Water conservancy project detection equipment

A technology for testing equipment and water conservancy projects, which is applied in measuring devices, mechanical measuring devices, angle/taper measurement, etc., can solve the problems of low efficiency of detection work and high labor intensity of staff, so as to improve practicability, facilitate length measurement, Avoid the effect of rebar landslide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

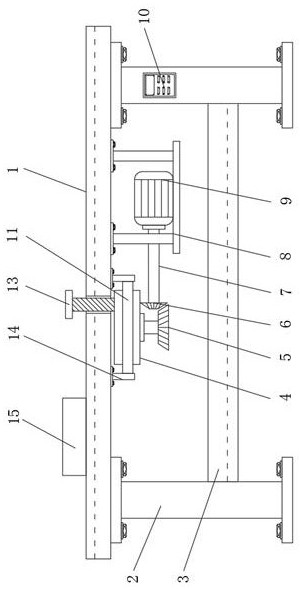

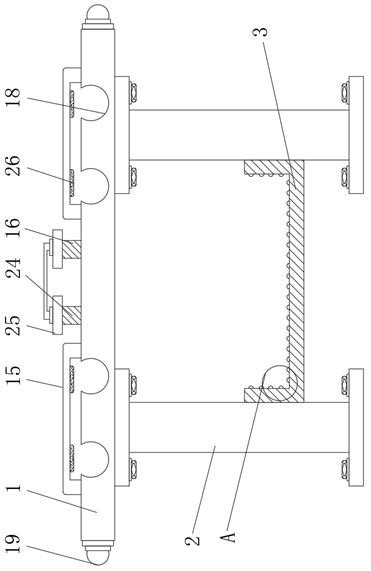

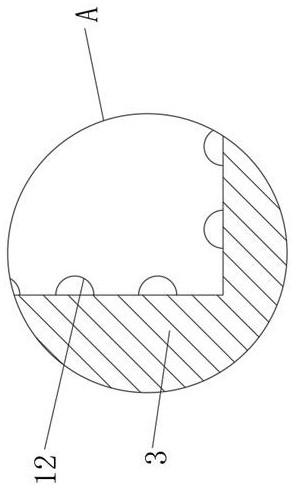

[0023] see Figure 1-5 , the present invention provides the following technical solutions: a water conservancy engineering testing equipment, including a workbench 1, the inside of the workbench 1 is provided with a circular groove, and the inside of the circular groove is welded with a fixed block 20, and the inside of the fixed block 20 is welded with a Fixed plate 22, the top surface of fixed plate 22 is provided with angle scale 23, and the top surface center position of fixed plate 22 is welded with fixed rod 24, and the top of fixed rod 24 is welded with top plate B25, and the top of top plate B25 is fixed with connecting rod 21, The bottom of workbench 1 is fixed with connecting rod 14 by bolts, and bearing frame 11 is welded between the inner side of connecting rod 14, and eccentric wheel 4 is installed in the inside of bearing frame 11, and the top of eccentric wheel 4 is welded with limiting rod 16, and limit The stop bar 16 is located inside the space formed by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com