A Pneumatic Control Method of Synchronizer Shift Based on On-Off Valve

A technology of switching valves and synchronizers, which is applied in the direction of transmission control, components with teeth, belts/chains/gears, etc., which can solve the problems of reduced shift quality, high speed of synchronizer movement, abnormal noise of synchronizer teeth, etc. problems, to achieve the effect of reducing the impact noise of the end face, improving the quality of shifting, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment the utility model is described in further detail.

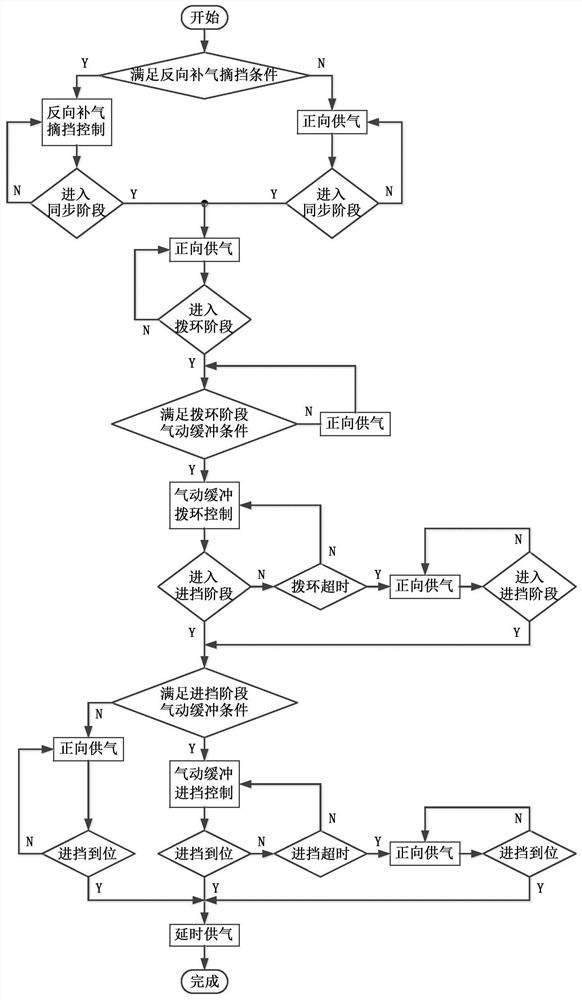

[0034] According to the moving position and moving speed of the synchronizer, the present invention divides the shifting process of the synchronizer into a shifting stage, a synchronizing stage, a ring shifting stage and a shifting stage. The shifting phase is the shifting process from the start of the shifting process to the synchronizer moving to the synchronous position; the synchronizing phase is the shifting phase from the synchronizer moving to the synchronizing position to the synchronizer starting to move. In the synchronizing phase, the synchronizer moves After the stop, the motion will be kept at a stopped state; the shifting stage is the shifting process from the end of the synchronization stage to the complete unlocking of the axial movement of the synchronizer, and the shifting stage is the shifting process from the end of the synchroniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com