Single-hobbing-cutter changing manipulator of shield tunneling machine

A technology of shield machine and manipulator, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome time-consuming, and the construction progress has a great influence, so as to speed up the construction progress and save the time of changing the pressure and entering the cabin. , The effect of improving the efficiency of tool change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

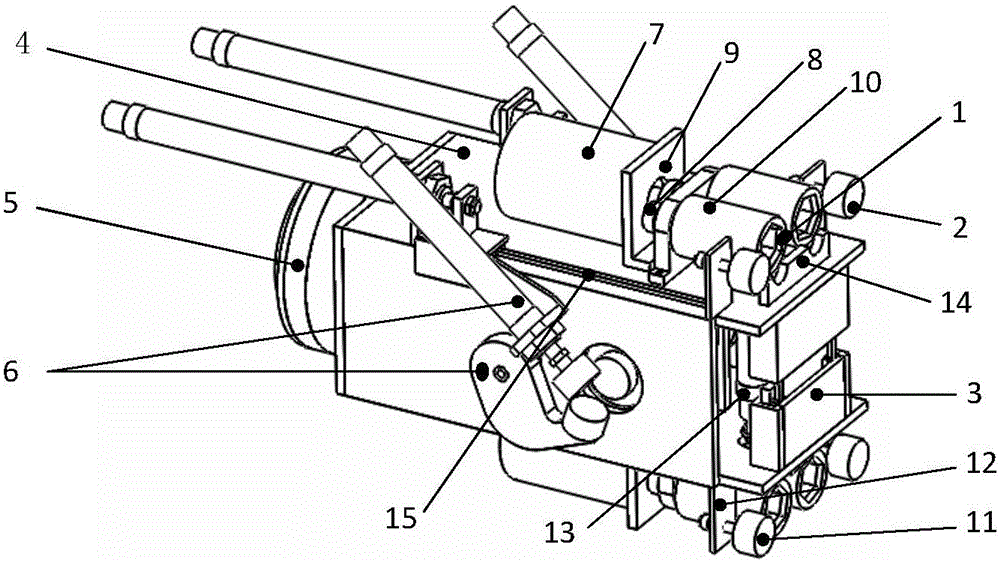

[0022] Such as figure 1 , figure 2 As shown, a shield machine single-hob tool changing manipulator includes a housing 4 on which a bolt disassembly module 1, a trapezoidal wedge disassembly module 2, a square wedge disassembly module 6, a shaft Disassemble the fixed module 3 to the rotating module 5 and the hob;

[0023] The trapezoidal wedge dismounting module 2 includes a second fixing flange 12, the second fixing flange 12 is fixed on the housing 4, and the first electromagnet 11 is fixed on the second fixing flange 12;

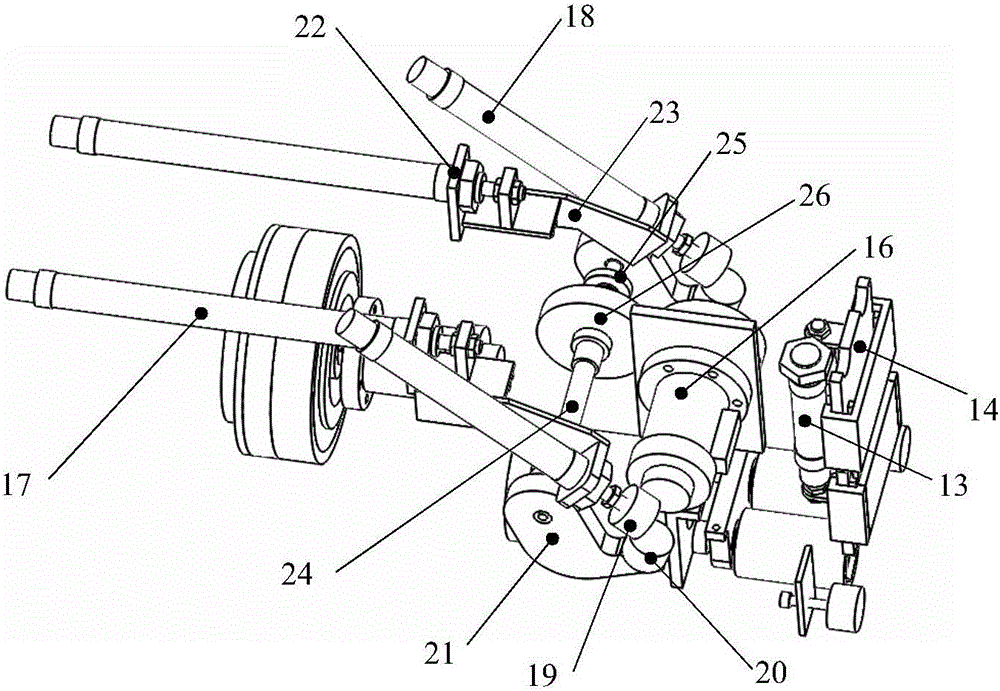

[0024] The square wedge dismounting module 6 includes a dismounting telescopic part and a dismounting rotating part, and the dismounting telescopic part includes a fixed bracket 22, and the fixed bracket 22 is fixed on the housing 4, and the fixed bracket 22 is provided with The first hydraulic cylinder 17 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com