspect the hollow fiber membrane bundles on the drying rack, remove damaged and creased hollow fiber membranes, straighten out , After ensuring that the end faces are basically flat, re-bundle, according to the filling quantity of a single module, hang 2 small bundles of hollow fiber membrane ...

Embodiment 3

[0043] S1. Cleaning of the membrane shell before making: add tap water and a certain amount of cleaning agent to the first cleaning tank of the ultrasonic cleaning equipment to make a cleaning solution of a certain concentration, add pure water to the second cleaning tank, and clean the inner shell of the component, Put the shell and end cap into the first cleaning pool for ultrasonic cleaning, drain off excess cleaning liquid, put the cleaned component inner shell, shell and end cap into the second cleaning pool for ultrasonic cleaning, take them out, and dry them;

[0044] S2. Fiber finishing and filling: Hang a group of 500 hollow fiber membrane bundles on a fiber drying rack, visually inspect the hollow fiber membrane bundles on the drying rack, remove damaged and creased hollow fiber membranes, straighten out , After ensuring that the end faces are basically flat, re-bundle, according to the filling quantity of a single module, hang 3 sorted small bundles of hollow fiber m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com