Waterborne vacuum plastic-absorbing glue and preparing method thereof

A vacuum absorption, water-based technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the limitation of increasing the feeding sequence, the high-density fiberboard bonding chip rate is not high, not introduced, etc. problems, to achieve excellent low temperature viscosity stability, reduce the risk of slag, and simplify the preparation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

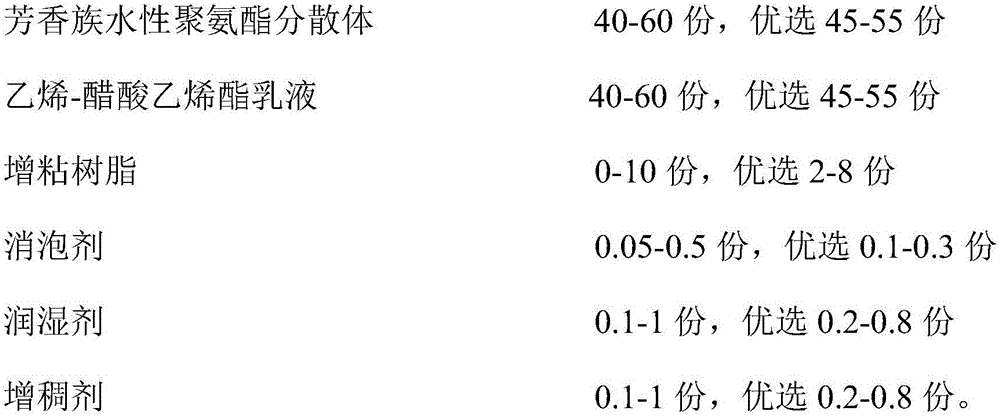

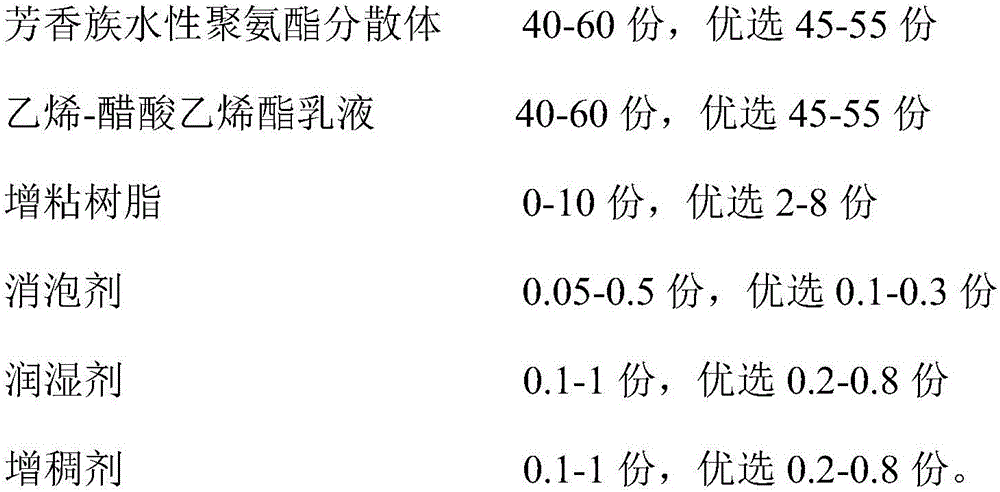

[0043] Water-based vacuum suction plastic is prepared from the following raw materials in parts by weight:

[0044] Aromatic waterborne polyurethane dispersion A 50 parts

[0045] Ethylene-vinyl acetate emulsion DA-102 (Dalian Chemical) 50 parts

[0046] Water-based terpene resin 968 (Shenzhen Yoshida Chemical Co., Ltd.) 10 parts

[0047] Defoamer BYK028 (Byk Chemicals) 0.1 parts

[0048] Wetting agent OT-75 (Cytec) 0.4 parts

[0049] thickener A801 (Wanhua Chemical) 0.5 parts

[0050] In this example, the preparation method of aromatic water-based polyurethane dispersion A is as follows: 200g of dehydrated poly-1,4-butylene adipate (number average molecular weight 3000), 55g of TDI-80, 50g of acetone, Add 20g of dimethylolpropionic acid and 4g of diethylene glycol into a 1L four-necked round-bottomed flask equipped with a nitrogen inlet and outlet, and stir the mixture at 60-80°C for 3.5h until the NCO% reaches 1.5%. Add 150g of acetone to dilute and cool down to 35°C,...

Embodiment 2

[0053] Water-based vacuum suction plastic is prepared from the following raw materials in parts by weight:

[0054] Aromatic waterborne polyurethane dispersion B 50 parts

[0055] Ethylene-vinyl acetate emulsion EP708 (Wacker Chemie) 40 parts

[0056] Water-based terpene resin 968 (Shenzhen Yoshida Chemical Co., Ltd.) 5 parts

[0057] Defoamer BYK024 (Byk Chemicals) 0.3 parts

[0058] Wetting agent OT-75 (cytec) 1 part

[0059] thickener A801 (Wanhua Chemical) 1 part

[0060] In the present embodiment, the preparation method of aromatic waterborne polyurethane dispersion B is as follows:

[0061] 200g of polyethylene adipate (number average molecular weight: 2000), 60g of TDI-80, 80g of acetone, 18g of dimethylol propionic acid, and 5g of diethylene glycol were added to an inlet filled with nitrogen gas after dehydration. In an outlet 1L four-necked round bottom flask, the mixture was stirred at 60-80° C. for 3 h until the NCO% reached 1.46%. Add 160g of acetone to dil...

Embodiment 3

[0065] Water-based vacuum suction plastic is prepared from the following raw materials in parts by weight:

[0066] Aromatic waterborne polyurethane dispersion C 60 parts

[0067] Ethylene-vinyl acetate emulsion DA-102 (Dalian Chemical) 40 parts

[0068] Defoamer BYK028 (Byk Chemicals) 0.3 parts

[0069] Wetting agent Tego wet270 (Di Gao) 1 part

[0070] thickener A801 (Wanhua Chemical) 1 part

[0071] In this example, the preparation method of aromatic water-based polyurethane dispersion C is as follows: 200g of dehydrated poly-1,6-hexanediol adipate (number average molecular weight 2000), 60g of TDI-80, 70g of acetone, Add 11.5g of dimethylolbutyric acid and 8g of diethylene glycol into a 1L four-neck round-bottomed flask equipped with a nitrogen inlet and outlet, and stir the mixture at 60-80°C for 2.5h until the NCO% reaches 2.20%. Add 160g of acetone to dilute and lower the temperature to 35°C, add 7.9g of triethylamine to neutralize for about 5min, then add 378g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com