Aviation clean bag and manufacturing method thereof

A production method and cleaning bag technology, which is applied to envelope/bag manufacturing machinery, paper/cardboard containers, containers, etc., can solve problems affecting product quality, poor waterproof performance of cleaning bags, and poor hemming effect, so as to improve product use Effect, not easy to be penetrated by water, effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

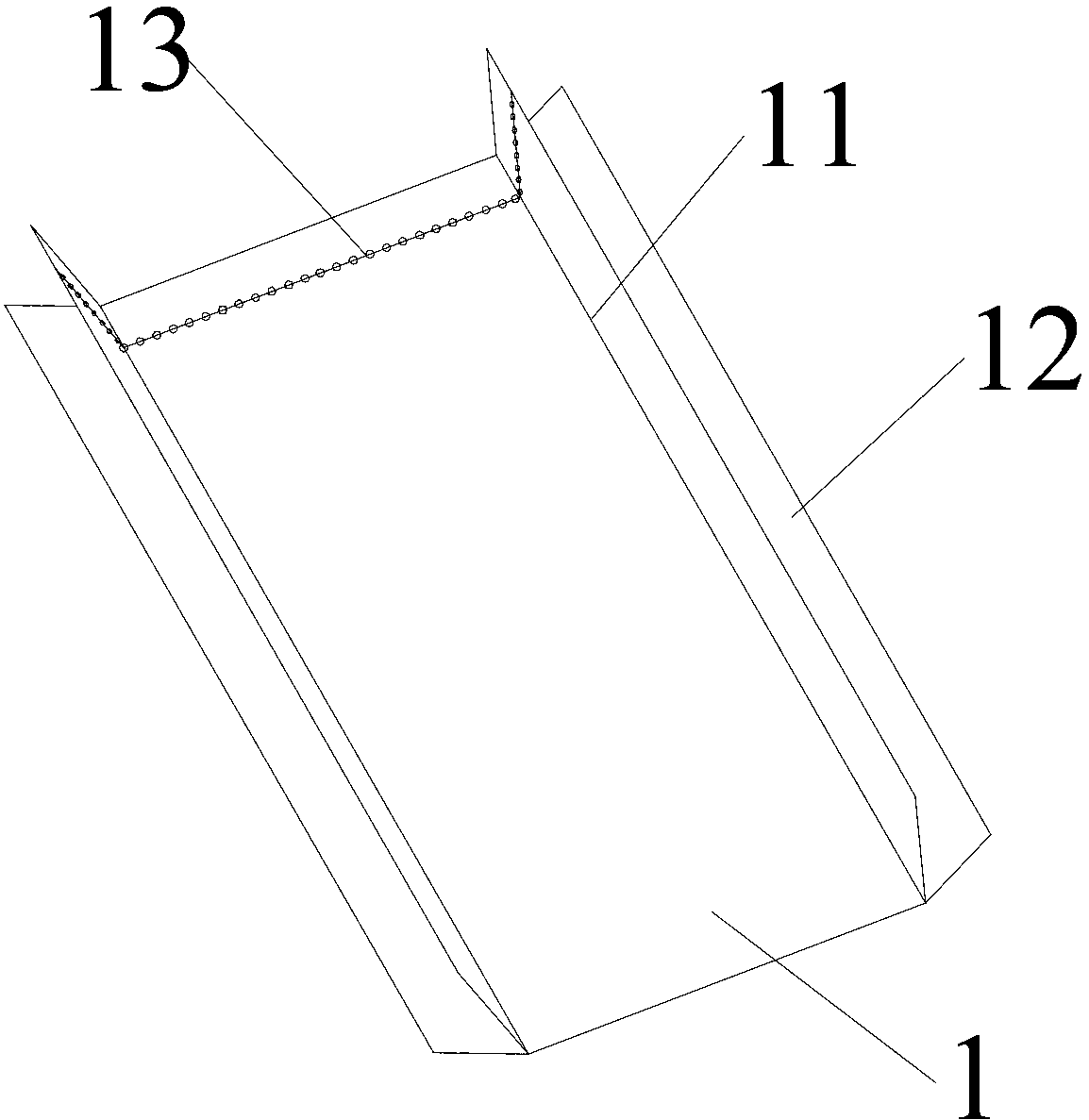

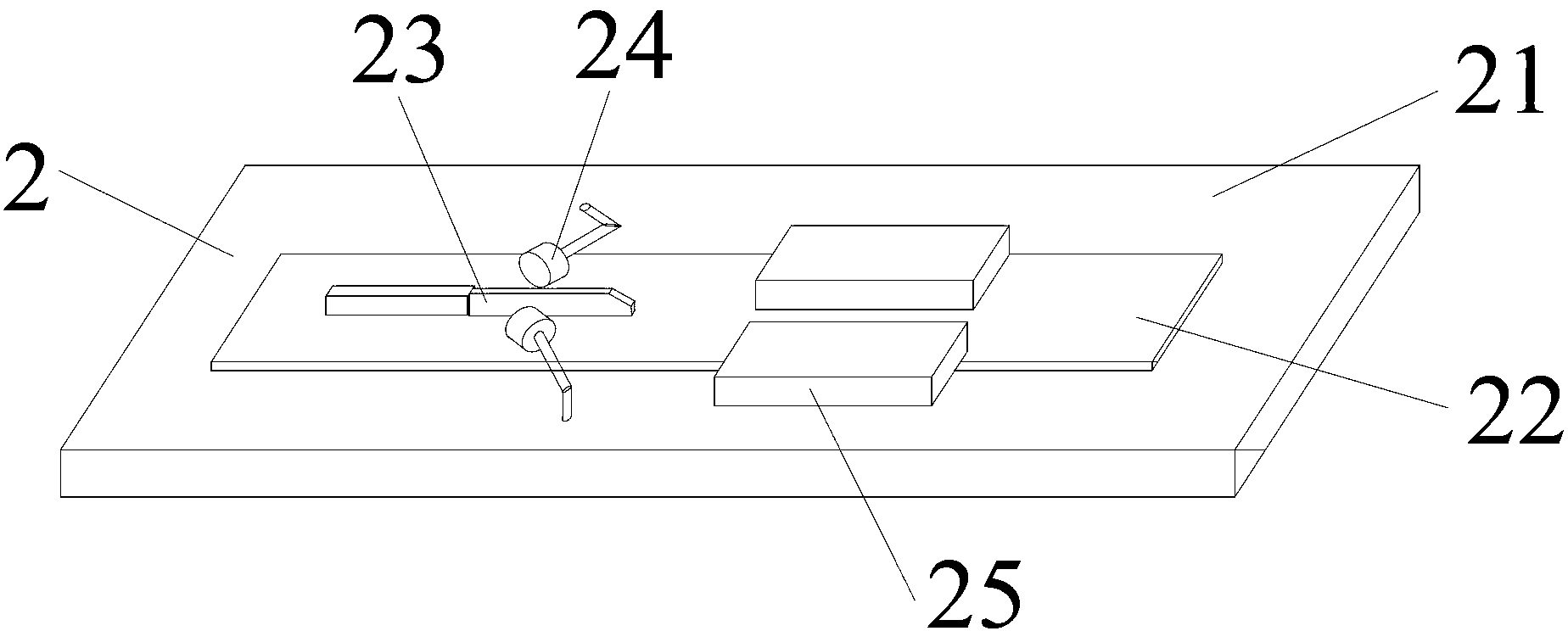

[0032] Such as figure 1 Shown is an aviation cleaning bag of the present invention, which includes a bag body 1 , both ends of the bag body 1 are closed, and there are folded edges 12 on both sides of the bag body 1 . The material of the bag body 1 adopts coated paper, which includes a plastic white paper layer and a film layer arranged on the plastic white paper layer. The plastic white paper layer is the outer surface of the bag body 1, and the film layer is the inner surface of the bag body 1. Good waterproof performance. A pattern layer can also be printed on the outer surface of the plastic white paper layer.

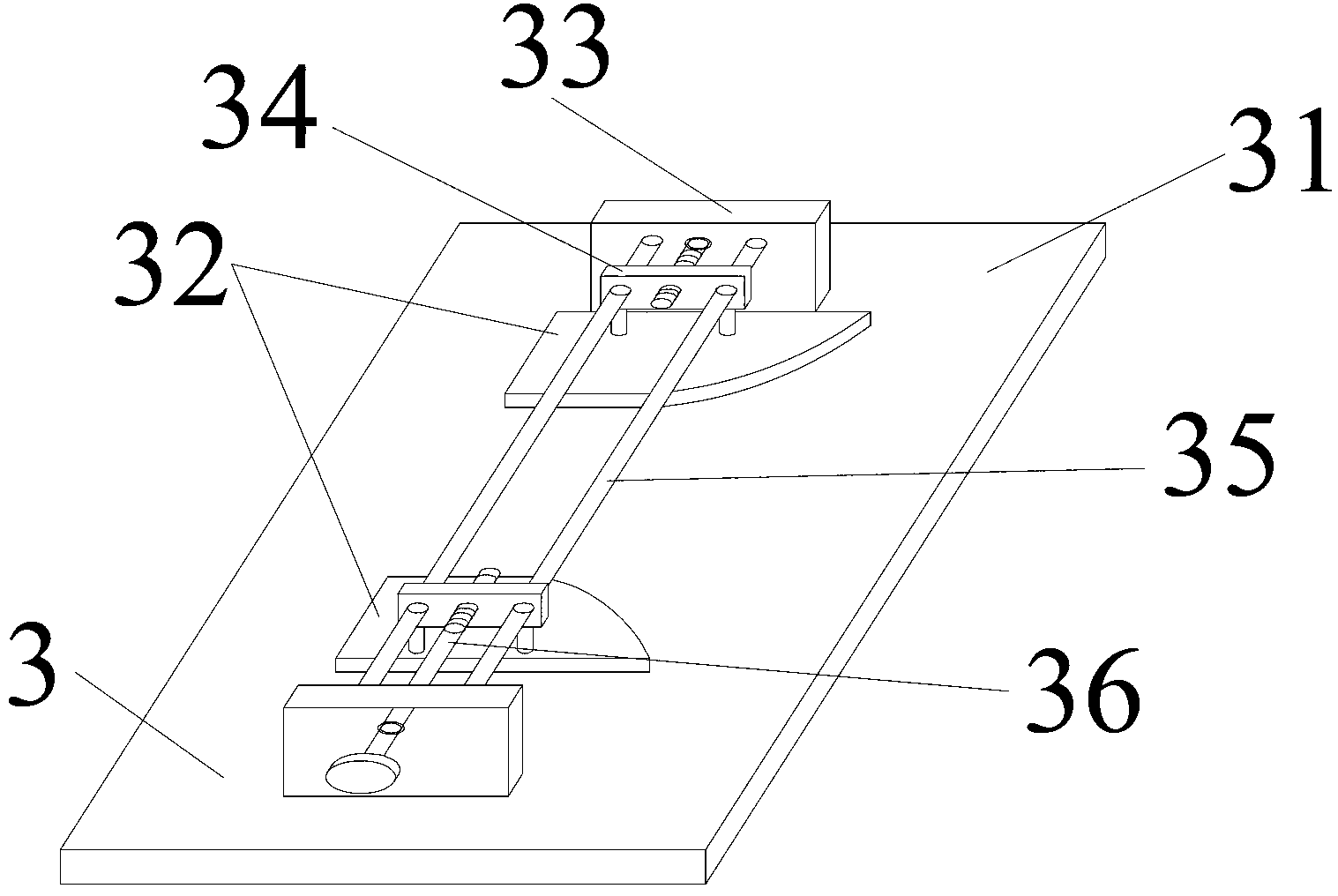

[0033] When the aviation cleaning bag is made, the crease line 11 is produced at the middle part of both sides of the bag body 1 by the folding machine 3 mechanism, so that two folded edges 12 are respectively formed on the both sides of the bag body 1, as shown in FIG. figure 1 shown.

[0034] In addition, a tear line 13 is set at the end of the bag body 1 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com