Broach spindle for numerical control vertical drill

A CNC vertical and spindle technology, applied in clamping, supporting, positioning devices, etc., can solve the problems of reducing the service life of the machine tool, long tool change time, affecting work efficiency, etc., to achieve convenient and fast tool change, and shorten tool change time. , the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples. It should be understood that the cited examples are only used to illustrate the present invention, and are not intended to limit the scope of the present invention.

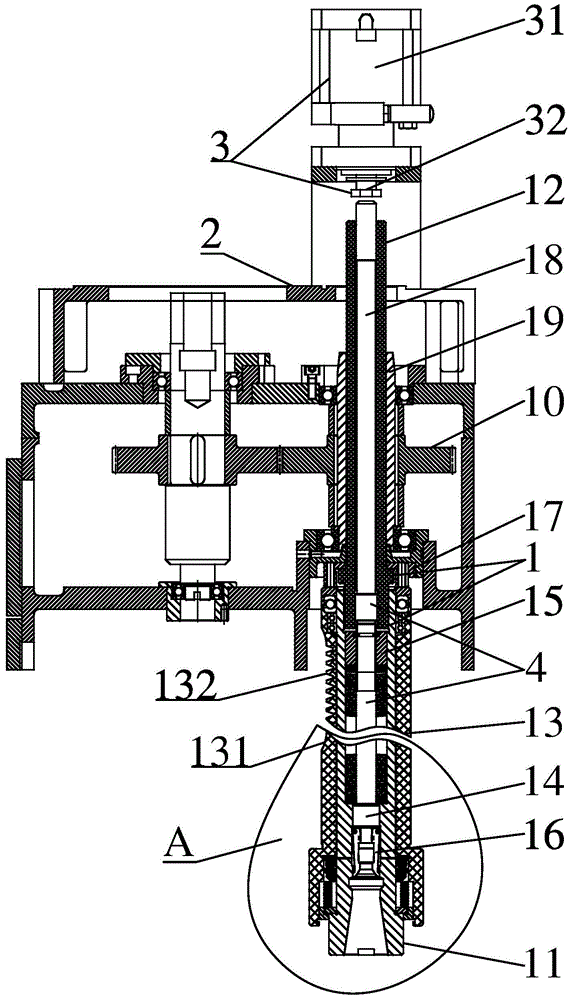

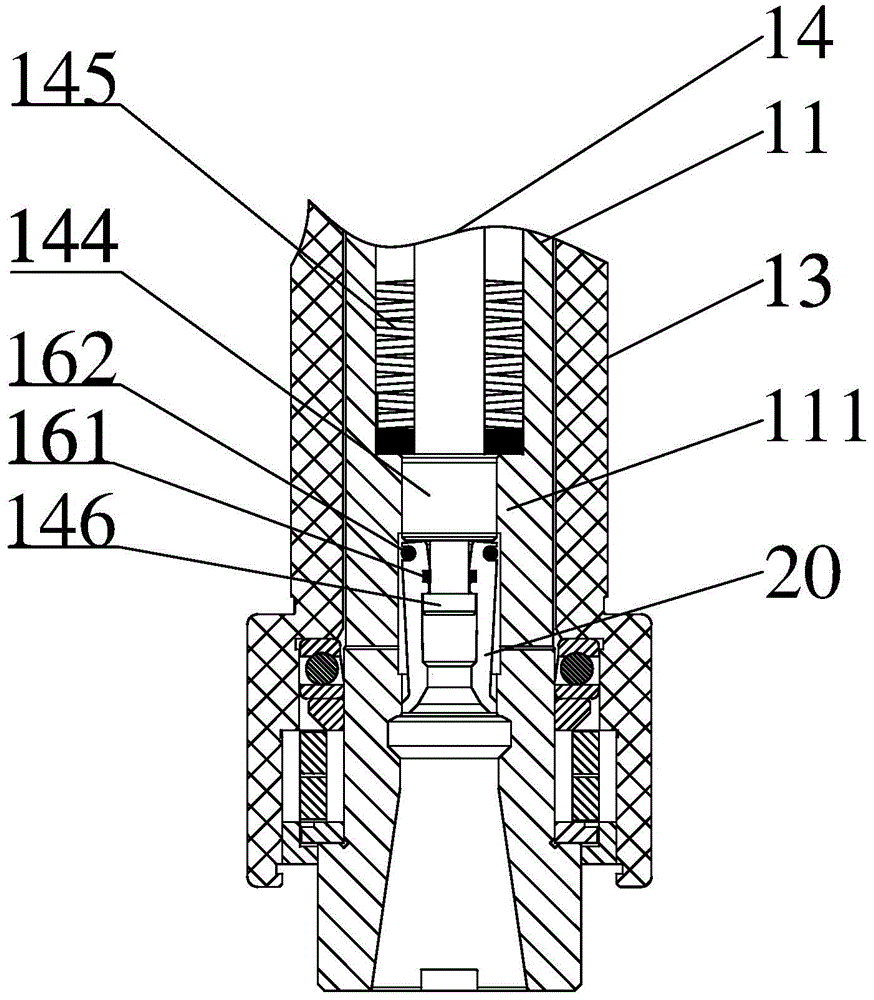

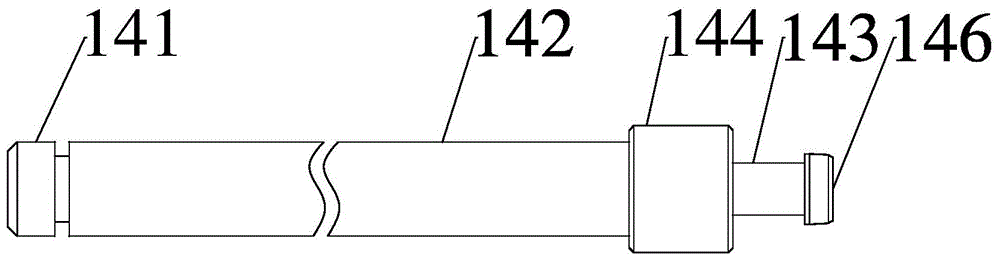

[0020] Such as Figure 1 to Figure 5 As shown, a broaching spindle of a CNC vertical drilling machine, the broaching spindle 1 is installed in the spindle box 2, the broaching spindle 1 includes a spindle 11 and a spline shaft 12; the spindle 11 is fixedly connected with a spindle sleeve 13, and the spindle sleeve 13 is provided with a concave cut surface 131 on the outside, and evenly distributed teeth 132 are arranged on the cut surface 131; the main shaft 11 is formed into a hollow cylinder along the axial direction, and the inner wall of the lower end of the main shaft 11 is provided with an inner annular protrusion 111, and the main shaft 11 is slidingly connected in the cylinder There is a pull rod 14, the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com