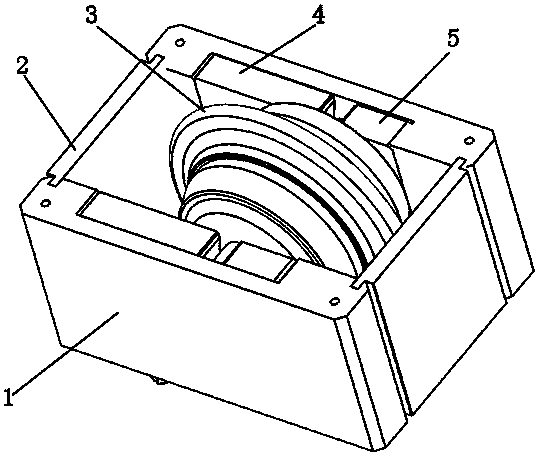

Portable hobbing cutter system and dismounting method thereof

A cutting tool system and a convenient technology, applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of poor fusion of hobs and low work efficiency, reduce the risk of manual tool change, and improve the efficiency of tool change , high practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

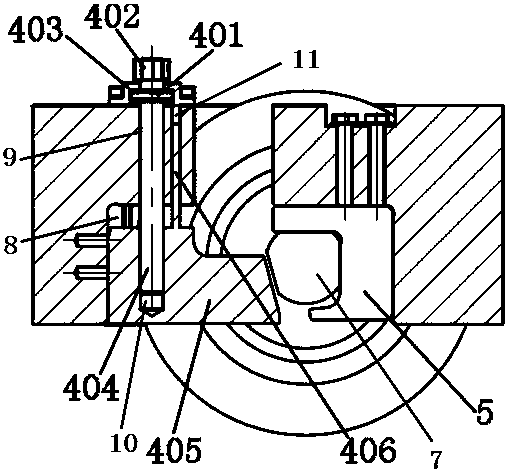

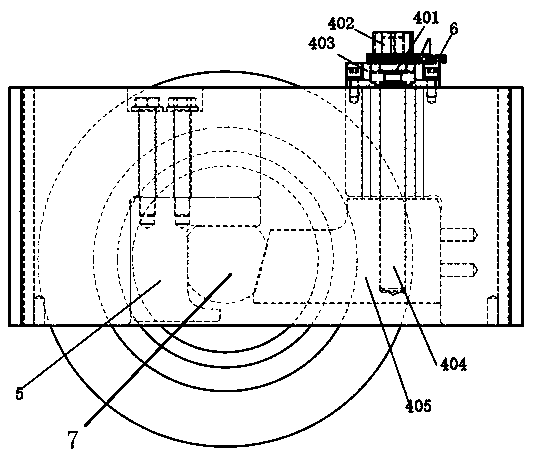

[0047] Embodiment 3: A method for disassembling and assembling a portable hob cutter system. The installation steps of the portable hob are as follows: S1: Put the block 5 into the cutter box 1, as shown in Figure 6 as shown,

[0048] S2: Assemble the threaded rod 404 and guide rod 406 in the locking push-pull mechanism 4 on the tool box plate 1, and assemble the anti-loosening washer 401 on the threaded rod 404 to prevent the threaded rod 404 from loosening;

[0049] S3: Assemble the cover plate 403 on the knife box 1 and tighten it with bolts, so that the cover plate 403 presses the anti-loosening washer 401 to prevent the anti-loosening washer from shaking;

[0050] S4: Put the slider 405 into the limit groove 8 on the two side walls of the tool box 1, and then thread the threaded rod 404 to the slider 405;

[0051] S5: Drive the slider 405 to move along the axial direction of the threaded rod 404 by turning the threaded rod 404, and install the hob 3 in the cutter box 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com