Method for exchanging tool of shield machine for tunnel construction

A construction method and technology for tunnel construction, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of inability to change tools, poor soil self-stabilization ability, loose stratum, etc., and achieve high practical value and enhanced stability. , to achieve convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

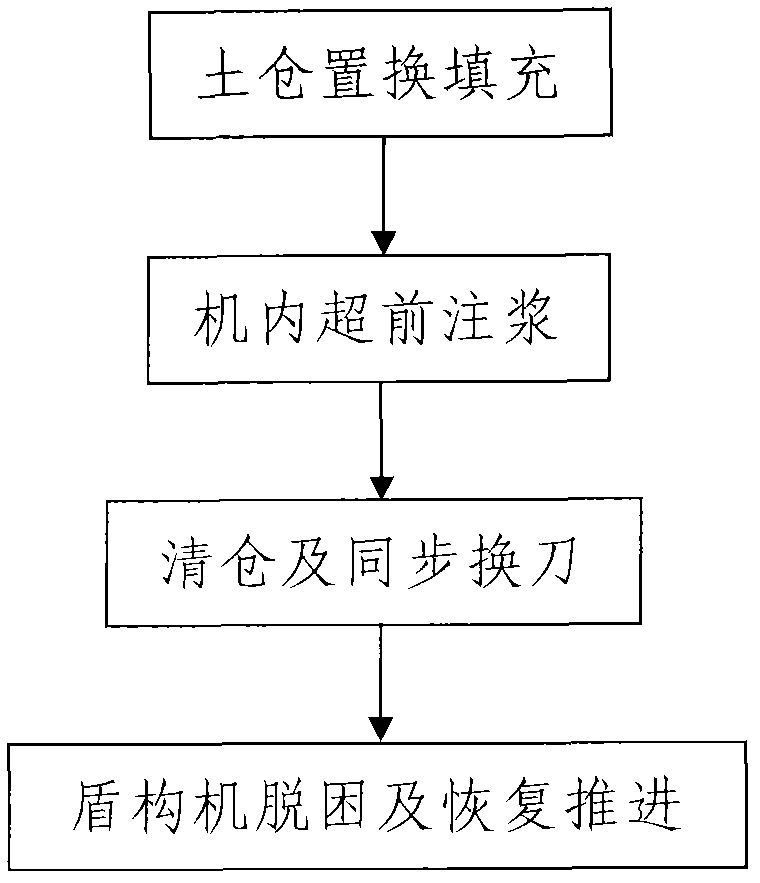

[0041] Such as figure 1 The one shown is suitable for conditions where the ground where the shield machine stops is relatively loose, the self-stabilization ability of the soil on the tunnel surface is poor, and there are structures directly above the cutter head. The shield machine cannot use the four methods commonly used in China at present ( For details, refer to the content recorded in the background technology part) when performing a tool change, the shield machine tool change construction method for tunnel construction is characterized in that the method includes the following steps:

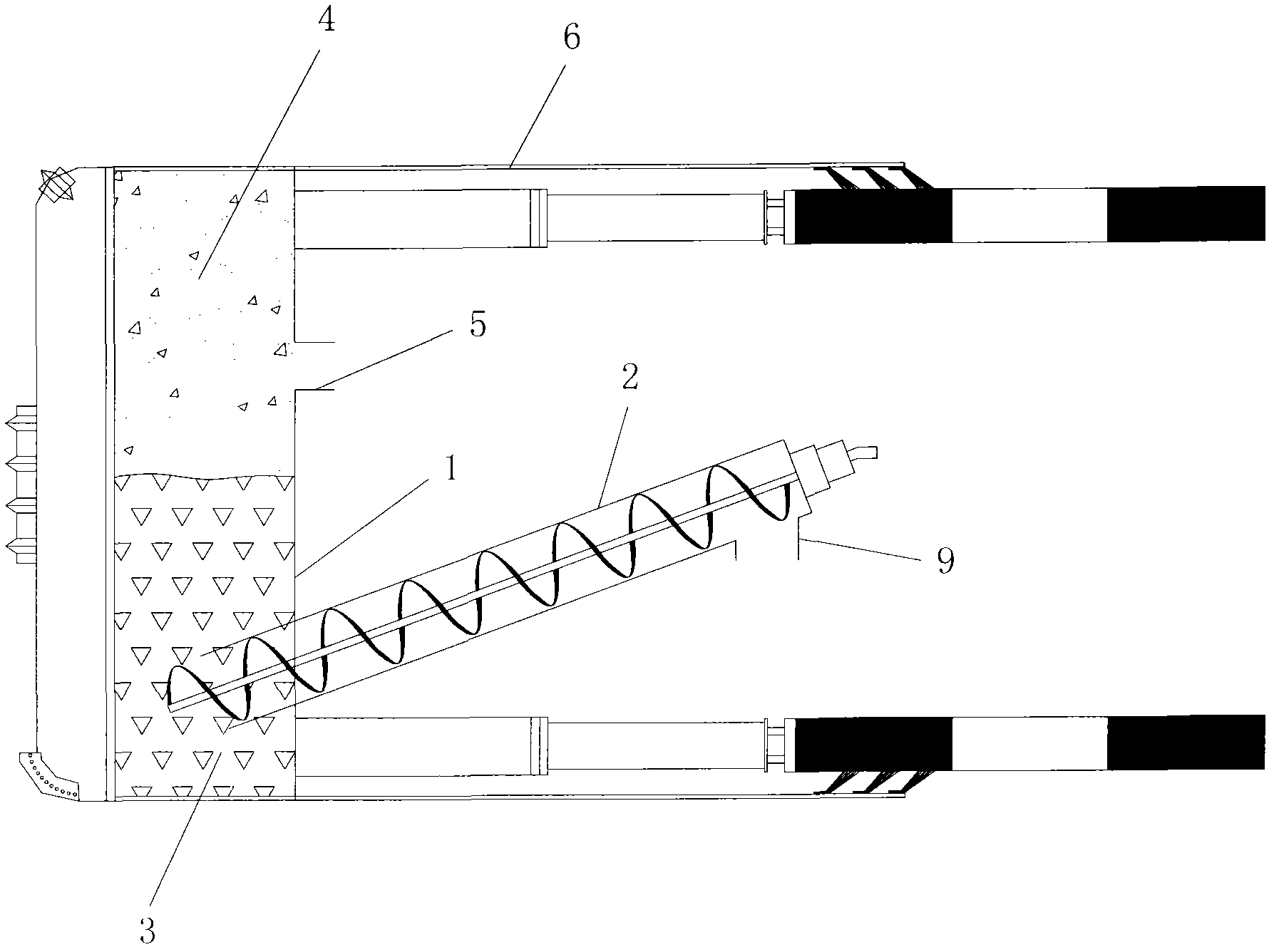

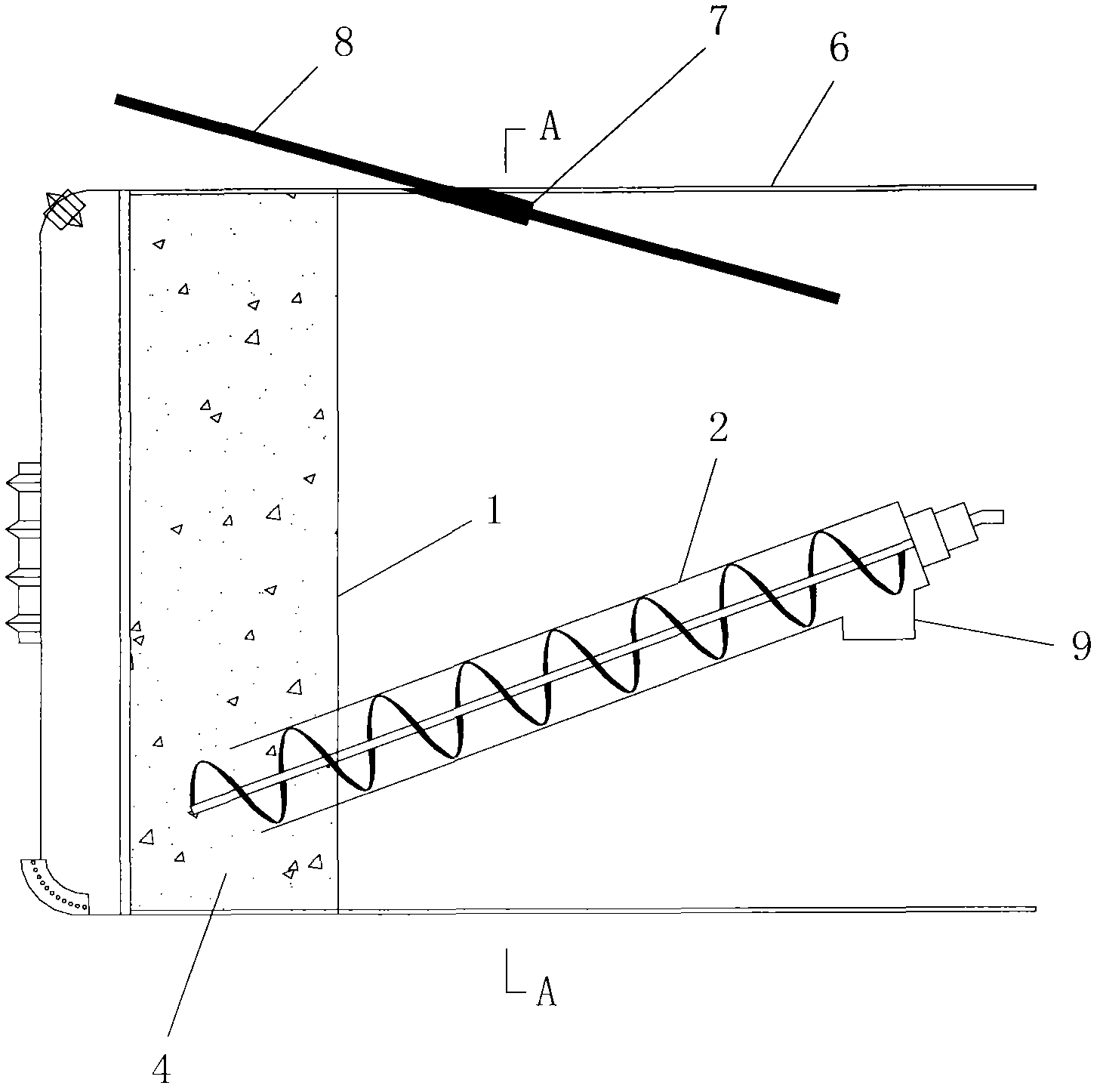

[0042] Step 1. Replacement and filling of the soil bin: use the screw excavator 2 and the grouting system that works synchronously with the screw excavator 2 to replace and fill the soil bin. The screw excavator 2 is installed on the side wall of the soil bin 1 in the shield machine 6 The lower part, the grouting system is installed on the upper part of the side wall of the soil bin 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com