Tool changing device and method for numerical control machine tool

A technology of CNC machine tools and tool changing devices, applied in positioning devices, metal processing mechanical parts, clamping and other directions, can solve problems such as poor tool changing efficiency, save time for tool loosening, good stability, and improve tool changing. the effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

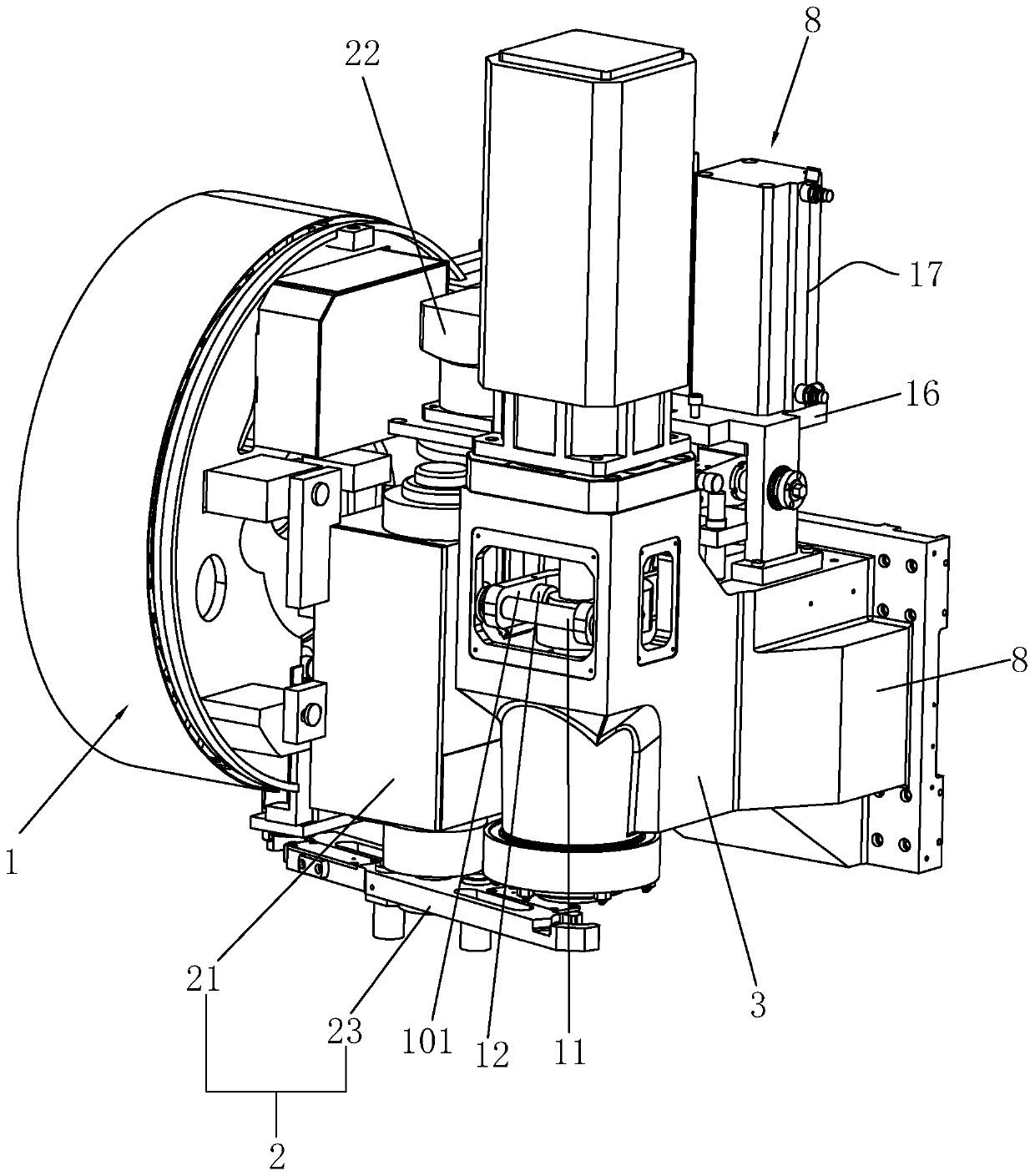

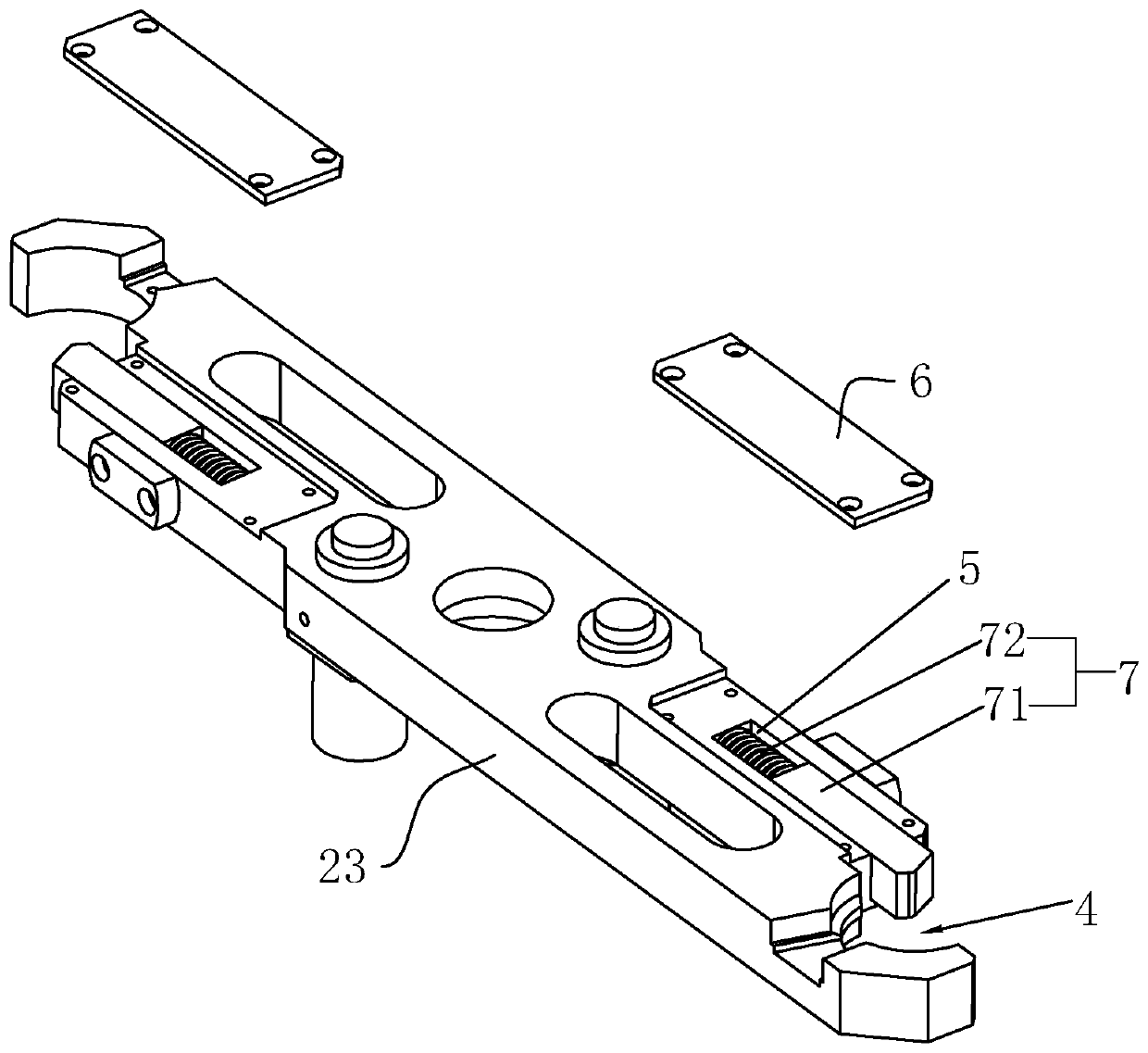

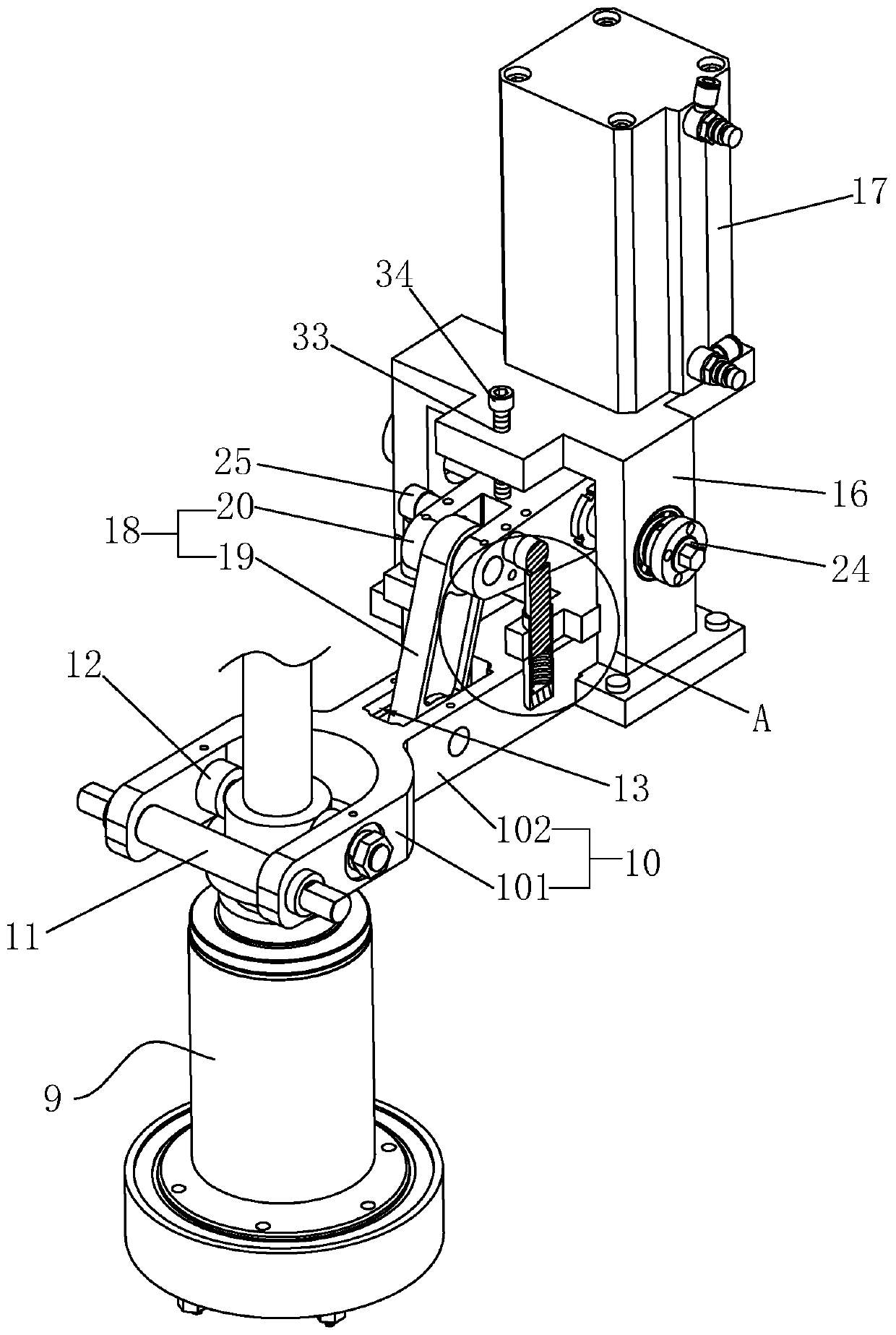

[0036] Such as figure 1 and 3As shown, a tool changing device for a CNC machine tool includes a tool magazine mechanism 1 , a spindle box 3 , and a tool changing mechanism 2 located between the tool magazine mechanism 1 and the spindle box 3 . The spindle box 3 is provided with a spindle 9 for clamping tools. For the specific structure of the spindle, refer to the Chinese patent with the notification number CN203266217U, including a gas-hydraulic pressurized cylinder, a spindle, a pressure rod, a disc spring, a pressure sleeve, a marble, and a gas cylinder. The hydraulic booster cylinder is located above the pressure rod, and the gas-hydraulic booster cylinder is used to press down the pressure rod. Used for clamping tools, the disc spring is sleeved on the pressure rod. The tools used by CNC machine tools usually include tool holders and pull studs. When the CNC machine tool equipped with the spindle tool release mechanism needs to release the tool, the worker presses the ...

Embodiment 2

[0048] A tool changing method for a numerically controlled machine tool. The tool changing method for a numerically controlled machine tool provided in this embodiment is applied to the tool changing device for a numerically controlled machine tool described in Embodiment 1. The specific steps of the tool changing method of the numerically controlled machine tool are as follows:

[0049] Preparation step: the tool changing arm 23 of the tool changing mechanism 2 is in the initial position to be ready;

[0050] Step of loosening the tool in advance: before the tool changing arm 23 of the tool changing mechanism 2 acquires the tool to be replaced on the main shaft 9, the piston rod of the servo drive device 17 pre-extends a part of the stroke to act on the floating end of the tool releasing arm 10, so that The tool release roller 12 forces the tool to be replaced clamped on the main shaft 9 to be in a state close to the tool release, that is, the tool is released in advance;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com