Manual maintenance switch

A technology for manual maintenance of switches and handles, applied to multi-core cable end parts, electrical components, coupling devices, etc., can solve problems such as poor locking effect, and achieve reliable locking function, reliable locking, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

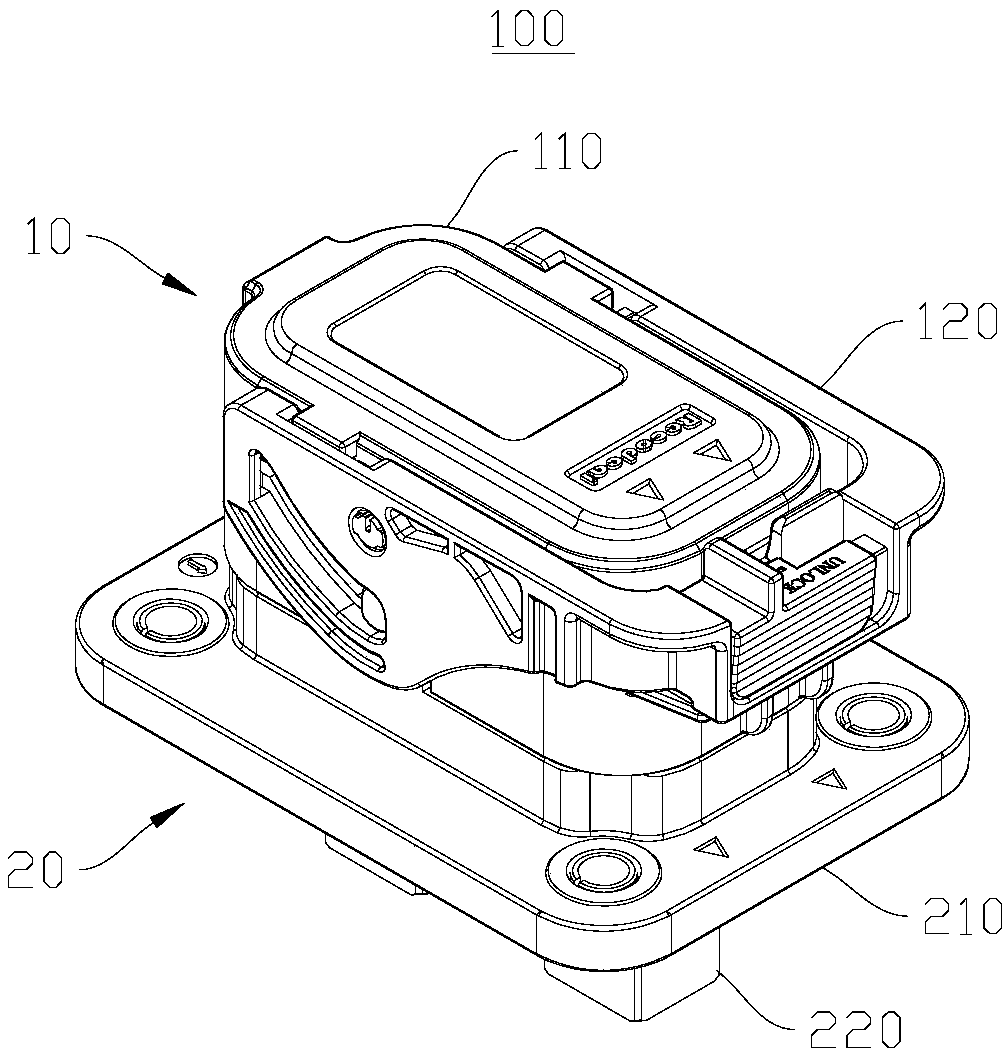

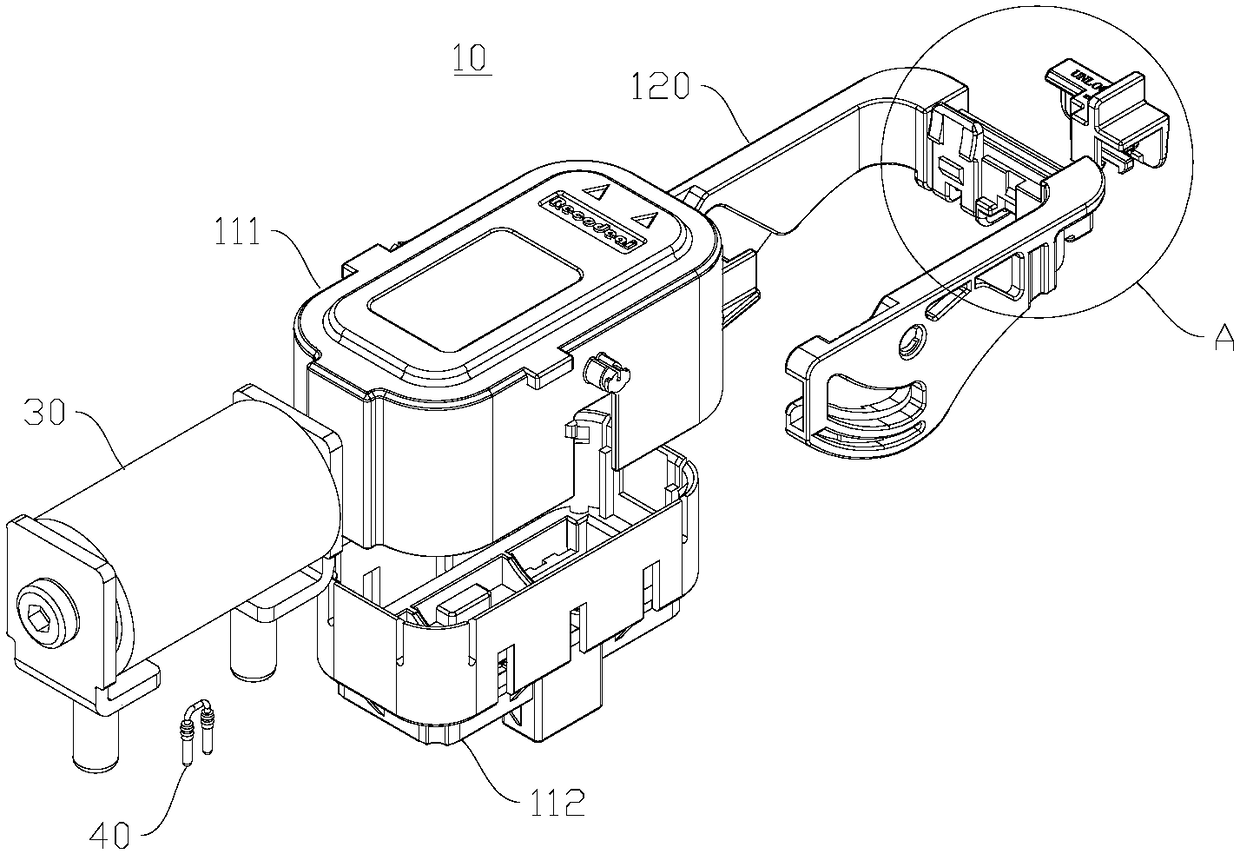

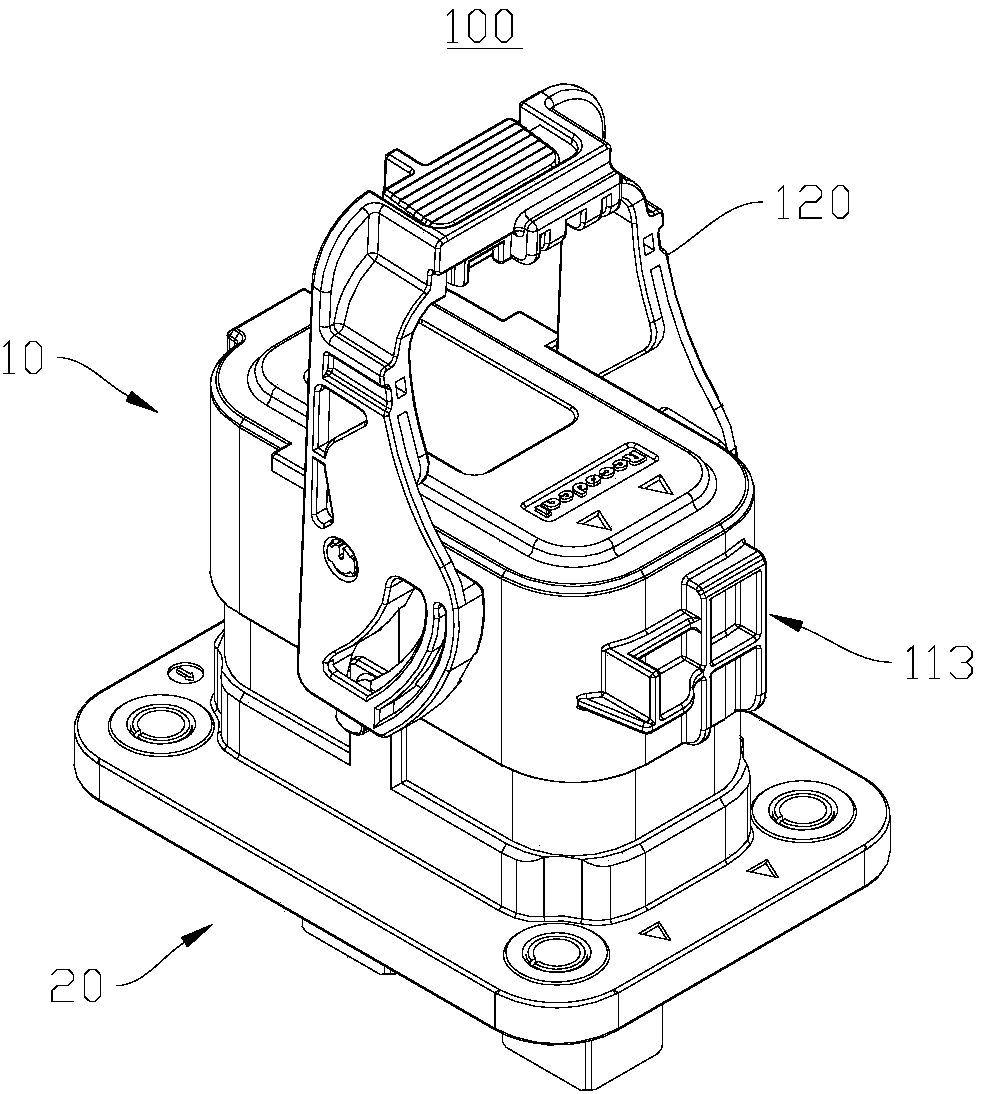

[0039] Please refer to figure 1 A schematic structural diagram of a manual maintenance switch 100 according to an embodiment of the present invention is shown. The manual maintenance switch 100 mainly includes a socket 20 and a plug 10 detachably connected to the socket 20 . In addition, the manual maintenance switch 100 also includes: a fuse with pin assembly 30 arranged in the plug 10 and two pins 40 for high current transmission, such as figure 2 shown. A fuse can be fixed between the two pins 40 for short-circuit protection, and the copper bar can also be directly connected to play the role of a switch. The socket 20 is provided with two jacks (not shown) that are mated with the pins 40, and the tails of the jacks need to be electrically connected to the outside. At the same time, the manual maintenance switch 100 of the embodiment of the present invention is also provided with a set of signal contact pairs for transmitting the signal of the connection status of the plug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com