Patents

Literature

151results about How to "Improve tool change efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

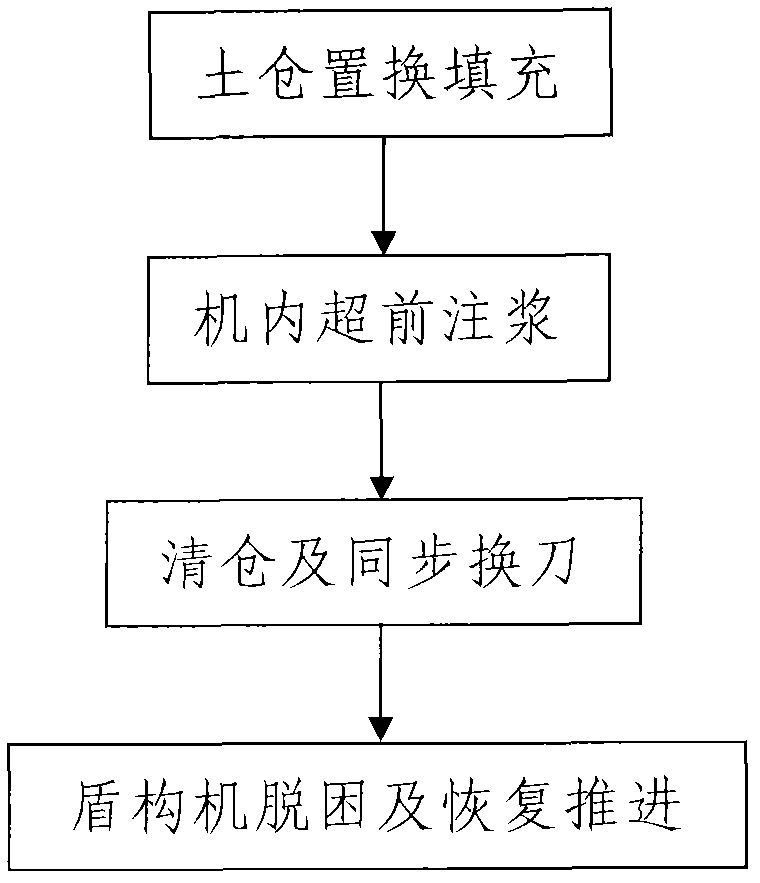

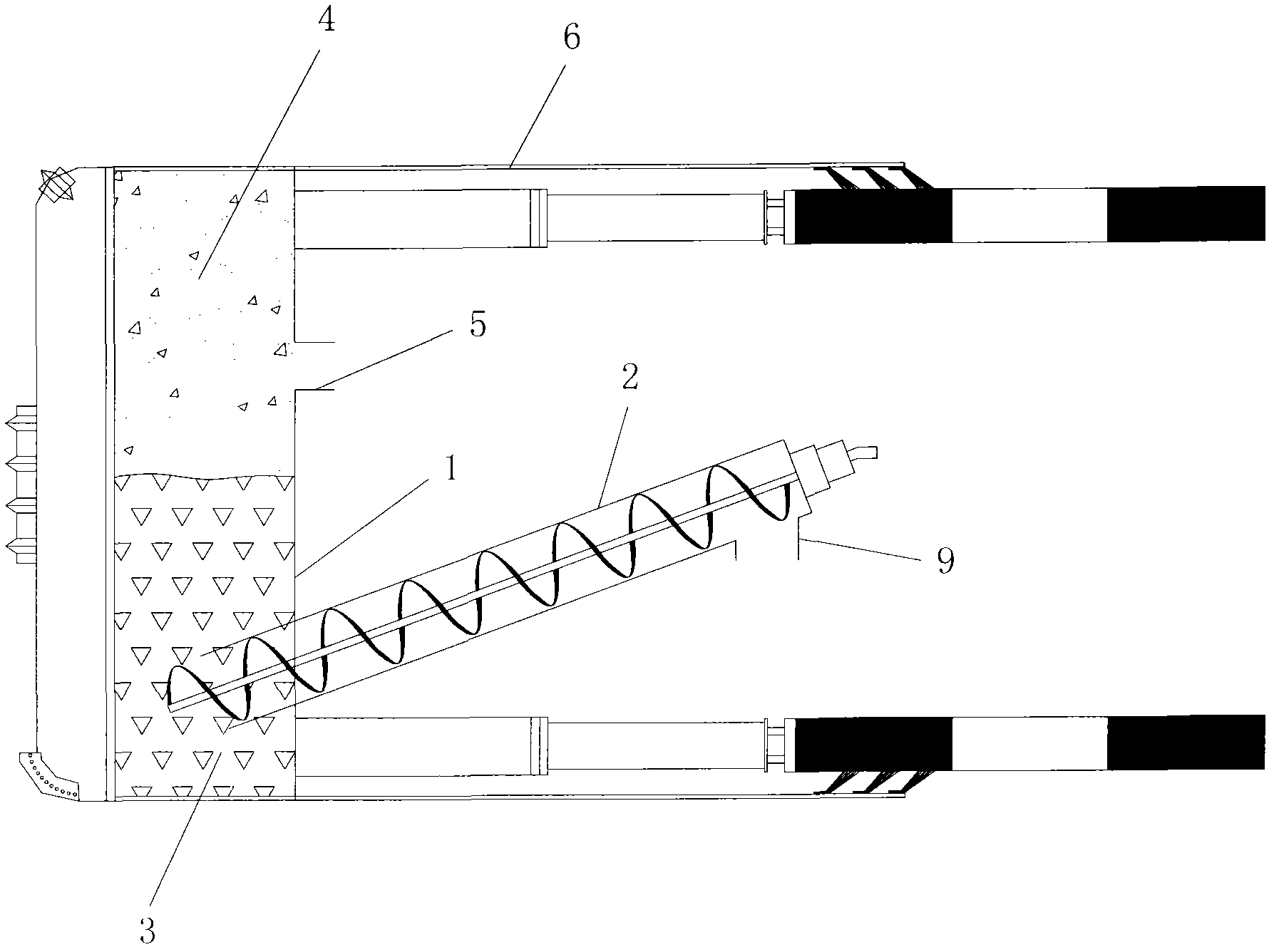

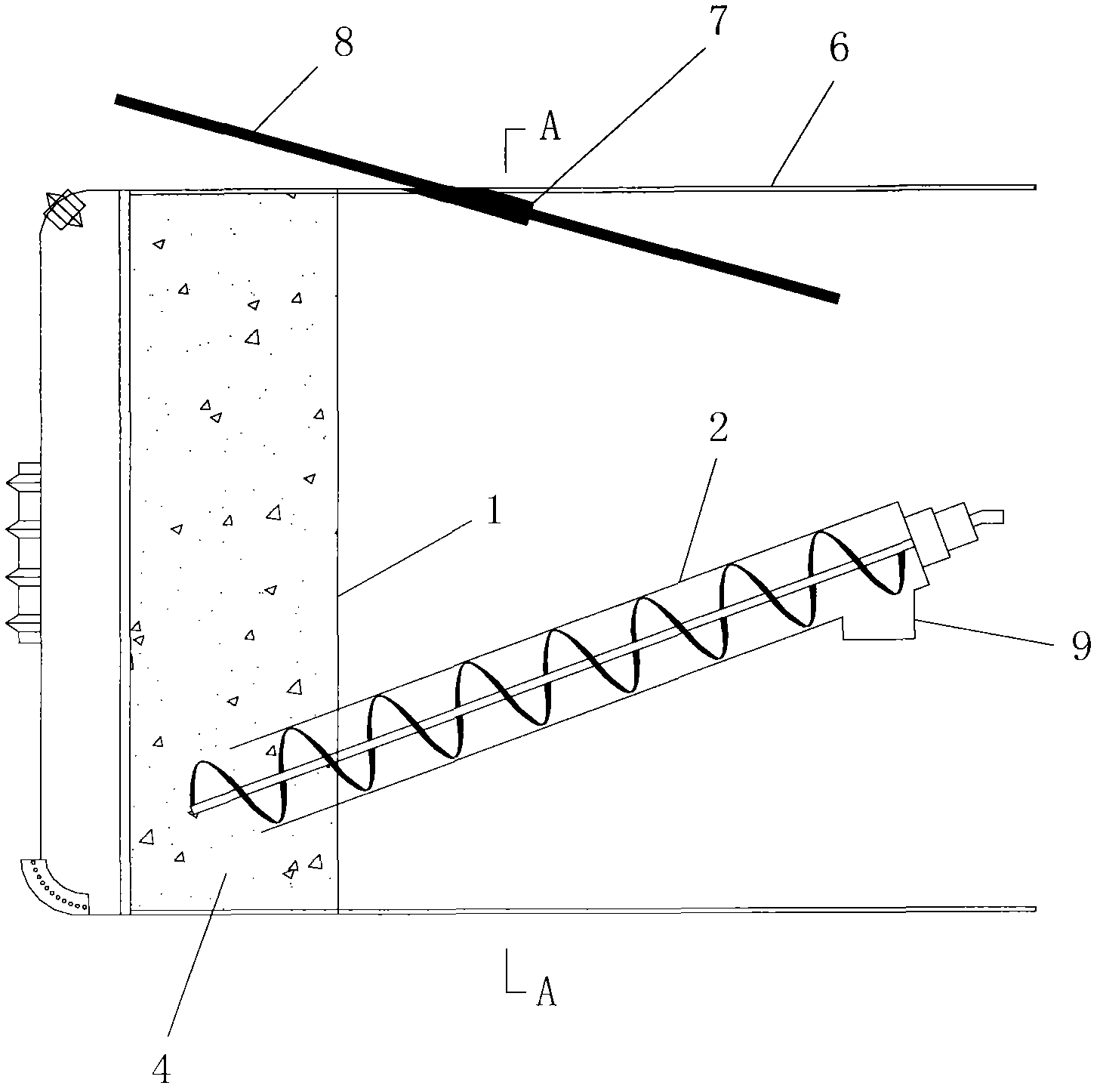

Method for exchanging tool of shield machine for tunnel construction

The invention discloses a method for exchanging a tool of a shield machine for tunnel construction, which comprises the steps of: (1) soil cabin replacement filling: performing the process of soil cabin replacement filling by using a spiral excavating machine and a slip casting system synchronously working with the spiral excavating machine; (2) advanced slip casting inside the machine: beating a plurality of slip casting pipes into the soil on the upper part of the shield machine from inner to outer inside the shield machine by respectively passing through a plurality of advanced geologic holes and then synchronously injecting cement paste into the soil on the upper part of the shield machine through the slip casting pipes by using a slip casting device till the cement paste cannot be injected any more; (3) cleaning cabin and exchanging tool synchronously: manually cleaning the cement plaster solidified inside the soil cabin and synchronously exchanging the tool mounted on the shield machine; and (4) getting rid of the difficult position of the shield machine and recovering the process. The method provided by the invention has the advantages of reasonable design, convenience for operation, low cost, high safety factor, good use effect and capable of solving the problem that the tool cannot be exchanged in the traditional tool exchanging mode under severe tool exchanging conditions.

Owner:URBAN RAIL TRANSIT ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

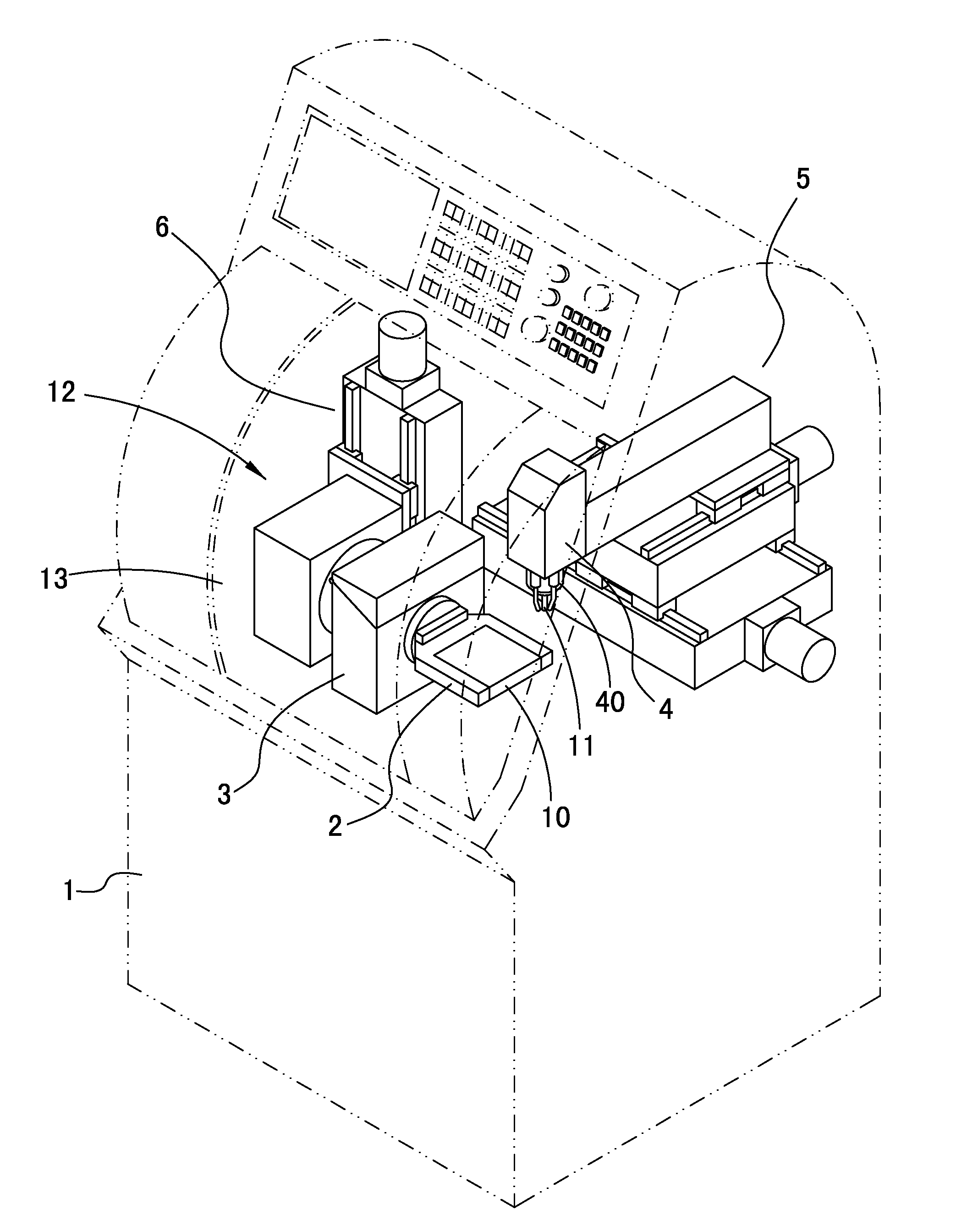

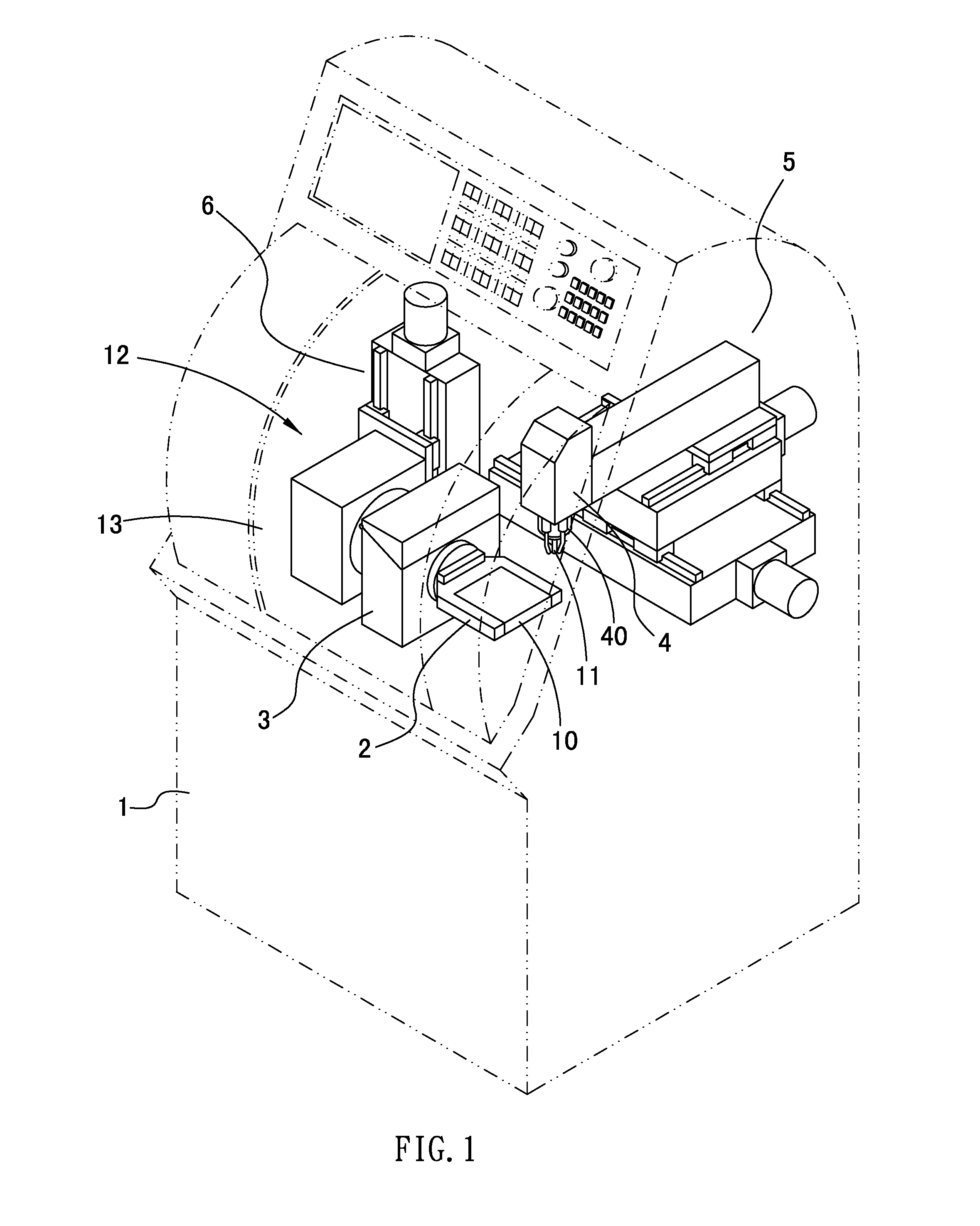

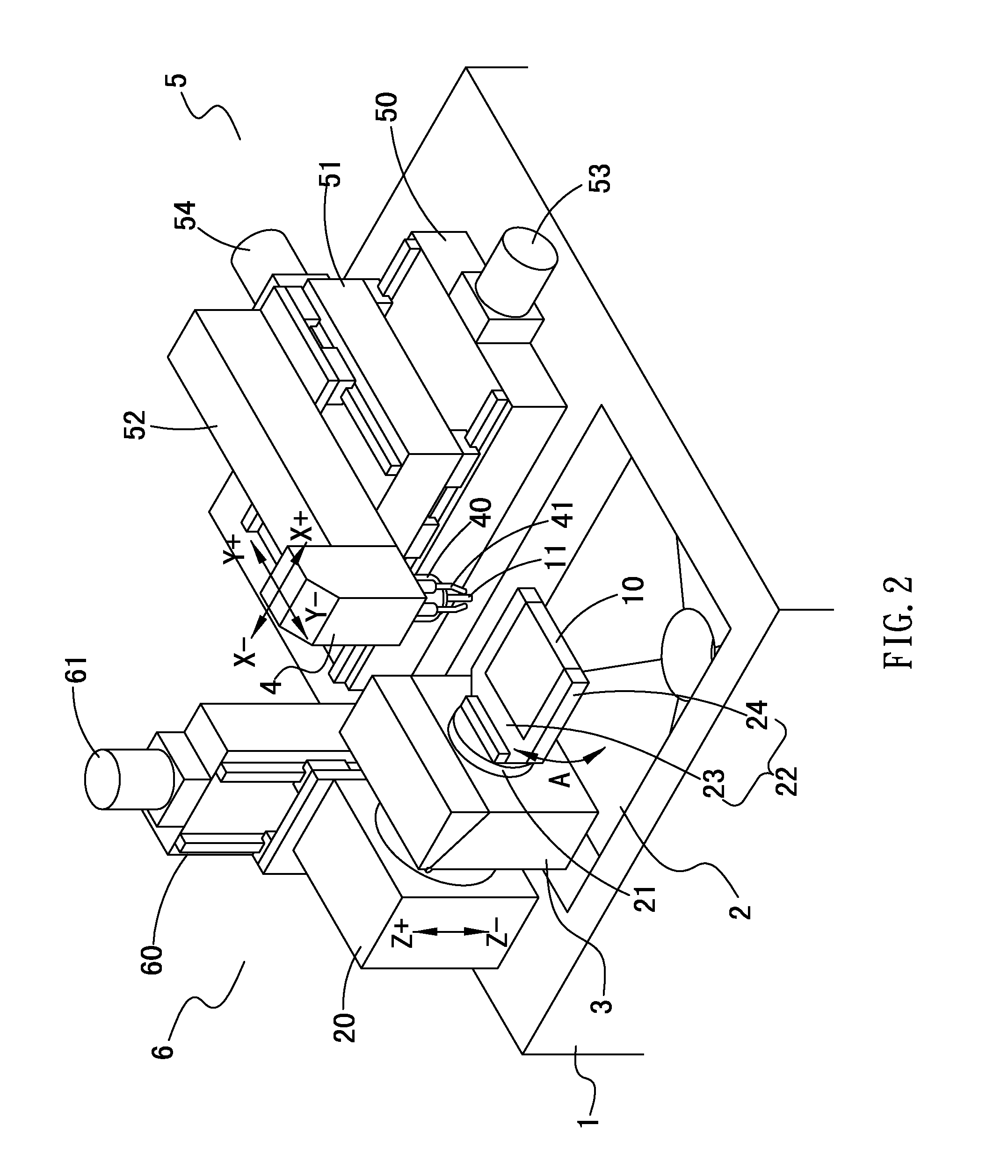

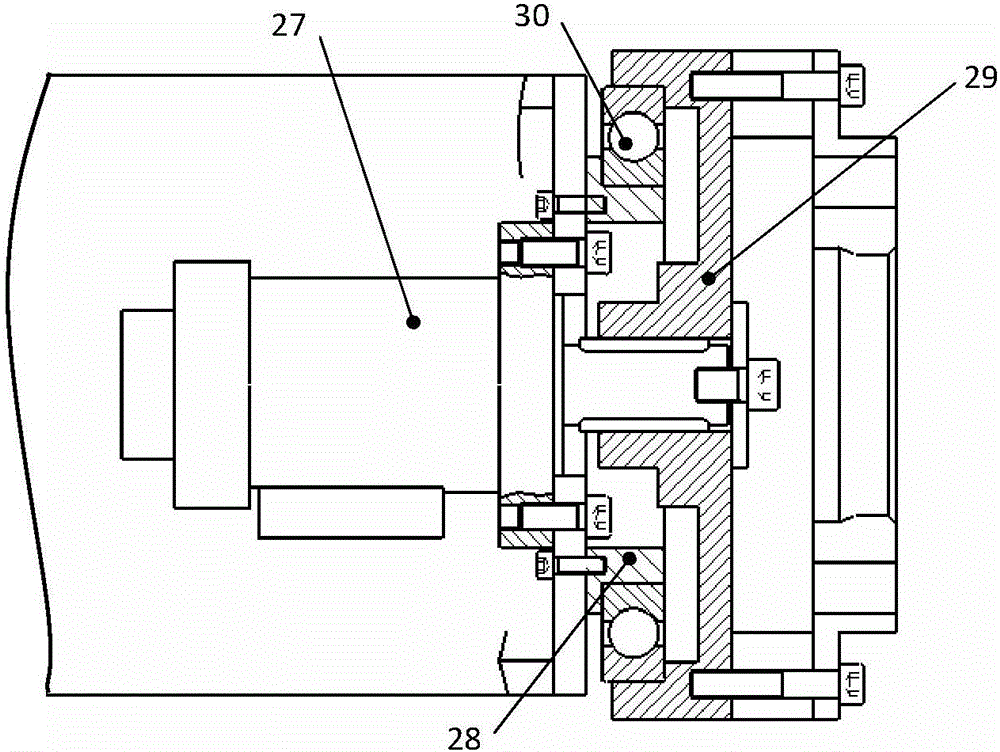

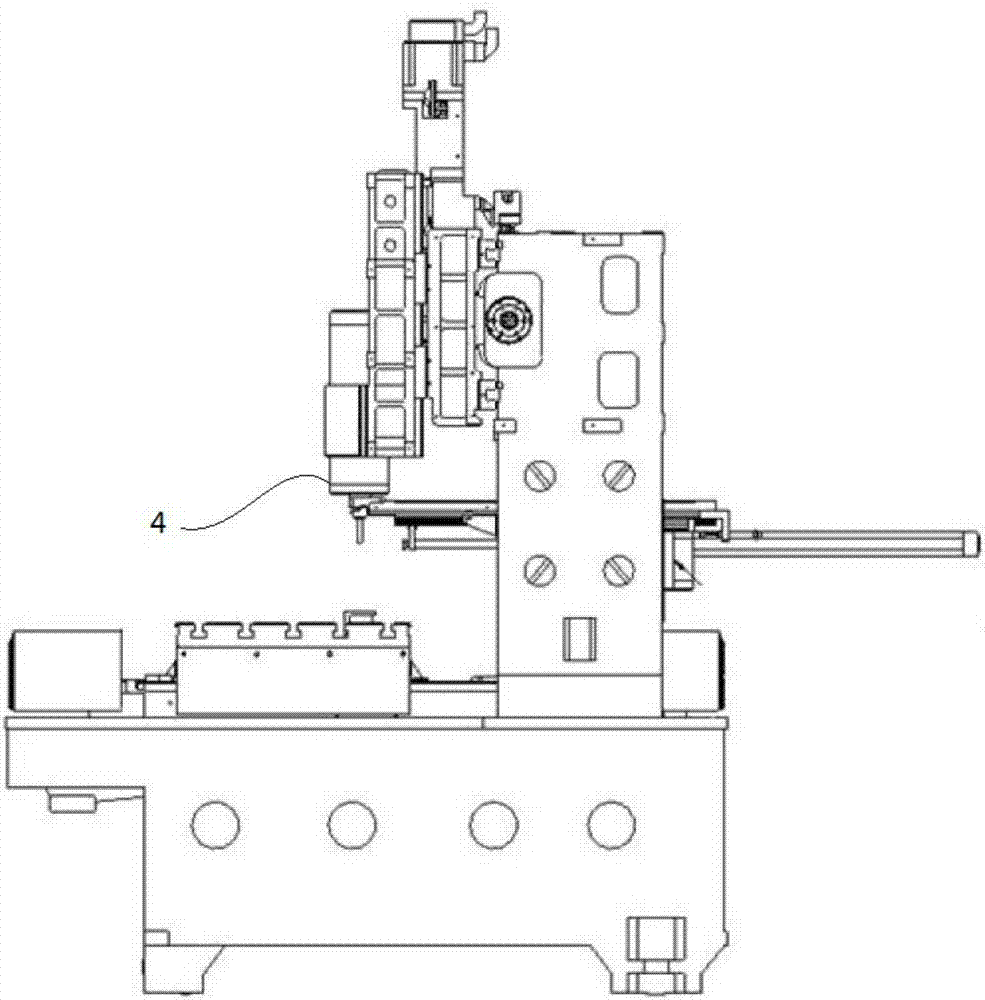

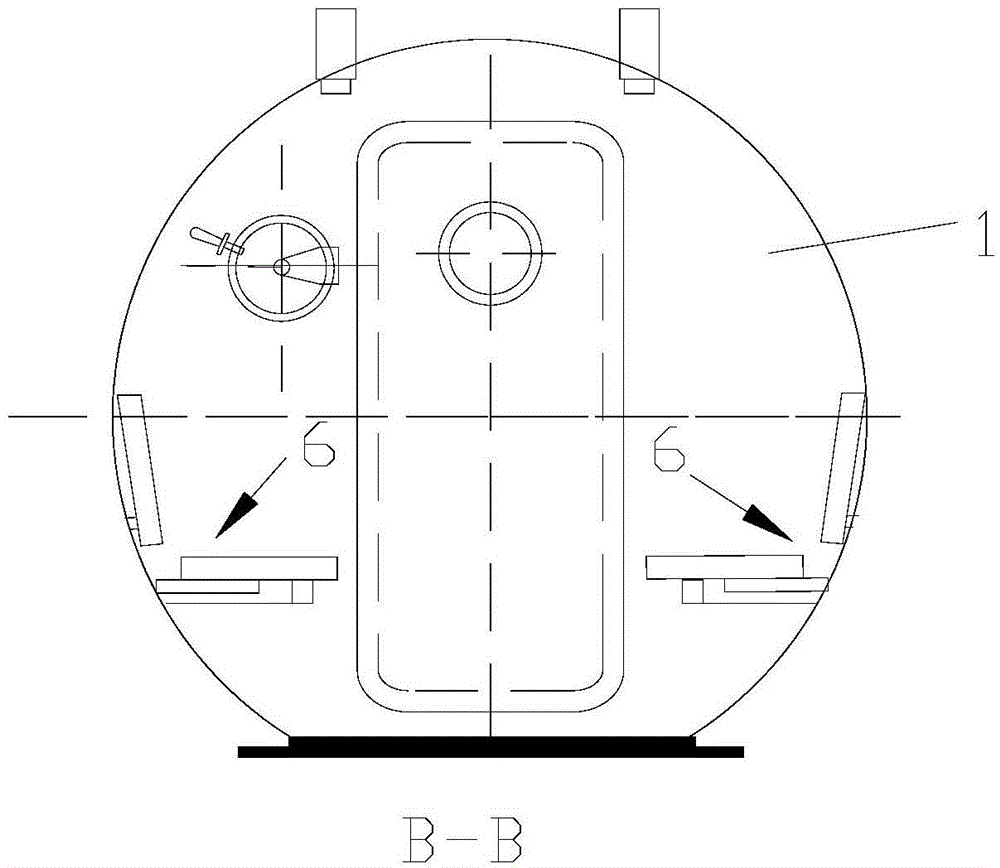

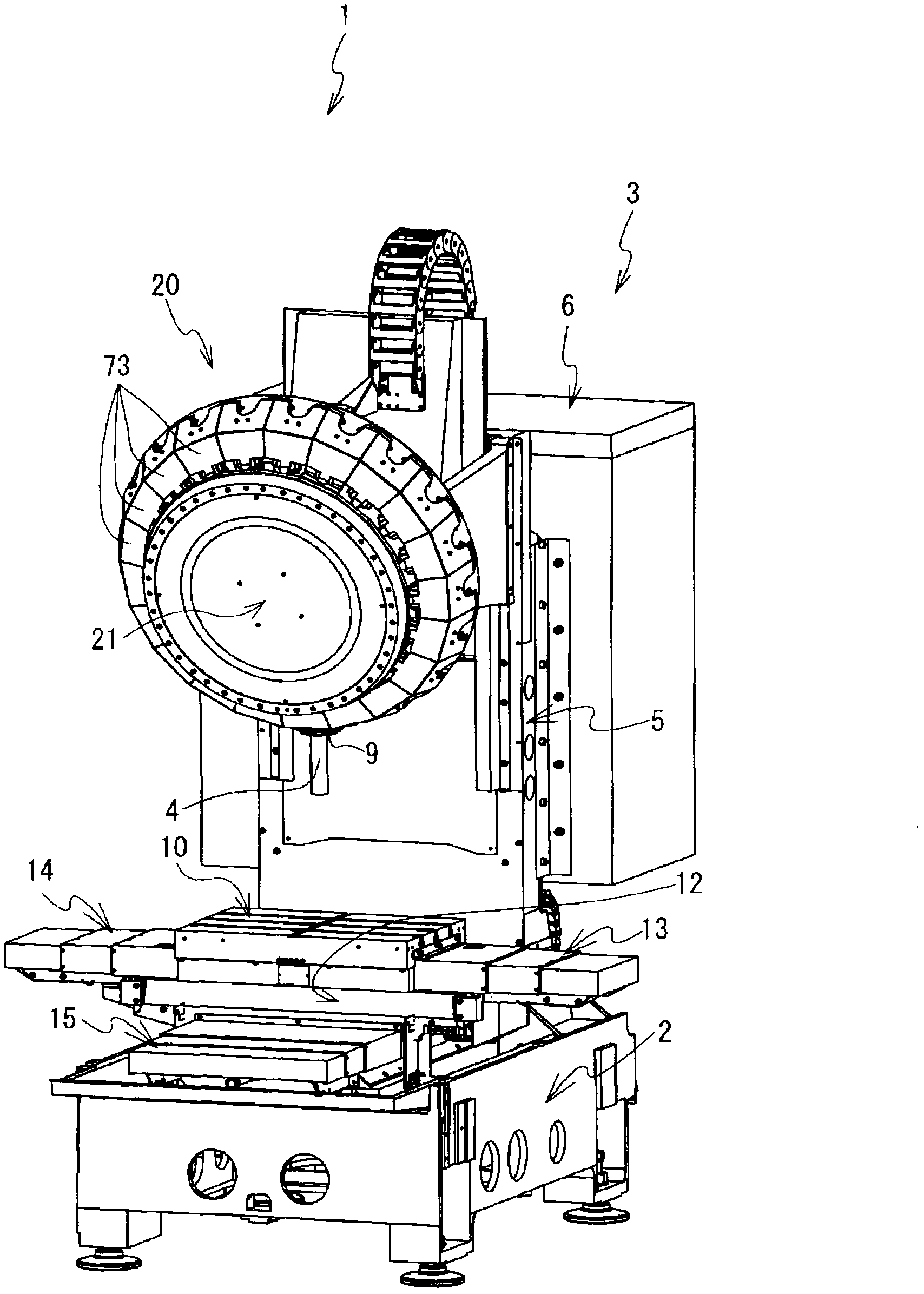

Multi-spindle machining machine with tool changing mechanism

InactiveUS20110083307A1Low production costReduce sizing costsDrilling machinesTransportation and packagingRotational axisEngineering

A multi-spindle machining machine with a tool changing mechanism comprising a base; a carrier including a seat to move in Z axis, a rotary shaft fixed on the seat laterally to drive the seat to rotate in A axis, and a fixing holder coupled to an end portion of the rotary shaft to fix a workpiece; a tool changing mechanism including a mount mounted to the rotary shaft to rotate with the rotary shaft and a monitor fixed on the seat to measure a length of the tool clamped on the driving spindle, and including a plurality of slots to receive the tools respectively; a working head moving above the carrier and the tool changing mechanism in X and Y axes and including a driving spindle mounted on a lower end thereof to rotate axially, and the lower end of the driving spindle allowing to engage and disengage the tool.

Owner:SHENQ FANG YUAN TECH

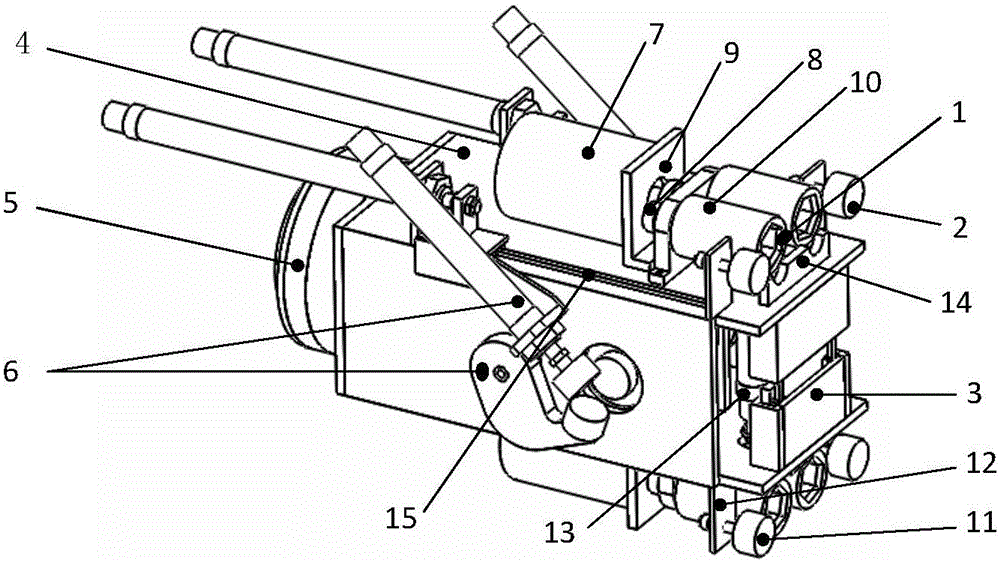

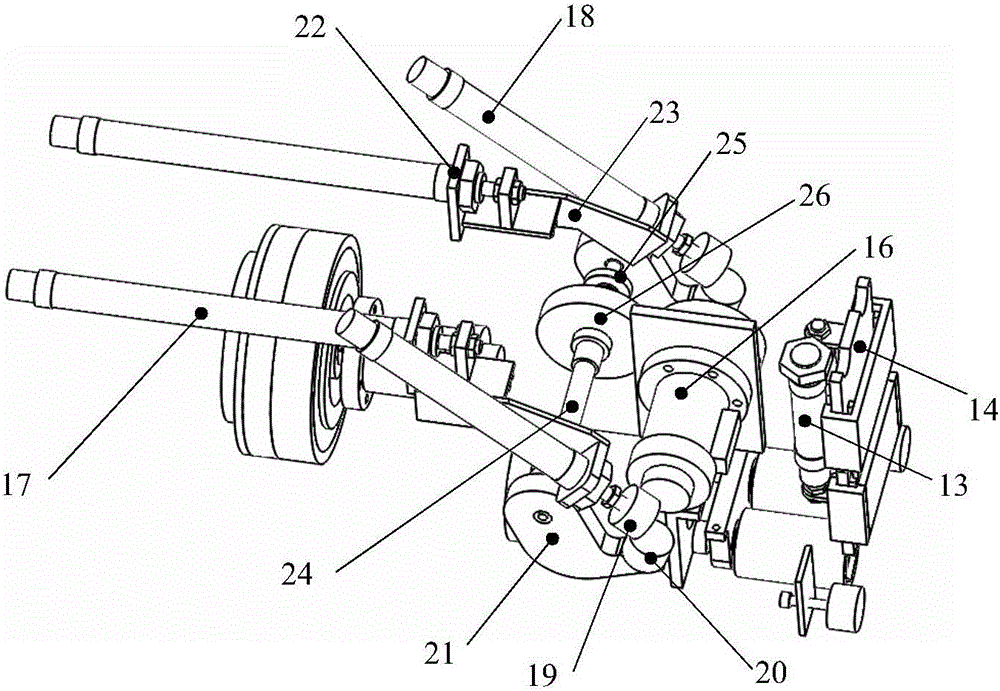

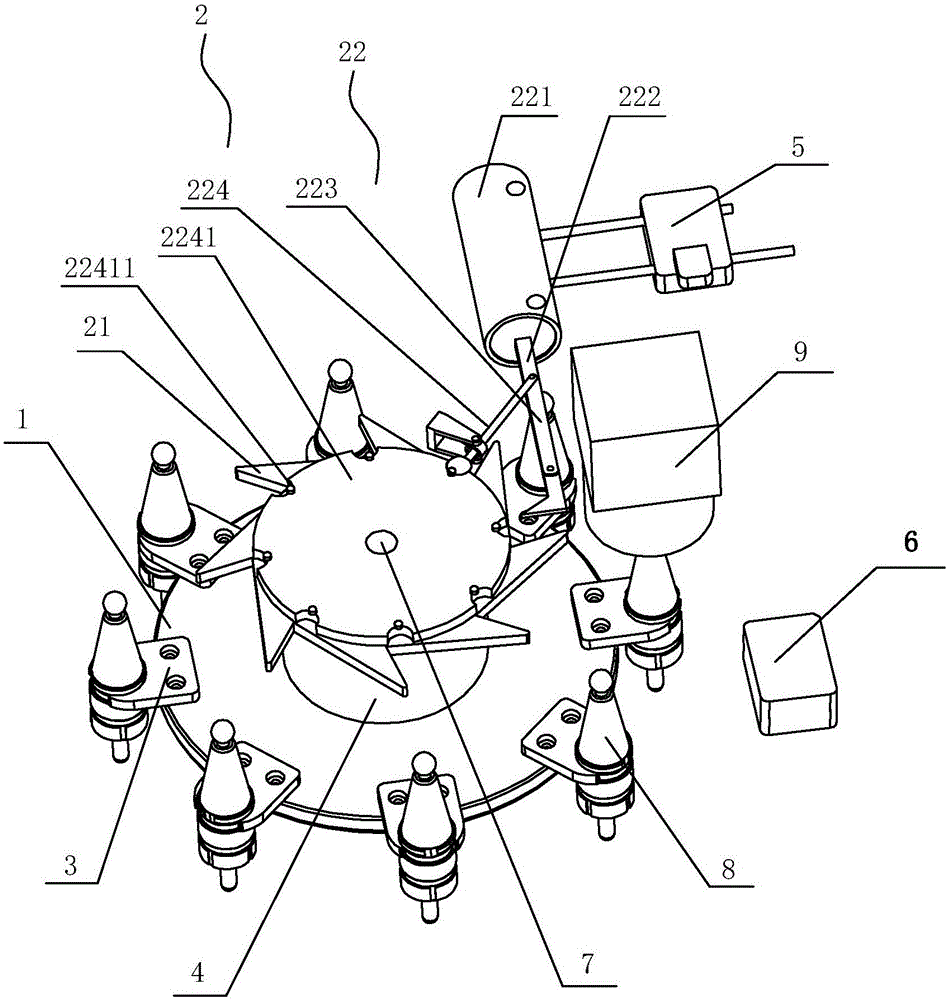

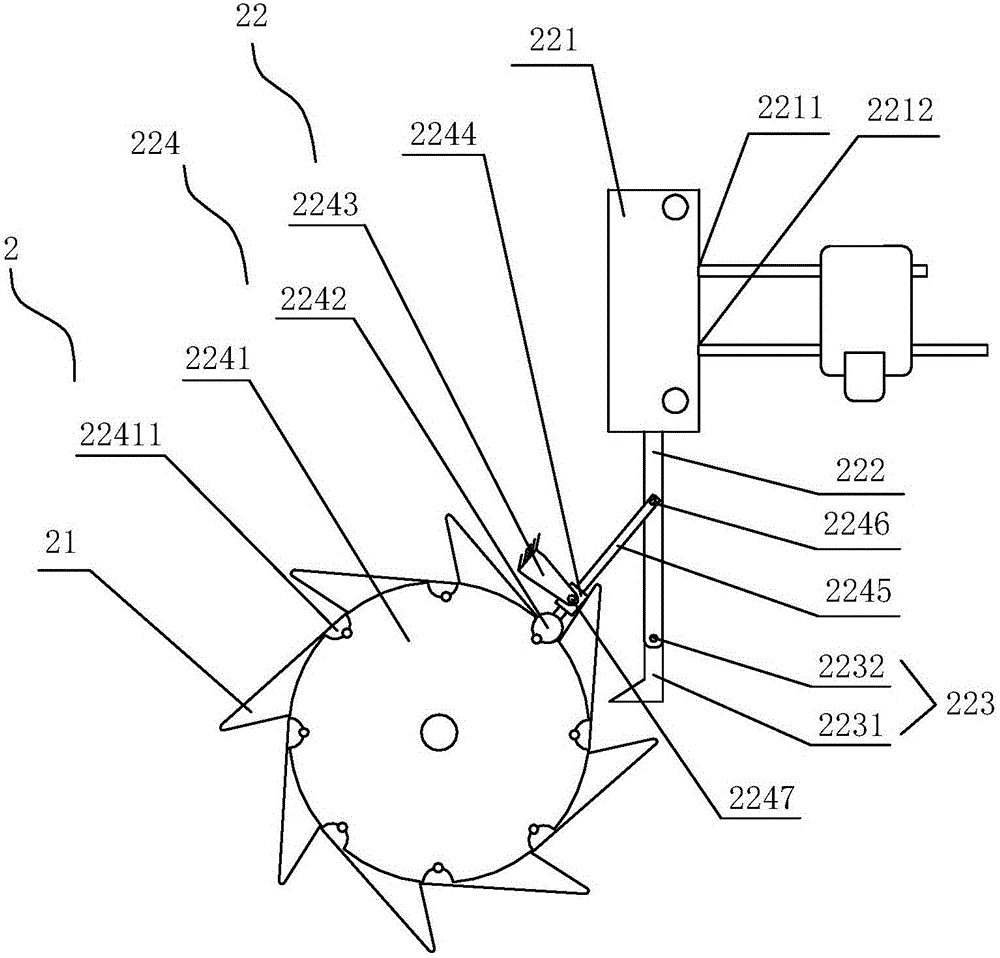

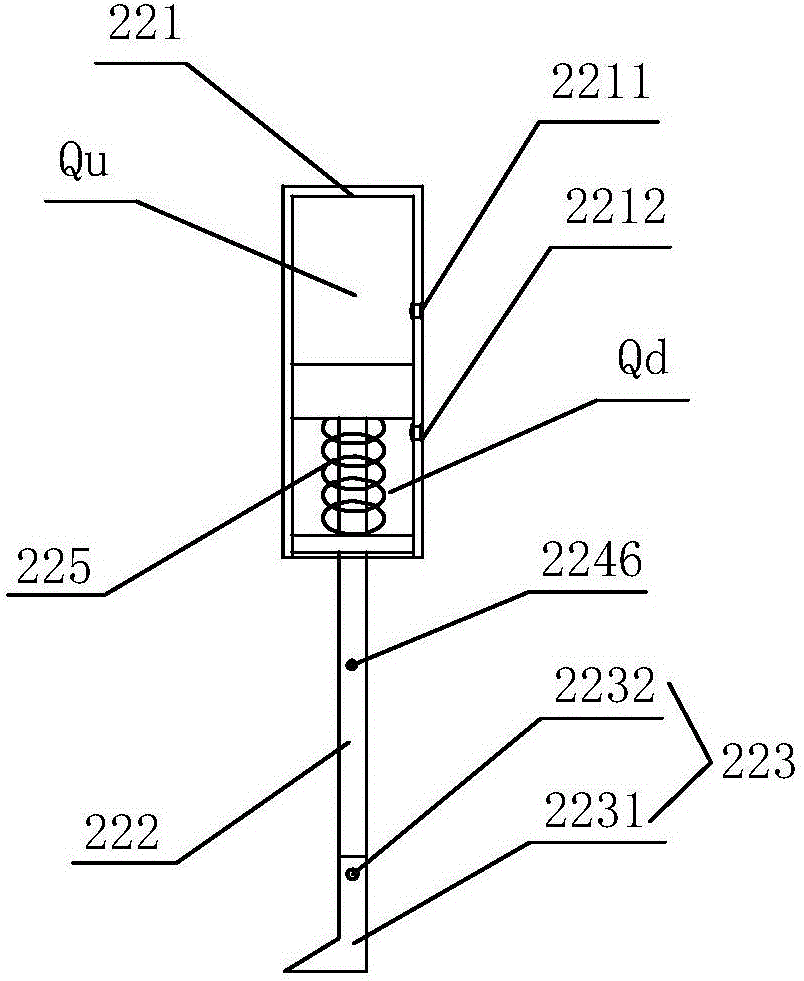

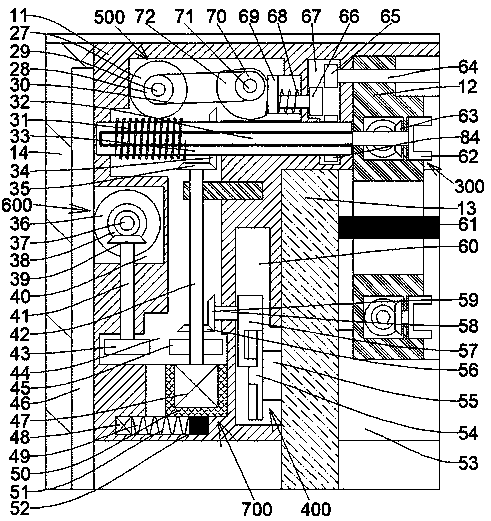

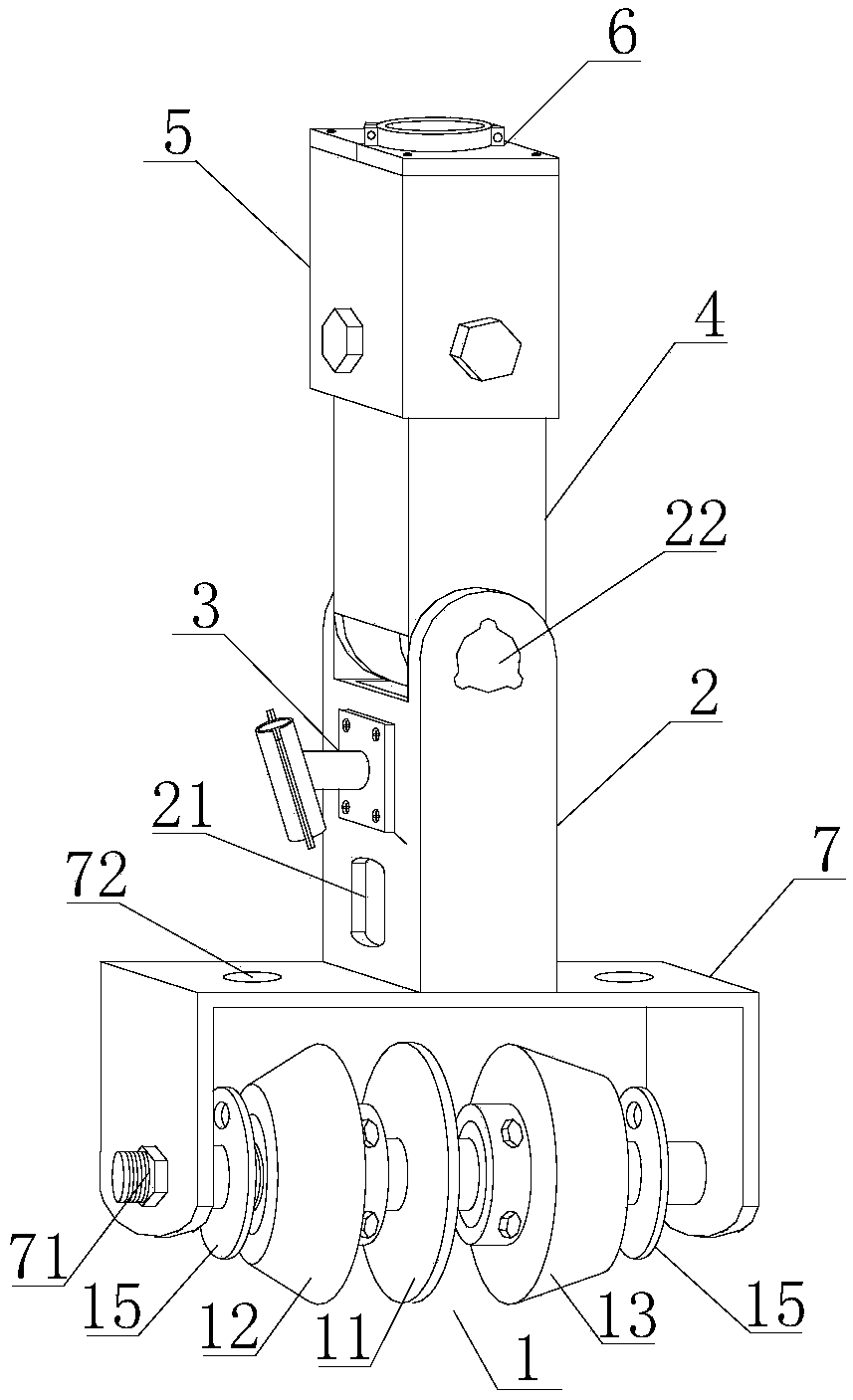

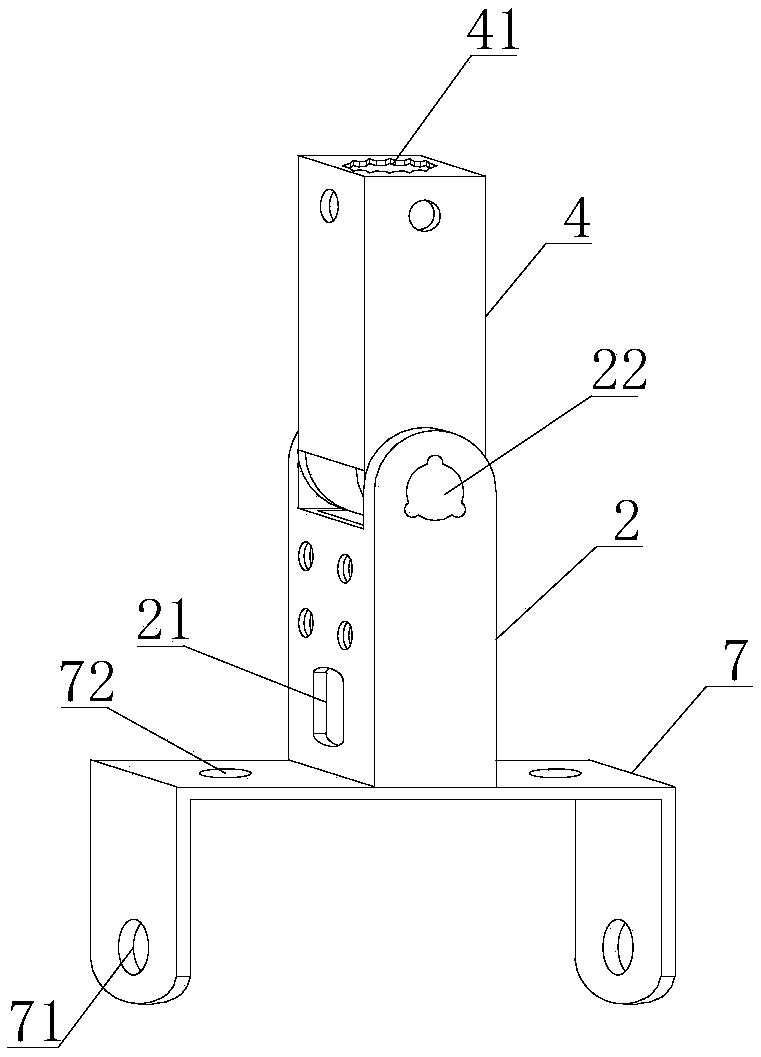

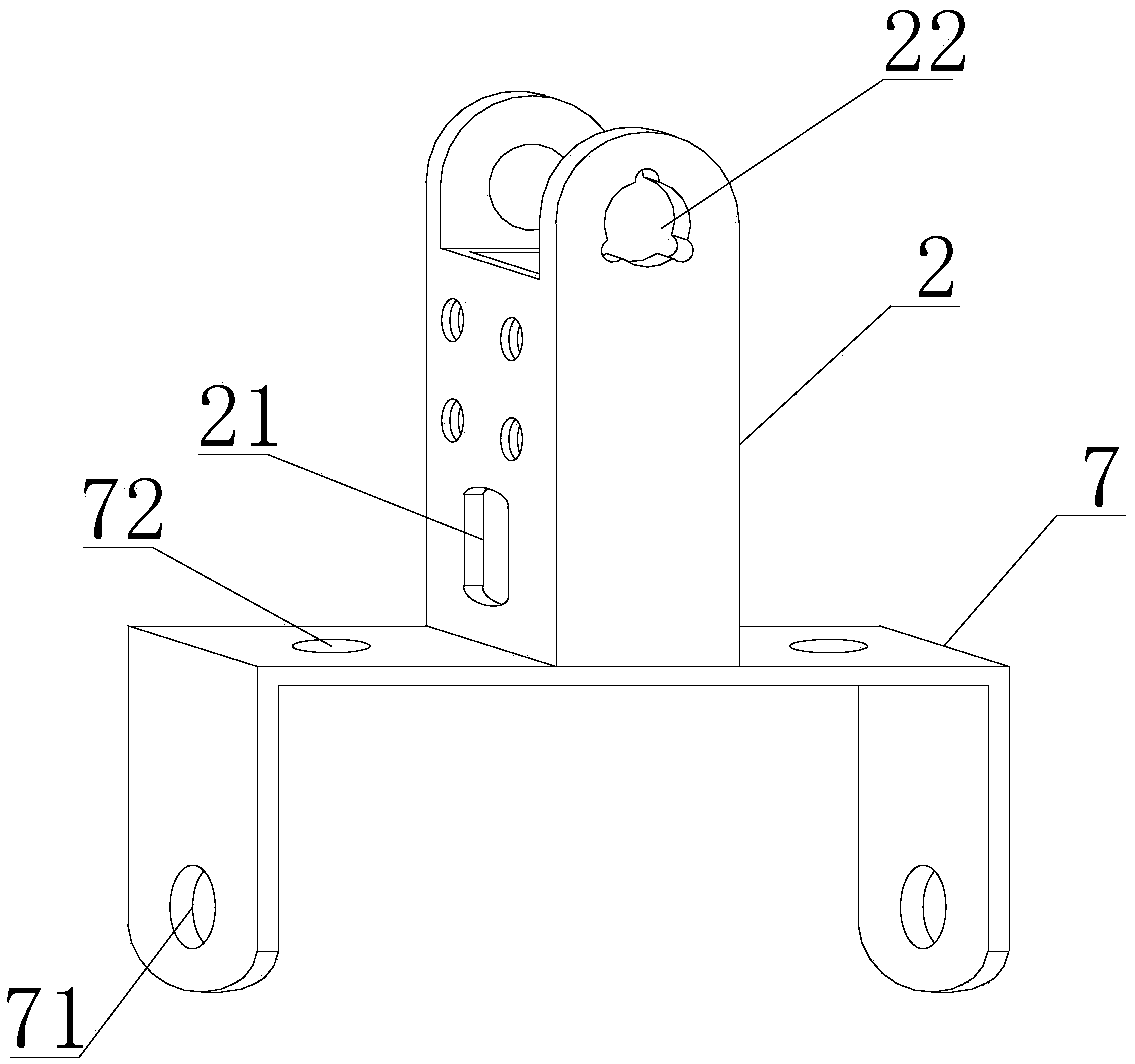

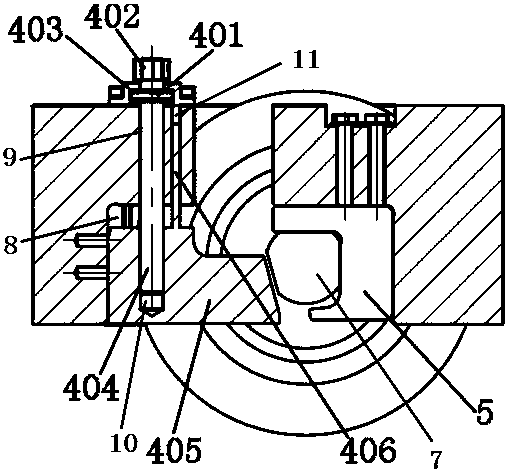

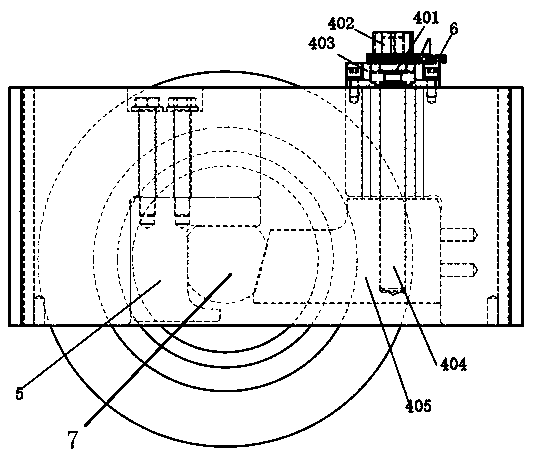

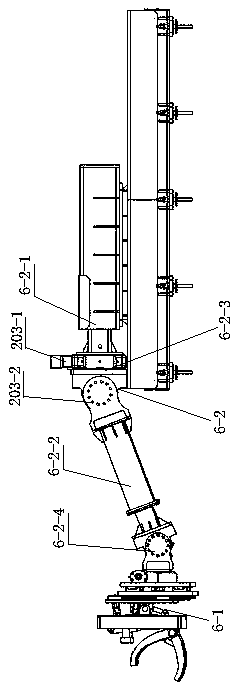

Single-hobbing-cutter changing manipulator of shield tunneling machine

InactiveCN105855849AOvercome the shortcomings of not being able to work continuously for a long timeImprove tool change efficiencyMetal working apparatusHydraulic cylinderHobbing

The invention discloses a single-hobbing-cutter changing manipulator of a shield tunneling machine and belongs to the technical field of maintenance of tunneling construction equipment. The single-hobbing-cutter changing manipulator can be used in cooperation with a telescopic mechanism to replace the manual cutter changing operation, thereby improving the cutter changing efficiency of the shield tunneling machine, ensuring personnel safety of constructors and accelerating the progress of the tunneling engineering. The single-hobbing-cutter changing manipulator comprises a shell, wherein the shell is provided with a bolt assembling and disassembling module, a trapezoidal wedge assembling and disassembling module, a square wedge assembling and disassembling module, an axial rotary module and a hobbing cutter assembling and disassembling fixing module; the trapezoidal wedge assembling and disassembling module comprises a second fixing flange fixed to the shell, and a first electromagnet is fixed to the second fixing flange; the square wedge assembling and disassembling module comprises an assembling and disassembling telescopic part and an assembling and disassembling rotary part; and the hobbing cutter assembling and disassembling fixing module comprises a third hydraulic cylinder fixed to the shell, and a piston rod of the third hydraulic cylinder is connected with a bolt fixing clamping position block.

Owner:NORTHEASTERN UNIV

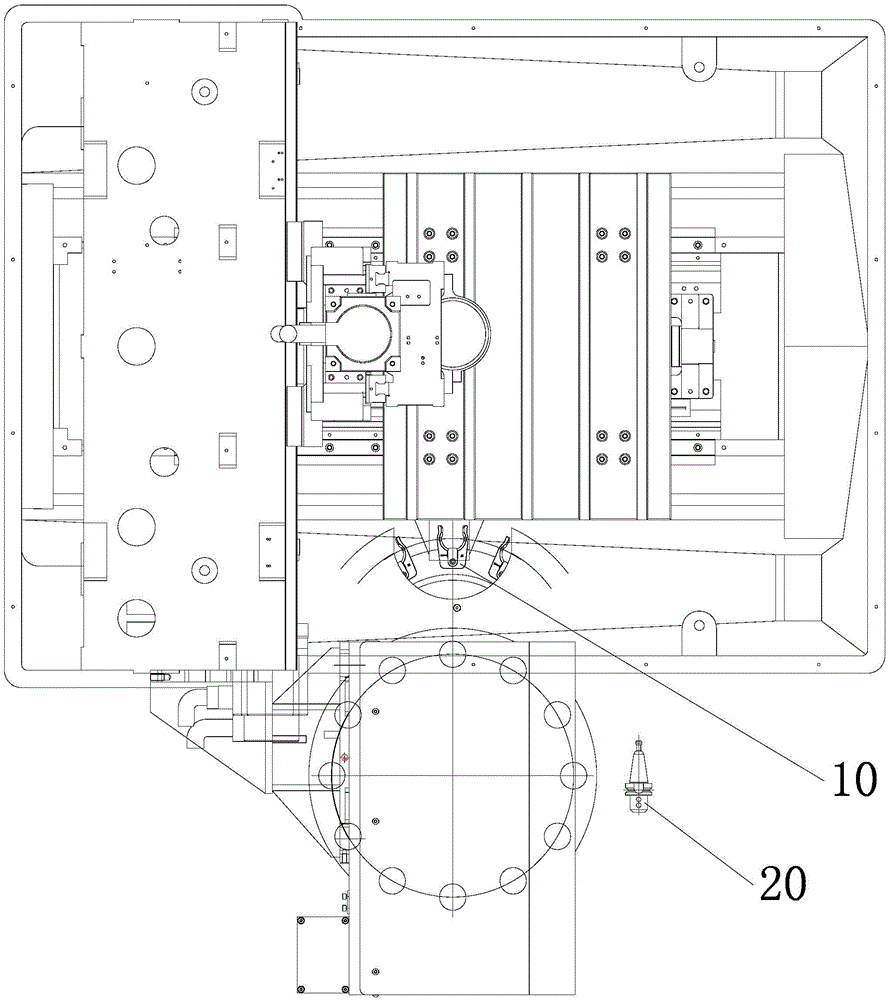

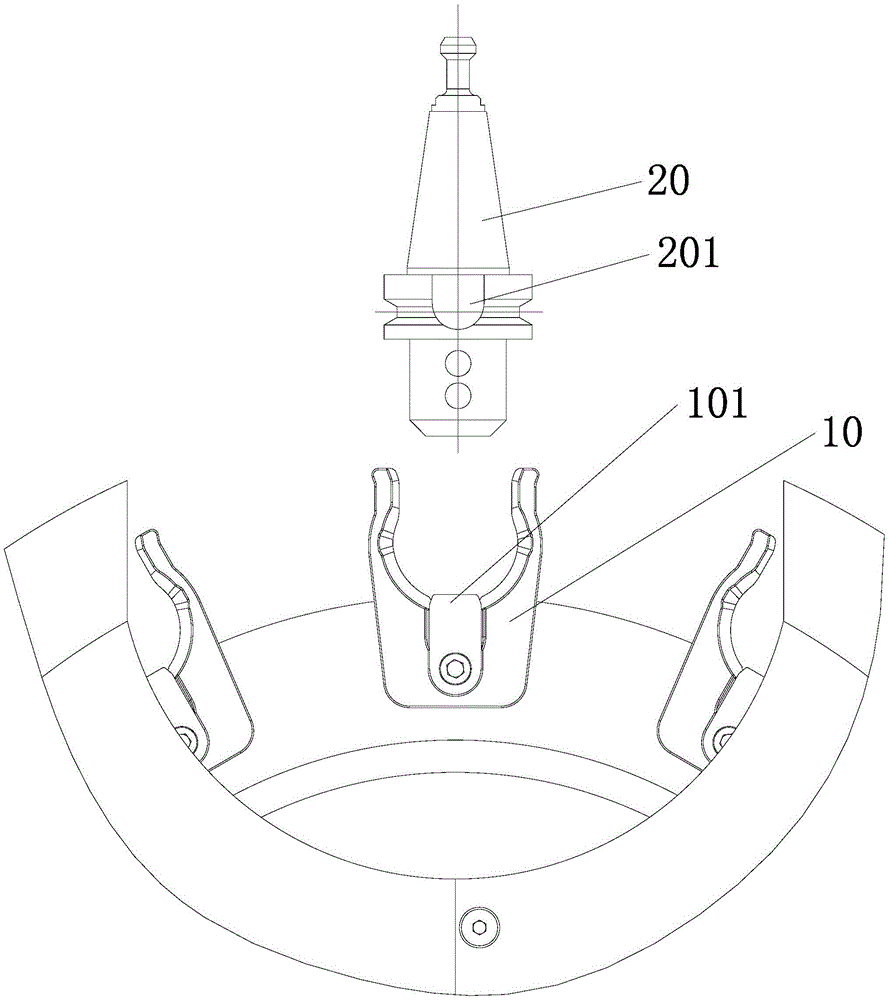

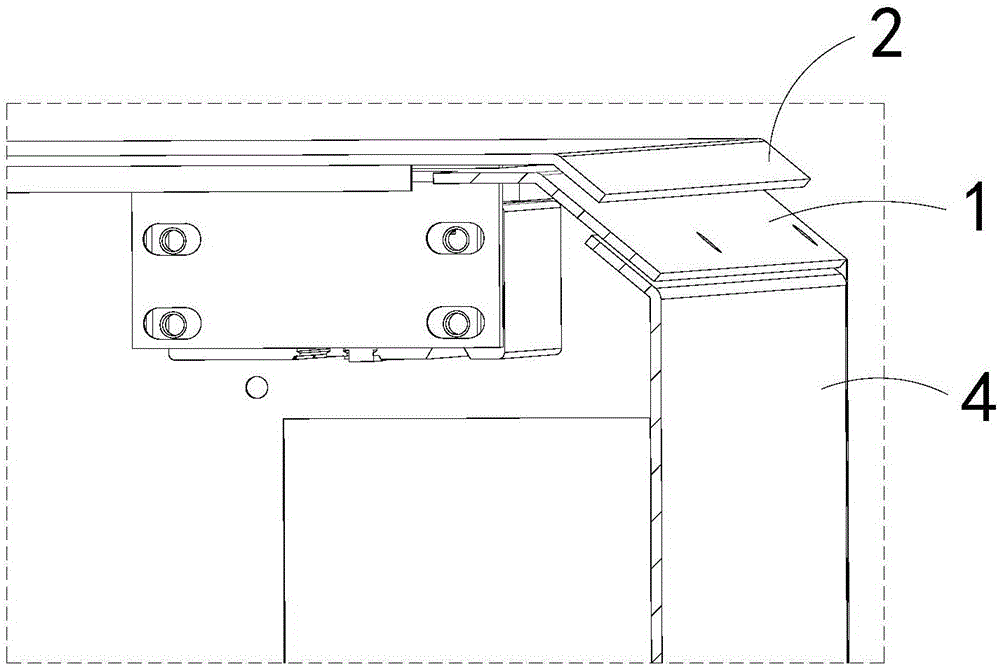

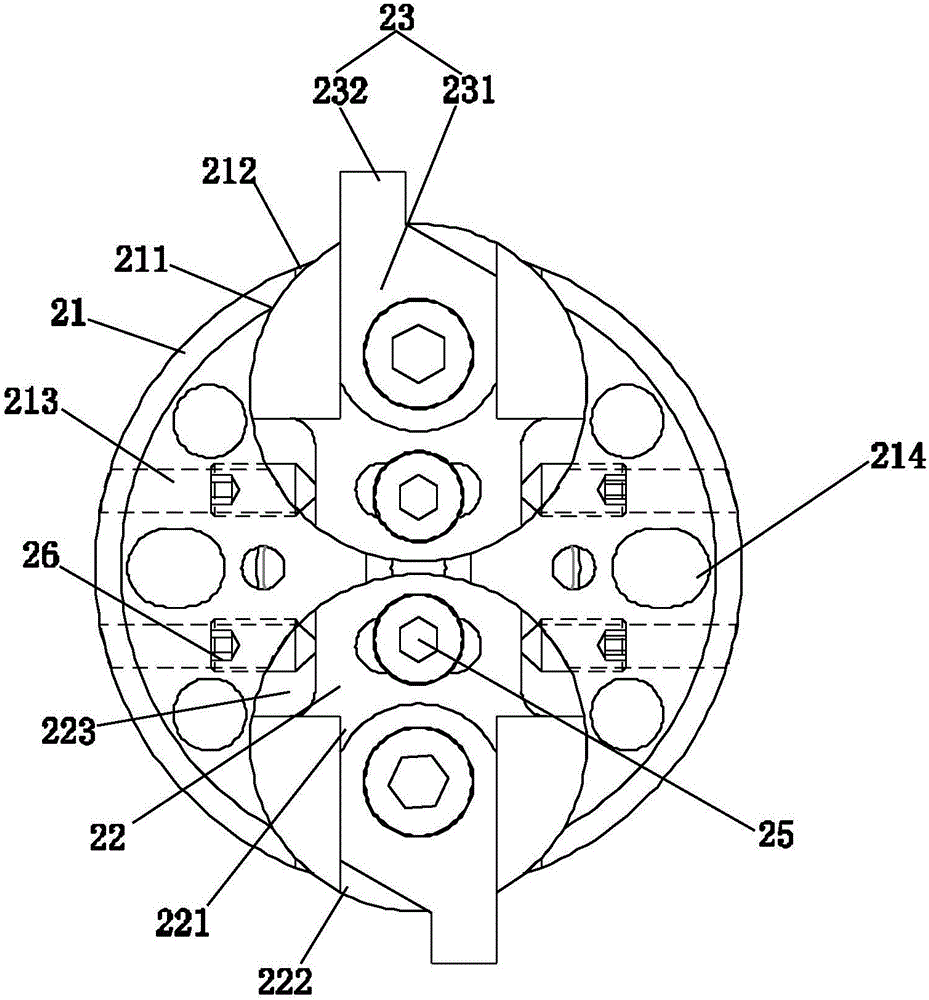

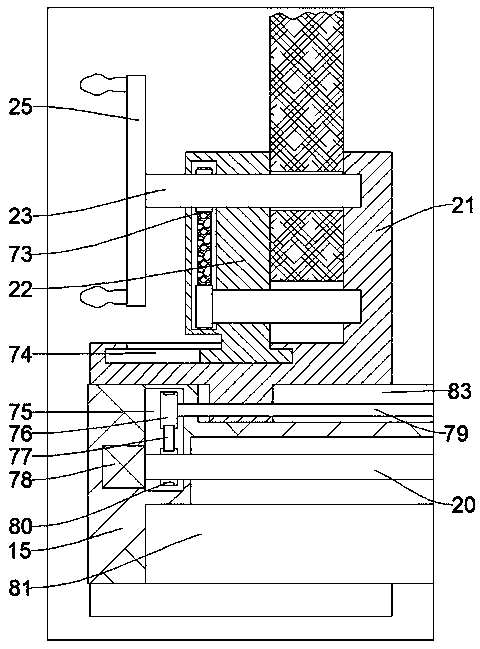

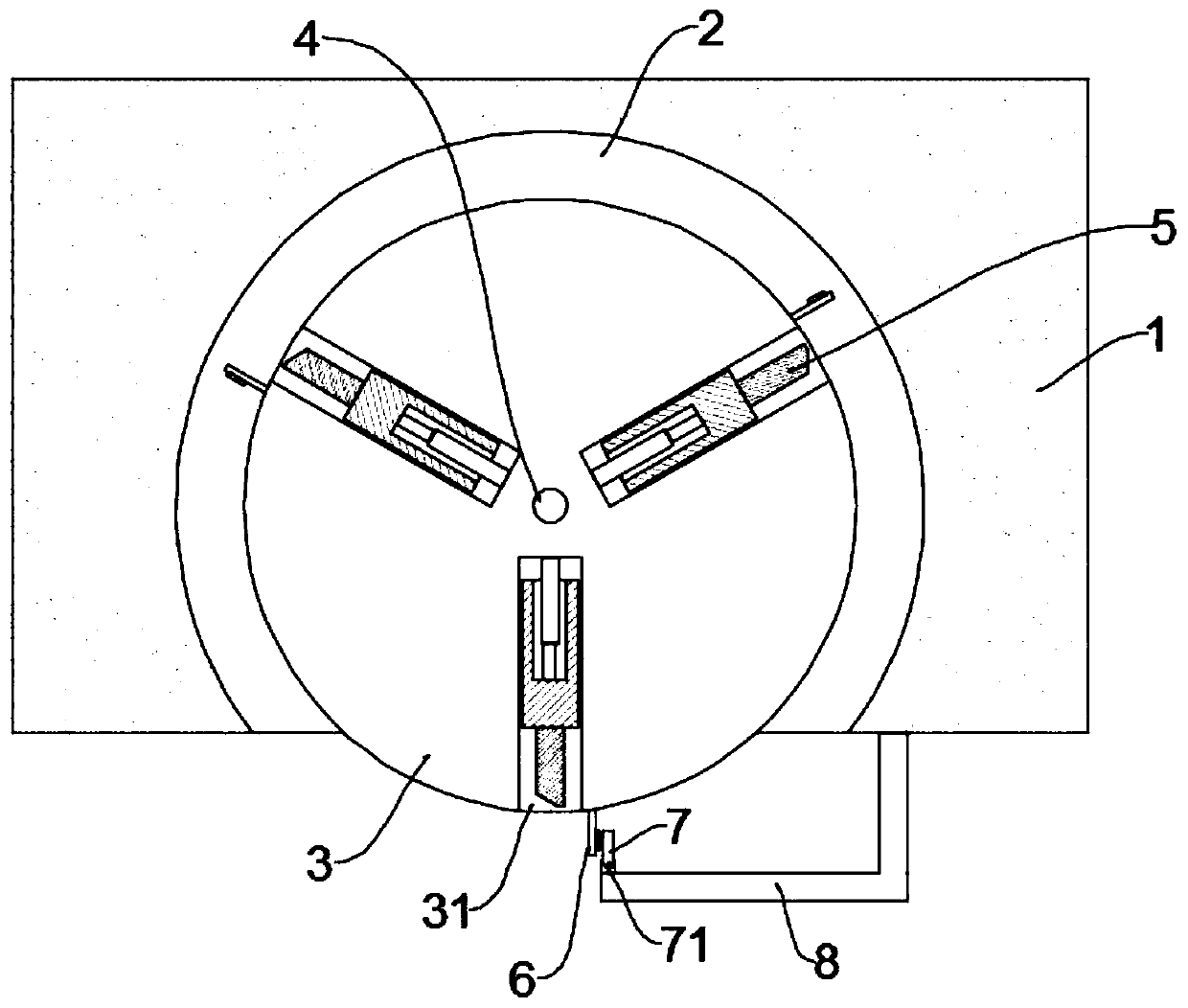

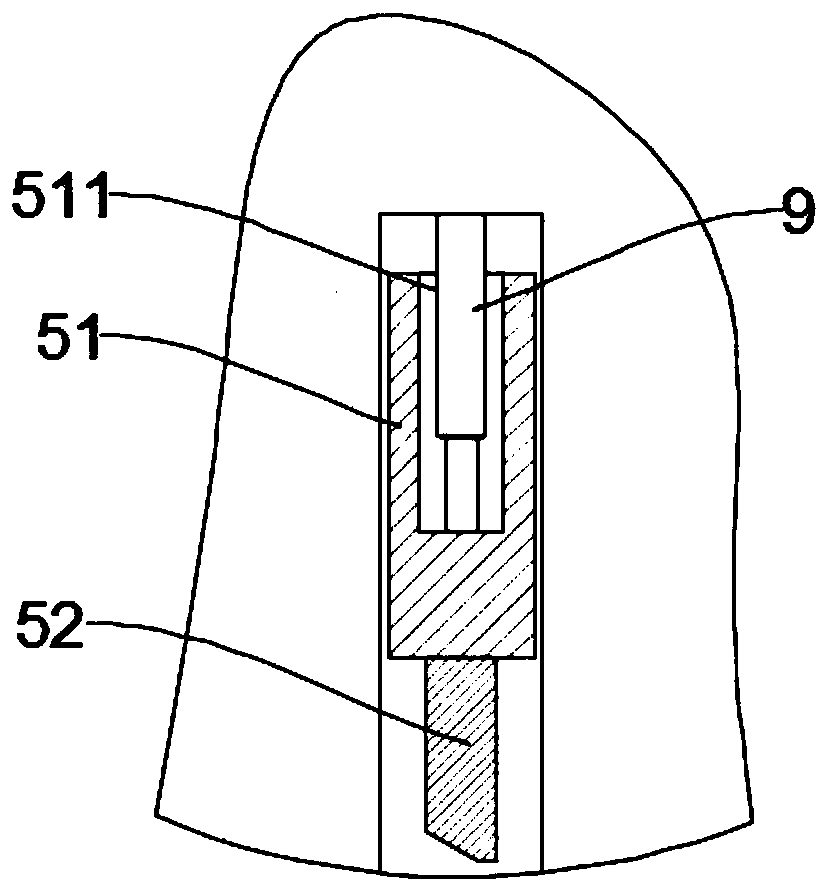

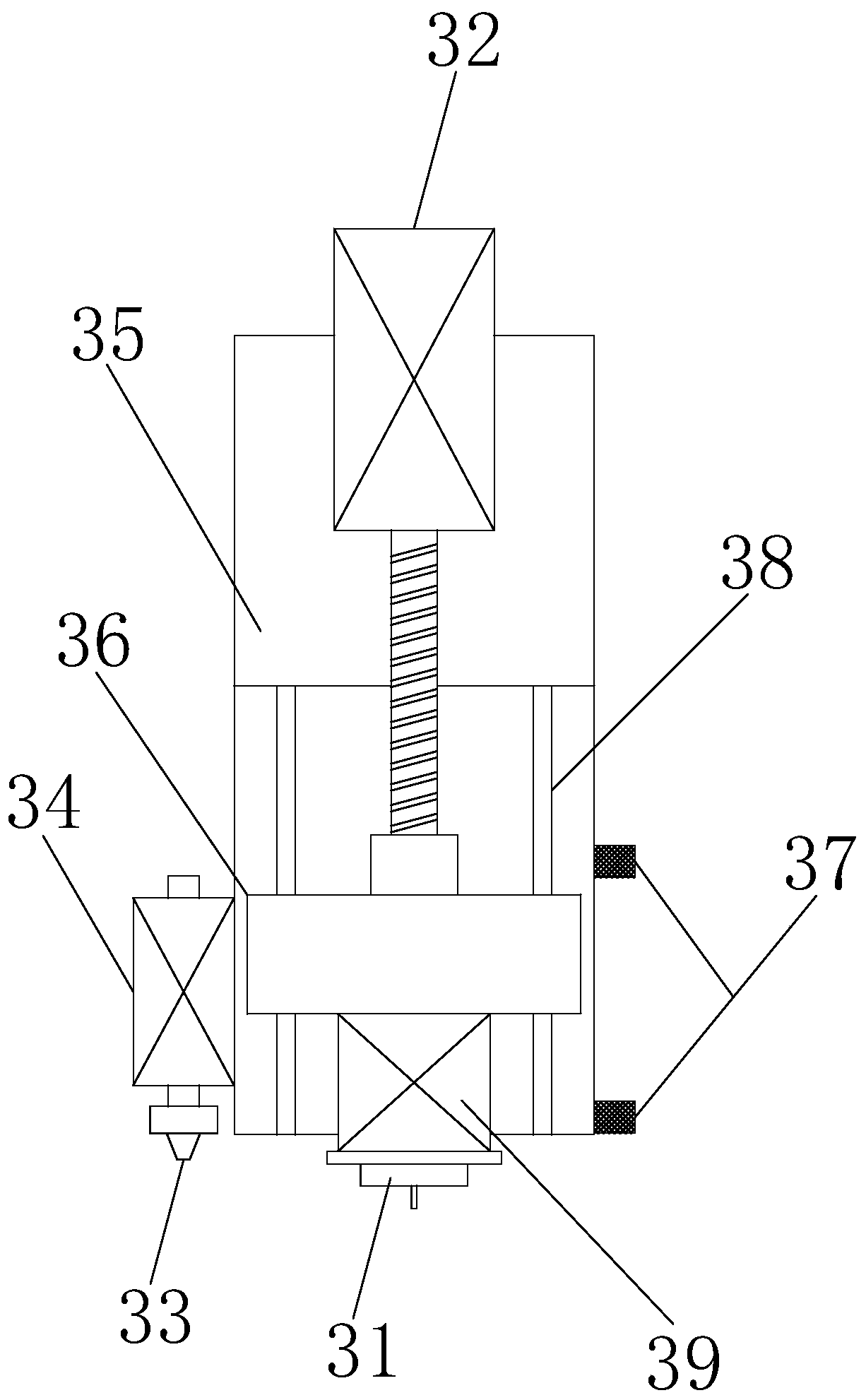

Bamboo hat-type tool magazine tool changer and control method thereof

InactiveCN106826334AHigh positioning accuracyAvoid error accumulationPositioning apparatusMetal-working holdersLocking mechanismEngineering

The invention discloses a bamboo hat-type tool magazine tool changer and a control method thereof and relates to a tool changer and a control method thereof. The tool changer comprises a cutter head, a cutter head rotating drive device and a plurality of tool posts, wherein the cutter head rotating drive device comprises a ratchet wheel and a ratchet wheel pushing and locking mechanism; the ratchet wheel is connected with the cutter head through a cutter head hub; the ratchet wheel pushing and locking mechanism comprises a drive cylinder, a piston connecting rod, a ratchet wheel pushing mechanism and a ratchet wheel locking mechanism; the piston connecting rod is connected with the ratchet wheel pushing mechanism and the ratchet wheel locking mechanism separately; and the ratchet wheel pushing mechanism and the ratchet wheel locking mechanism are connected with the ratchet wheel separately. According to the method, a PLC controls a drive cylinder piston to continuously expand and contract through an electromagnetic directional valve, a pawl continuously pushes the ratchet wheel to rotate to achieve tool changing, and meanwhile, a sheave dividing plate is locked through a locking block to achieve locking of the cutter head, so that the whole tool changing process is completed. The bamboo hat-type tool magazine tool changer has the characteristics of being high in locating accuracy, good in stability, good in reliability, simple in structure, convenient to maintain, low in cost and simple in method, and is easy to popularize and use.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH +1

Intellectual automatic tool changer speed moderating system

InactiveUS20180354085A1Improve tool change efficiencyImprove environmental safetyMeasurement/indication equipmentsTool changing apparatusComputer scienceImage capture

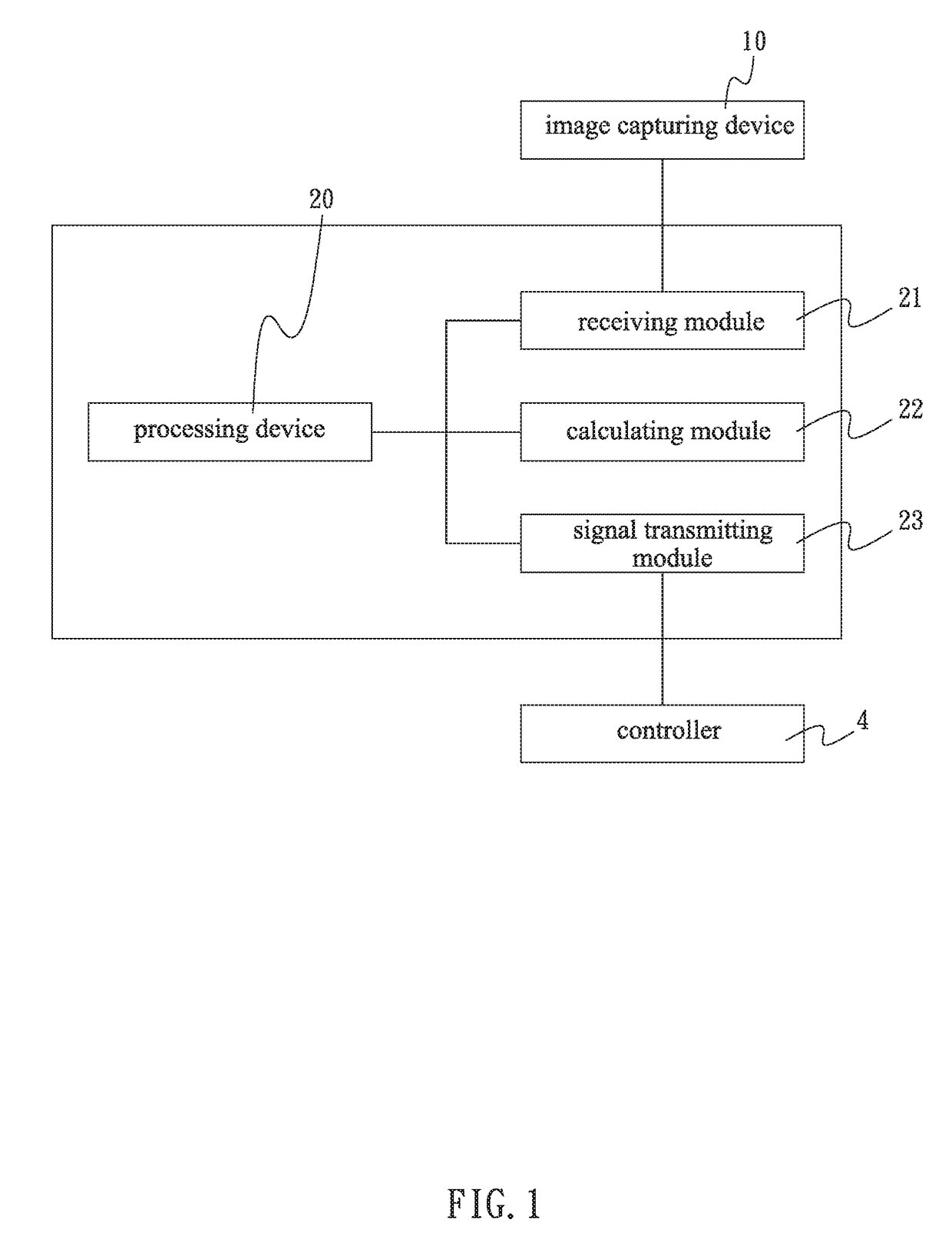

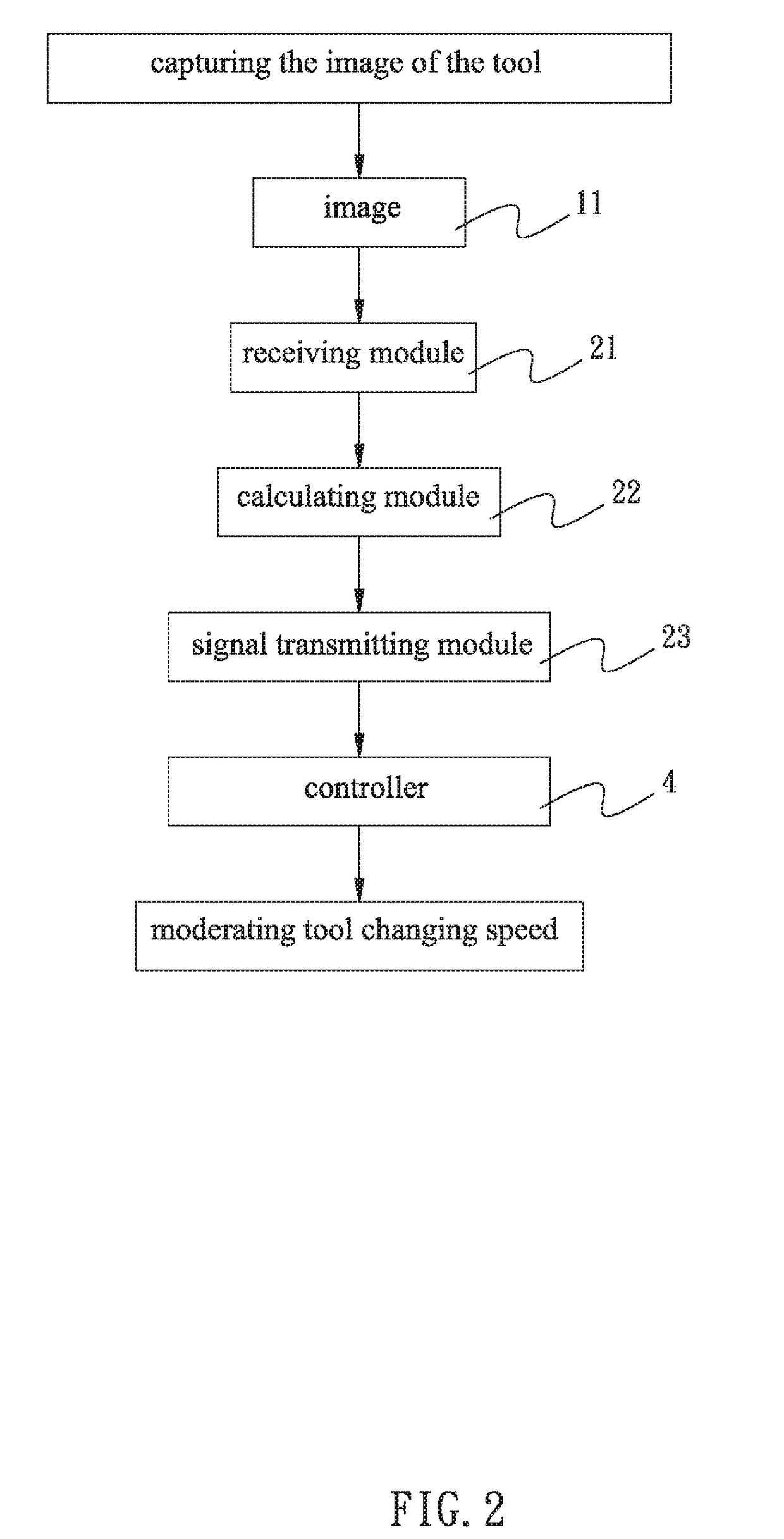

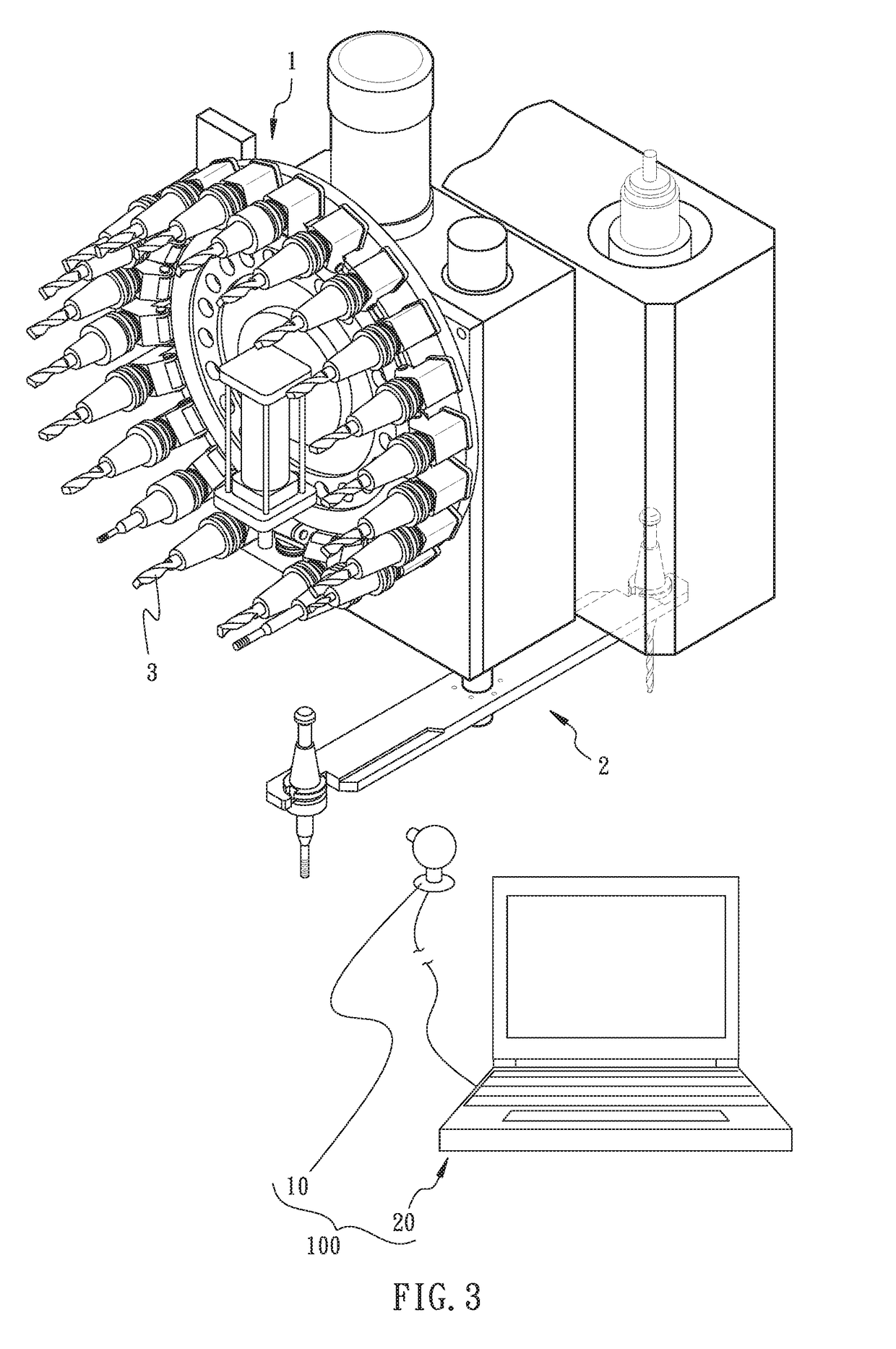

An intellectual automatic tool changer (ATC) speed moderating system, which is disposed between a tool magazine and a tool exchanging arm, includes an image capture device for capturing the image of tools, and a processing device connected with the image capturing device. The processing device includes a receiving module for receiving the images of tools, a calculating module for calculating an assessment value of a tool according to the image of the tool, and a signal transmitting module connected with a controller of the tool exchanging arm for transmitting the assessment value of the tool to the controller. Therefore, the tool changing speed of the tool changing arm is controlled and moderated.

Owner:POJU INT CO LTD

Complete-section tunnel boring machine disk cutter management method

InactiveCN101418692AExtended service lifeImprove tool change efficiencyTunnelsTunnel boring machineEngineering

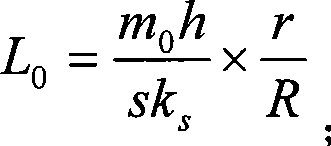

The invention belongs to the technical field of disc cutter management, and especially relates to a management method for disc cutter of full section tunnel boring machine. The method comprises the steps of (1) monitoring the service life of the disc cutter; (2) setting the limit service life value L<max> of the disc cutter and replacing the broken cutter; (3) dividing area for the cutterhead; (4) judging the unqualified cutter; and (5) replacing the unqualified cutter. The method of the invention can scientifically forecast the service life of the disc cutter, correctly forecast the cutter replacing position and cutter replacing time, and not only improves the service life and cutter replacing efficiency of the disc cutter and reduces the construction cost of the full section tunnel boring machine, but also improves the utilization ratio of the full section tunnel boring machine.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Engraving and milling machine tool with servo magazine

InactiveCN105643333ACompact structureReasonable structurePositioning apparatusMetal-working holdersEngravingMilling cutter

The invention discloses an engraving and milling machine tool with a servo magazine. The engraving and milling machine tool is characterized in that the magazine is obliquely mounted on a cutter head supporting oblique plane of a cutter head supporting seat, faces a spindle and comprises a turntable, a plurality of sets of jaw groups and shanks, the turntable is parallelly mounted on the cutter head supporting oblique plane of the cutter head supporting seat, the multiple sets of jaw groups are circularly distributed at the peripheral edge of the turntable, and the shanks with milling cutters are clamped on the jaw groups; the set of jaw groups at the lowermost end of the magazine is positioned at a horizontal location. The engraving and milling machine tool has the advantages that the magazine can easily avoid cutter shafts when rotating, the jaw groups can be horizontally shifted after the shanks are mounted on or detached from the cutter shafts in the vertical directions, accordingly, the magazine only needs to rotate on the cutter head supporting oblique plane of the cutter head supporting seat in integral cutter changing procedures and can avoid the cutter shafts without translating in the X-axis direction, cutters can be changed without large spaces, and the integral engraving and milling machine tool is compact in integral structure and small in occupied space; the integral cutter changing procedures are simple, the cutter changing time can be greatly shortened, accordingly, the engraving and milling machine tool is reasonable in structure and low in production cost, and the cutter changing efficiency can be greatly improved.

Owner:赛佳智能科技(中山)有限公司

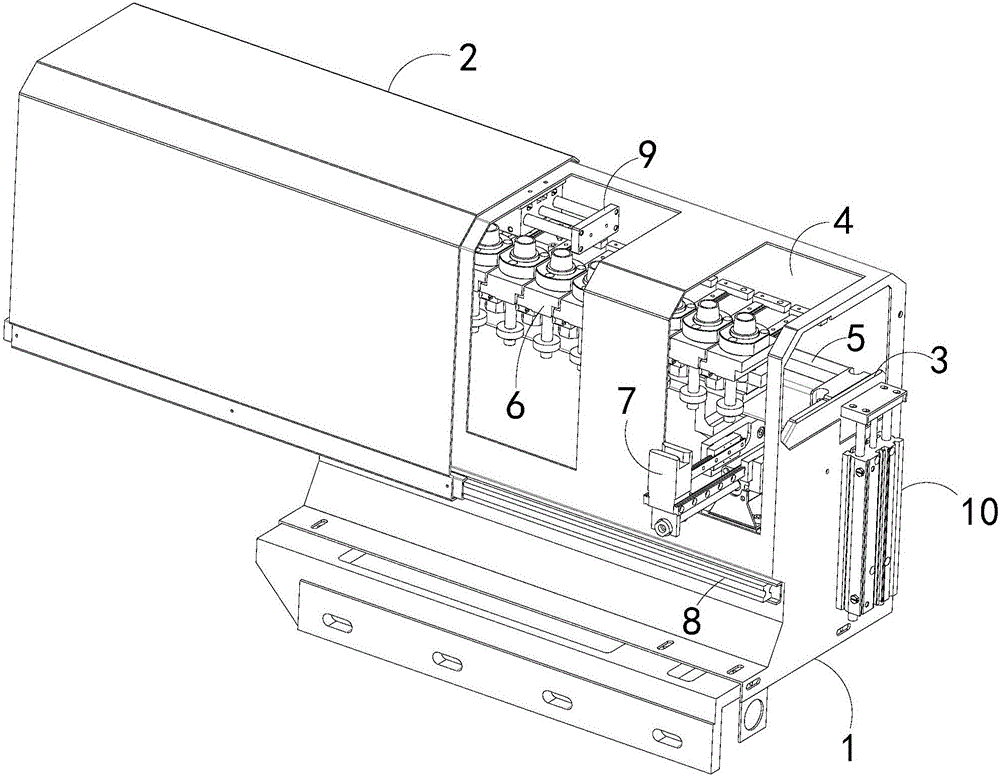

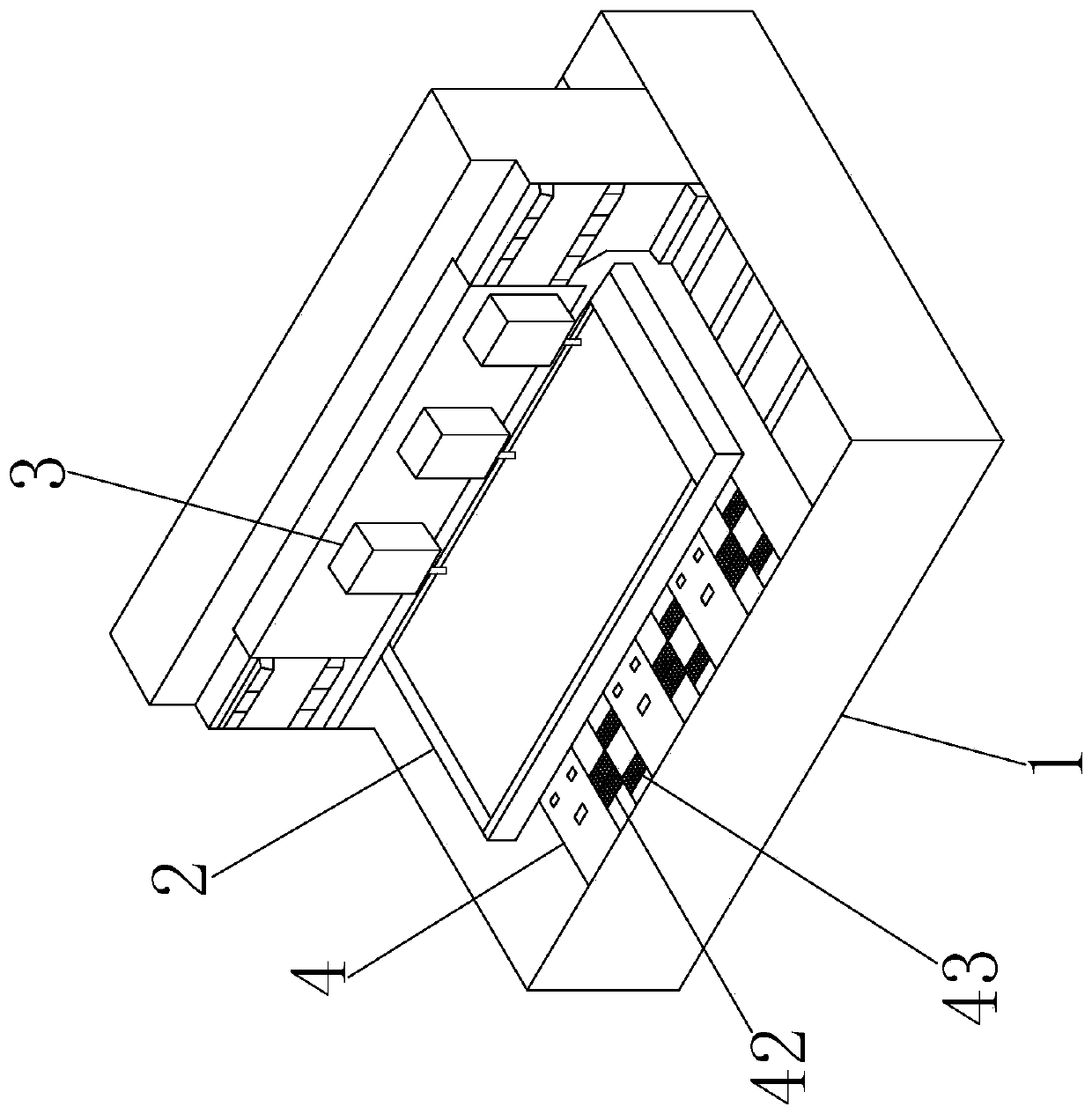

Linear type automatic tool changing device and method

ActiveCN106002425ASmall sizeReduce weightPositioning apparatusMaintainance and safety accessoriesEngineeringChange positions

The invention discloses a linear type automatic tool changing device and method. The tool changing device comprises a protection body, an upper cover plate door covering the protection body in a sliding manner, a side edge small door arranged on one side of the protection body, a rear cover plate installed on the inner side of the side, away from the upper cover plate door, of the protection body, an electric linear sliding table arranged in the protection body and used for sending to-be-replaced tools or vacant tool handle seats to tool feeding positions, a guide rail horizontal-moving tool handle seat module installed on the electric linear sliding table and a guide rail tool feeding module which is installed below the electric linear sliding table, located on the side, close to the side edge small door, of the electric linear sliding table and used for driving the tools or the vacant tool handle seats to stretch out to tool changing positions for tool changing. By means of the linear type automatic tool changing device and method, the manner with the linear movement, the compact structure and sealing metal plate protection is adopted, so that the tool changing device is a set of automatic tool changing device small in overall size, low in weight, wholly sealed and high in positioning precision.

Owner:YUANMENG PRECISION TECH SHENZHEN INST

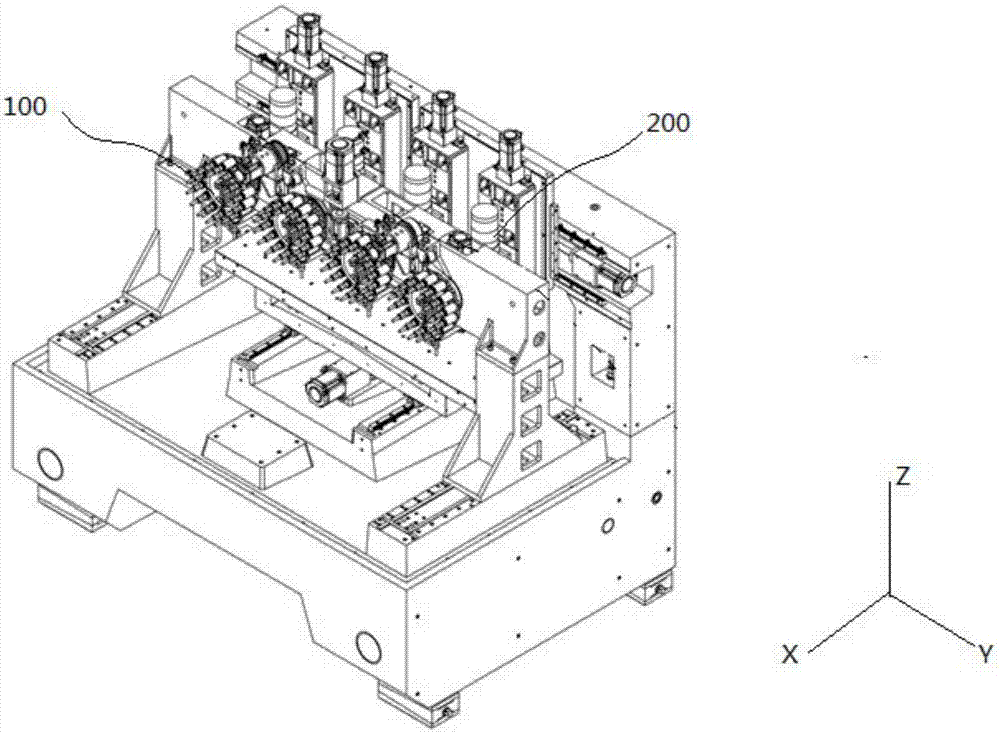

Multi-head machining center and tool changing method using multi-head machining center

InactiveCN107470957AIncrease capacityOptimize layoutPositioning apparatusMetal-working holdersTool wearEngineering

The invention discloses a multi-head machining center and a tool changing method using the multi-head machining center. The multi-head machining center comprises at least two machining machine heads, at least two tool magazines, a tool driving mechanism, at least two tool arms and a tool arm driving mechanism, wherein each tool magazine is used for changing tools with one corresponding machining machine head, and is provided with multiple tools; all the tools are mounted on the tool magazines in the peripheral direction; the tool driving mechanism is used for driving each tool to move to a tool changing fixed point in the peripheral direction; two ends of the tool arms can respectively hold the tools to be changed of the machining machine heads and preset tools of the tool magazines; and the tool arm driving mechanism is used for driving the tool arms to rotate to enable two ends of each tool arm to respectively take the preset tools and the tools to be changed from the tool magazines and the machining machine heads and respectively charging the preset tools and the tools to be changed in the tool magazines and the machining machine heads. The multi-head machining center realizes the tool arrangement of multiple tool magazines cooperating with multiple tools, improves the capacity of the tool magazines, optimizes overall layout thereof, reduces the size thereof, and improves the tool changing efficiency.

Owner:SUZHOU GFD AUTOMATION TECH

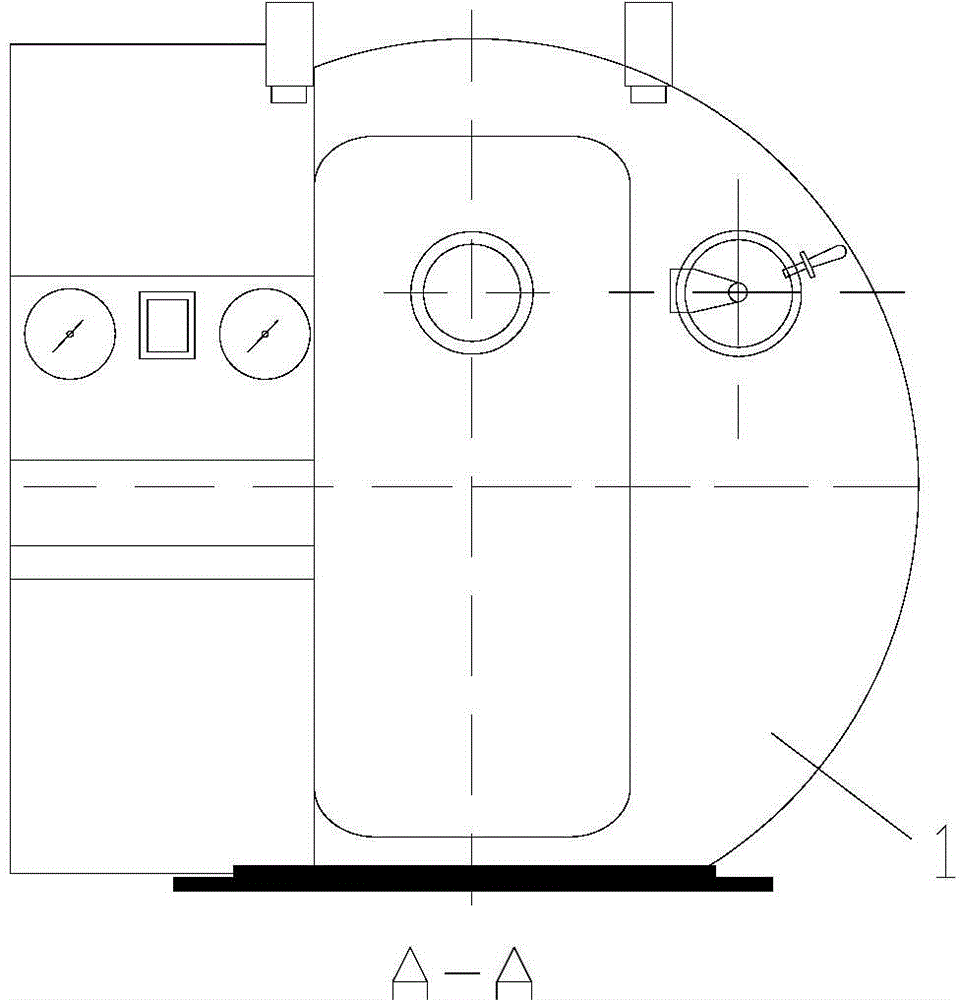

Saturation open cabin operation method and saturation open cabin operation equipment under shielding pneumatic conditions

InactiveCN103821526AReduce personal injuryEliminate the effects of inefficienciesTunnelsSafety equipmentsControl theoryCompressed air

The invention discloses a saturation open cabin operation method and saturation open cabin operation equipment under shielding pneumatic conditions. According to the technical scheme, the saturation open cabin operation method and the saturation open cabin operation equipment have the advantages that the highest born pressure can reach 20bar, decompression can be omitted during operation in each shift, the influence of low efficiency due to decompression in an operation method implemented by means of filling compressed air in cabins in the prior art can be eliminated, and the tool changing efficiency can be greatly improved; operators do not need to be repeatedly decompressed, and accordingly personal injury to the workers can be greatly relieved.

Owner:CCCC TUNNEL ENG

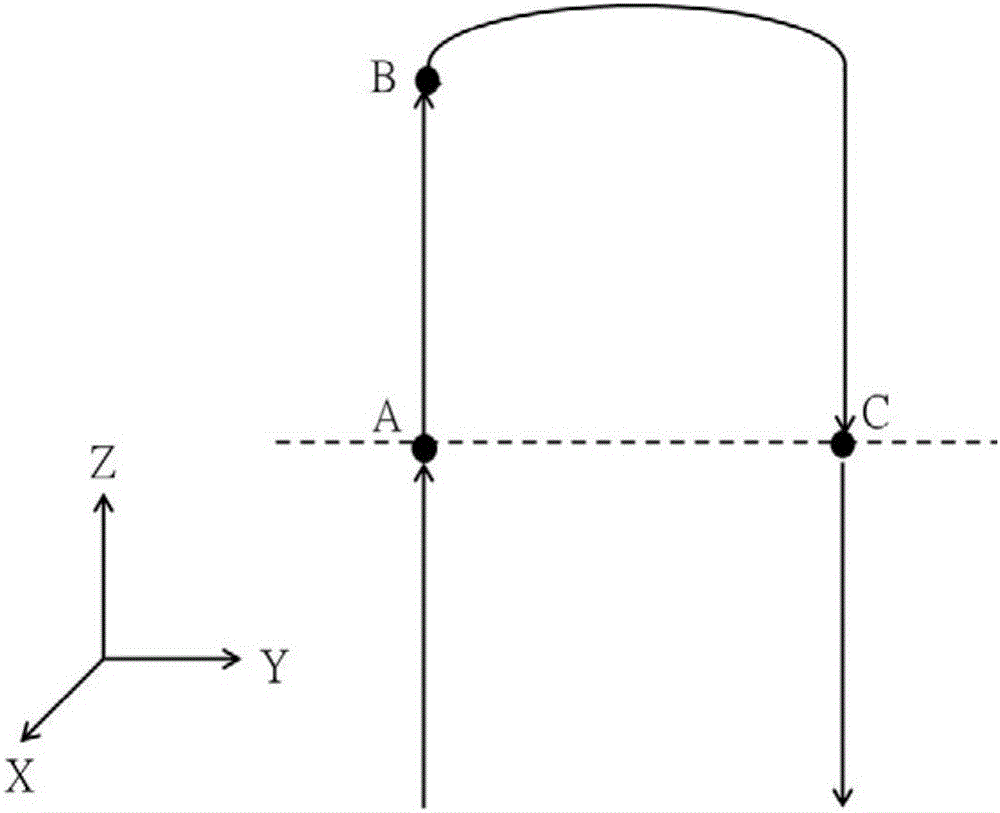

Machine tool

ActiveCN102729083AReduce tool change timeWill not impose a burdenAutomatic control devicesPrecision positioning equipmentProduction rateEngineering

The present invention provides a machine tool capable of shortening tool changing time and increasing machining production rate. When the machine tool begins to change a tool, a main shaft directionally motions; a main shaft head rises from a machining position to a Z-axis original point with a Z-axis highest speed (S11); when the main shaft finishes the directional motion (S12: YES), the main shaft head rises from the Z-axis original point to an ATC original point with a Z-axis ATC rising speed (S13); when the main shaft head arrives the ATC original point (Z615) (S13), a tool changer performs driving; the tool changer rotates to position the next tool (S14); then the main shaft head decreases from the ATC original point to the Z-axis original point (S15) with a speed same as the A-axis highest speed; and then, the main shaft head decreases from the Z-axis original point to the machining starting position of a workpiece to be machined with a Z-axis highest speed (S16). The machine tool uses a tool to perform machining on the workpiece to be machined.

Owner:BROTHER KOGYO KK

Automatic tool changing vertical machine tool and continuous machining method thereof

PendingCN108655798ARealize automatic tool change processIncrease productivityPositioning apparatusMetal-working holdersEngineeringDrive motor

The invention discloses an automatic tool changing vertical machine tool and a continuous machining method of the automatic tool changing vertical machine tool. The automatic tool changing vertical machine tool comprises a workbench, a slide saddle and a base, wherein the workbench, the slide saddle and the base are arranged from top to bottom in sequence. One side of the base is provided with a bracket arranging a main shaft to the workbench in an erecting manner, the bracket is provided with a fixing frame, the fixing frame is provided with a disc tool changer, and a tool changing device isarranged between the disc tool changer and the main shaft. The tool changing device comprises a tool changing drive motor and a lifting drive piece, wherein the tool changing drive motor is arranged on a tool changing rod and drives the tool changing rod to rotate, and the lifting drive piece drives the tool changing rod to move up and down. The middle of the tool changing rod is fixedly connectedwith the drive end of the lifting drive piece. The two ends of the tool changing rod are provided with C-shaped clamping slots for clamping tools, and the clamping slots are internally provided withjacking rods driven by clamping air cylinders. The automatic tool changing vertical machine tool is reasonable in structure, through the disc tool changer and the tool changing device, the automatic tool changing process of the vertical machine tool is realized, and the production efficiency of the machine tool is greatly improved; and through the clamping slots in the two ends of the tool changing rod, the tool at a tool changing opening and the tool in the main shaft are clamped rapidly, and the tool changing efficiency is improved.

Owner:东莞市同振五金机械有限公司

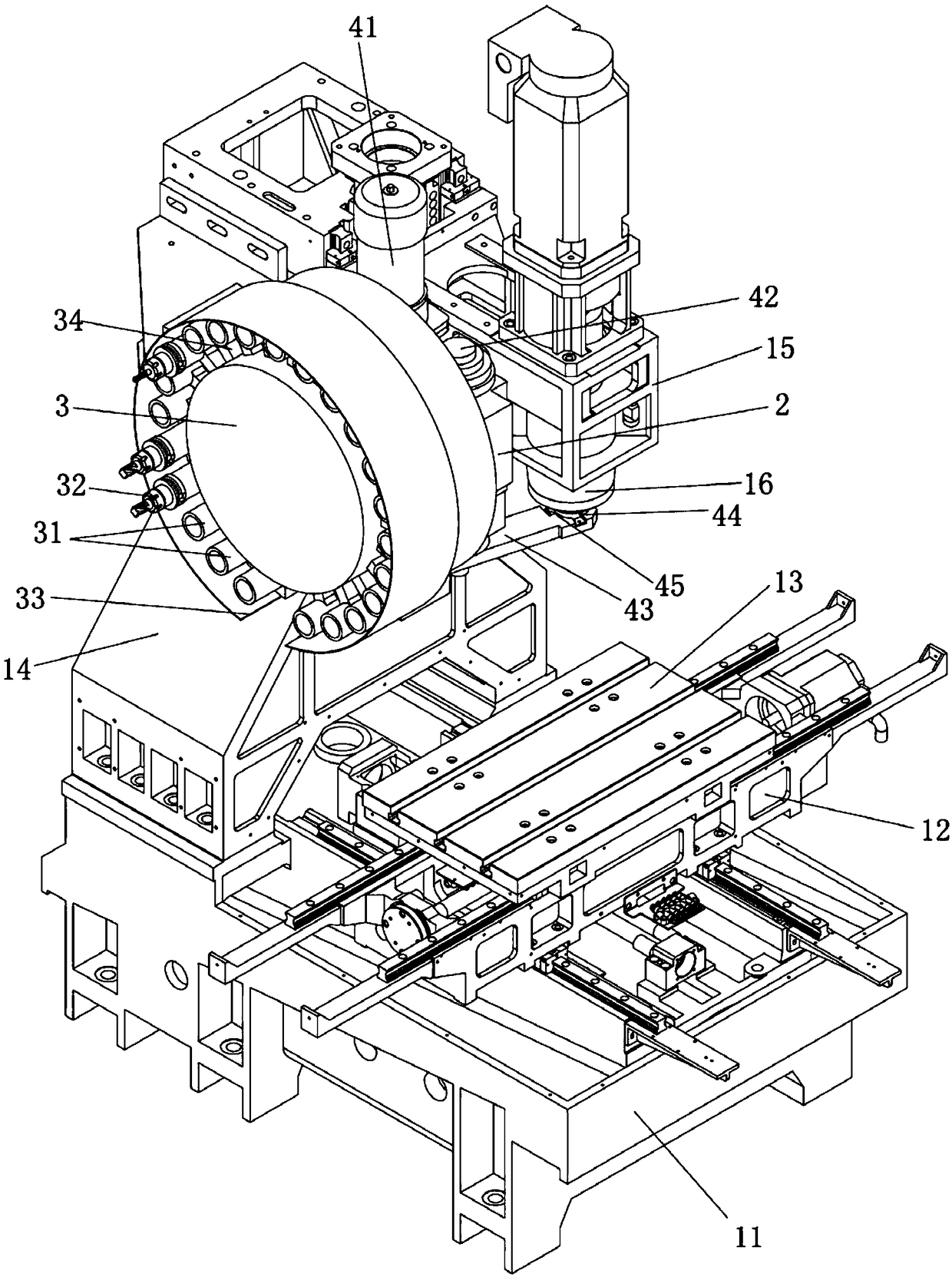

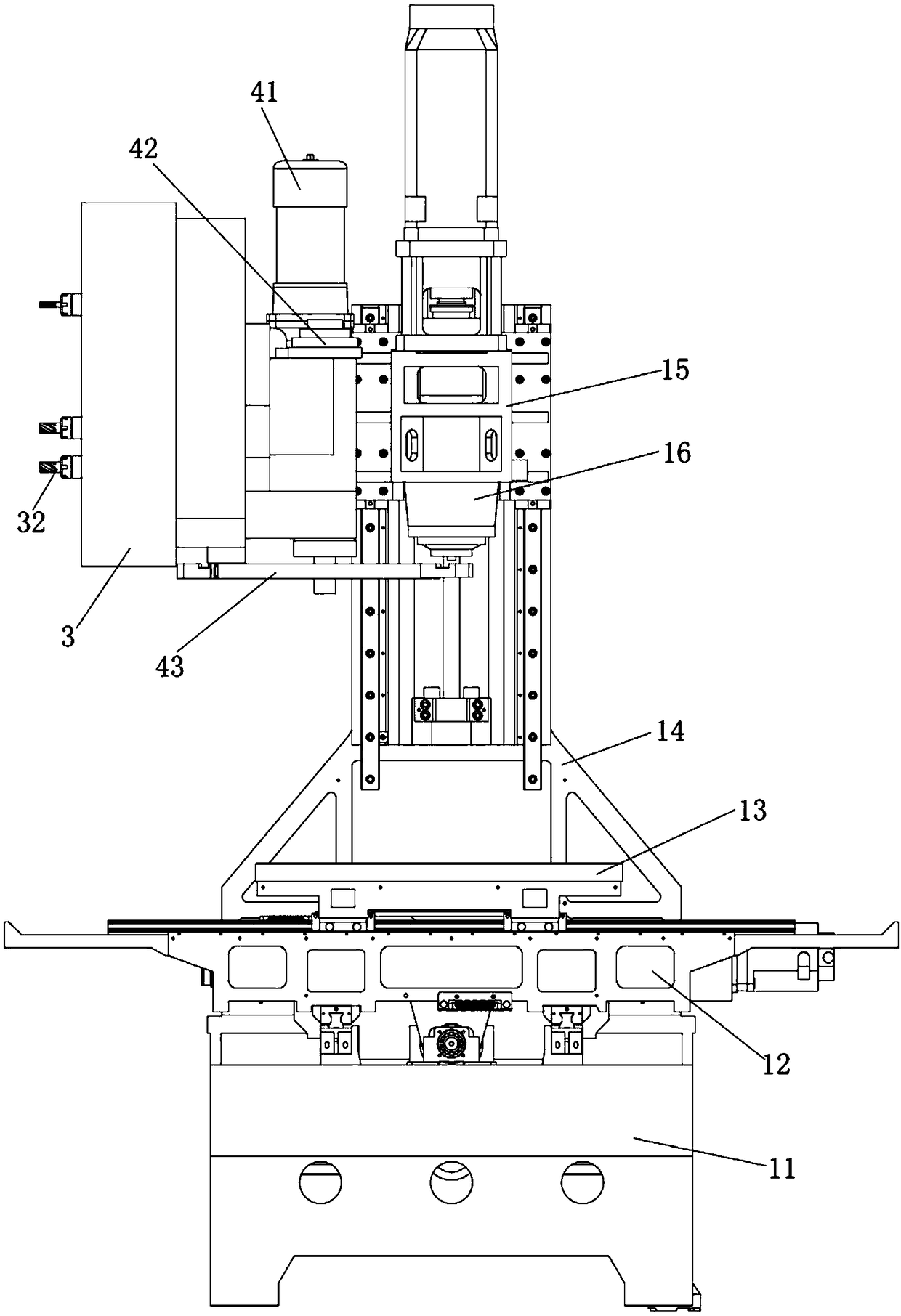

Horizontal machining center and umbrella-shaped tool magazine

PendingCN108637763AImprove tool change efficiencyPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses an umbrella-shaped tool magazine of a horizontal machining center. The tool magazine comprises a mounting frame arranged on the horizontal machining center, and a first tool magazine body and a second tool magazine body which are arranged on the mounting frame and are of the same structure. The first tool magazine body comprises a tool magazine support, a tool disc, a sliding mechanism and a rotating mechanism, wherein the tool magazine support comprises a base plate connected with the mounting frame and a connecting component arranged on the base plate; the sliding mechanism comprises a first slide rail arranged between the base plate and the connecting component and a first drive component driving the connecting component to slide along the first slide rail; the tool disc is arranged on the connecting component, and tool clamps used for fixing tools are further arranged at the outer edge of the tool disc; and the rotating mechanism is arranged on the connecting component, connected with the tool disc and used for driving the tool disc to rotate. According to the umbrella-shaped tool magazine, by arranging the tool magazine supports on a machine tool and arranging the tool discs, the sliding mechanisms and the rotating mechanisms on the tool magazine supports, the sliding mechanisms drive the tool discs to stretch and retract, the rotating mechanisms drive the tool discs to rotate so as to implement tool changing action, and therefore, the tool changing efficiency is improved.

Owner:SHENZHEN CREATE CENTURY MACHINERY

Highlight face milling cutterhead and highlight face milling cutter

ActiveCN105772820AImprove the knife patternGood highlight effectMilling cuttersMilling cutterEngineering

The invention discloses a highlight face milling cutterhead. The highlight face milling cutterhead comprises a face milling cutterhead body, two rotating plates, two milling cutters and a cover plate. Two circular grooves are symmetrically distributed in the end face of the face milling cutterhead body. Each rotating plate is installed in one circular groove and provided with a milling cutter installation groove. Each milling cutter comprises a milling cutter handle and a milling cutter head arranged at one end of the milling cutter handle. The milling cutter handles of the milling cutters are fixedly installed in the milling cutter installation grooves. The milling cutter head of each milling cutter sequentially penetrates a second notch and a first notch and extends outwards, wherein the second notch and the first notch correspond to the milling cutter head. The cover plate is fixedly connected with the end face of the face milling cutterhead body. The invention further discloses a highlight face milling cutter. By means of the highlight face milling cutterhead and the highlight face milling cutter, the highlight effect of products can be improved, the mirror surface effect that Ra is smaller than or equal to 25 nm is achieved, and cutter patterns are eliminated; and an upper chamfer and a lower chamfer can be machined at the same time, the machining efficiency is improved, the balance performance of the whole cutterhead can be effectively ensured, and the subsequent balancing difficulty is lowered.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

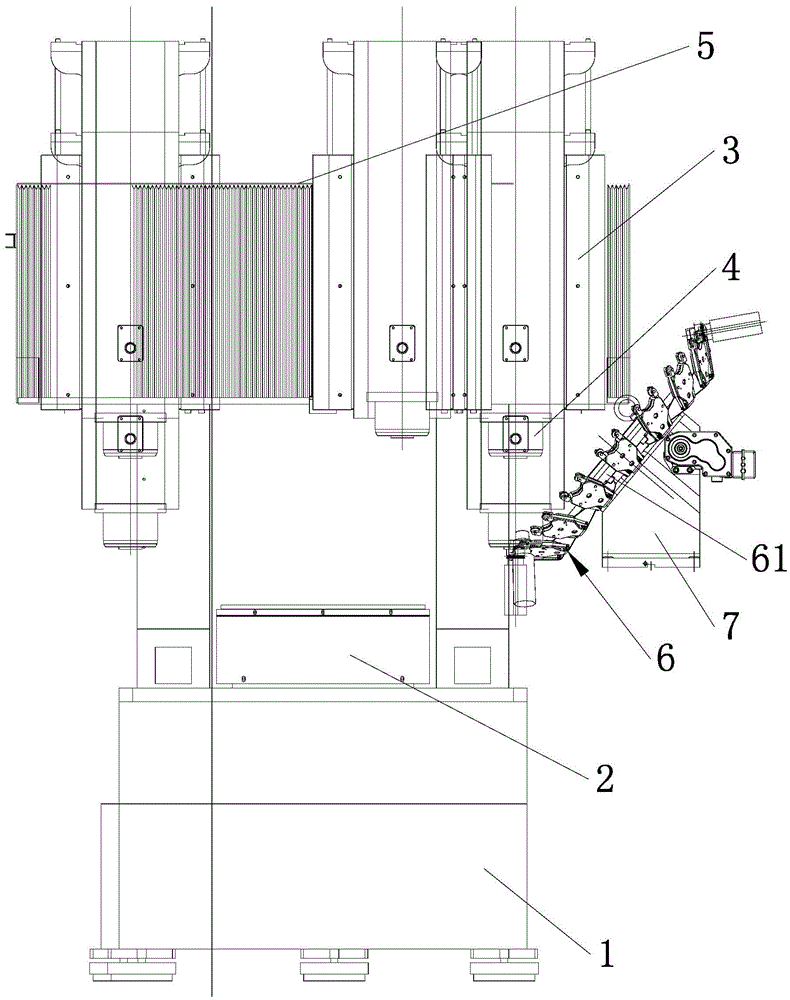

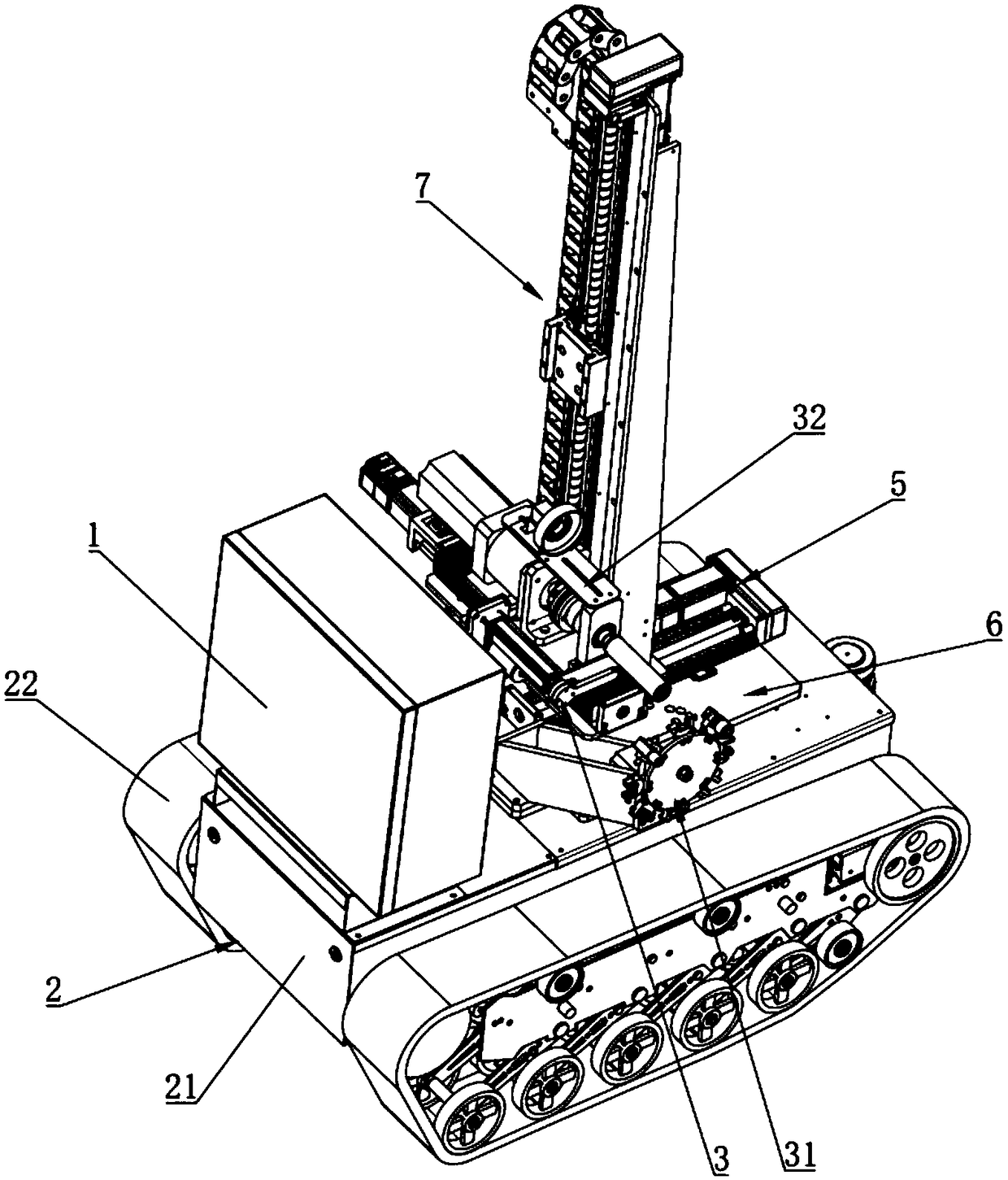

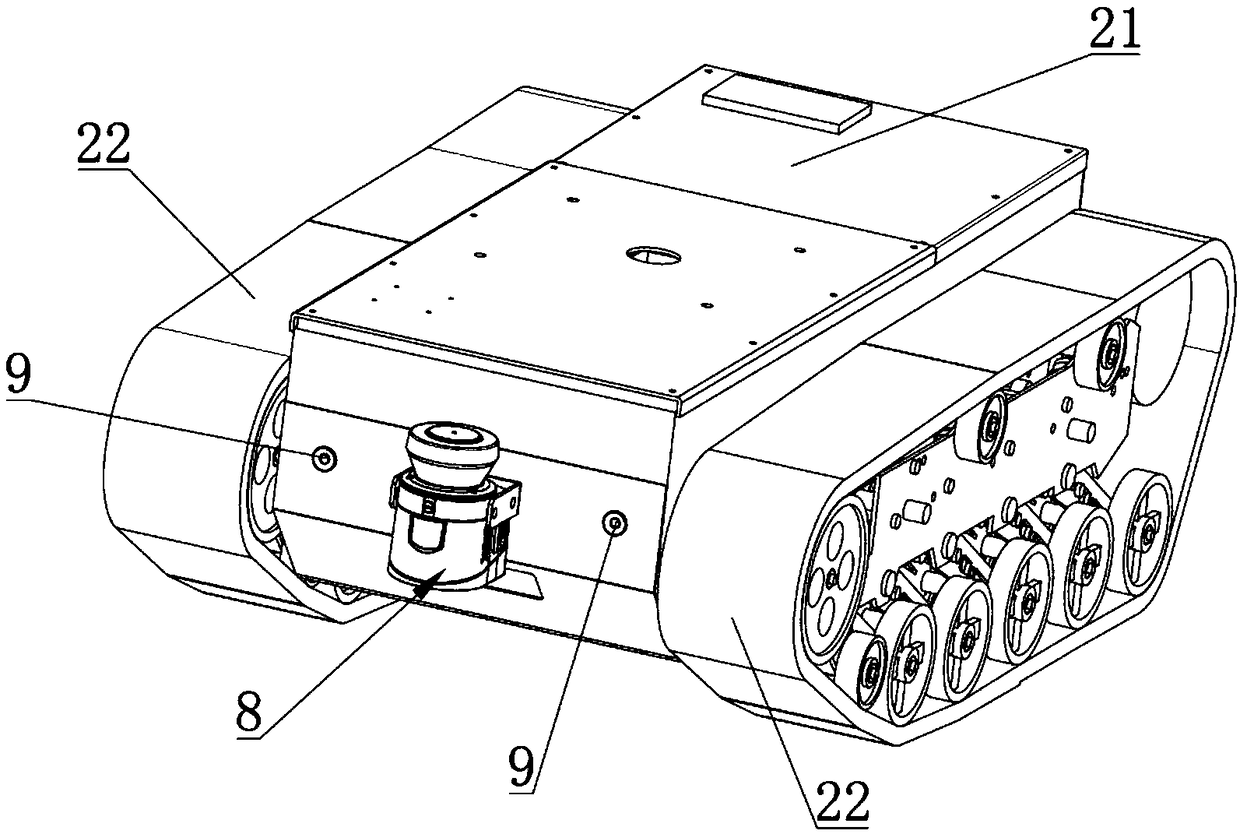

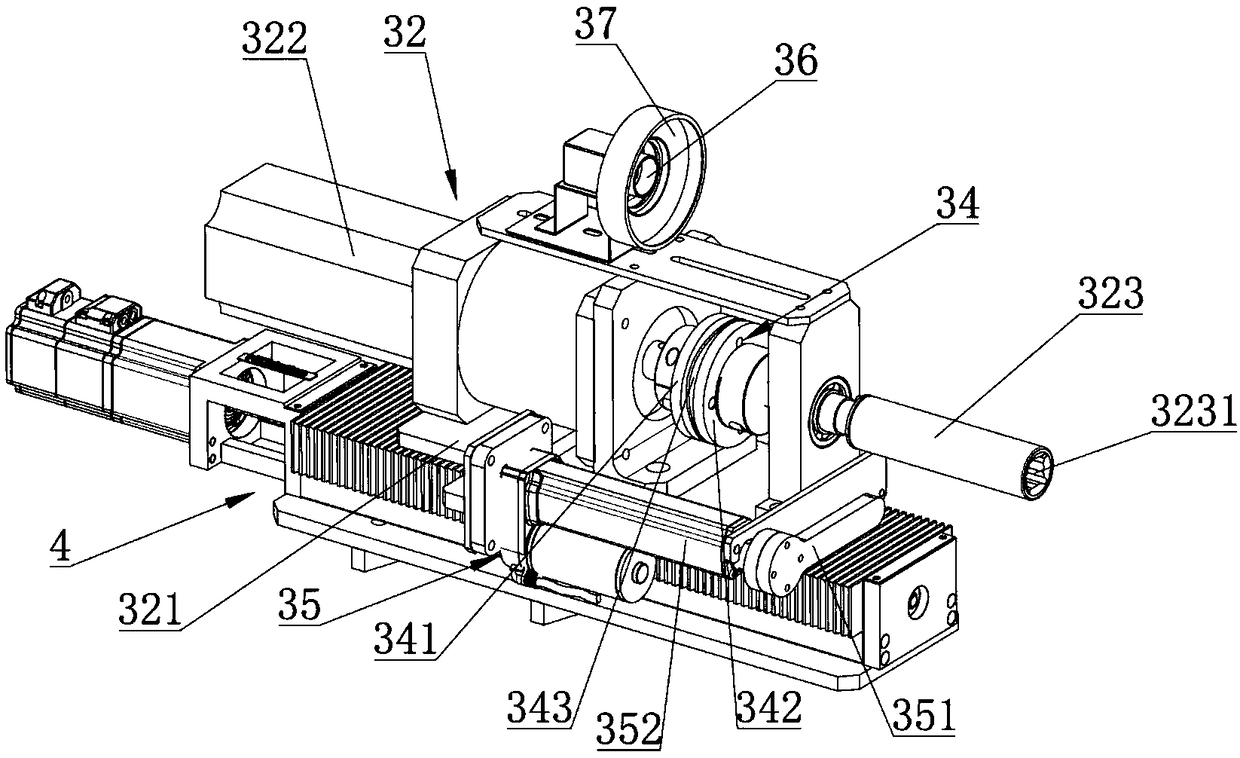

Power distribution switchgear auxiliary operation robot

PendingCN109202851ACompact structureSmall footprintProgramme-controlled manipulatorGripping headsElectricitySwitchgear

The present invention relates to the technical field of power distribution switchgear operation and more particularly to a power distribution switchgear auxiliary operation robot. The robot comprisesa control device and also comprises a moving device, an operation device, an X-axis moving device, a Y-axis moving device, a rotation seat and a Z-axis moving device electrically connected to the control device. The operation device comprises a tool change assembly and an operation assembly, and the operation assembly comprises an X-axis moving seat, a clamp rotating unit and an operating clamp. The operating clamp is connected to a power output end of the clamp rotating unit, and the clamp rotating unit is connected to the X-axis moving device through the X-axis moving base to move along an X-axis direction. The tool change assembly includes a tool change driving unit, a support frame and a tool change disc. A first end of the support frame is fixed to the moving device, the tool change driving unit and the tool change disc are installed on a second end of the support frame, and the tool change driving unit is connected to the tool change disc to rotate the tool change disc for the operating clamp to change a tool. According to the power distribution switchgear auxiliary operation robot, the efficiency of the operation of a power distribution switchgear is effectively improved.

Owner:广东省机器人创新中心有限公司

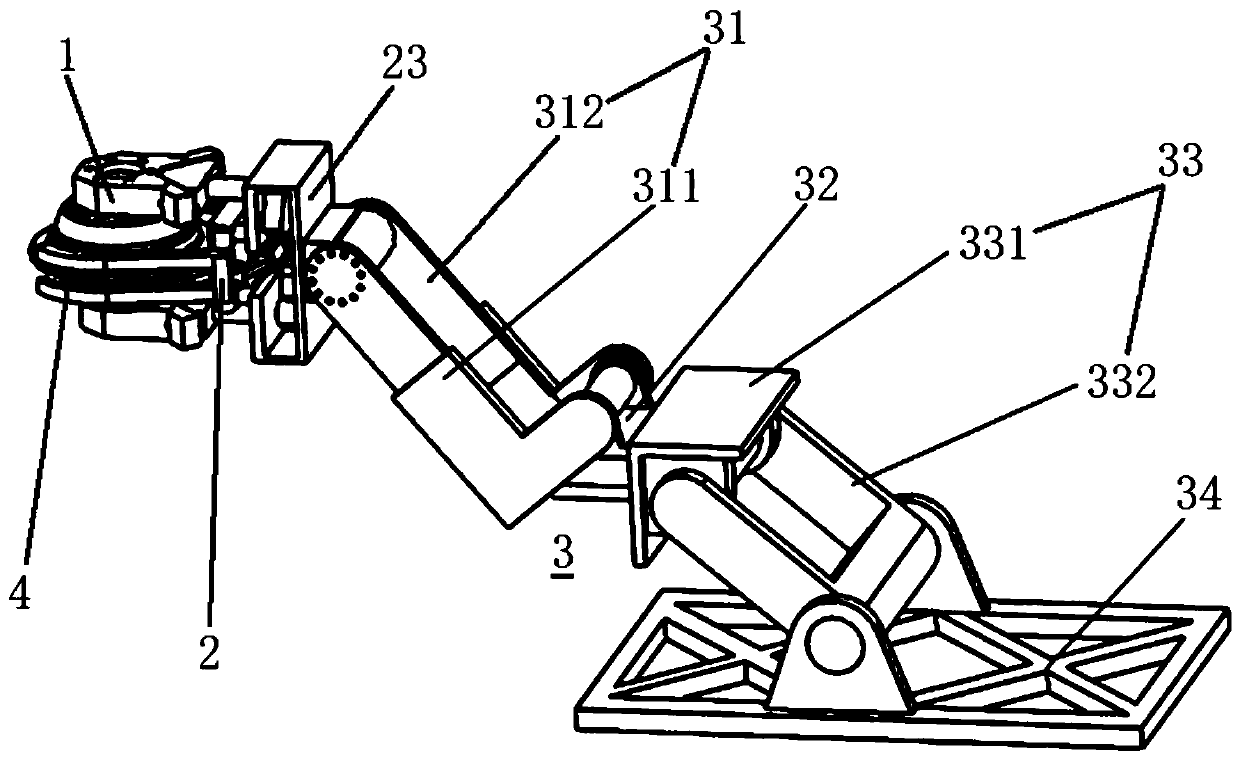

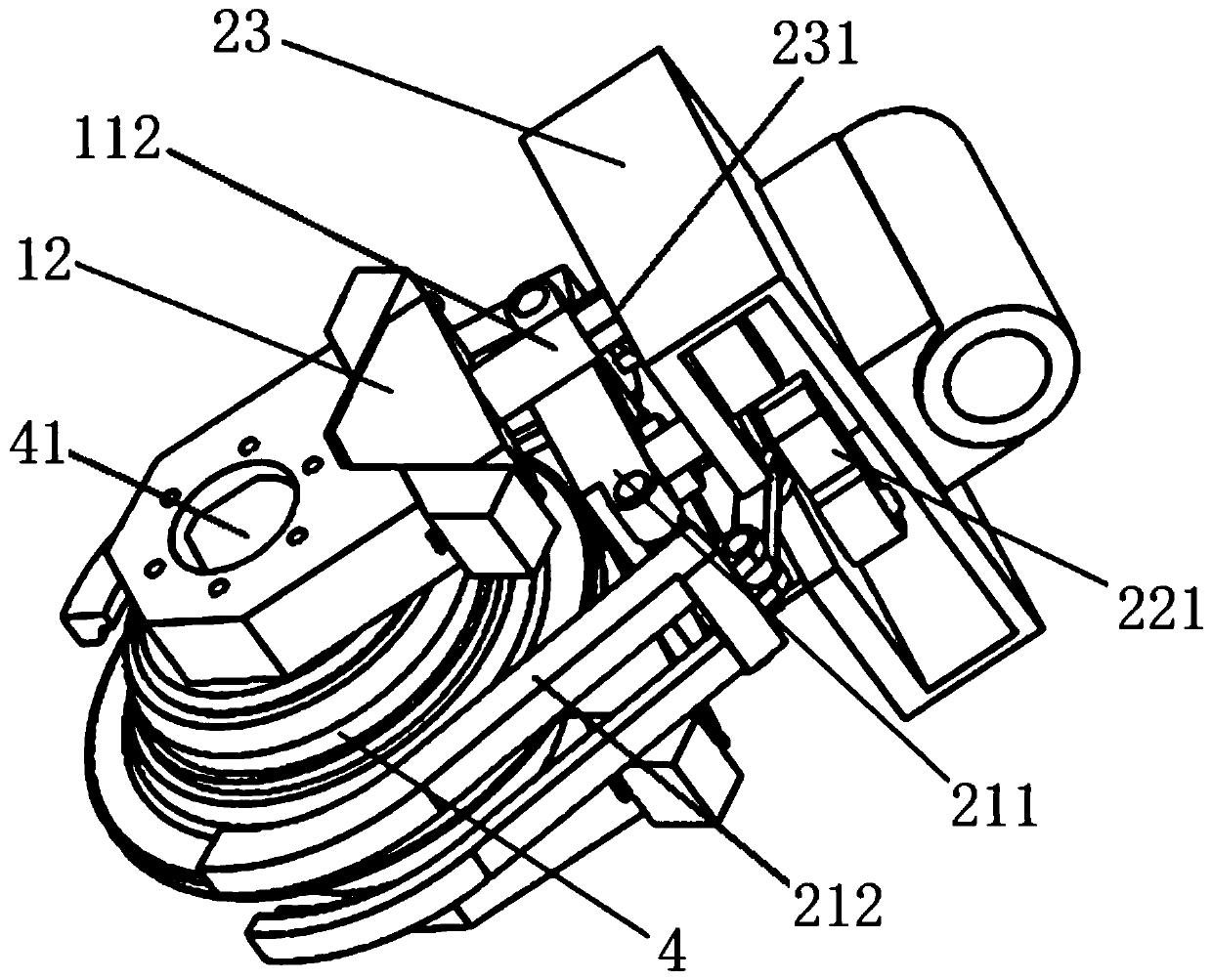

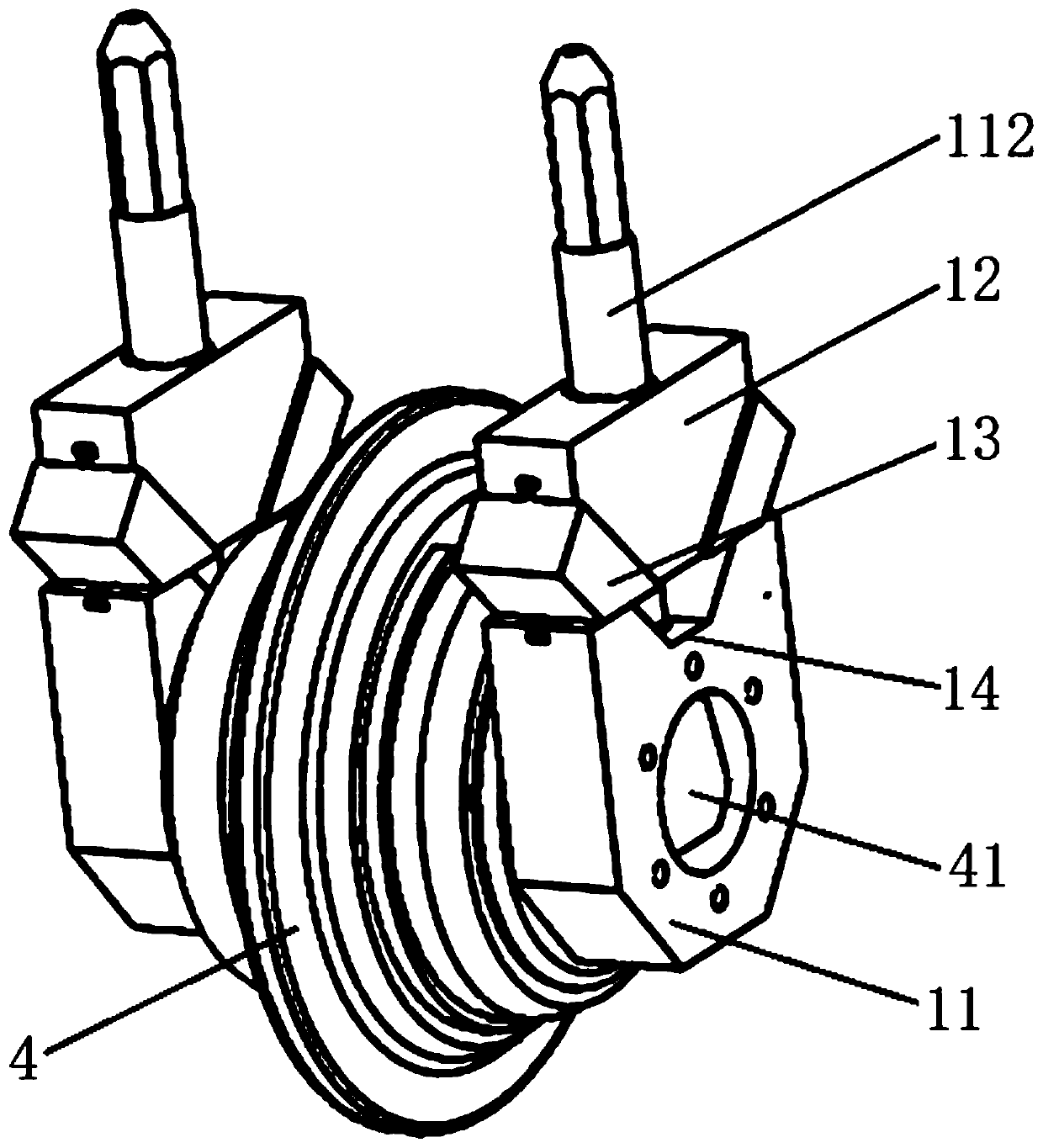

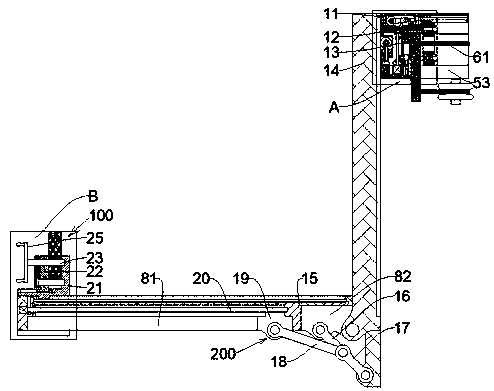

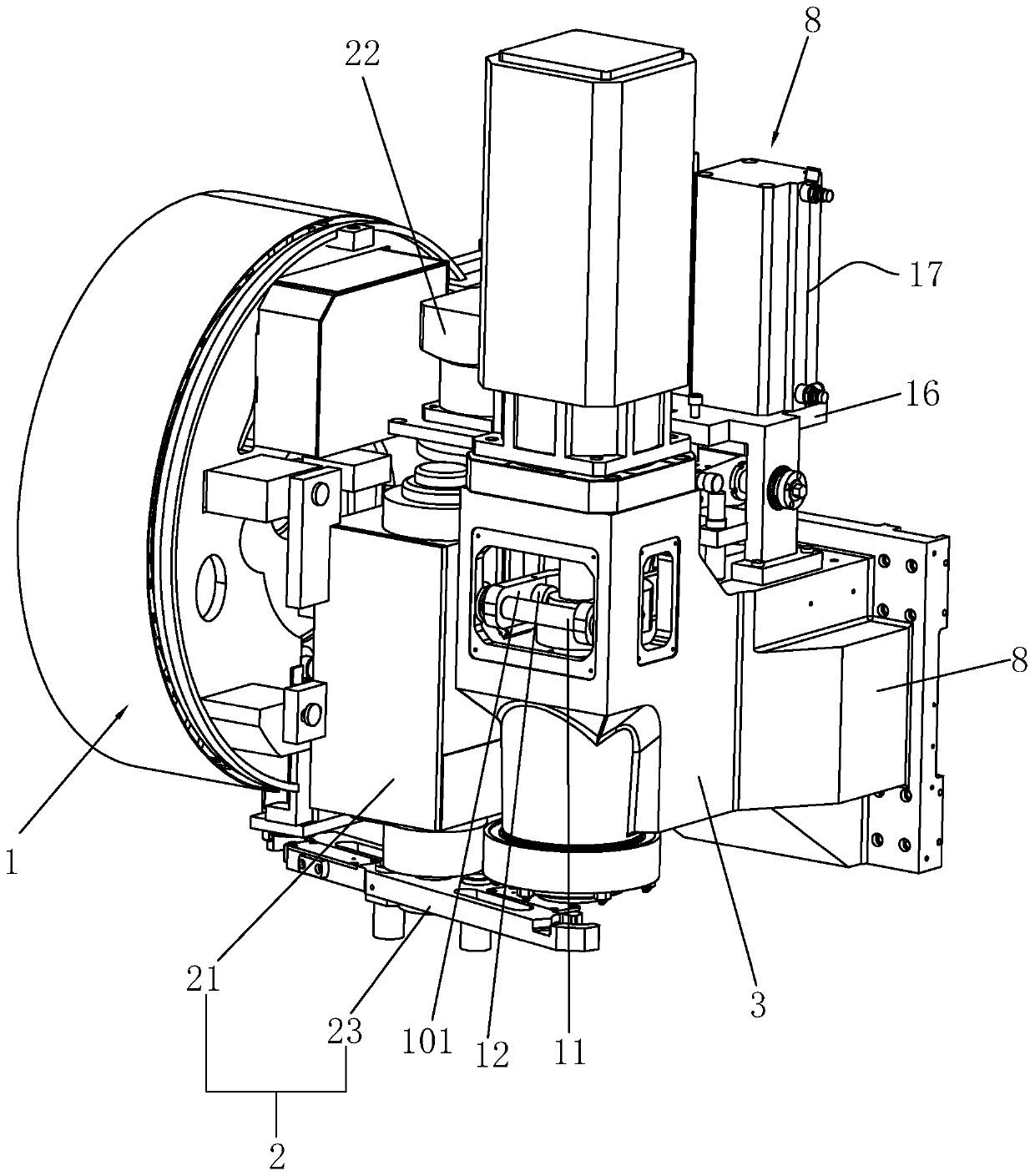

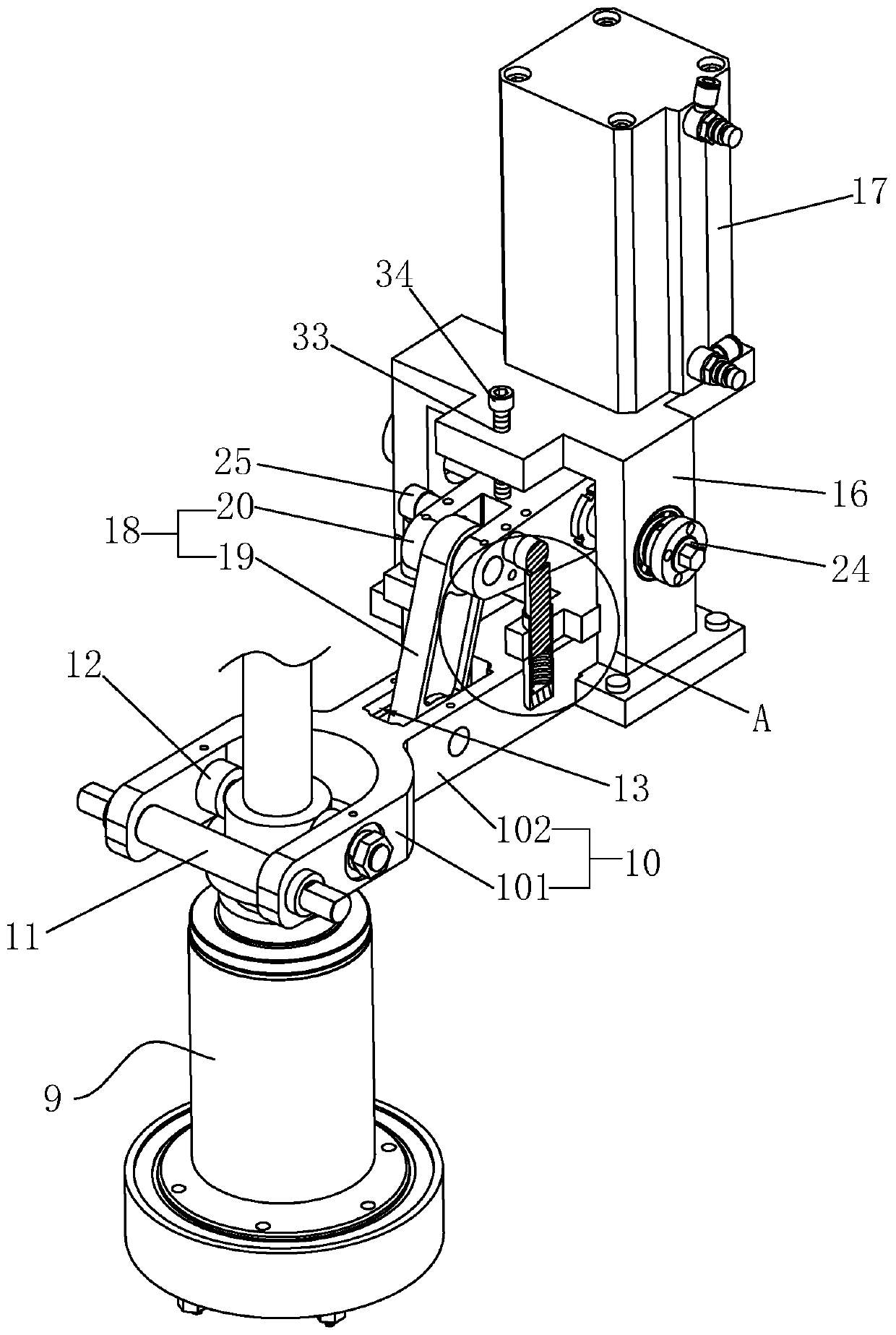

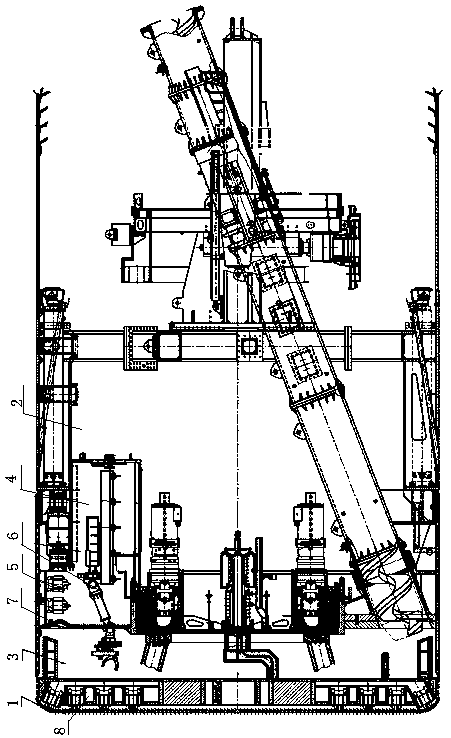

Cutter changing robot execution mechanism suitable for shield

ActiveCN111468932ARealize machine tool change operationImprove construction efficiencyProgramme-controlled manipulatorGripping headsHobbingRobot hand

The invention provides a cutter changing robot execution mechanism suitable for a shield. The cutter changing robot execution mechanism comprises a hobbing cutter dismounting and mounting mechanism, acutter changing mechanical arm and an action execution mechanism. The hobbing cutter dismounting and mounting mechanism is connected with a hobbing cutter and meanwhile is detachably connected with acutter box on a cutter disc of a shield tunneling machine. The cutter changing mechanical arm is arranged at the execution end of the action execution mechanism, the state of the hobbing cutter dismounting and mounting mechanism can be switched, so that the hobbing cutter dismounting and mounting mechanism and the cutter box are locked or loosened, meanwhile, the cutter changing mechanical arm can clamp the whole hobbing cutter and hobbing cutter dismounting and mounting mechanism, and movement along the cutter changing path is achieved through drive of the multi-freedom-degree action execution mechanism. According to the cutter changing robot execution mechanism, machine cutter changing work of the shield narrow space is achieved, dismounting, mounting and changing of the hobbing cutterof the total disc face of the cutter disc can be completed, traditional manual tool changing is completely replaced, the cutter changing efficiency and the shield overall construction efficiency are improved, and safety of shield construction is guaranteed.

Owner:CENT SOUTH UNIV +1

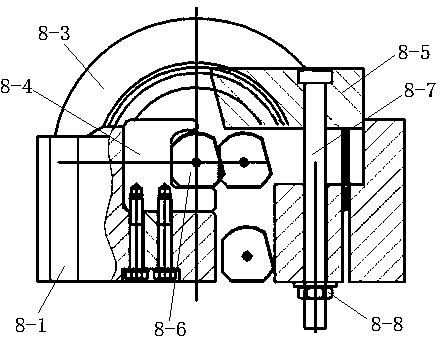

A shield machine hob automatic replacement device

ActiveCN110064908BAvoid homeworkEnsure physical safetyMetal working apparatusTunnelsHobbingShield tunneling

The invention discloses an automatic replacing device for a hobbing cutter of a shield tunneling machine. The automatic replacing device comprises a main board, wherein a slide slot is formed in the main board; a fixed plate capable of sliding is arranged in the slide slot; a fixing device for fixing equipment is arranged in the fixed plate; a folding slot is formed in the bottom wall of the slideslot; and a slide block capable of sliding is arranged in the folding slot. The automatic replacing device is simple in structure, is convenient in operation, is convenient in maintenance, can automatically replace the hobbing cutter, prevents staff from operating under an environment higher than barometric pressure, guarantees body safety of staff, reduces labor intensity of a worker, improves cutter replacing efficiency of the shield tunneling machine, and has a relatively high use and popularization value.

Owner:湖北神龙市政建设工程有限公司

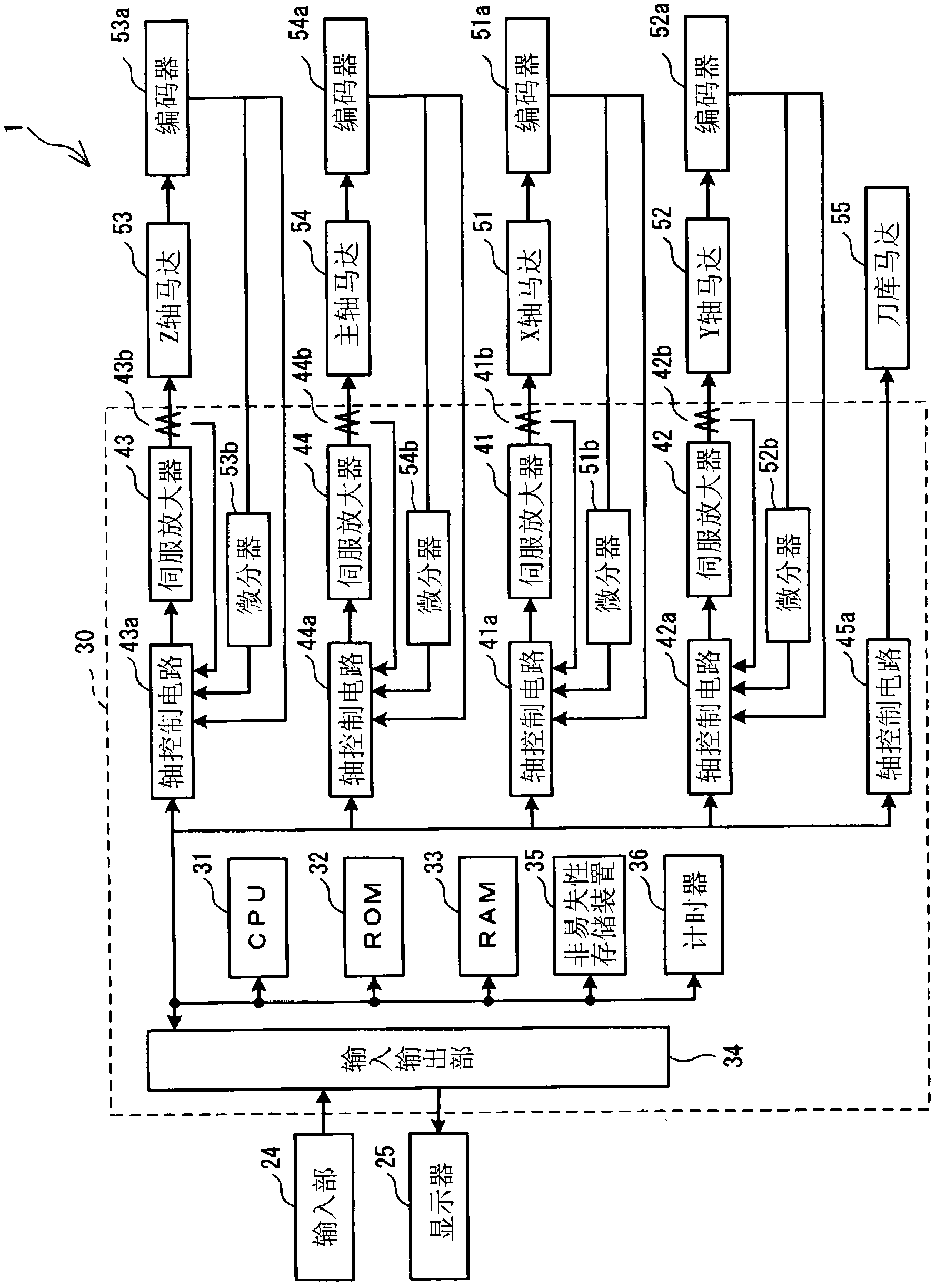

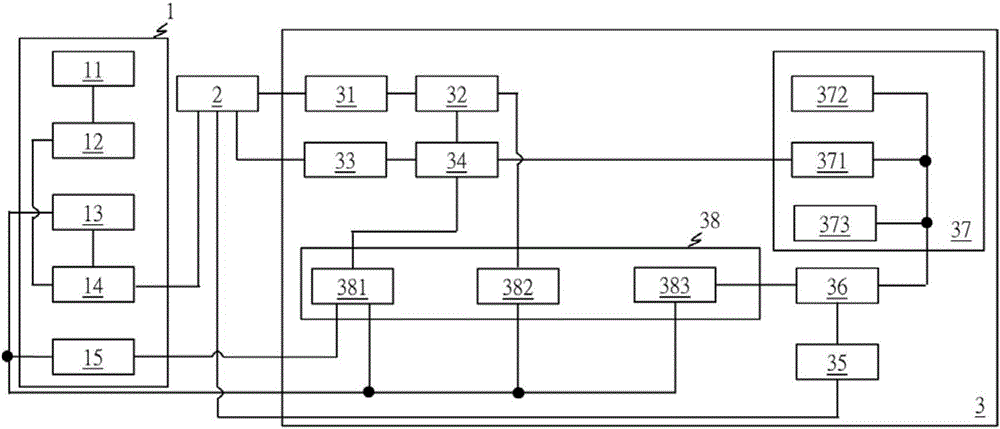

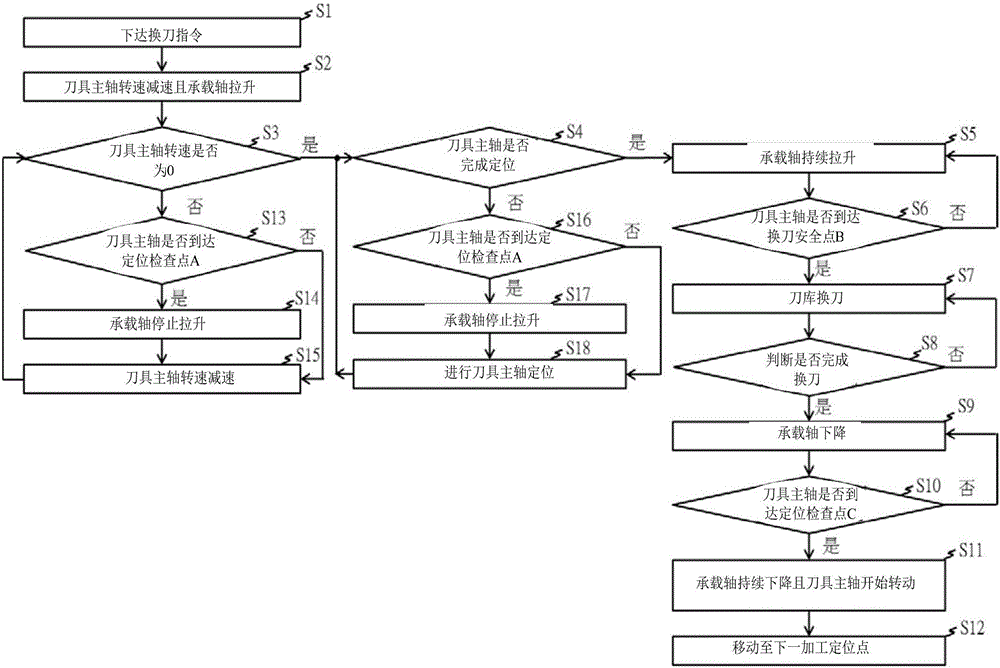

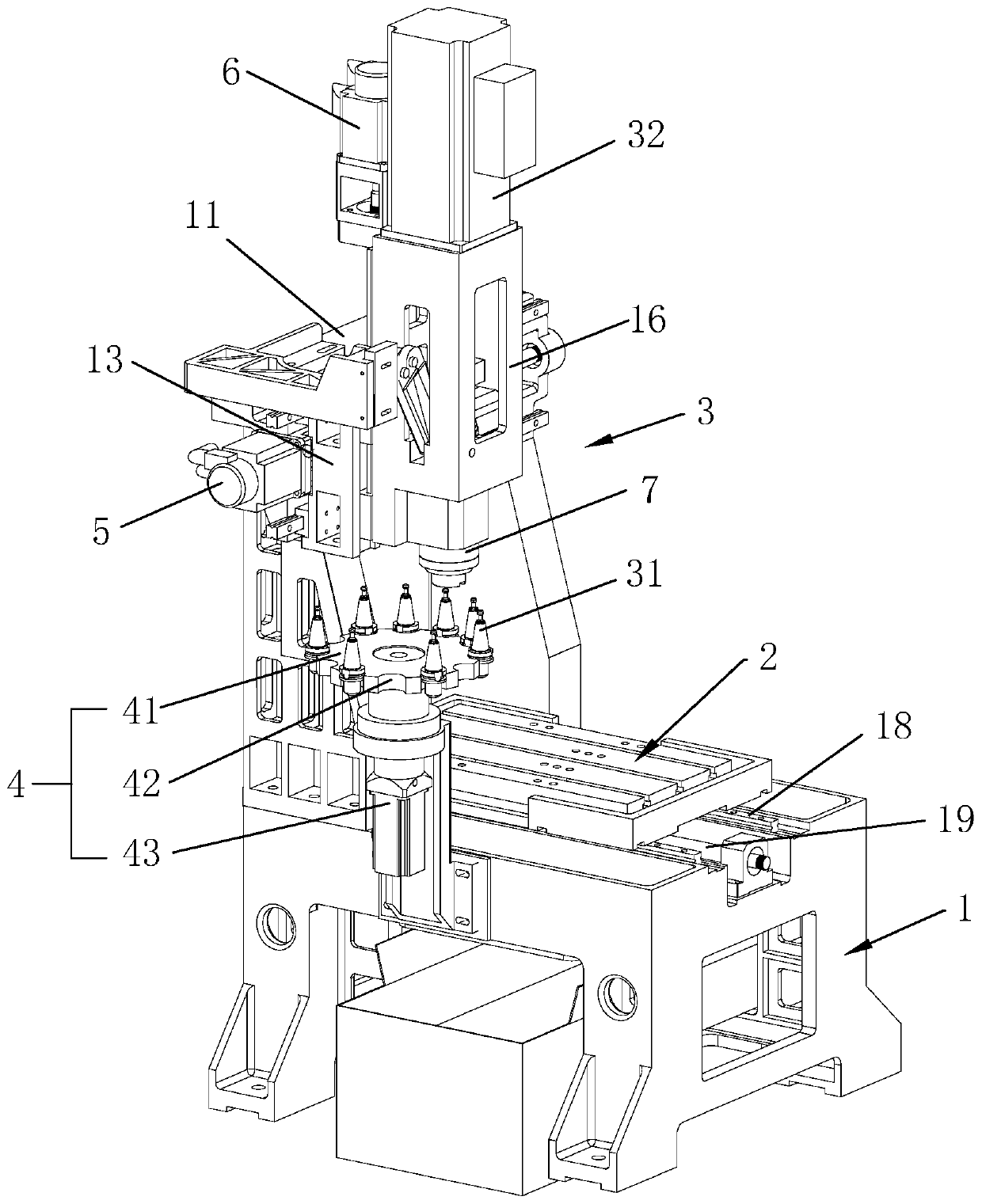

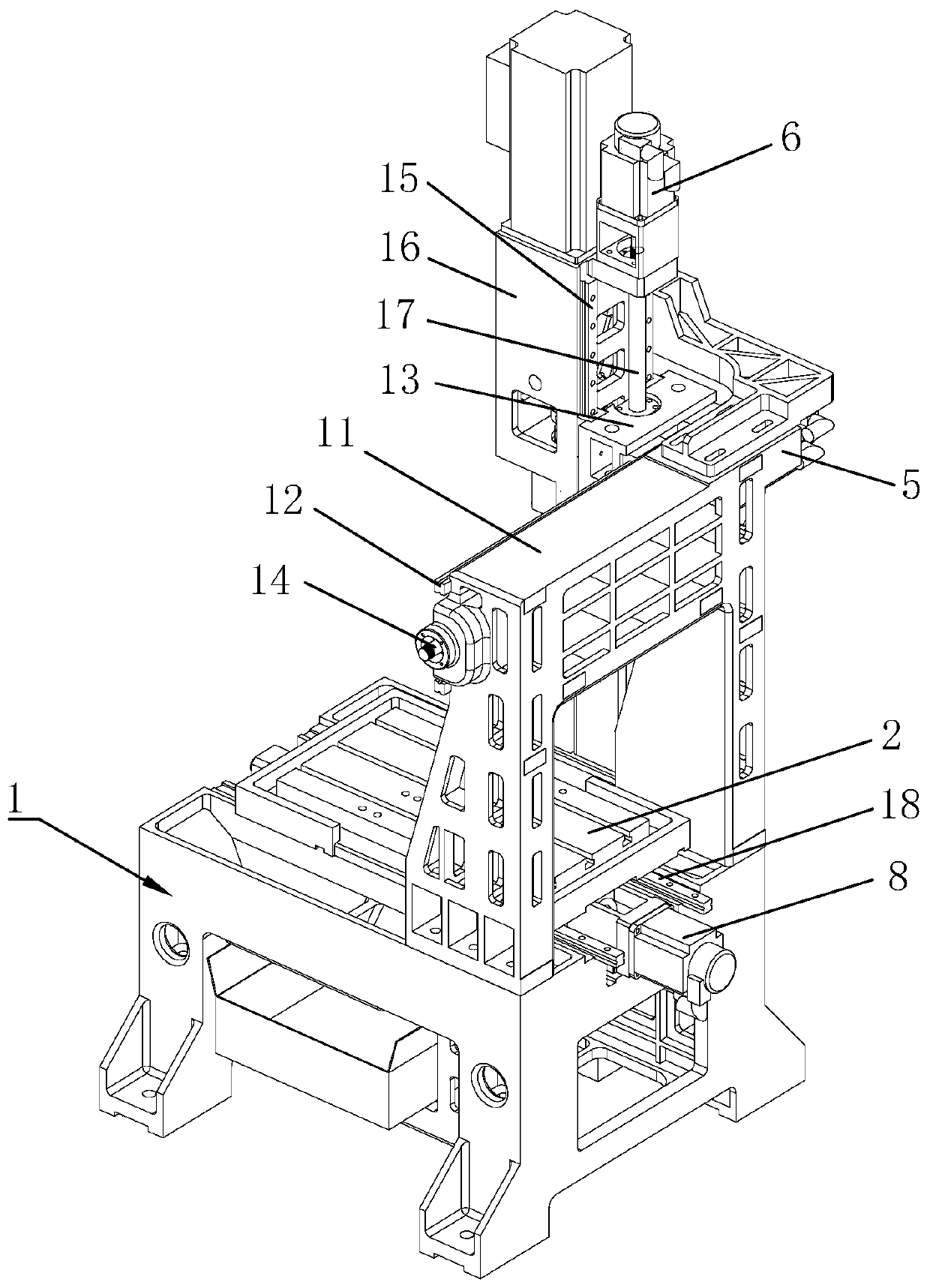

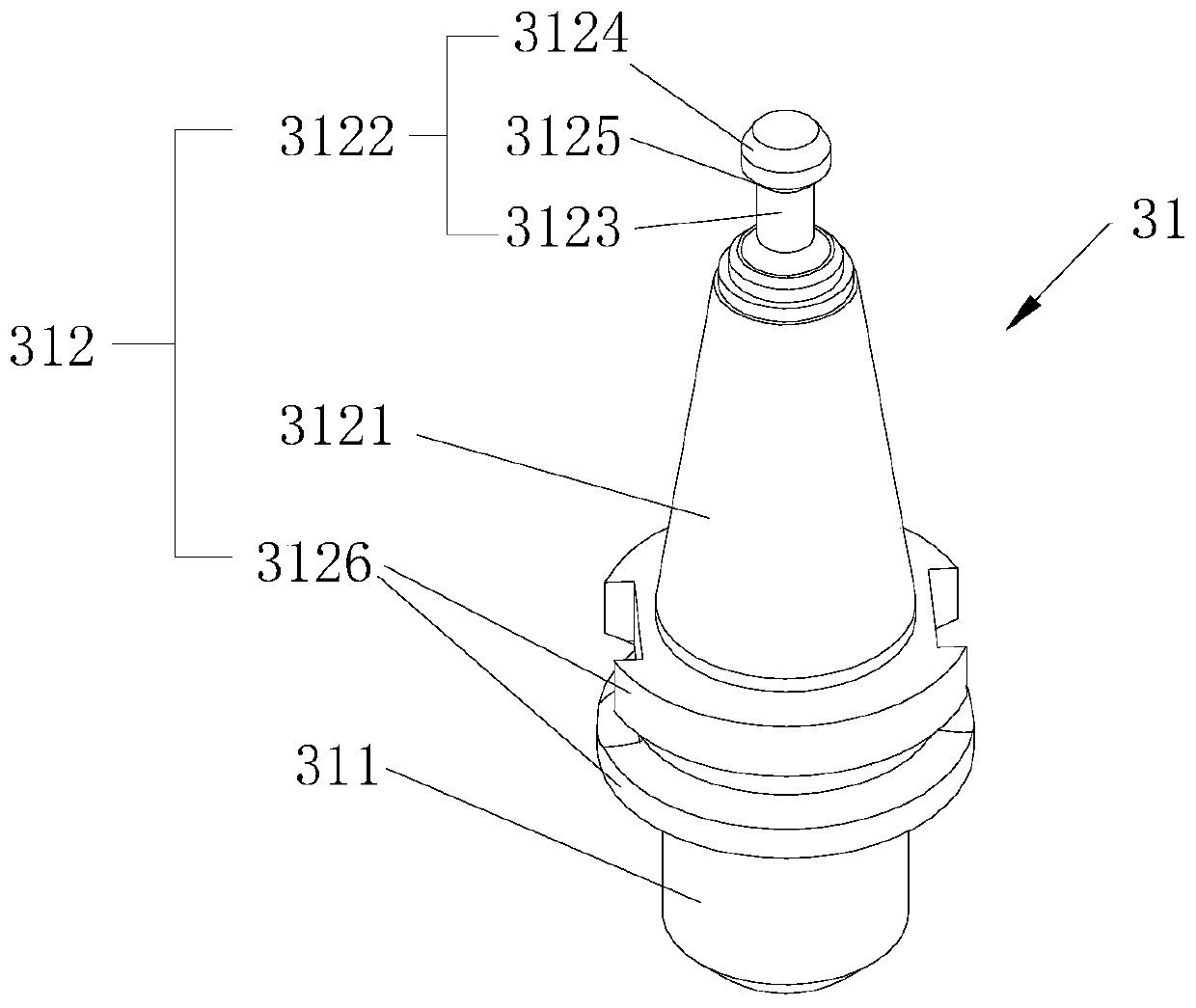

Numerical control system with cutter changing function and numerical control method of numerical control system

ActiveCN105750971AReduce tool change timeIncrease production capacityPositioning apparatusNumerical controlControl systemEngineering

The invention discloses a numerical control system with a cutter changing function and a numerical control method of the numerical control system. The numerical control system comprises a numerical control device, a driving device and a processing device. A detecting machine of the processing device detects the position of a cutter spindle in a Z-axis direction and the rotating angle of the cutter spindle, and outputs the rotating angle and the position information of the cutter spindle to the numerical control device; the numerical control device calculates out the rotating speed of the cutter spindle according to the rotating angle of the cutter spindle, generates a judgment signal after judging the rotating speed, the position and the rotating angle of the cutter spindle, and plans the rotating speed, the position and the rotating angle of the cutter spindle according to the judgment signal so as to perform cutter changing; when the numerical control system performs the cutter changing, the decision whether the operation of perpendicularly pulling up a cutter along a Z axis is stopped or not can be made according to the actual movement and rotation conditions of the cutter, so that the cutter changing time can be greatly shortened, the productivity is increased, and the cutter changing efficiency is improved.

Owner:新代科技(苏州)有限公司

Machining center with multi-tool-bit quick tool-replacement mechanism

PendingCN111168451AEasy to processReduce work stepsTurning machine accessoriesPositioning apparatusTool bitPower apparatus

The invention discloses a machining center with a multi-tool-bit quick tool-replacement mechanism. The machining center comprises a rack, a working table and a machining tool, the machining tool comprises tool bits and a first power device driving the tool bits to rotate, and the machining center further comprises a tool magazine, a third power device, a fourth power device and a broach device; the tool magazine is located on the side of the working table to allow the broach device to provide tool-replacement tool bits, the tool magazine comprises a cutterhead with a plurality of tool rests, the tool bits clamped on the tool rests, and a second power device driving the cutterhead to rotate forwards and reversely to enable one of the vacant tool rests or the replaced tool bit to directly face the broach device; the third power device is used for driving the broach device to quickly move in the horizontal direction to get close to or away from the tool magazine; and the fourth power device is used for driving the broach device to quickly move in the vertical direction to get close to or away from the tool magazine. Compared with the prior art, in the tool-replacement step, the working step of the tool magazine is omitted, the redundant upward-moving step is avoided after tool replacement, and thus the tool-replacement efficiency of the whole machining center is effectively improved.

Owner:YUHUAN BEIJING DIGITAL CONTROL MACHINE TOOL CO LTD

Tool changing device and method for numerical control machine tool

InactiveCN110216509AImprove tool change efficiencySave the time of unclampingPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention discloses a tool changing device and method for a numerical control machine tool. The device comprises a tool magazine mechanism, a main shaft box, a main shaft and a tool changing mechanism. The main shaft box is provided with a main shaft tool loosening mechanism used for releasing a tool at the lower end of the main shaft, the main shaft tool loosening mechanism comprises a tool loosening base and a tool loosening arm, the tool loosening base is fixedly installed on the main shaft box, the tool loosening arm is provided with a tool loosening roller used for pressing a pressingrod on the main shaft, the main shaft tool loosening mechanism further comprises a servo driving device, the servo driving device is arranged on the tool loosening base, the driving end of the servodriving device is vertically downward, one end of the tool loosening arm is rotationally connected to the main shaft box, the other end of the tool loosening arm is located under the driving end of the servo driving device, a connecting rod mechanism is arranged between the middle of the tool loosening arm and the tool loosening base, and the connecting rod mechanism is used for enabling the end,located below the servo driving device, of the tool loosening arm to be in a suspended mode. According to the key point of the technical scheme, the tool changing device of the numerical control machine tool improves tool changing efficiency in the way of loosening the tool in advance.

Owner:TAIZHOU YIKONG AUTOMATION EQUIP

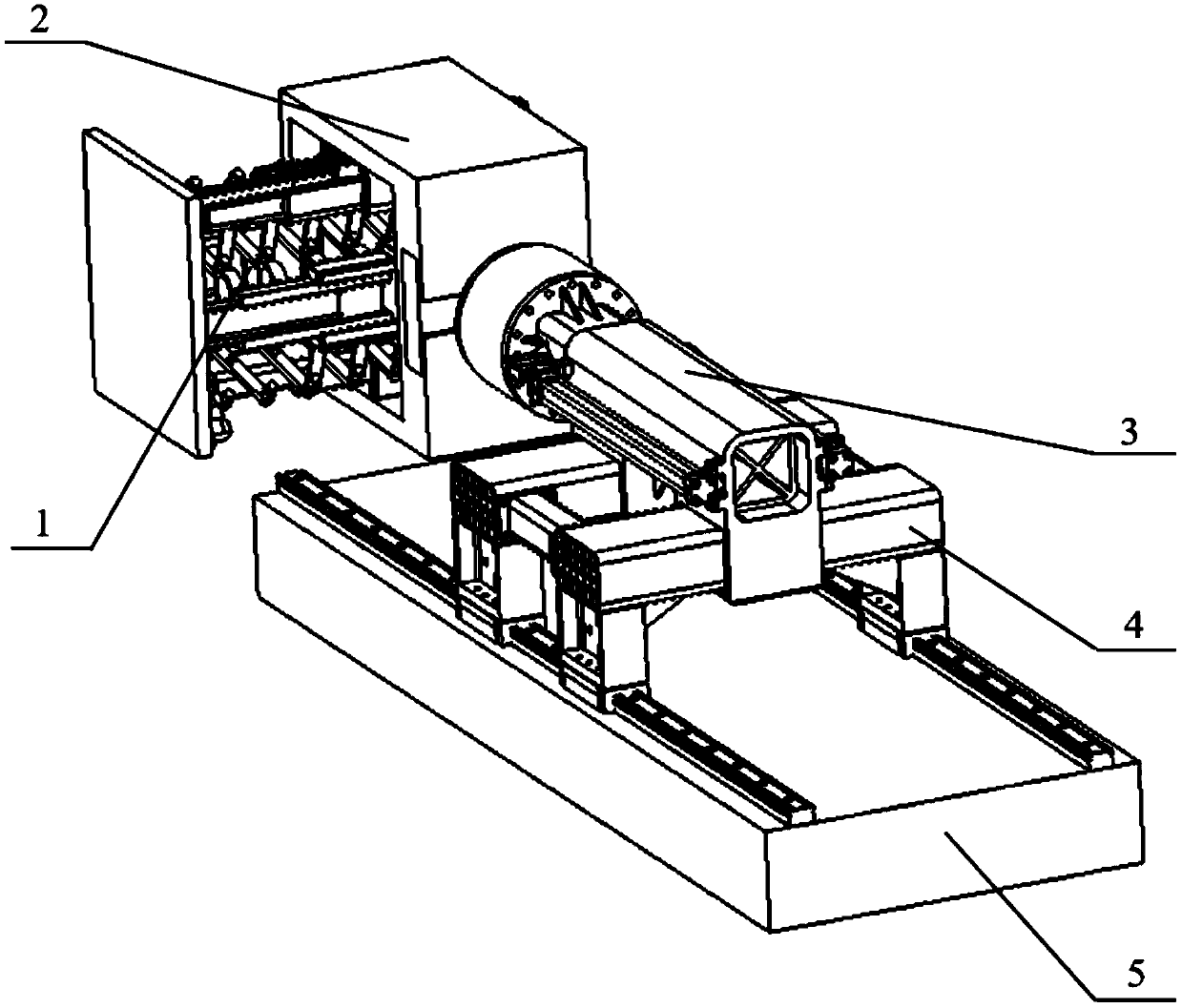

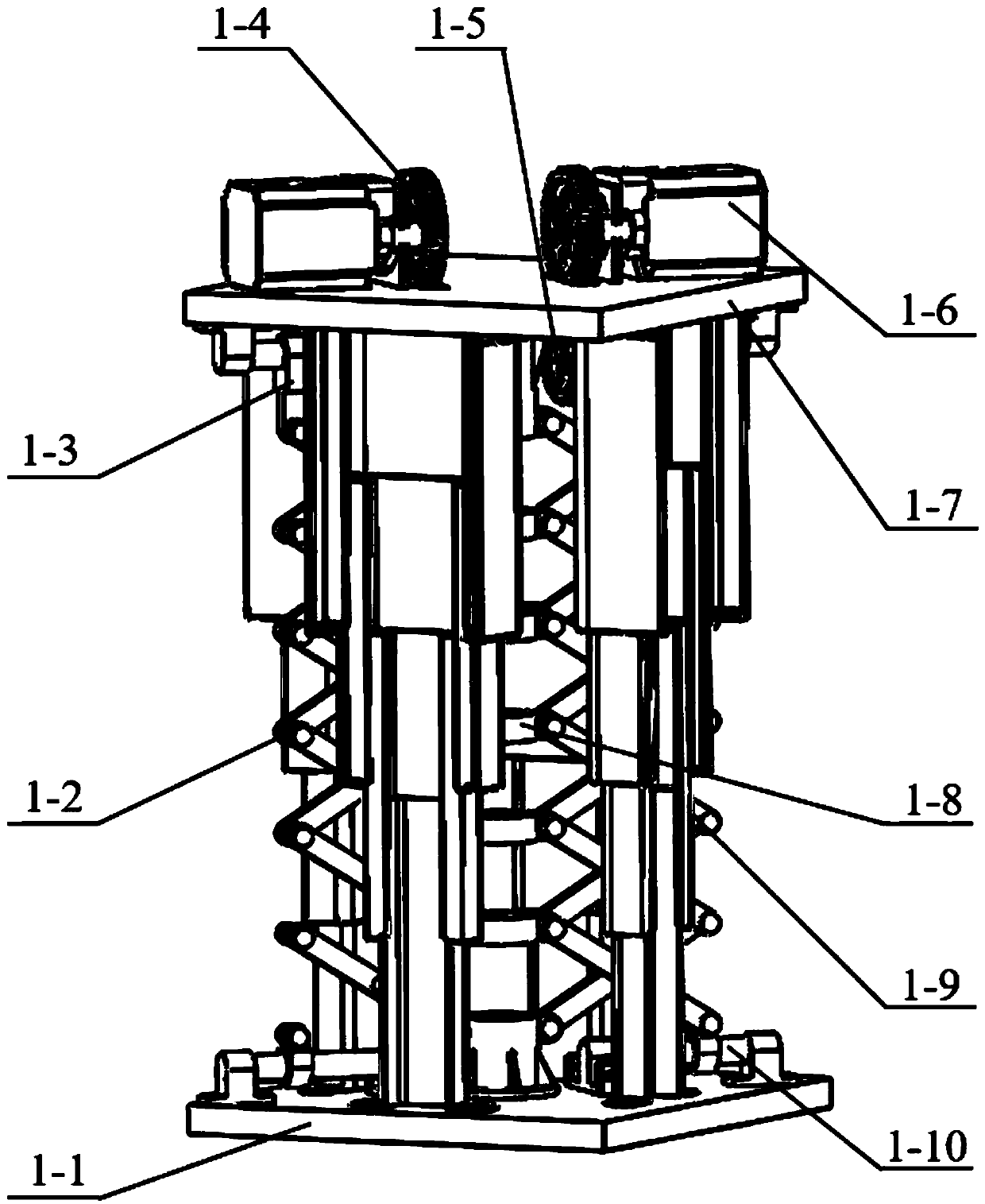

Tool changing robot body applied to full face tunnel boring machine

ActiveCN109594997AReduced risk of tool changeImprove tool change efficiencyTunnelsHobbingTunnel boring machine

The invention belongs to the technical field of tunnel construction, and relates to a tool changing robot body applied to a full face tunnel boring machine according to the internal structure of fullface tunnel boring machine cutter head and the distribution mode of hobbing cutters on the cutter head. The tool changing robot body mainly comprises a lifter body, a sleeve rail, a robot upper arm, arobot sliding base and a robot base. The tool changing robot body aims at solving the problem that the full face tunnel boring machine is difficult and dangerous to change tools, guaranteeing the life safety of tool changing workers, improving the tool changing efficiency and reducing the construction cost. The tool changing robot can drive an end effector to accomplish the changing of worn hobbing cutters on the cutter head in extremely severe environment, such as high voltage, and further accomplish the breakthrough of replacing human by a machine.

Owner:DALIAN UNIV OF TECH

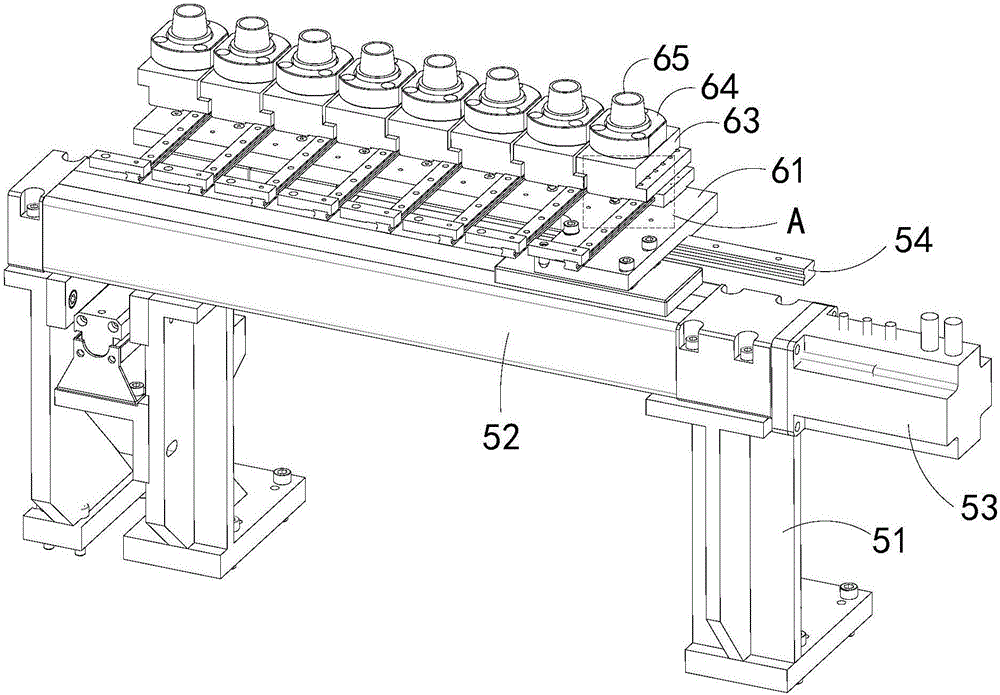

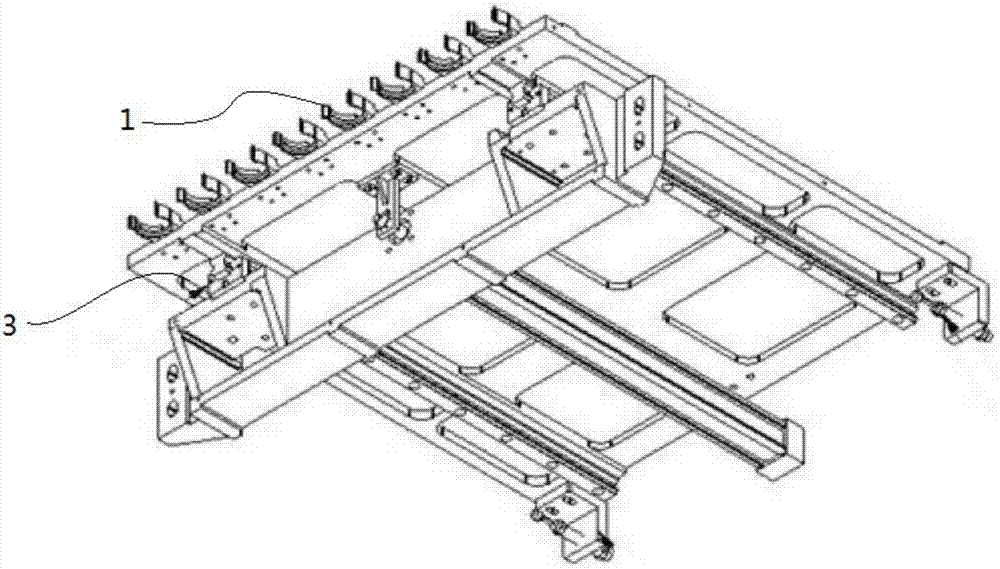

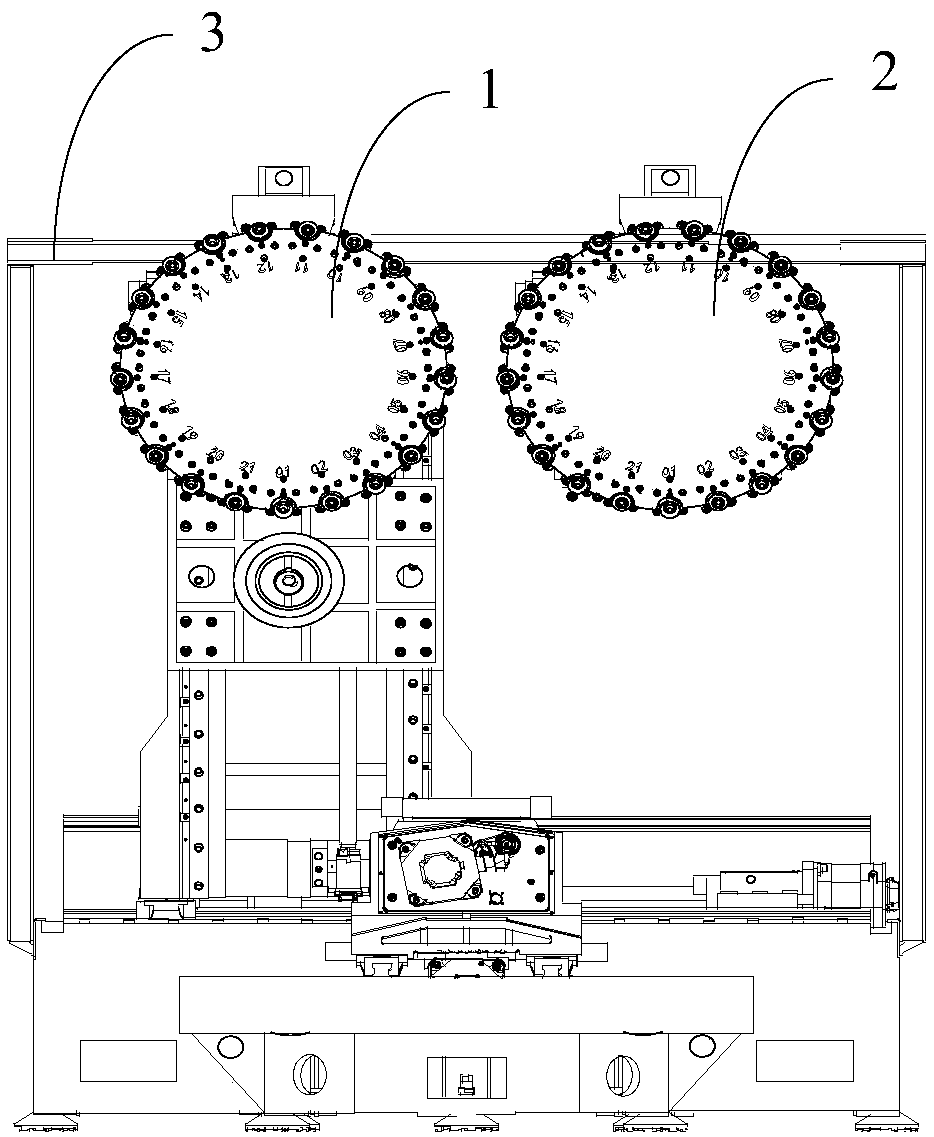

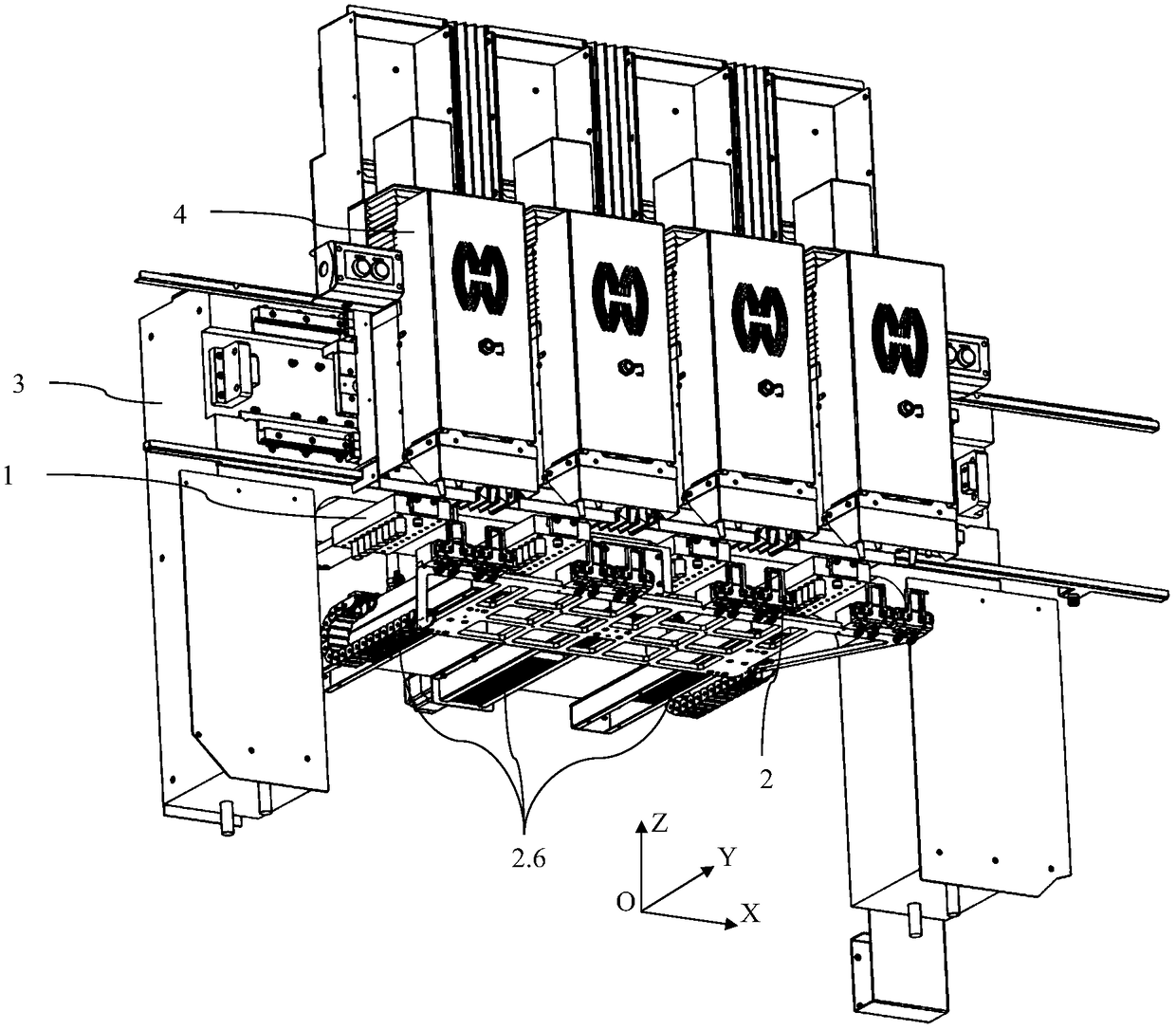

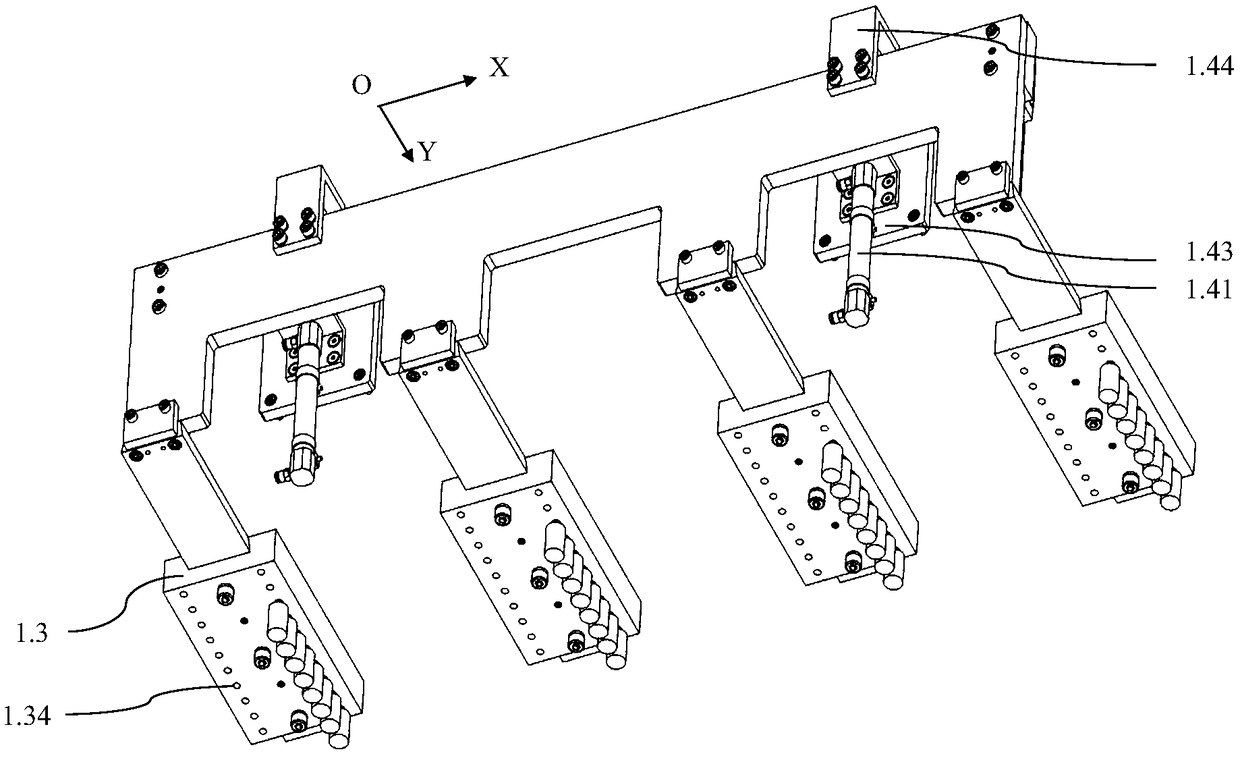

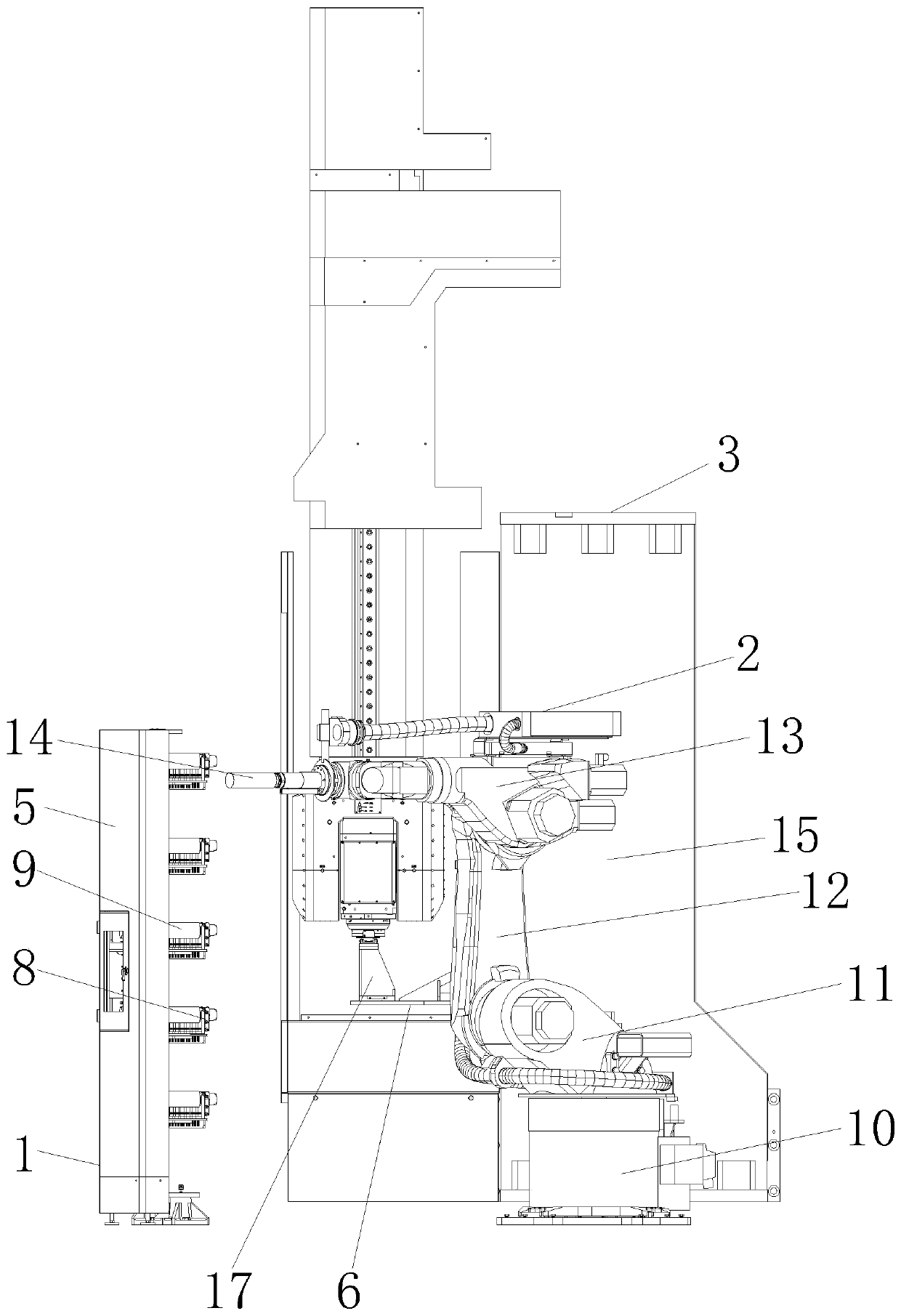

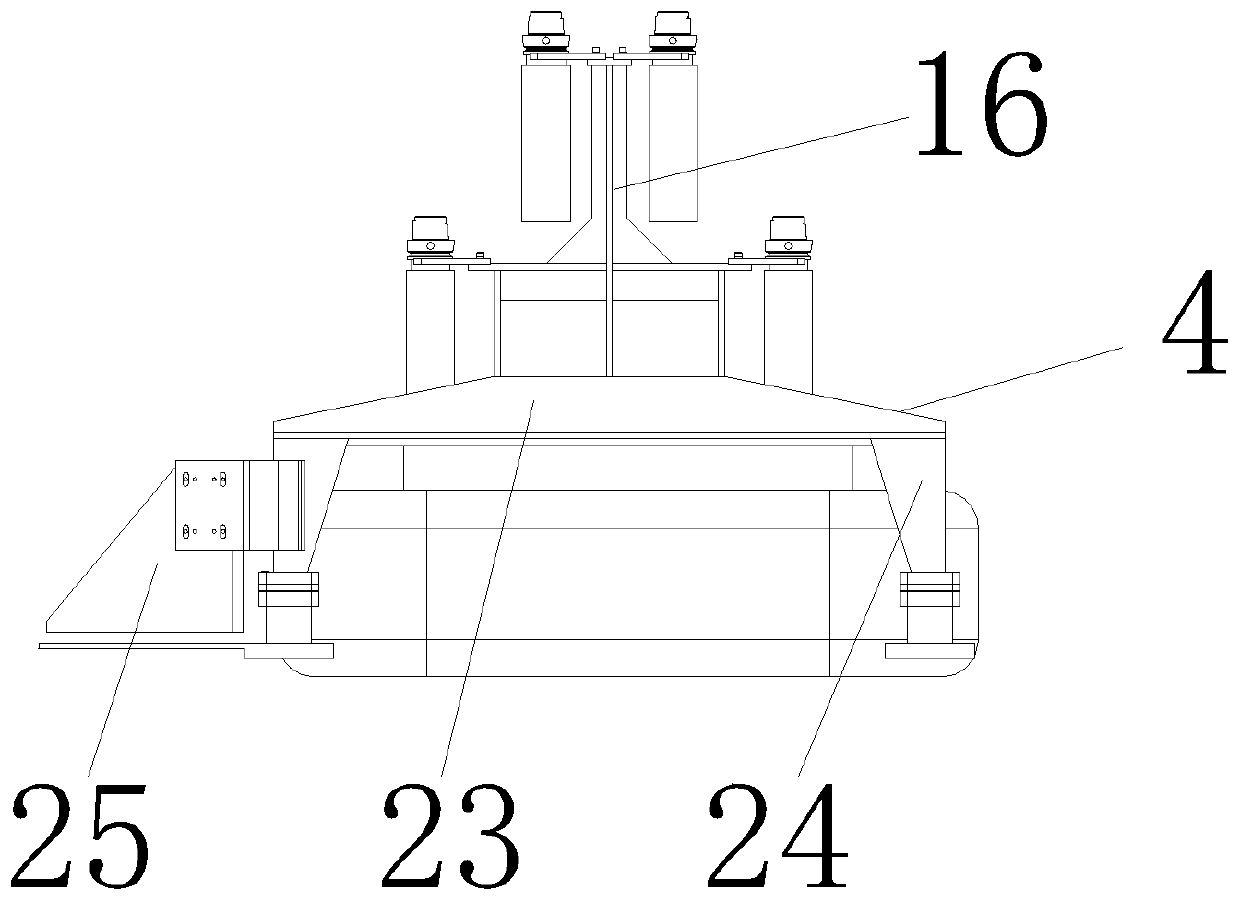

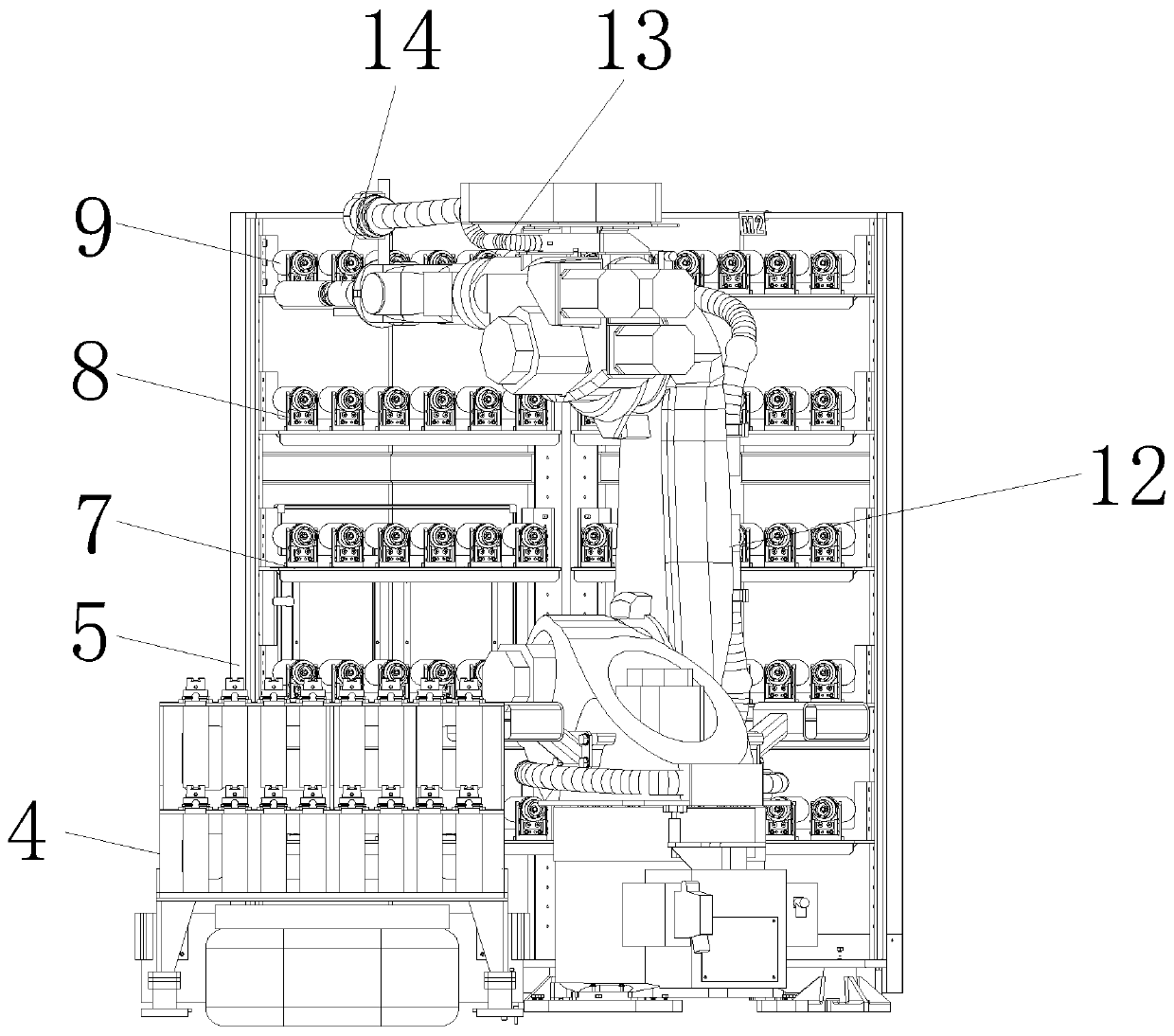

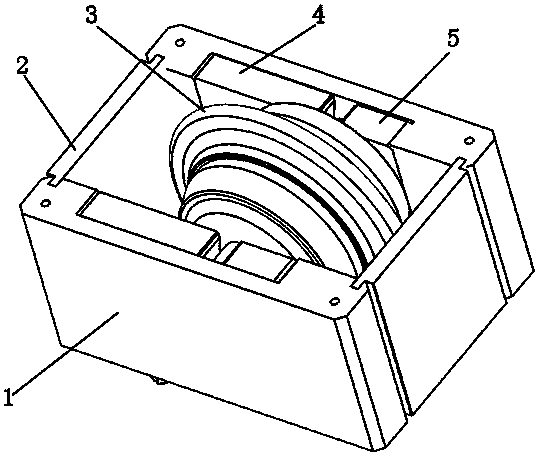

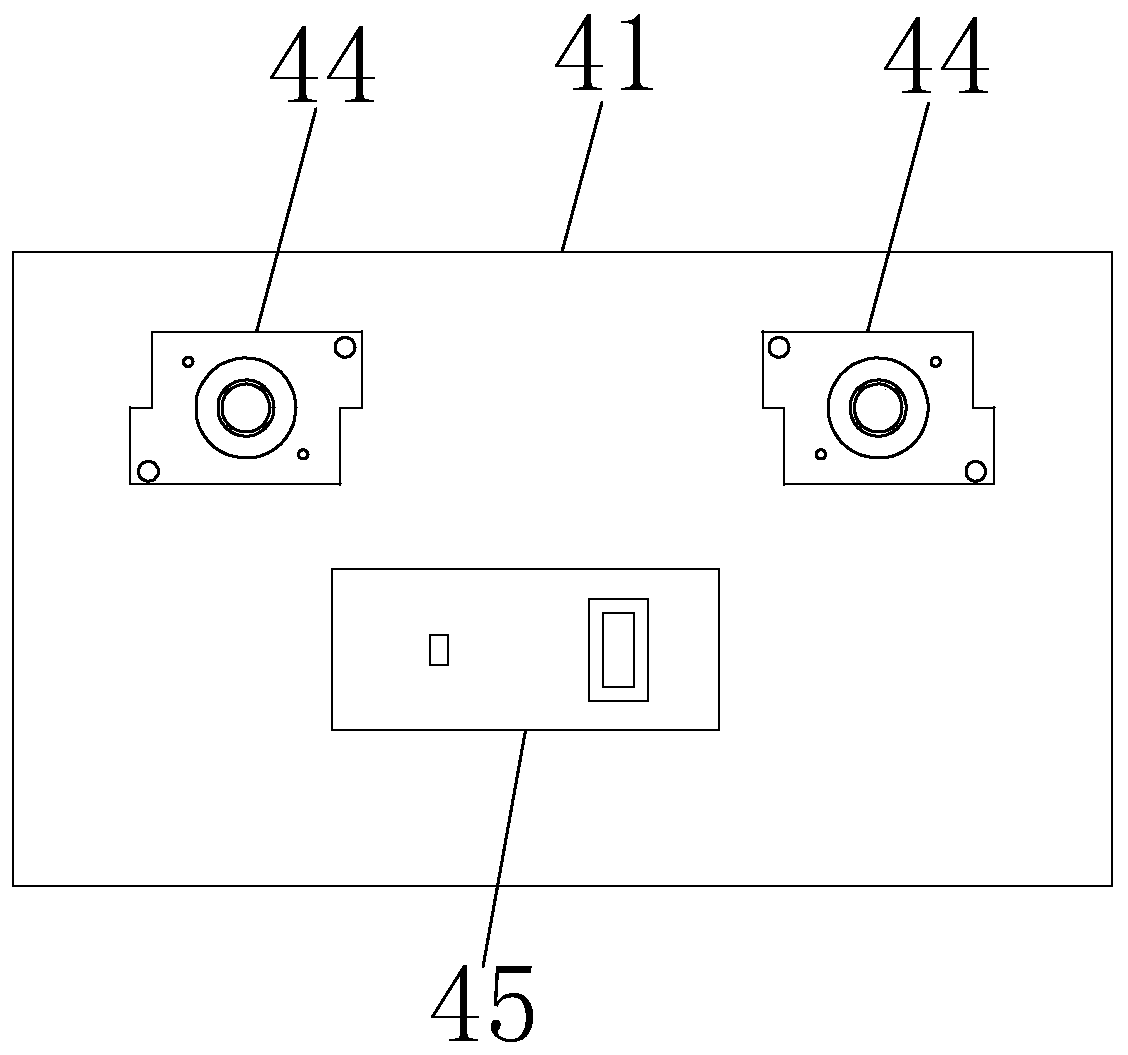

Tool magazine, tool changing mechanism and multi-spindle machining center

PendingCN108655797AIncrease tool storage capacityImprove tool change efficiencyPositioning apparatusMetal-working holdersMachine toolMachining

The invention provides a tool magazine, a tool changing mechanism with the tool magazine and a multi-spindle machining center comprising the tool changing mechanism. The tool magazine comprises a toolmagazine mounting bracket, a tool magazine bracket and multiple tool storage bins. The tool magazine mounting bracket is configured to be fixed to a machine tool spindle beam. The tool magazine bracket is mounted on the tool magazine mounting bracket. The tool storage bins are fixed to the tool magazine bracket. Each of the tool storage bins comprises multiple tool storage cavities and is characterized in that the tool storage cavities in each of the tool storage bins are formed into a tool storage cavity matrix; and the tool storage cavities formed in the direction parallel to the machine tool spindle beam form a row of the tool storage cavity matrix, and the number of rows of the tool storage cavity matrixes is larger than 1. The tool magazine has large tool storage capacity, good toolprotection and long maintenance period, the tool changing efficiency of the tool changing mechanism using the tool magazine is high, and the machining efficiency of the machining center is high.

Owner:江西衡源智能装备股份有限公司

Tool magazine tool replacement device for machine tool

PendingCN110614523AEasy to transportImprove storage efficiencyPositioning apparatusMetal-working holdersMachine toolRobot

The invention discloses a tool magazine tool replacement device for a machine tool. The device comprises a tool magazine wall, a robot tool replacement mechanism, the machine tool and a tool vehicle.The tool magazine wall is located on the left side of the robot tool replacement mechanism, the machine tool is located on the rear side of the robot tool replacement mechanism, the tool magazine wallcomprises a box body, an inner cavity of the box body is fixedly connected with a transverse plate, the top of the transverse plate is provided with a clamping plate, the top of the clamping plate isprovided with a tool, the robot tool replacement mechanism comprises a base, the top of the base is fixedly connected with a first rotating arm, the rear side of the first rotating arm is movably connected with a supporting arm, and the top of the supporting arm is movably connected with a second rotating arm. The device has the advantages that tool replacement of the machine tool can be automatically achieved and replaced tools are sorted and stored, and the problems that manual tool replacement wastes time and labor, the working efficiency is low, the tools are likely to be misplaced and products are scrapped when the situation is severe are solved.

Owner:沈阳中捷航空航天机床有限公司

Edge folding device of full-automatic four-door robot edge rolling equipment

InactiveCN108637059AEasy to operateImprove Tool Change EfficiencyShaping toolsVehicle componentsCar doorEngineering

The invention provides an edge folding device of full-automatic four-door robot edge rolling equipment. The device comprises an edge folding roller and a roller adjusting mechanism, the edge folding roller comprises a first roller and a second roller, the axis position of the first roller is connected with the axis position of the second roller through a connecting device, the first roller and thesecond roller each are of a circular truncated cone structure, the lower bottom surface of the first roller and the lower bottom surface of the second roller are arranged on the adjacent sides, the side face of the first roller and the side face of the second roller are used for edge folding, the roller adjusting mechanism comprises a roller fixing unit, a fixing arm and a vertical angle adjusting unit. According to the edge folding device of the full-automatic four-door robot edge rolling equipment, the horizontal angle and the vertical angle of the edge folding roller can be effectively andquickly adjusted, the positions of the first roller and the second roller can be quickly exchanged, intelligent adjustment is achieved, the operation is convenient, and the tool changing efficiency in the edge folding process is effectively improved.

Owner:GAOJIN TIANJIN AUTOMOTIVE EQUIP CO LTD

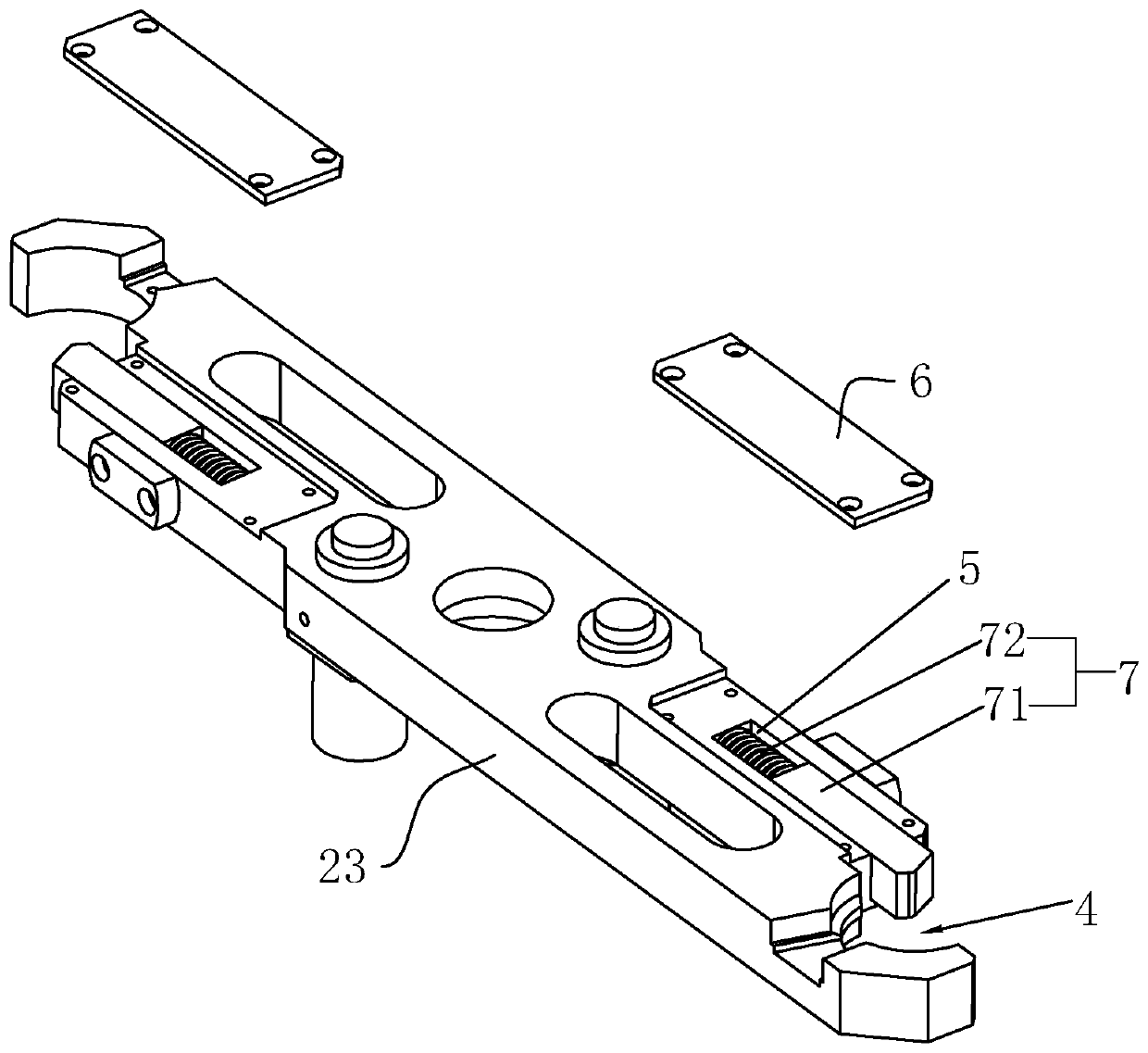

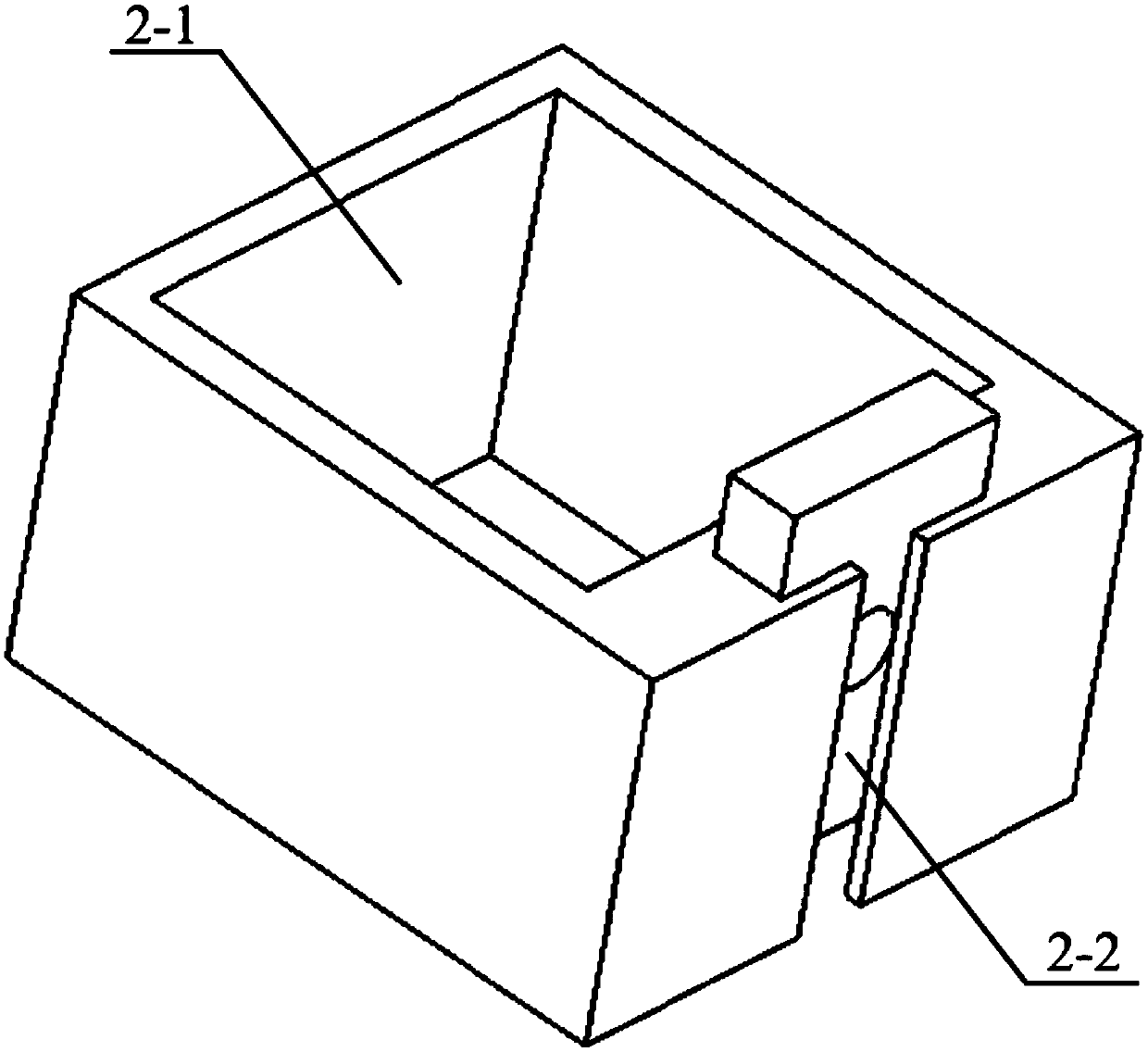

Portable hobbing cutter system and dismounting method thereof

PendingCN111156015ATo achieve compression or notPrecise tool changeTunnelsHobbingStructural engineering

The invention discloses a portable hobbing cutter system and a dismounting method thereof. With the portable hobbing cutter system and the dismounting method thereof, the problems that a robot is lowin cutter changing work efficiency and poor in fusion with an existing hob in the prior art are solved. The hobbing cutter system comprises a cutter box and a hobbing cutter, wherein a clamping blockused for clamping and fixing a hobbing cutter shaft is arranged on the inner wall of the cutter box, a push-pull locking mechanism is arranged on the cutter box, a sliding block is in threaded connection with the lower part of the push-pull locking mechanism, and the sliding block is matched with the hobbing cutter shaft. The push-pull locking mechanism is connected with the sliding block and a box body in a threaded mode, the push-pull locking mechanism is controlled and operated by a tool changing robot, a nut is rotated to drive a threaded rod to rotate, and then the sliding block makes translational motion up and down, so that whether the hobbing cutter shaft is tightly pressed or not is detected, rapid and accurate tool changing is achieved, the matching degree with the tool changingrobot is high, and the tool changing efficiency is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Automatic extension cutter frame device for numerical control machine

ActiveCN110202396AImprove tool change efficiencyImprove work efficiencyPositioning apparatusMetal-working holdersEngineeringElectric machine

The invention discloses an automatic extension cutter frame device for a numerical control machine, relates to the field of numerical control, and mainly solves the problem of lower cutter change efficiency in an existing numerical control machine. The device comprises a mounting base; the mounting base is provided with a groove; a rotating disc is arranged in the groove, and is rotationally connected into the groove through a rotating shaft; a motor for driving the rotating disc to rotate is mounted in the mounting base; at least two chutes are formed in the rotating disc at equal intervals in the peripheral direction; cutters capable of moving back and forth in the length directions are arranged in the chutes; driving modules for driving the cutters to slide back and forth are arranged in the chutes; and the driving modules are electrically connected with trigger modules. The cutters are slidingly arranged on the rotating disc; through cooperation between the driving modules and thetrigger modules, the cutter change can be realized through rotation of the rotating disc without needing excessive manual operations, so that the cutter change efficiency can be effectively improved,and the working efficiency is improved.

Owner:SHANDONG TRANSPORT VOCATIONAL COLLEGE

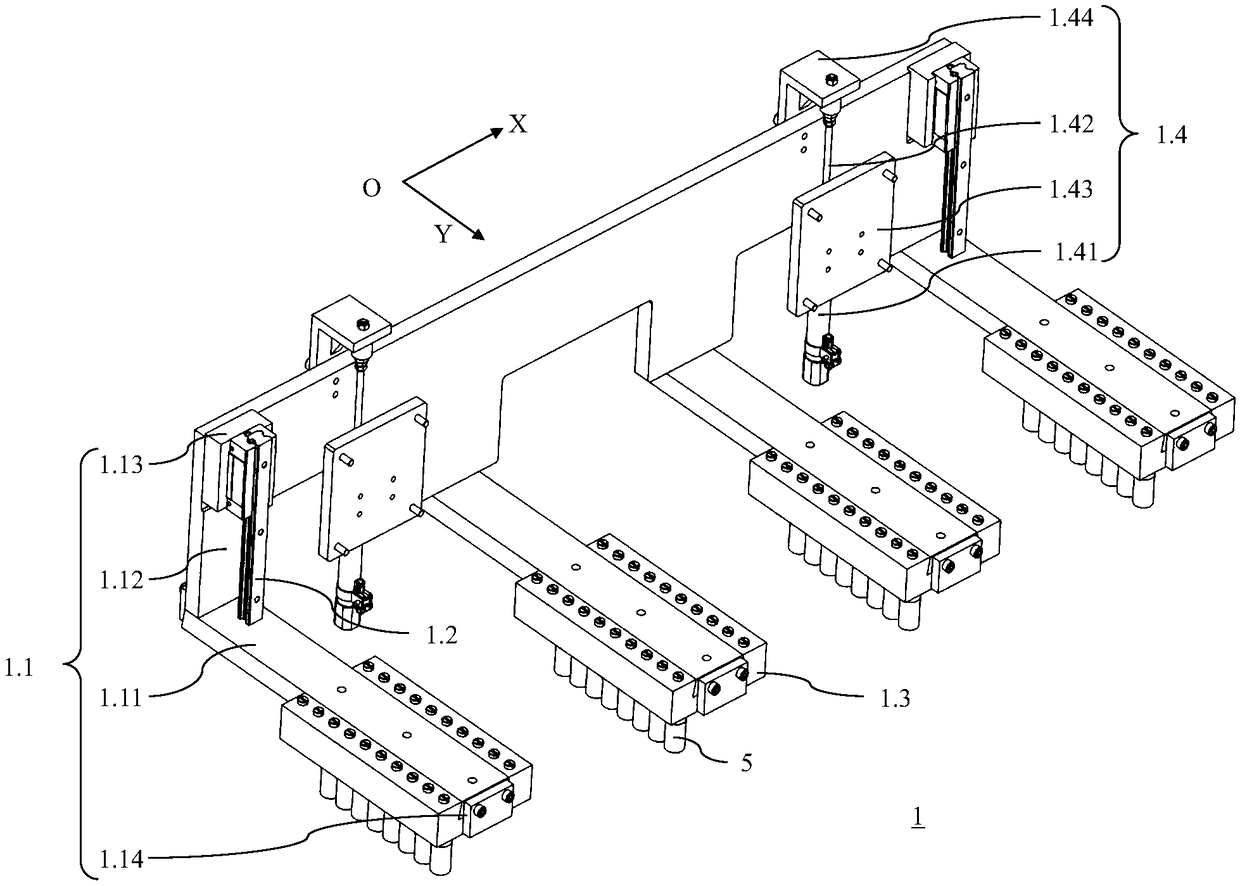

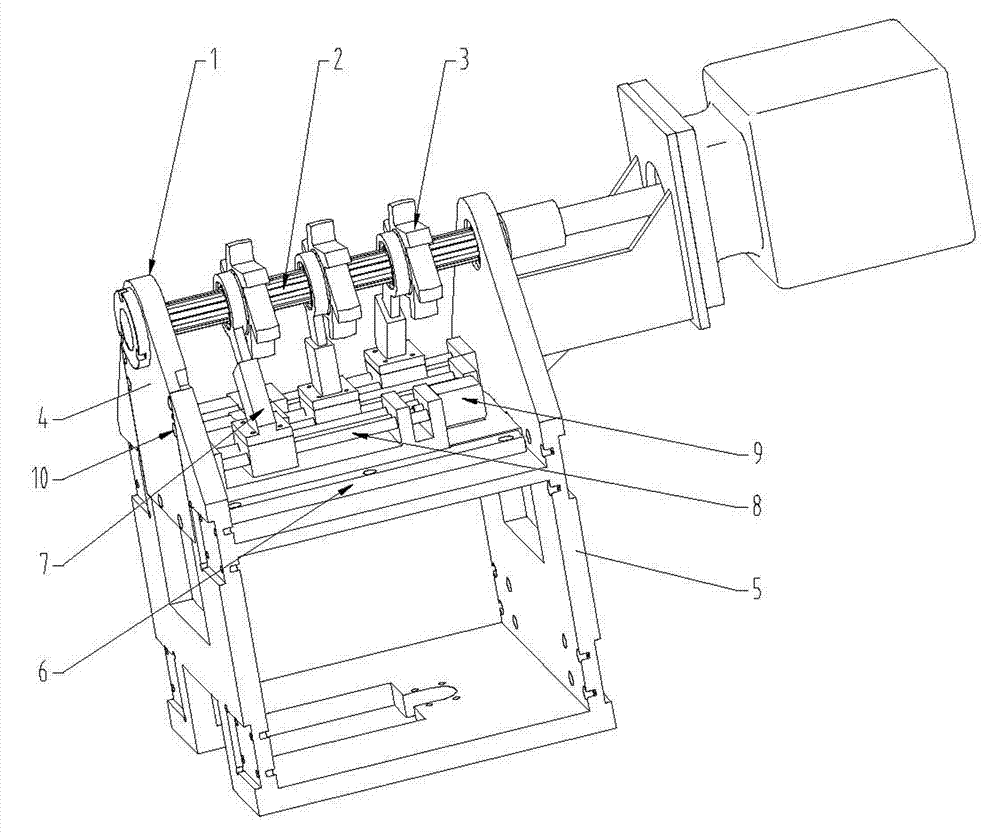

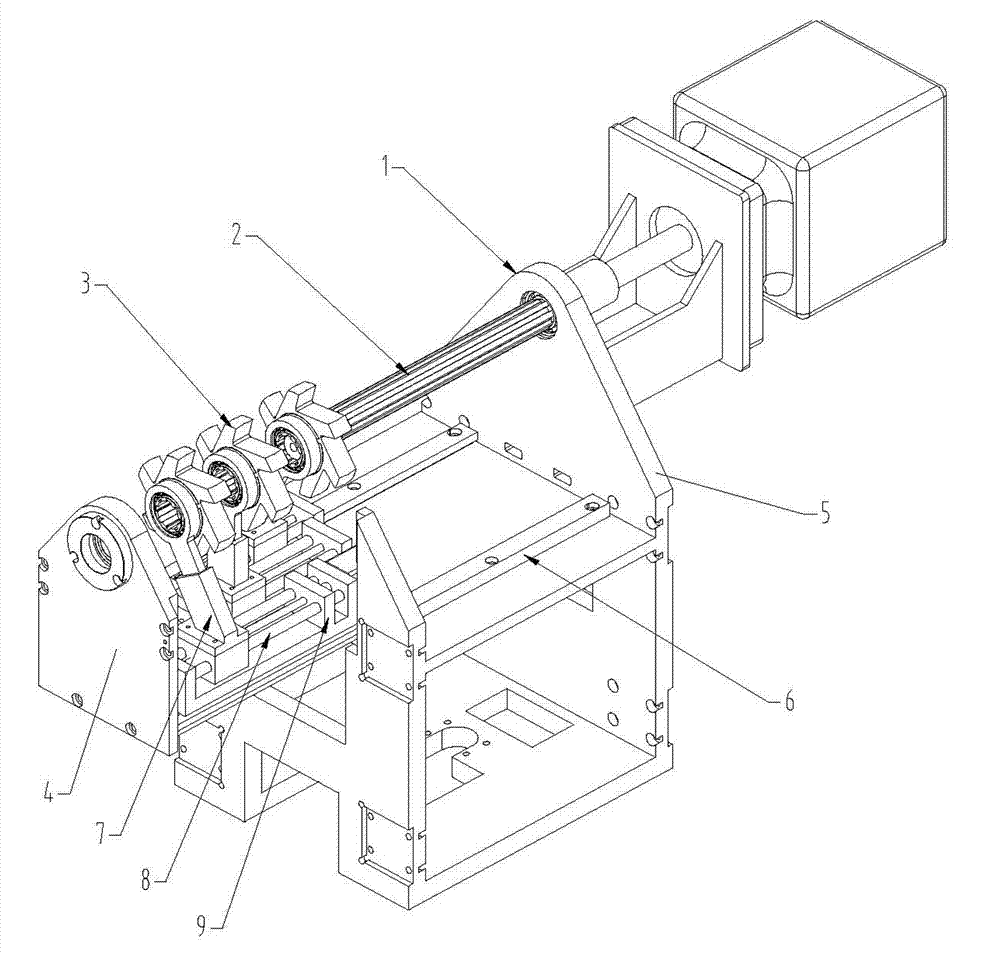

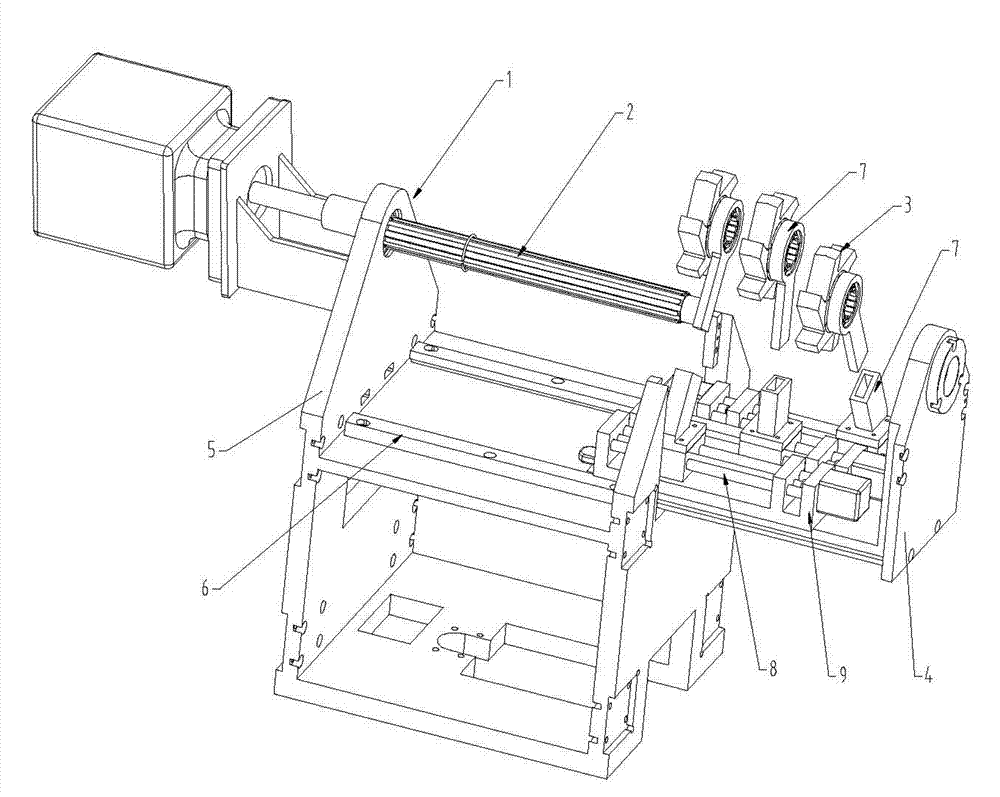

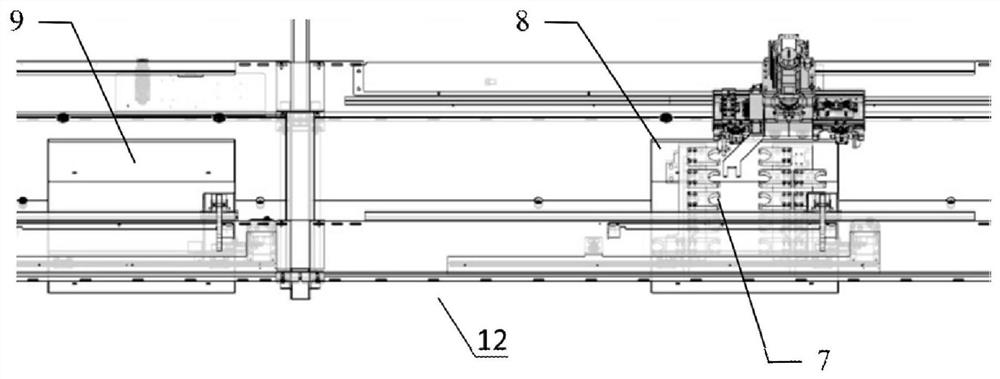

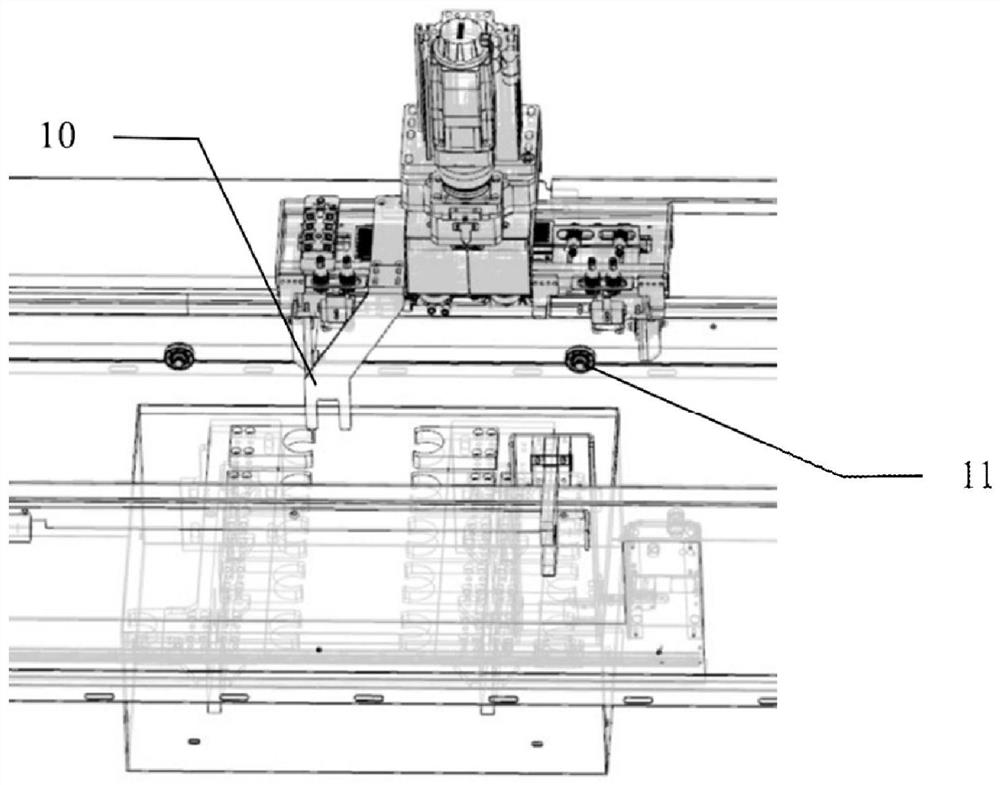

Rapid cutter-changing mechanism for multi-cutterhead cutting system

InactiveCN103286829AAchieve the effect of breaking away from the movable bracketFor quick replacementProfiling/shaping machinesPositioning apparatusStructural engineeringEngineering

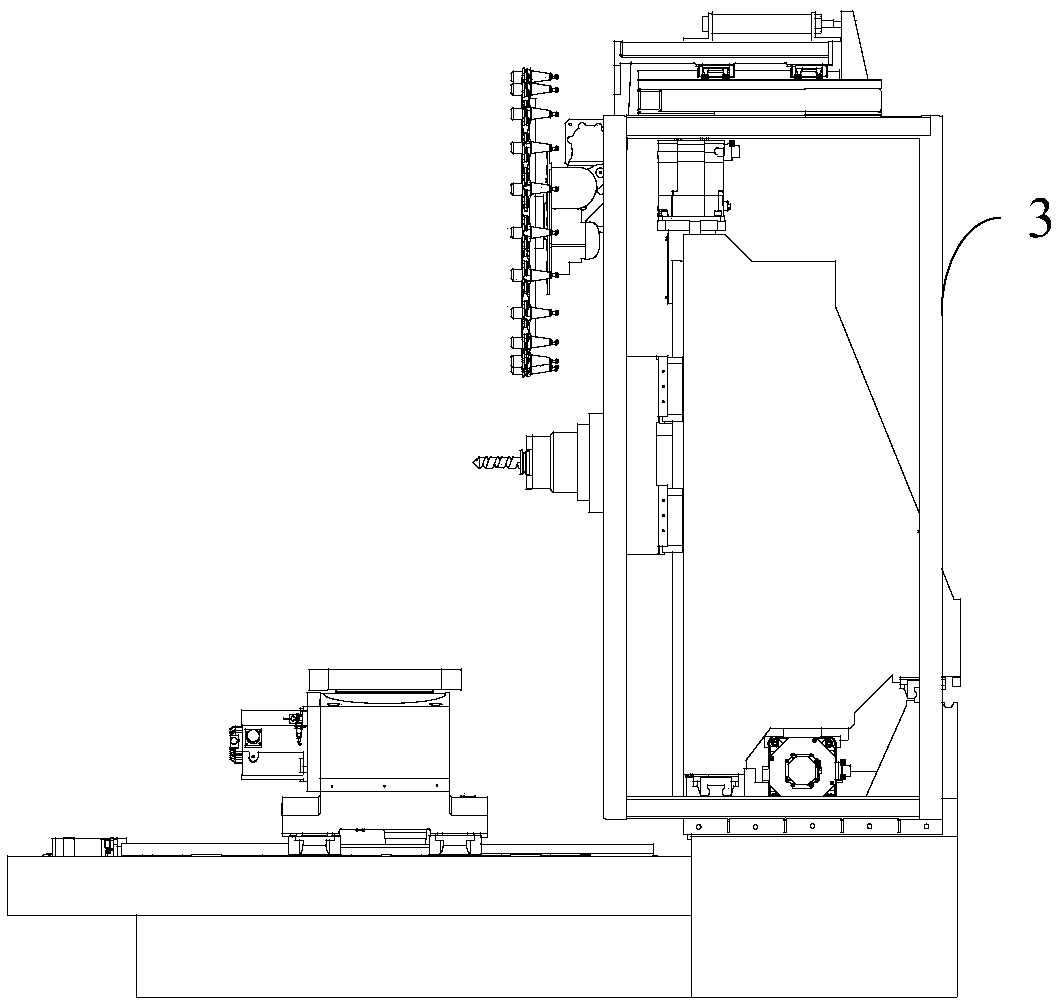

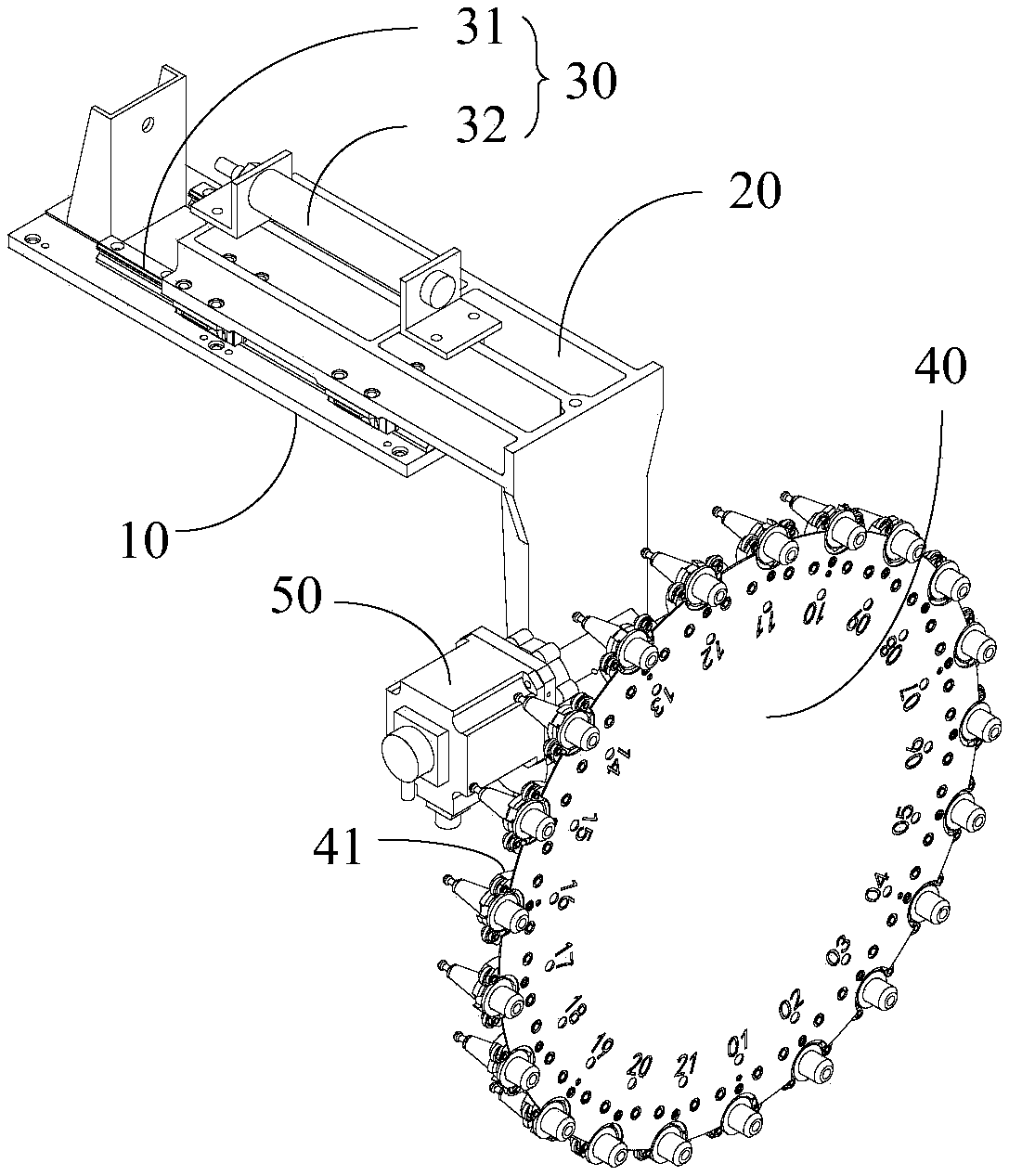

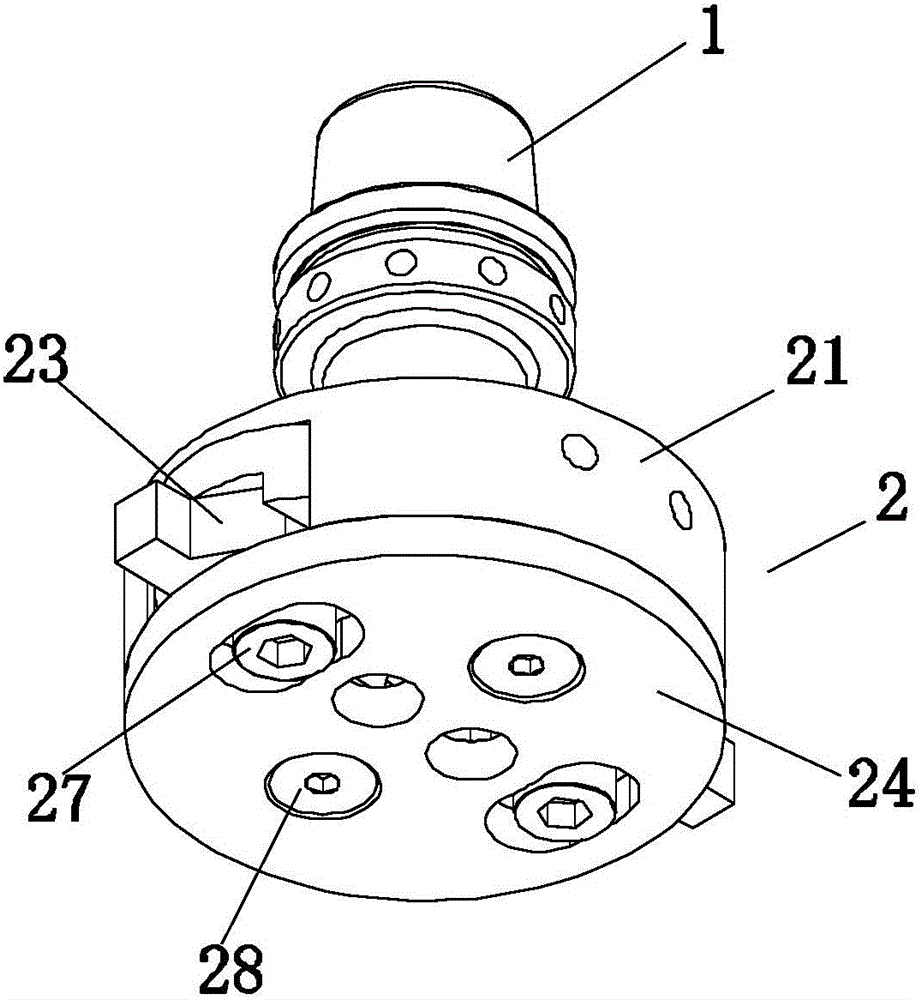

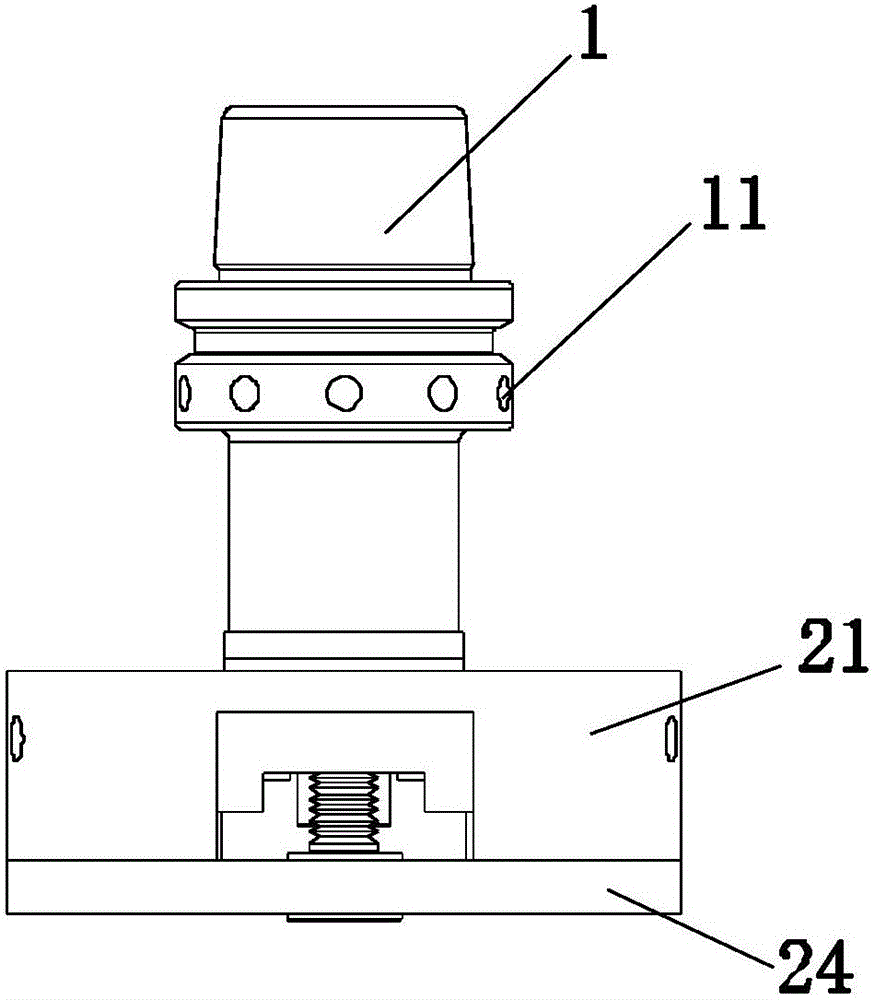

The invention discloses a rapid cutter-changing mechanism for a multi-cutterhead cutting system. The rapid cutter-changing mechanism comprises a main-shaft bracket (1), a main shaft (2), cutter-disk combinations (3), a bar-pulling mechanism (7) and a linear guide rail set (8). The main-shaft bracket (1) comprises a movable bracket (4) and a fixed bracket (5), wherein vertical sections of the movable bracket (4) are L-shaped. Two sliding-rail structures (6) are arranged on a platform of the fixed bracket (5), and the two sliding-rail structures (6) correspond with each other. A horizontal plane of the movable bracket (4) is embedded in the sliding-rail structures (6) and in sliding connection with the sliding-rail structures (6). The vertical end face of the movable bracket (4) is fixedly connected with the vertical end face of the fixed bracket (5). One end of the main shaft (2) is movably arranged in a bearing of the vertical end face of the movable bracket (4), and the other end of the main shaft (2) is arranged in a bearing of the vertical end face of the fixed bracket (5). Through use of the rapid cutter-changing mechanism, rapid replacements can be realized by means of the separated main-shaft bracket, cutter-disk combinations and bar-pulling mechanism, and the rapid cutter-changing mechanism has a compact structure, low cost and a high cutter-changing speed.

Owner:盐城飞优科技有限公司

Shield tunneling machine having robot tool changing function

ActiveCN110630279ATool change program is simple and orderlyImprove tool change efficiency and operational safety factorTunnelsShield machineHigh pressure

The invention discloses a shield tunneling machine having a robot tool changing function. The shield tunneling machine having the robot tool changing function solves the problem that a shield tunneling machine difficultly changes tools in the prior art. The shield tunneling machine having the robot tool changing function comprises a tool disc, a main machine and a rear accessory sleeve, wherein asoil bin is arranged between the main machine and the tool disc, a robot bin and a tool magazine are arranged at the top of the interior of the main machine, the tool magazine is located in the robotbin, the robot bin is located at the rear of the soil bin, a tool changing gate is arranged on the bin wall of the soil bin, a tool changing robot is arranged in the robot bin, and novel tools suitable for tool changing of the tool changing robot are arranged on the tool disc. According to the shield tunneling machine having the robot tool changing function, the robot is used for the tool changing, the tool changing robot can move in the robot bin for the tool changing, the tool changing procedure is concise and orderly, a tail end executing mechanism of the tool changing robot realizes the purposes of performing clamping hoisting for the tools, loosening and tightening bolts, preforming high pressure cleaning for the tools, and meanwhile preforming image acquisition through a moving adjustment mechanism, a bolt loosening and tightening mechanism, a high pressure cleaning mechanism and an image acquisition mechanism, performs real-time monitoring, and improves tool changing efficiencyand operation safety coefficient.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

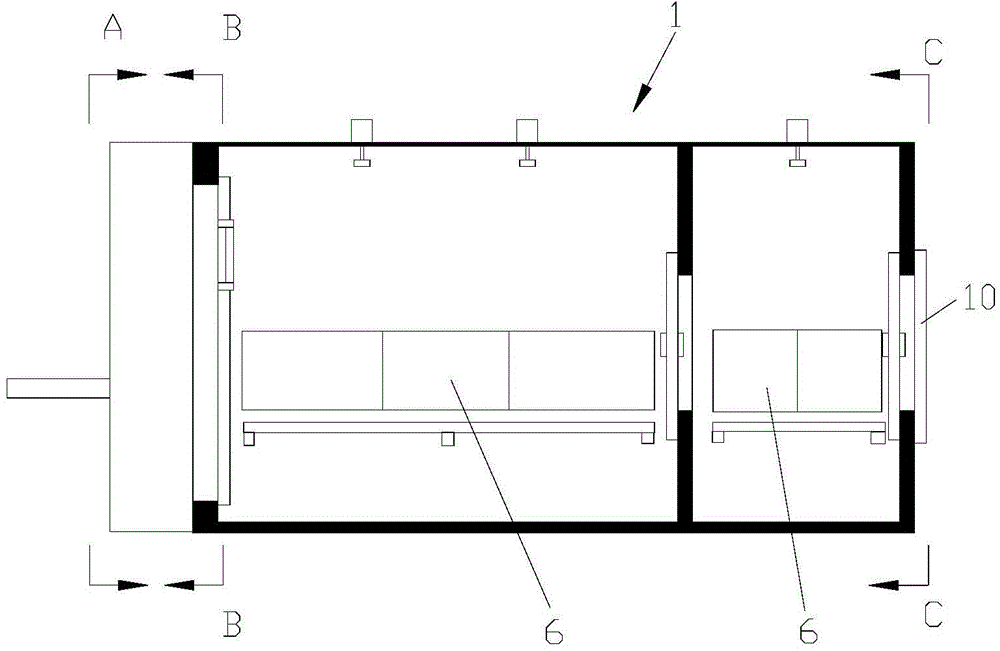

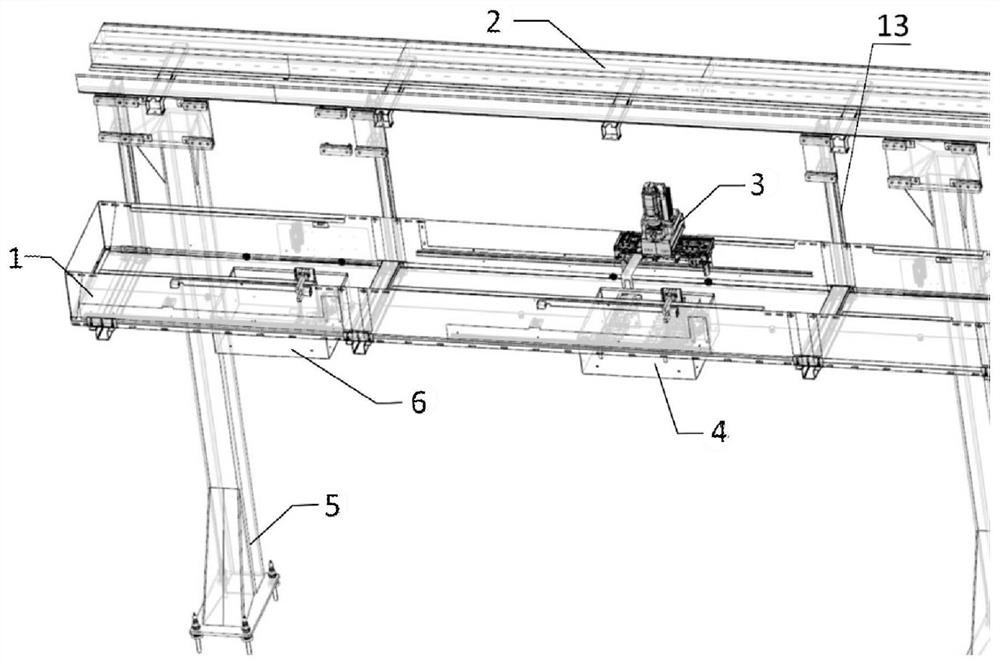

Truss composite tool magazine

InactiveCN112192291AReduced areaResolution timePositioning apparatusMetal-working holdersStructural engineeringMachine tool

A truss composite tool magazine comprises a truss box body, a guide rail, a tool changing gripper and a truss stand column, the guide rail is arranged at the top of the truss stand column, the truss box body is arranged on the guide rail, and the tool changing gripper is movably arranged on the guide rail; the truss box body comprises a box body, a truss and machine tool magazine connector, a toolprotective cover and a connecting bracket; a cover plate used for opening and closing is arranged at the top of the tool protective cover, and a tool storage rack is arranged in the tool protective cover; a truss tool changing door is arranged on the truss and machine tool magazine connector; a tool changing arm is arranged at the front end of the tool changing gripper, and the direction of the tool changing arm is adjustable; and a compressed air cleaning port is formed in the guide rail. According to the truss composite tool magazine, by arranging the guide rail, the path of the tool changing gripper in the tool changing process is reduced, the tool protective cover is used for preventing tools from being polluted, centralized storage and management of the tools in a factory can be achieved, the occupied space of a central tool magazine is reduced, the path needing to be passed in the tool changing process can be shortened, the tool changing efficiency is improved, and interferenceof the tool changing process on normal production is reduced.

Owner:SHANGHAI JIAO TONG UNIV +2

Digital controlled drill for machining PCBs (Printed Circuit Boards) and tool changing method of digital controlled drill

PendingCN110062530ANo manual operationImprove tool change efficiencyPrinted circuit manufacturePositioning apparatusEngineeringDigital control

The invention relates to the technical field of PCB machining, in particular to a digital controlled drill for machining PCBs (Printed Circuit Boards) and a tool changing method of the digital controlled drill. The digital controlled drill comprises a base, a workbench, a drill bit assembly and a tool changing assembly, wherein the workbench is movably arranged on the base; the drill bit assemblycan move relative to the workbench; and the tool changing assembly is arranged on one side of the workbench. According to the digital controlled drill disclosed by the invention, one side of a tool apron is provided with a clamping assembly for transferring a drilling tool, the clamping assembly can transfer a new drilling tool from a new tool magazine to one of tool holders along with the tool apron, a drilling tool to be replaced on the tool apron is placed on the other tool holder, and the clamping assembly transfers the replaced drilling tool into a used tool magazine after the tool apronclamps the new drilling tool, so that automatic tool changing is realized; manual operation is not required; and the tool changing efficiency is improved. According to the tool changing method disclosed by the invention, a tool setting operation is performed before and after tool changing, so that the relative position accuracy of the drilling tool relative to the tool apron and / or the workbench is ensured; size error after replacement of the drilling tool is reduced; and the drilling accuracy is improved.

Owner:珠海德景电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com