Machine tool

A technology of machine tools and moving mechanisms, applied in machine tool parts, metal processing machinery parts, clamping and other directions, can solve the problem of not being able to shorten the tool change time, and achieve the effect of shortening the tool change time and improving the tool change efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

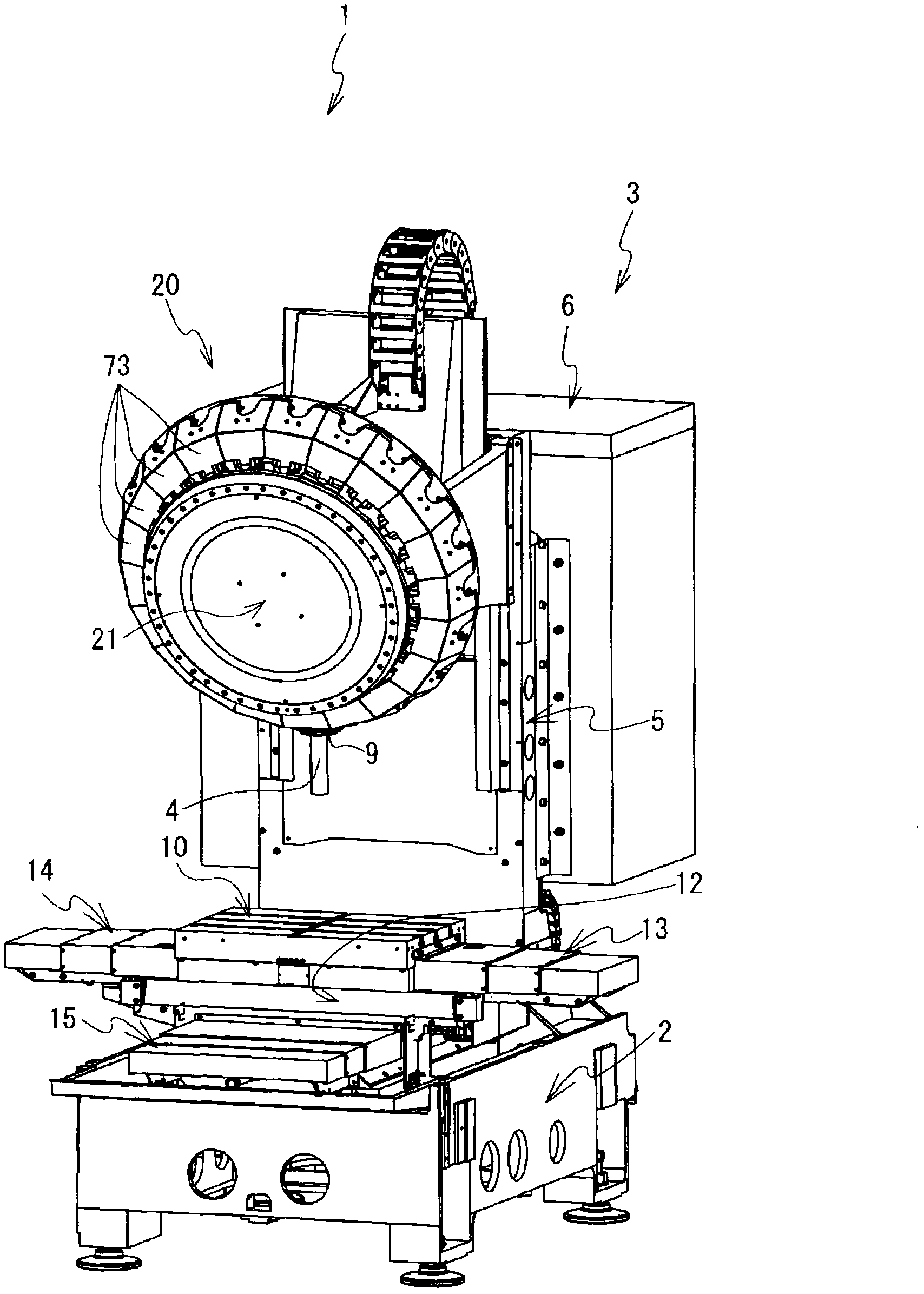

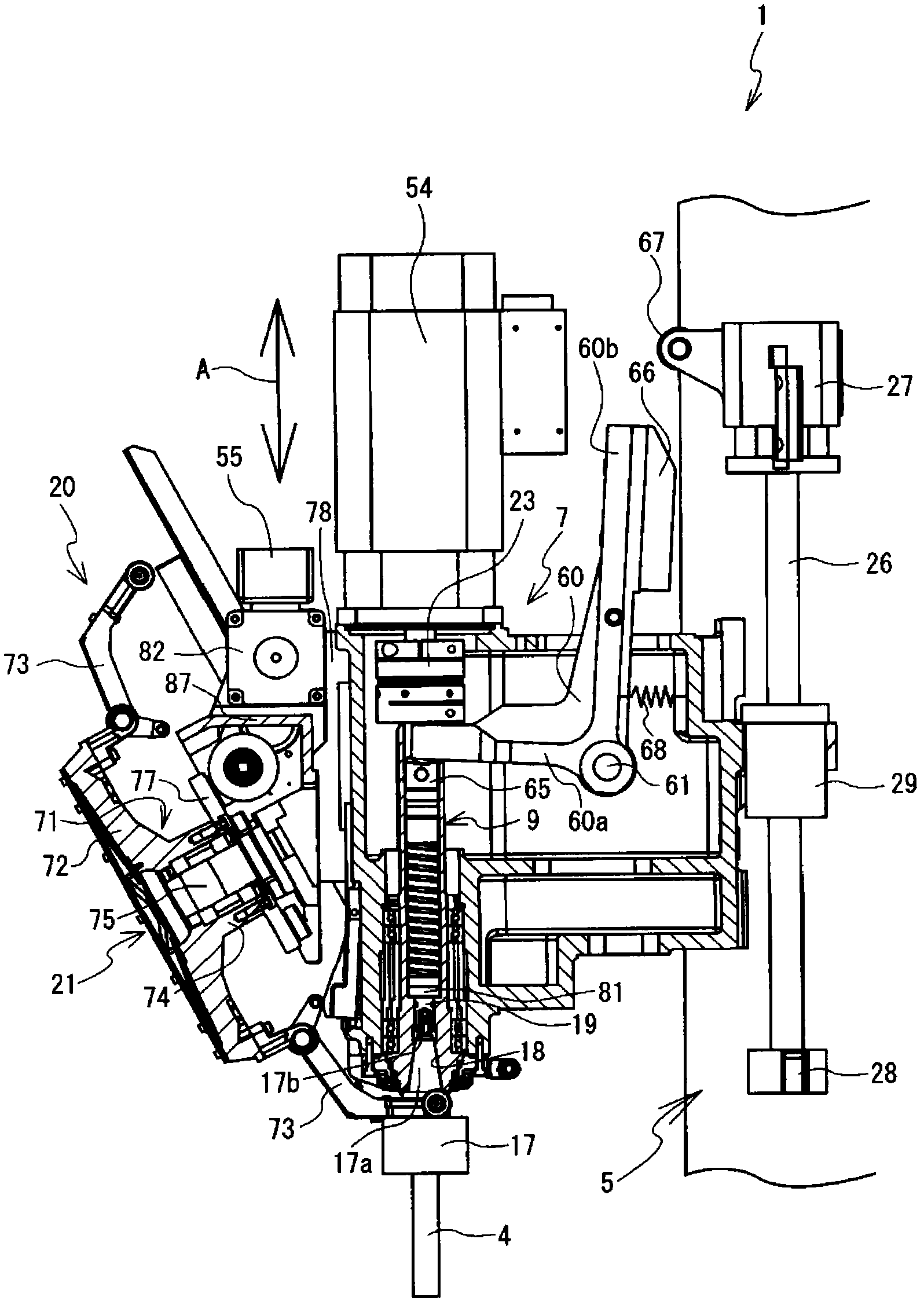

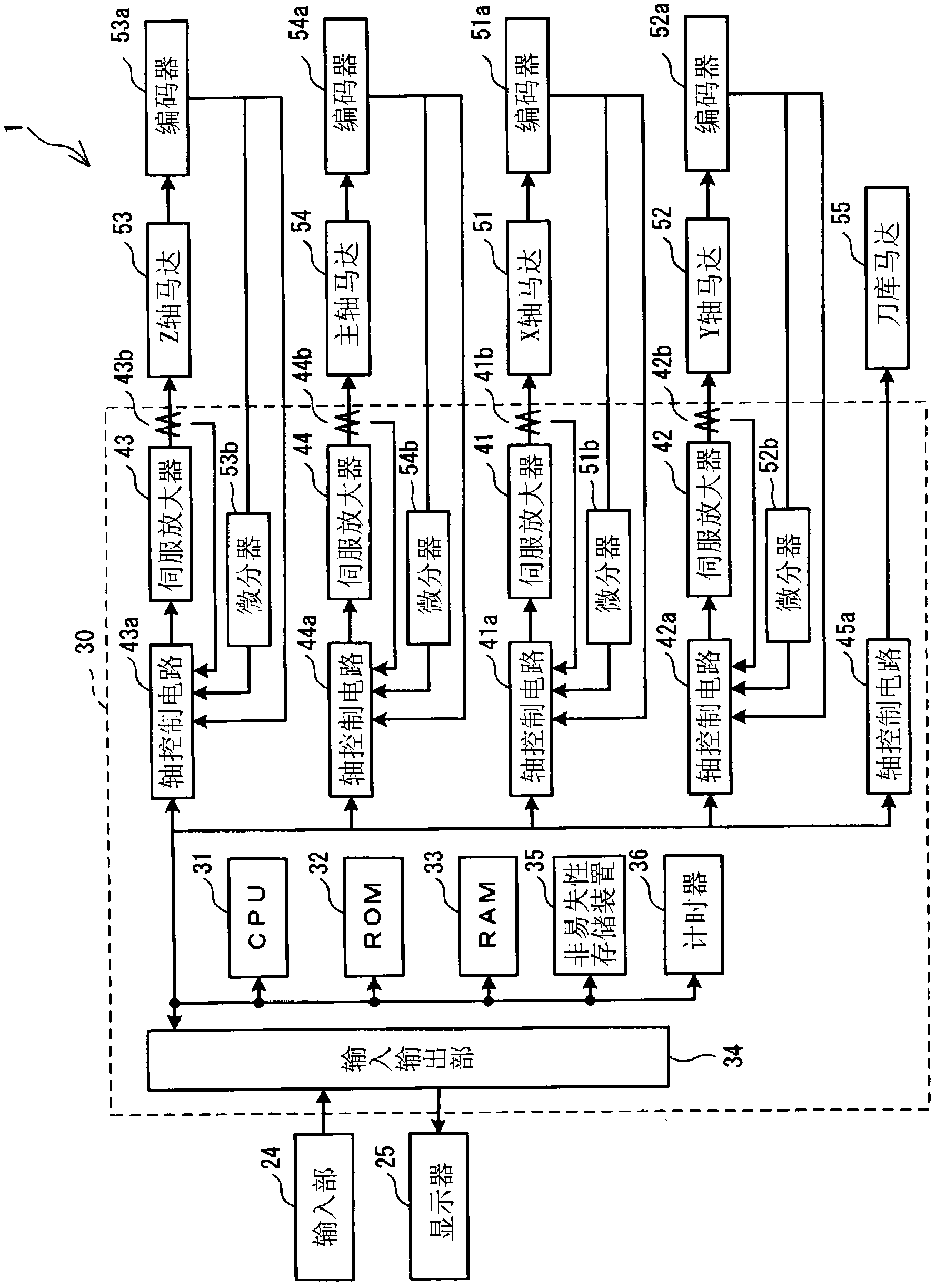

[0018] Hereinafter, a machine tool 1 according to a first embodiment of the present invention will be described based on the drawings. figure 1 The front direction, the depth direction, the right side, and the left side of the paper refer to the front, the rear, the right side, and the left side of the machine tool 1, respectively. The left-right direction of the machine tool 1 is the X-axis direction, the front-back direction is the Y-axis direction, and the up-down direction is the Z-axis direction. The machine tool 1 has a base 2, a machine tool body 3, a tool changer 20, and a protective cover (not shown). Base 2 is made of iron. The machine tool body 3 is located on the upper part of the base 2 and cuts the workpiece. The tool changer 20 is located on the upper part of the machine tool body 3 , and replaces the tool 4 mounted on the spindle 9 of the machine tool body 3 . The protective cover surrounds the machine tool main body 3 and the tool changer 20 .

[0019] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com