Paperboard production and conveying line and use method thereof

A conveying line, cardboard technology, applied in conveyors, paper/cardboard containers, papermaking, etc., can solve problems such as cardboard shedding, cardboard drift, and equipment transmission production efficiency, so as to improve production efficiency, avoid measurement errors, and improve contact The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

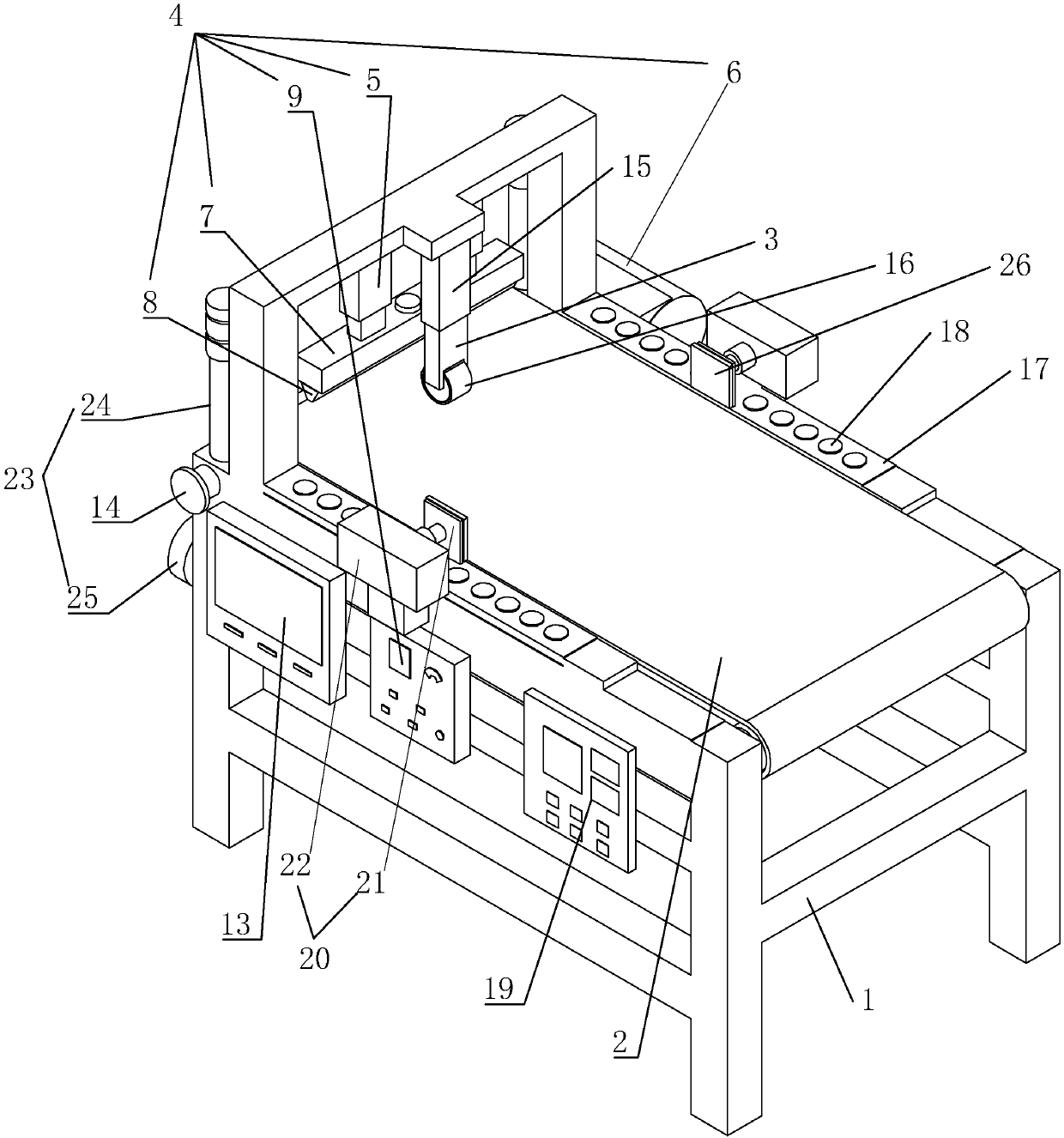

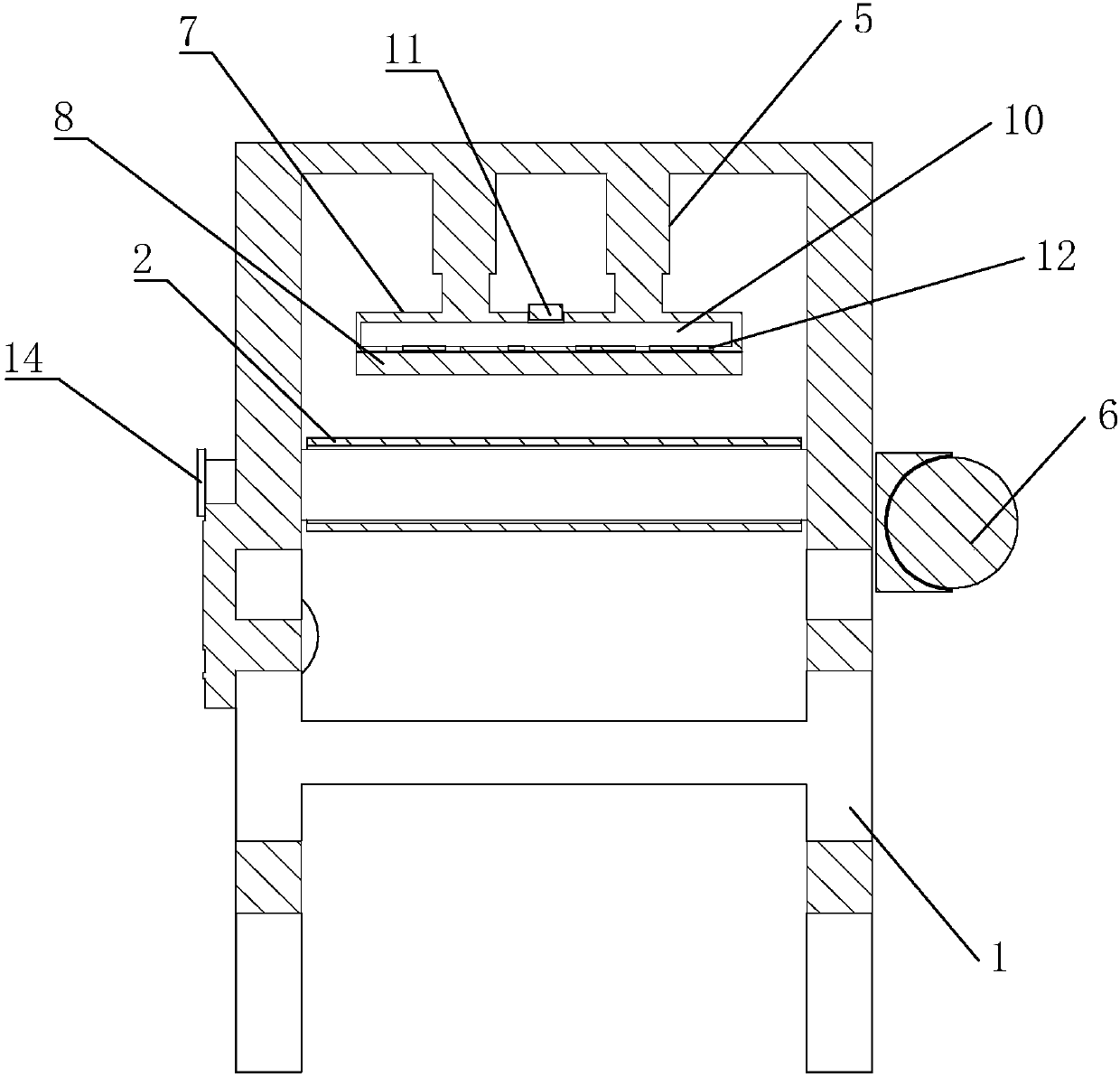

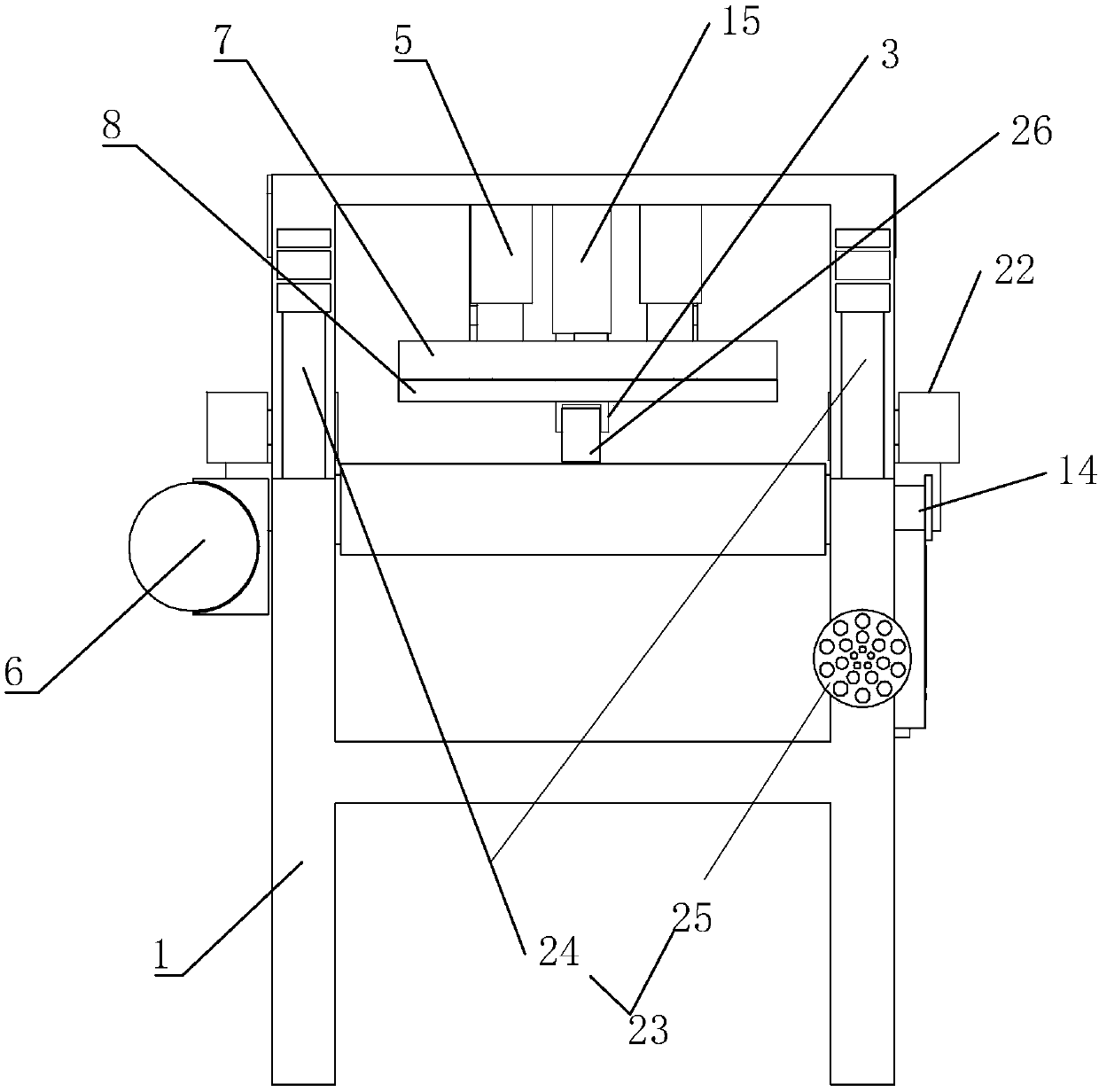

[0037] refer to Figures 1 to 3 As shown, a cardboard production conveying line in this embodiment includes a frame 1 and a conveyor belt 2 arranged on the frame 1, and the frame 1 is provided with a stroke detection device 3 that touches the surface of the conveyor belt 2, The frame 1 is provided with a marking device 4, and the marking device 4 is arranged above the conveyor belt 2, and the marking device 4 includes a cylinder 5, a miniature air pump 6, a stamping block 7, a stamp sponge 8, and a controller 9, Cylinder 5 is arranged on the frame 1, micro-air pump 6 is installed on the frame 1, and the air inlet of micro-air pump 6 connects the air inlet of cylinder 5, and stamping block 7 is installed on the push rod of cylinder 5, and stamping The pressing block 7 is arranged parallel to the conveyer belt 2, and the seal sponge 8 is arranged on the side surface of the pressing block 7 facing the conveying belt 2, and a cavity 10 is arranged in the pressing block 7, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com