Tool changing robot body applied to full face tunnel boring machine

A technology of tunnel boring machine and robot, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc. It can solve problems such as difficulty in tool change, achieve the effect of improving tool change efficiency and reducing tool change risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

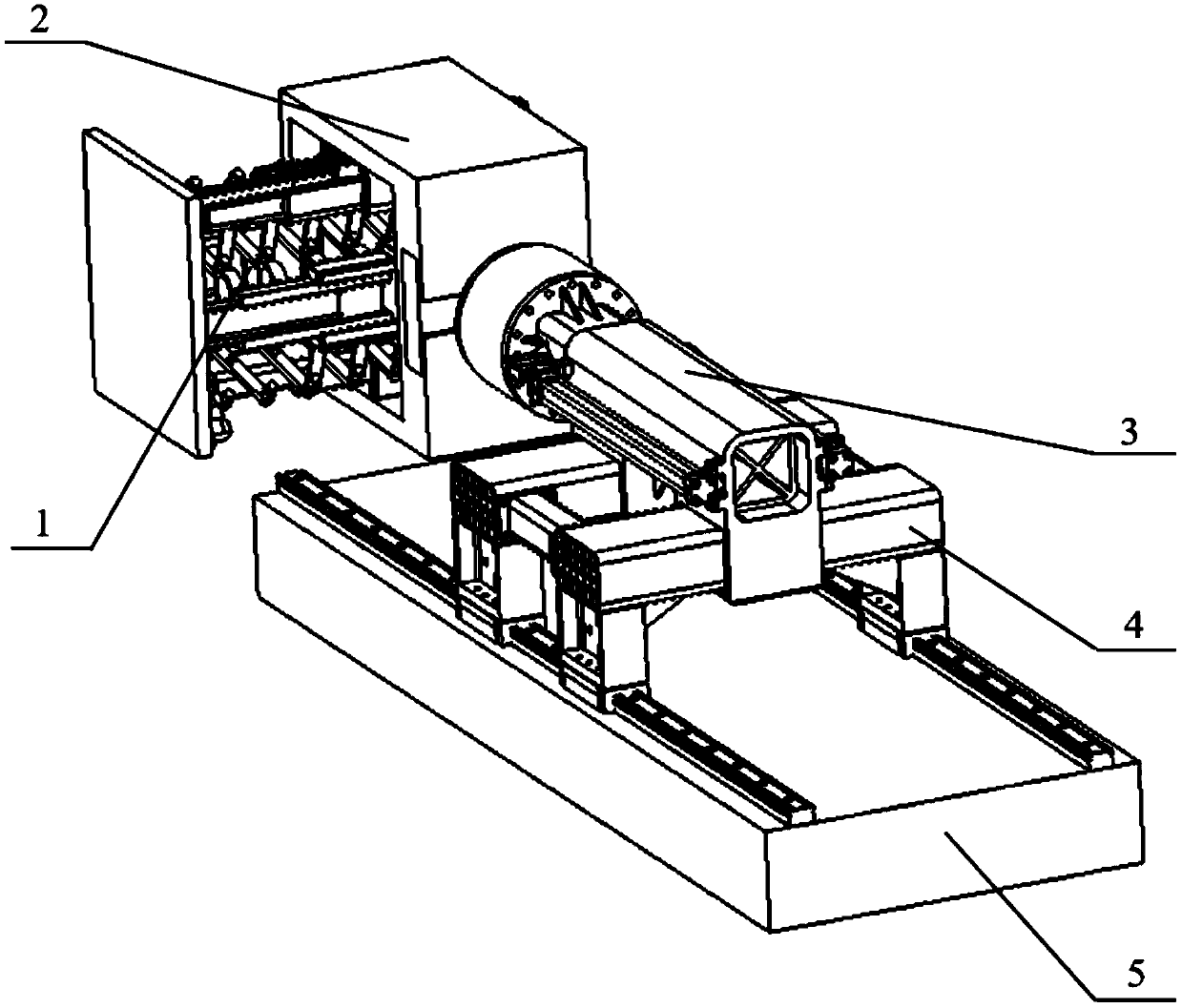

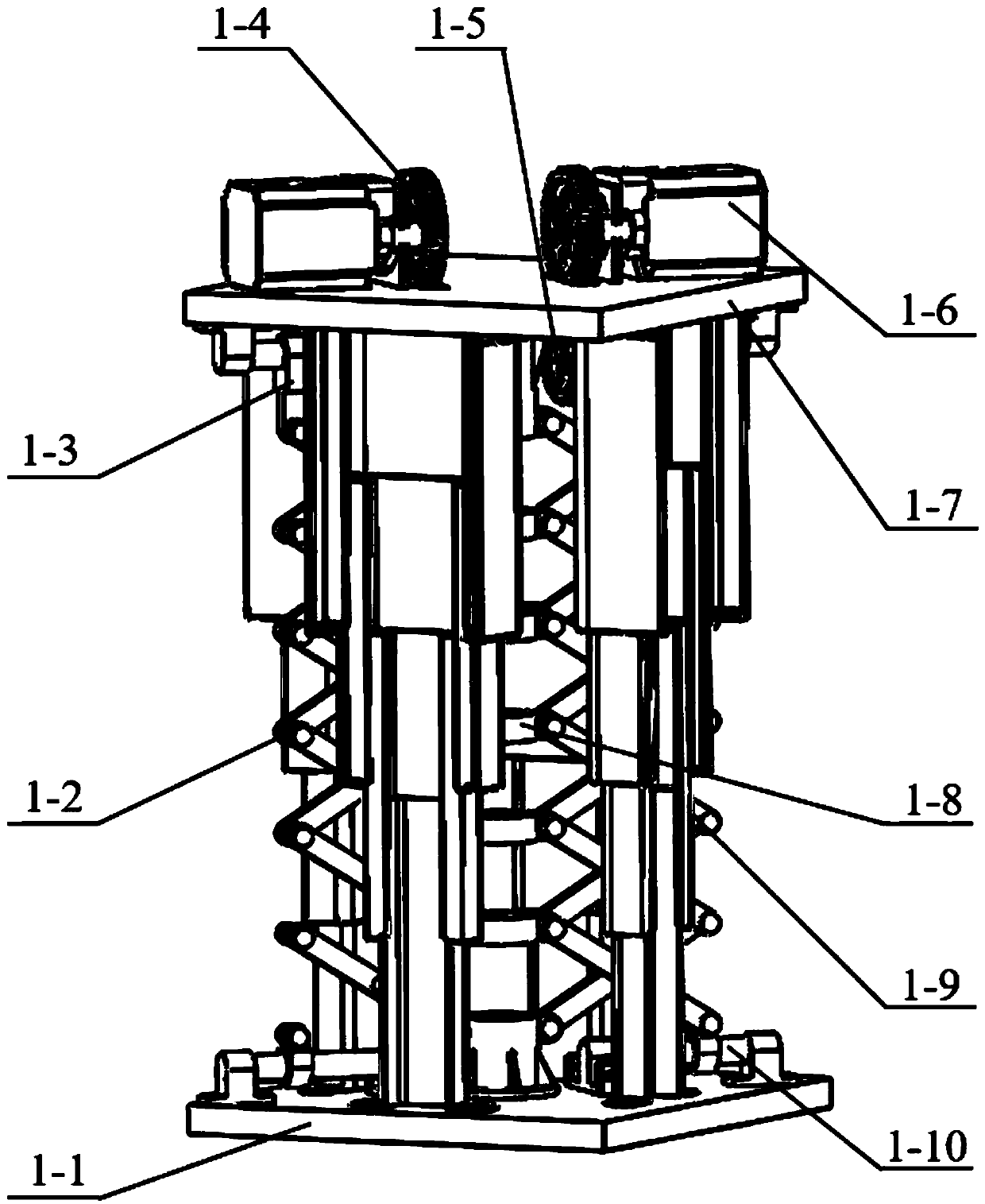

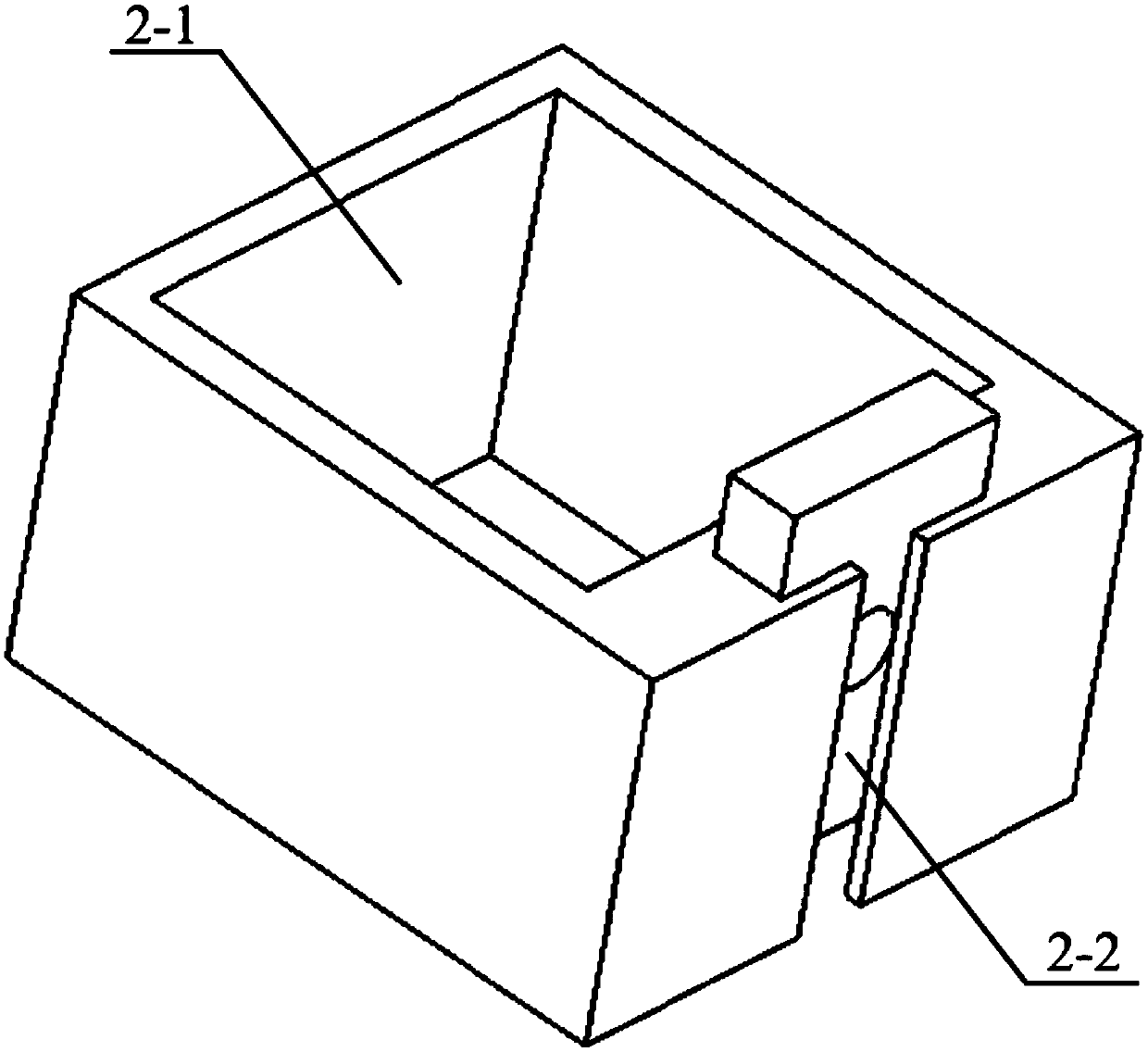

[0029] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

[0030] Step 1: When the tunnel boring machine is excavating, the robot gestures at the position when the tool is not changed Figure 6 It is shown in the robot cabin behind the cutter head. At this time, the door of the robot cabin is closed, and the soil and rock slag in the cutter head will not touch the robot body. The main body 1 part of the lift is in a retracted state.

[0031] Step 2: When the tunnel boring machine is shut down for maintenance, the replacement of the hob is started. At this time, the robot cabin door is in an open state, and the main part of the robot moves to the robot cabin door along the robot base slide rail 5-2. The stroke here is shorter. Long, you can choose the hydraulic motor to drive the ball screw to push the track seat to slide on the track. The schematic diagram of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com