Engraving and milling machine tool with servo magazine

A technology for tool magazines and machine tools, which is applied to metal processing machinery parts, clamping, and supports, and can solve the problems of increased production costs, prolonged tool change time, and low tool change efficiency, achieving low production costs and improved tool change efficiency , the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

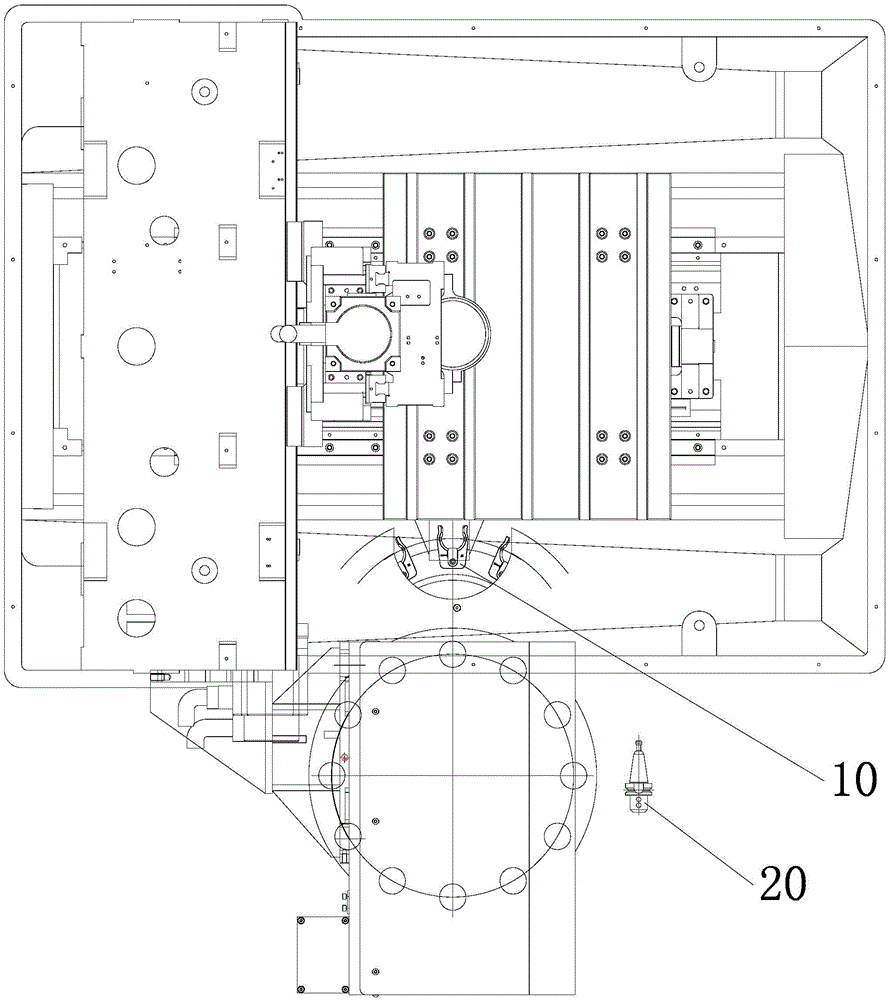

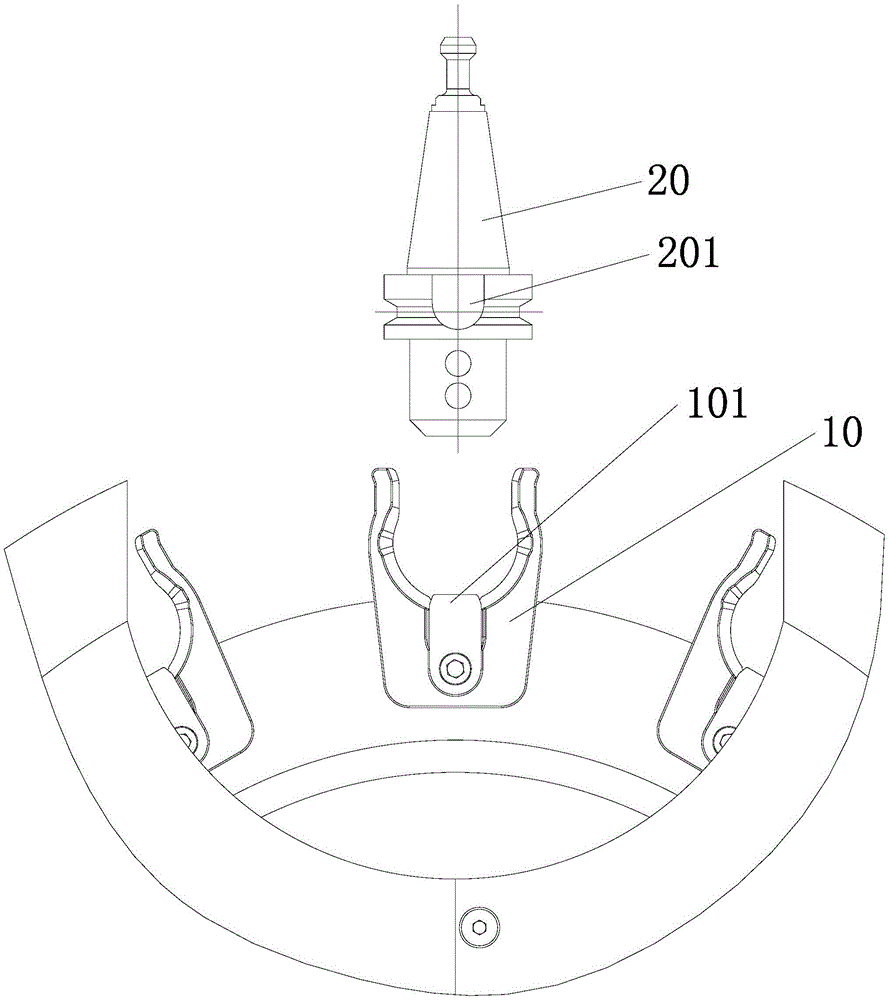

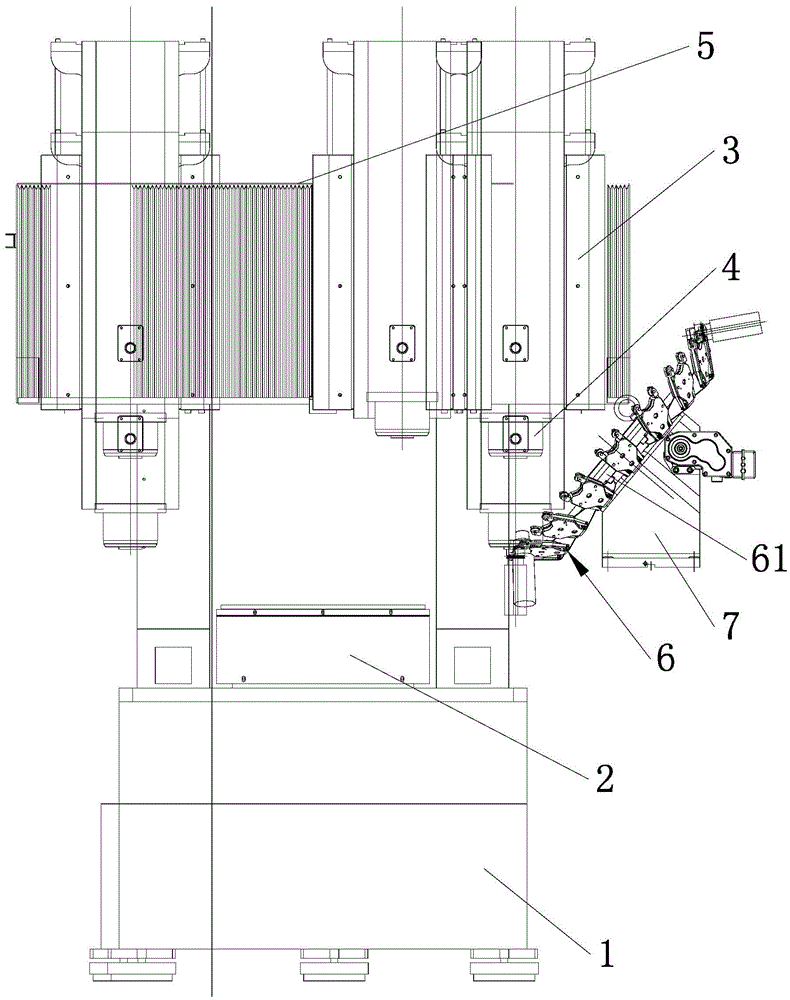

[0020] An engraving and milling machine with a servo tool magazine, such as Figures 3 to 7 As shown, it includes a base 1, a workbench 2, a main shaft machine 3, a main shaft 4 installed on the main shaft machine 3, a machine base 5 for installing the main shaft machine 3, and a tool magazine 6. Here, the tool magazine 6 is obliquely installed on the cutter head support slope of the cutter head support seat 7; Several sets of knife claw groups 62 on the periphery of the rotating disk 61, the handle of a knife 63 with a milling cutter clamped on the knife claw group 62, all handles of a knife 63 are installed on the knife claw group 62 to form a tool magazine; The set of claws 62 at the bottom of the tool magazine 6 is in a horizontal position, so that the tool handle it clamps is in a vertical state so that the main shaft 4 can move in and out of the claws horizontally in the direction of the X axis, and lift the rear sleeve in the direction of the Z axis. Put in the handle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com