Truss composite tool magazine

A compound knife and truss technology, which is applied in the field of tool magazines, can solve the problems of easy dead corner accumulation of debris, slow tool change speed, and cumbersome structure, so as to improve tool change efficiency, reduce interference, and reduce tool corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

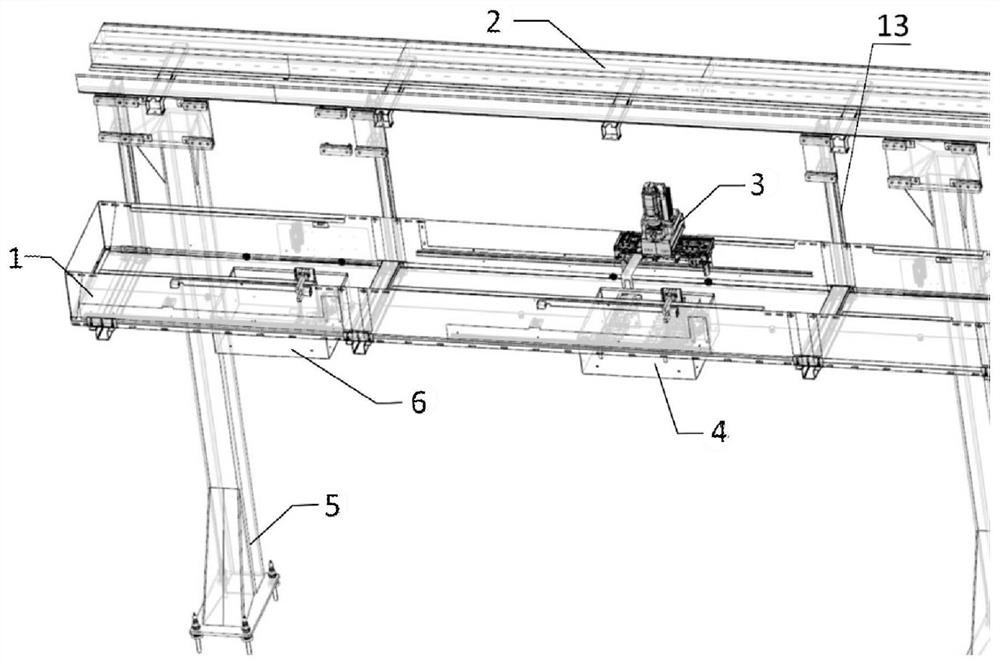

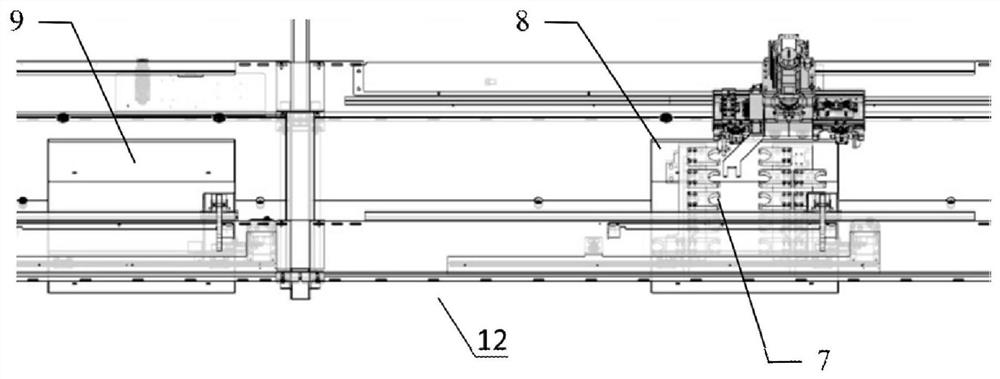

[0017] Such as figure 1 As shown, it is a truss compound tool magazine related to this embodiment, which includes: a truss box 1, a guide rail 2, a tool change handle 3 and a truss column 5, wherein: the guide rail 2 is arranged on the top of the truss column 5, and the truss box The body 1 is arranged on the guide rail 2, and the tool changing gripper 3 is movably arranged on the guide rail 2.

[0018] Described truss box body 1 comprises: box body 12, truss and machine tool magazine interface 6, tool shield 4 and connection support 13, wherein: box body 12 is arranged on guide rail 2 by connection support 13, truss and machine tool magazine The interface 6 is arranged at the bottom of the box body 12 , and the tool guard 4 is arranged inside the box body 12 .

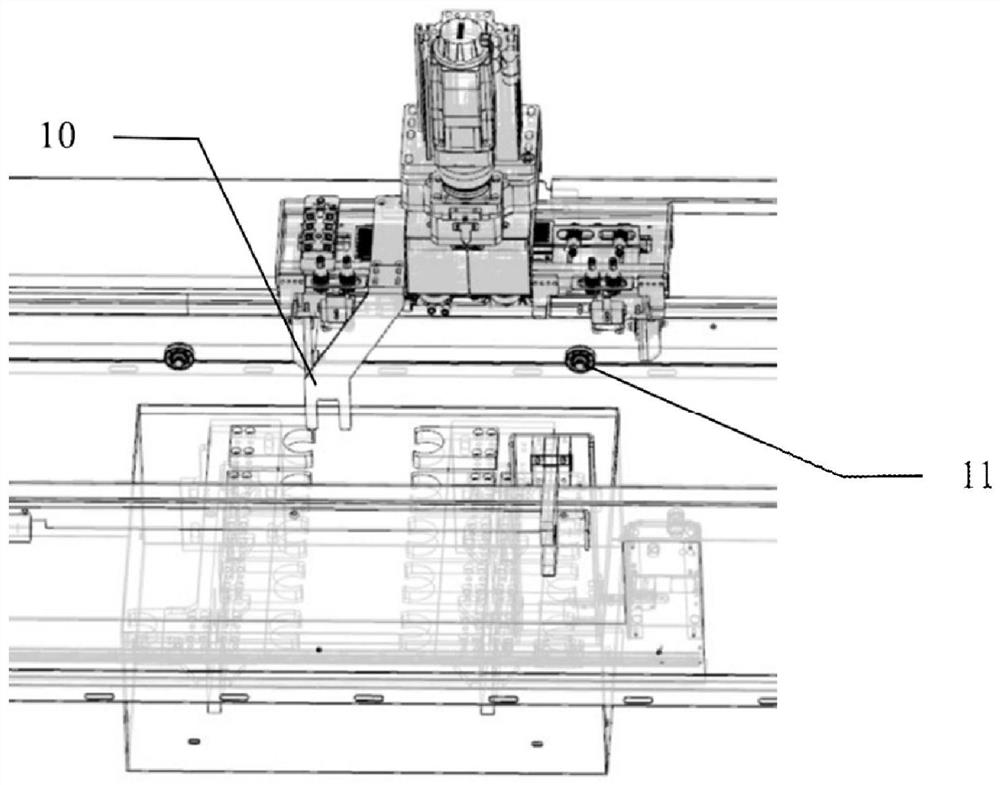

[0019] The top of the cutter protective cover 4 is provided with a cover plate 8 for switching to prevent corrosion of sundries such as oil stains and swarf, and several cutter storage racks 7 are arranged in the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com