Swing push-pull hob tool system and tool-changing method thereof

A cutting tool system and hob technology, applied in earthwork drilling, mining equipment, tunnels, etc., can solve the problems of low cooperation and low automation of tool changing robots, reduce the risk of manual tool changing, and achieve a high degree of automation , Improve the effect of construction safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

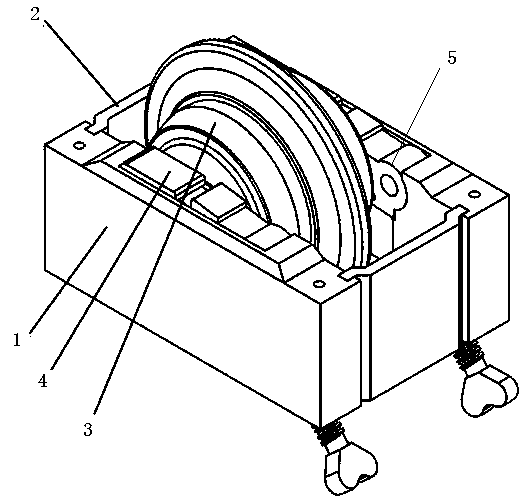

[0025] Example 1, such as figure 1 As shown, a swing push-pull hob cutter system includes a cutter box 1 and a hob 3. The hob is located in the cutter box and is detachably connected to the cutter box. The two ends of the cutter box 1 are clamped with connecting plates 2 for connecting The plate 2 is detachably connected with the knife box 1 to realize the sealing of the knife box. The inner walls on both sides of the knife box 1 are provided with a block 4 for fixing the hob cutter shaft 6 and a swing push-pull locking mechanism 5 , and the block 4 corresponds to the swing push-pull lock mechanism 5 . During installation, the hob cutter shaft is located between the block and the swing push-pull locking mechanism, and whether the hob cutter shaft is pressed or not is realized through the up and down swing movement of the swing push-pull lock mechanism.

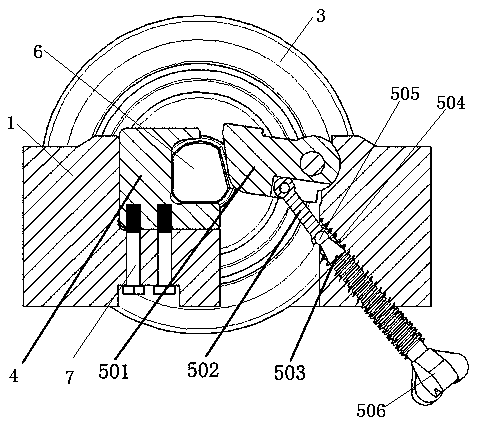

[0026] further, such as figure 2 As shown, the clamping block 4 is fixedly connected with the cutter box 1 through the fa...

Embodiment 2

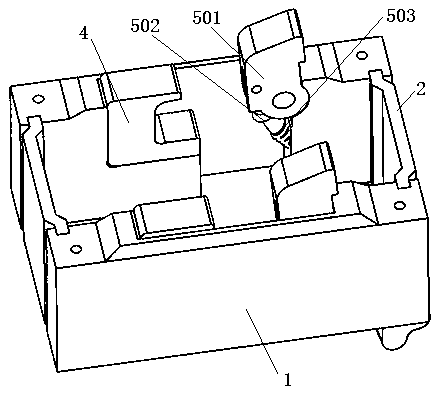

[0029] Example 2, such as Figure 5 , 6 A swinging push-pull hob cutter system is shown, the inside of the knife box 1 is provided with a mounting groove 8, and the bottom of the mounting groove 8 is provided with a mounting hole 9, and the mounting hole 9 cooperates with the swinging push-pull locking mechanism 5. The swinging push-pull locking mechanism 5 cooperates with the installation groove, and the swing pressing block 501 of the swinging push-pull locking mechanism is hinged with the tool box 1, and the positioning swing push-pull locking mechanism and its direction of motion realize quick tool change.

[0030] Further, the swinging push-pull locking mechanism 5 includes a swinging pressing block 501 and a push-pull rod 5-2, the swinging pressing block 501 is located in the installation groove 8, and the swinging pressing block 501 is hinged with the tool box 1, and the pressing edge of the swinging pressing block 501 is connected to the The hob cutter shaft cooperate...

Embodiment 3

[0035] Example 3, such as Figure 7 , 8 As shown, a swinging push-pull hob cutter system, the mounting hole 9 is a vertical through hole, the push-pull rod 5-2 includes an upper connecting rod 201, a middle connecting rod 202 and a lower screw 203, and the two ends of the middle connecting rod 202 They are respectively hinged with the upper connecting rod 201 and the lower screw rod 203, and the upper connecting rod 201, the middle connecting rod 202 and the lower screw rod 203 are all matched with the vertical through holes. The upper connecting rod 201 is rotatably arranged in the light hole, and the lower screw rod 203 is located in the vertical through hole and fixed by a locking nut.

[0036] Other structures are the same as in Embodiment 2.

[0037] The tool changing method of the above-mentioned swinging push-pull hob tool system is characterized in that it includes the following steps: S1: tool disassembly: the tool changing robot reversely turns the lock nut, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com