Edge folding method and edge folding device

A technology of hemming device and working pressure, applied in the field of hemming and hemming device, can solve the problems of inability to position and fold the sheet material, high production cost, troublesome operation, etc., and achieve good hemming effect, low production cost, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

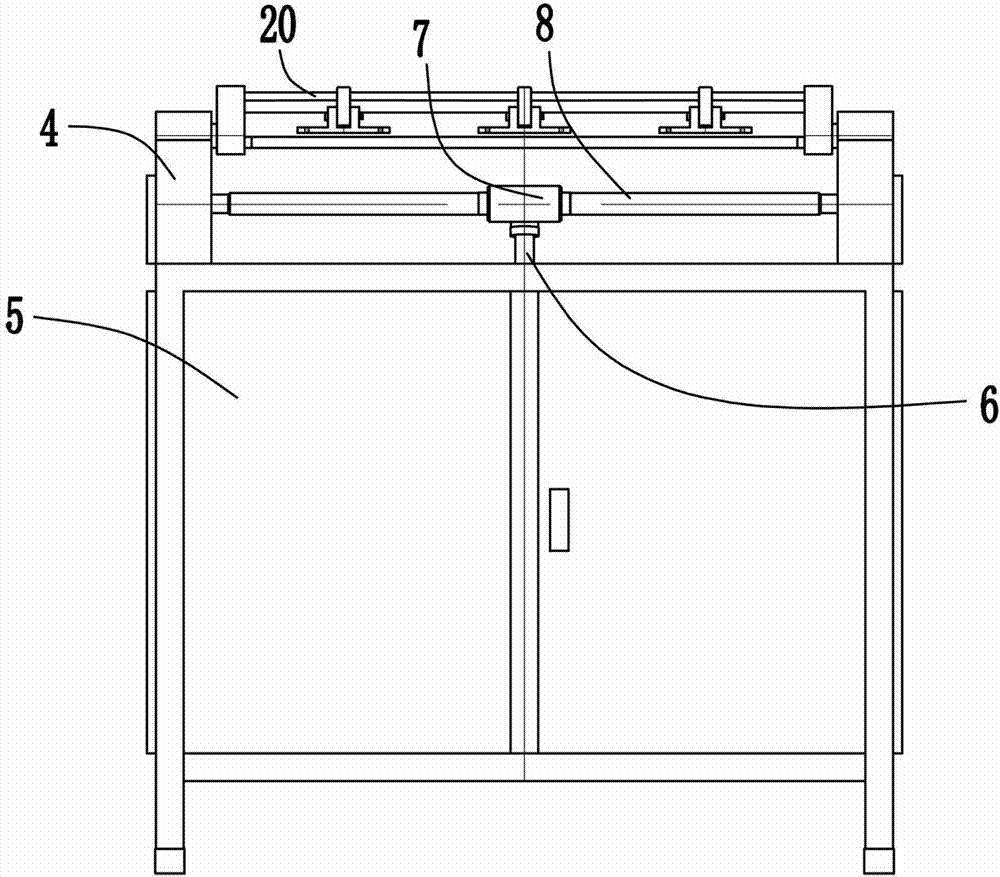

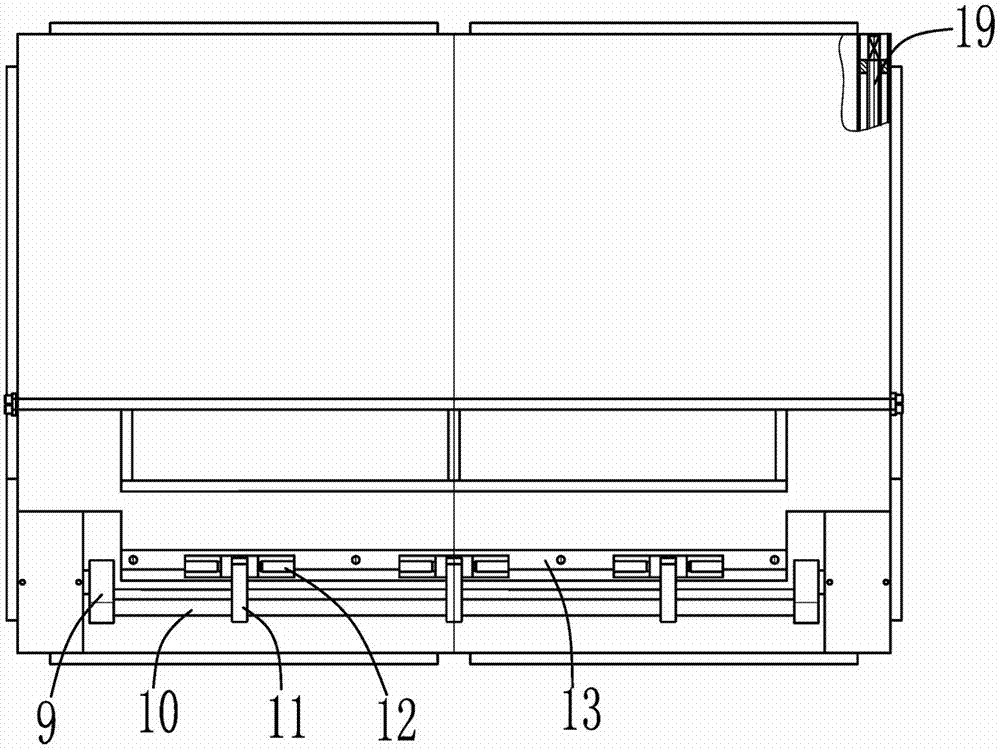

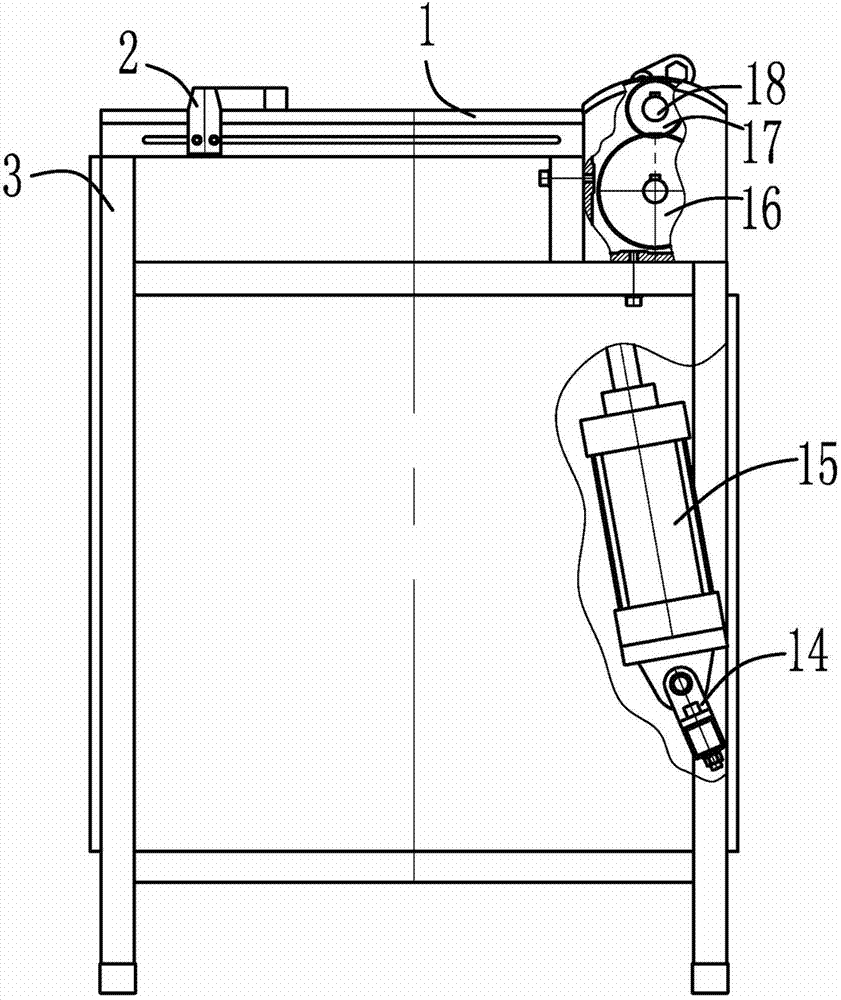

[0022] See Figure 1 to Figure 3 , Figure 1 to Figure 3 What is disclosed is a hemming device, comprising: a main work panel 1 arranged on the main frame 3, a main work pressure plate 12 and a turning mechanism (not shown), the turning mechanism includes a drive gear 16 at both ends. Both ends of the main transmission long shaft 8 and the driven shaft 10 are provided with a main transmission short shaft 18 and a power mechanism (not shown), and the power mechanism is connected to the main transmission long shaft 8 and drives the main transmission long shaft. 8 rotate, the driving gear 16 meshes with the driven gear 17, and drives the driven shaft 10 to rotate, the rocker arm 9 is arranged on the driven shaft 10, and the rocker arm 9 drives the main working pressure plate 12 turns.

[0023] In this embodiment, both ends of the driven shaft 10 are provided with a main transmission stub shaft 18 , and the main transmission stub shaft 18 is connected to the inner side of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com