Machining center with multi-tool-bit quick tool-replacement mechanism

A technology of tool changing mechanism and machining center, which is applied in metal processing, accessories of tool holders, metal processing equipment, etc., and can solve problems such as inconvenient maintenance, complex structure, cumbersome tool changing steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings, wherein the horizontal, vertical and vertical directions described in the present invention are It refers to the X axis, Y axis and Z axis in the machine tool.

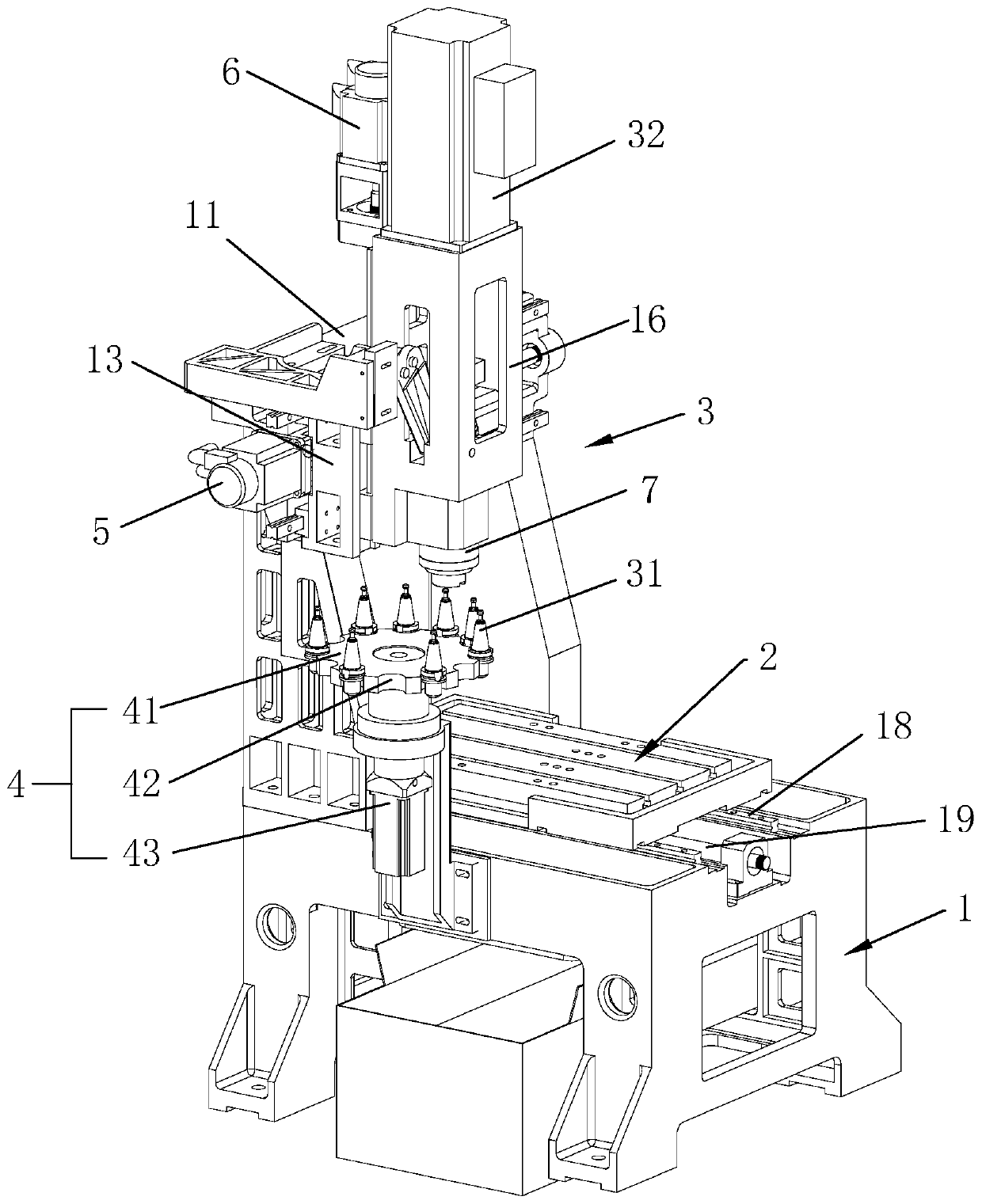

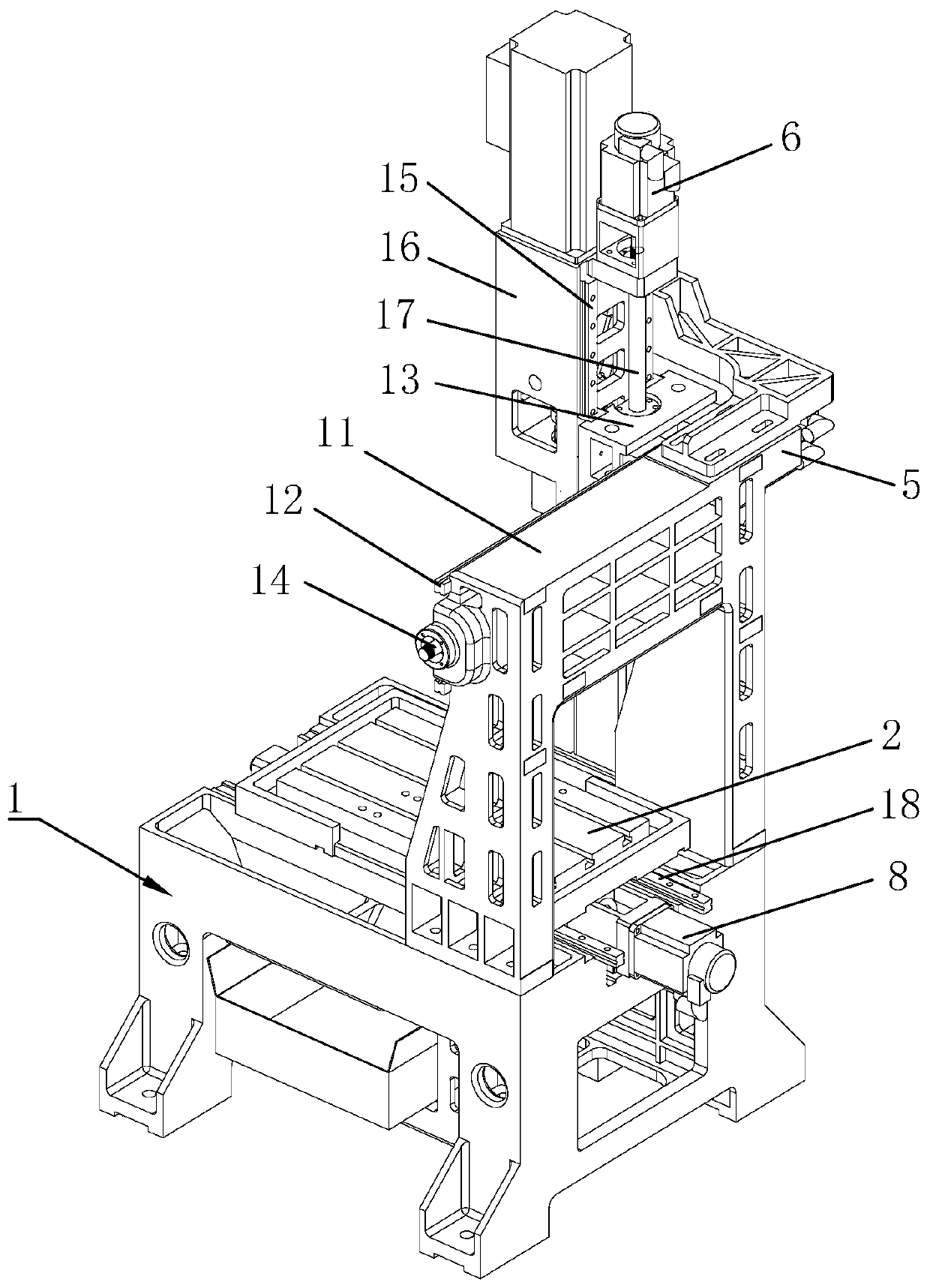

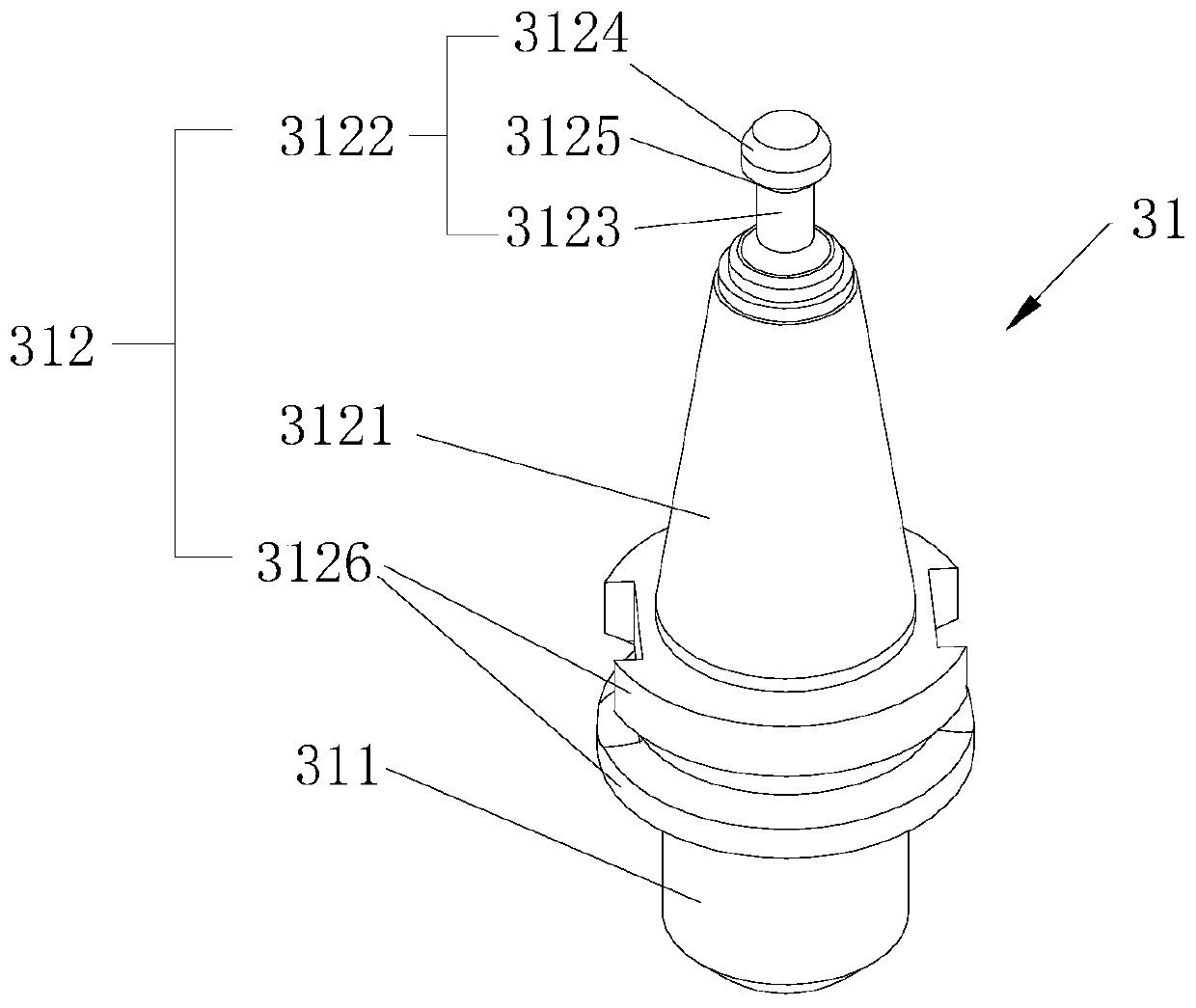

[0045] A machining center with a multi-head quick tool change mechanism, such as figure 1 and figure 2 As shown, it includes a frame 1, a workbench 2 arranged on the frame 1 and a processing tool 3 above the worktable 2. The processing tool 3 includes a cutter head 31 and a first power unit 32 that drives the cutter head 31 to rotate, wherein , the machining center also includes

[0046] The tool magazine 4 is located at the side of the workbench 2 to provide a tool changing tool head for the broaching device 7. The tool magazine 4 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com