Slag deposition and mud deposition prevention structure of normal-pressure tool changer

A tool changing device and slag accumulation technology, which is applied in mining equipment, mining equipment, tunnels, etc., can solve the problems of limited cleaning effect of water flushing, and achieve the effects of reducing the risk of tool changing, increasing construction efficiency, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

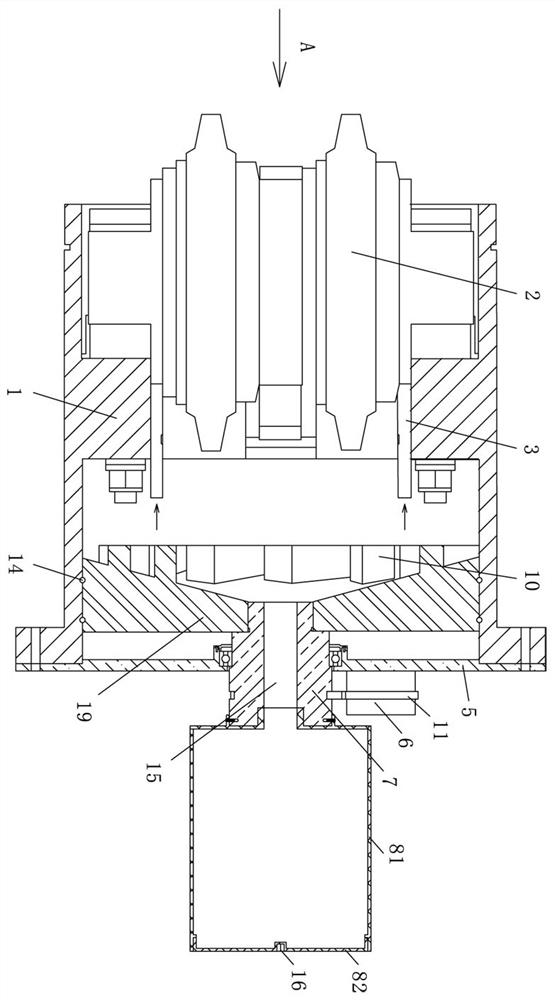

[0032] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

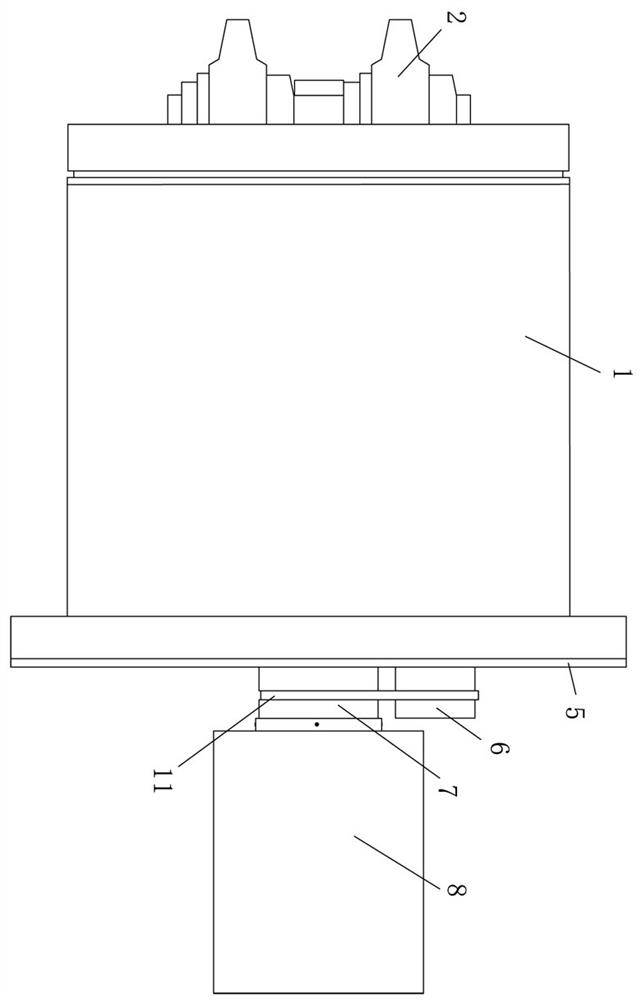

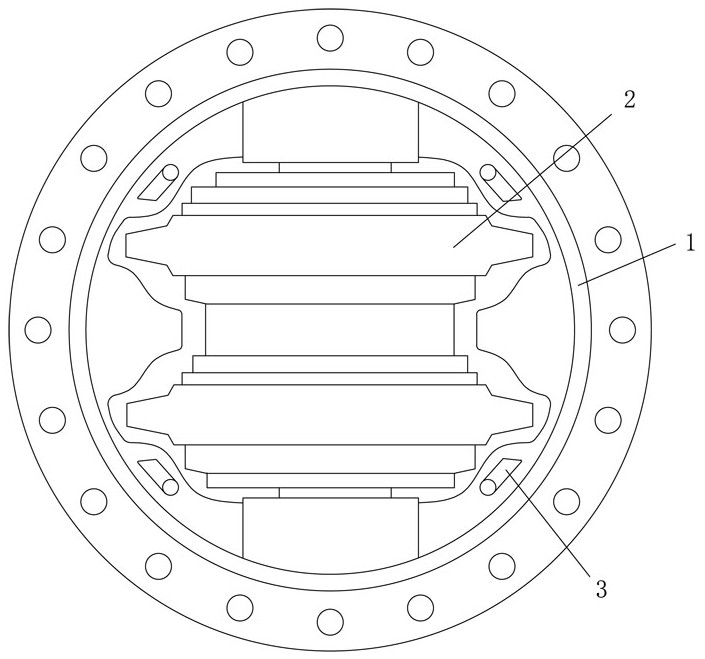

[0033] Such as Figure 1~Figure 7 As shown, a normal pressure tool changing device anti-slag and mud accumulation structure includes a knife barrel 1 and a hob 2 arranged in the knife barrel 1. The knife barrel 1 is hollow and cylindrical with two ends open, and the knife barrel 1. The hob 2 is arranged on the front end, and the hob 2 protrudes from the knife barrel 1.

[0034] In order to realize the flushing of the hob 2, four water spray pipes 3 with fan-shaped water spray holes 4 are provided on the upper circumference of the knife barrel 1 on the side of the hob 2, and the section of the water spray pipe 3 is " " " shape, and is positioned at knife barrel 1 front end.

[0035] Specifically, the water spray pipe 3 includes an axial section 31 and a radial section 32, and the axial section 31 and the radial section 32 are connected in a """ shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com