Bamboo hat-type tool magazine tool changer and control method thereof

A hat-style tool magazine and tool changing device technology, applied in positioning devices, manufacturing tools, clamping, etc., can solve the problems of poor stability and reliability, insufficient positioning accuracy, complicated operation, etc., and achieve good reliability and structure. Simple and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

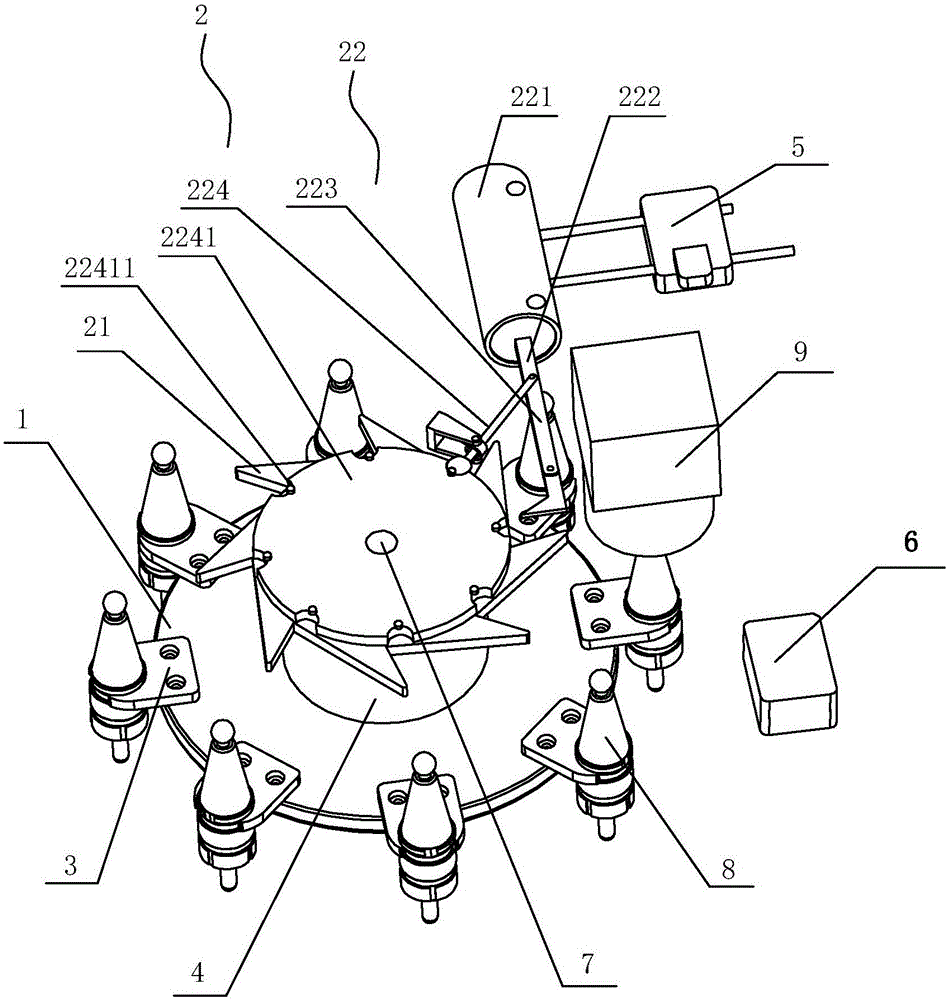

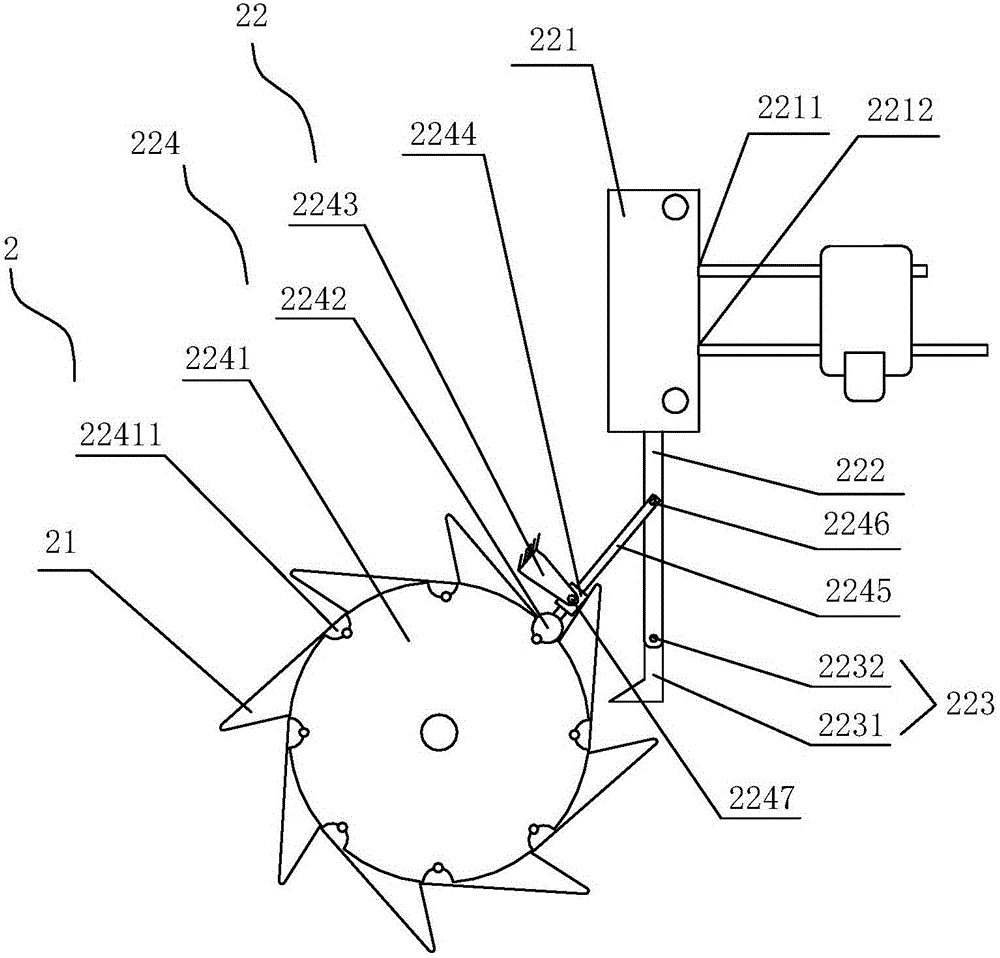

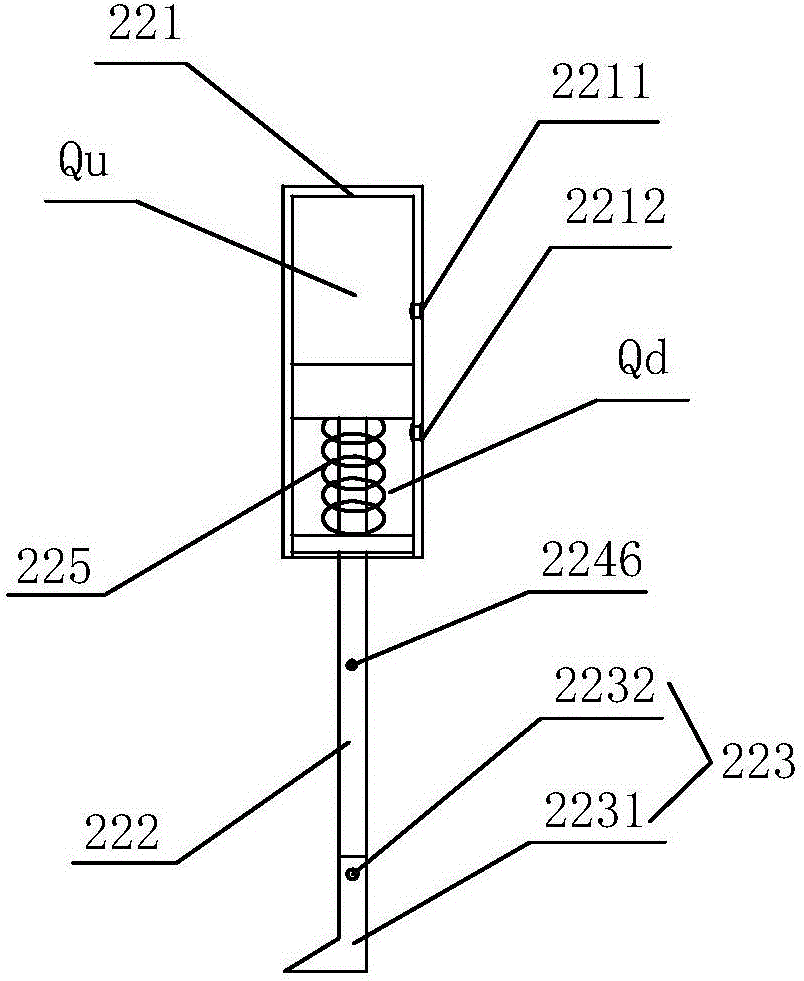

[0046] figure 1 Disclosed in is a bucket hat type tool magazine tool change device, including a cutter head 1, a cutter head rotation drive device 2, and eight tool holders 3, and the eight tool holders 3 are evenly distributed on the circumference of the cutter head 1, The cutterhead 1 is connected to the cutterhead rotation drive device 2 through the cutterhead hub 4, the cutterhead rotation drive device 2 includes a ratchet 21, and a ratchet push lock mechanism 22, and the ratchet 21 is connected through the cutterhead hub 4, the connecting shaft 7 is connected with the cutter head 1, and the number of ratchets of the ratchet wheel 21 is the same as that of the knife holder 3; the ratchet wheel pushes the locking mechanism 22 to include a drive cylinder 221, a piston connecting rod 222, a ratchet wheel pushing mechanism 223 and a ratchet wheel locking mechanism 224, Piston connecting rod 222 is connected with the output end of the piston of drive cylinder 221, and piston co...

Embodiment 2

[0056] A control method for a tool changing device of a bucket hat type tool magazine. The method is that the CNC system of a machine tool first sends a signal to PLC6 to change a certain tool position according to the processing program, and PLC6 controls the electromagnetic reversing valve 5 after receiving the control signal. And control the continuous expansion and contraction of the piston of the driving cylinder 221, so that the ratchet 2231 continuously promotes the rotation of the ratchet 21, and when it turns to the knife position point, it triggers the proximity switch installed on the knife position point, and the proximity switch feeds back the trigger signal to PLC6, which PLC6 immediately stops supplying power to the electromagnetic reversing valve 5, the piston of the drive cylinder 221 is pushed back to the initial position by the return spring 225, and at the same time locks the sheave indexing plate 2241 through the locking block 2242, thereby realizing locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com