Industrial robot automobile engine end cover machining flexible production automatic line and method

A technology of industrial robots and automobile engines, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of low work efficiency such as time-consuming tool changes, and achieve the effects of easy reorganization, novel ideas, and meeting processing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

[0036] The working content of the present invention has six processes of leveling the slag bag, trimming the die, leveling the nozzle, deburring, removing the front and removing the casting point.

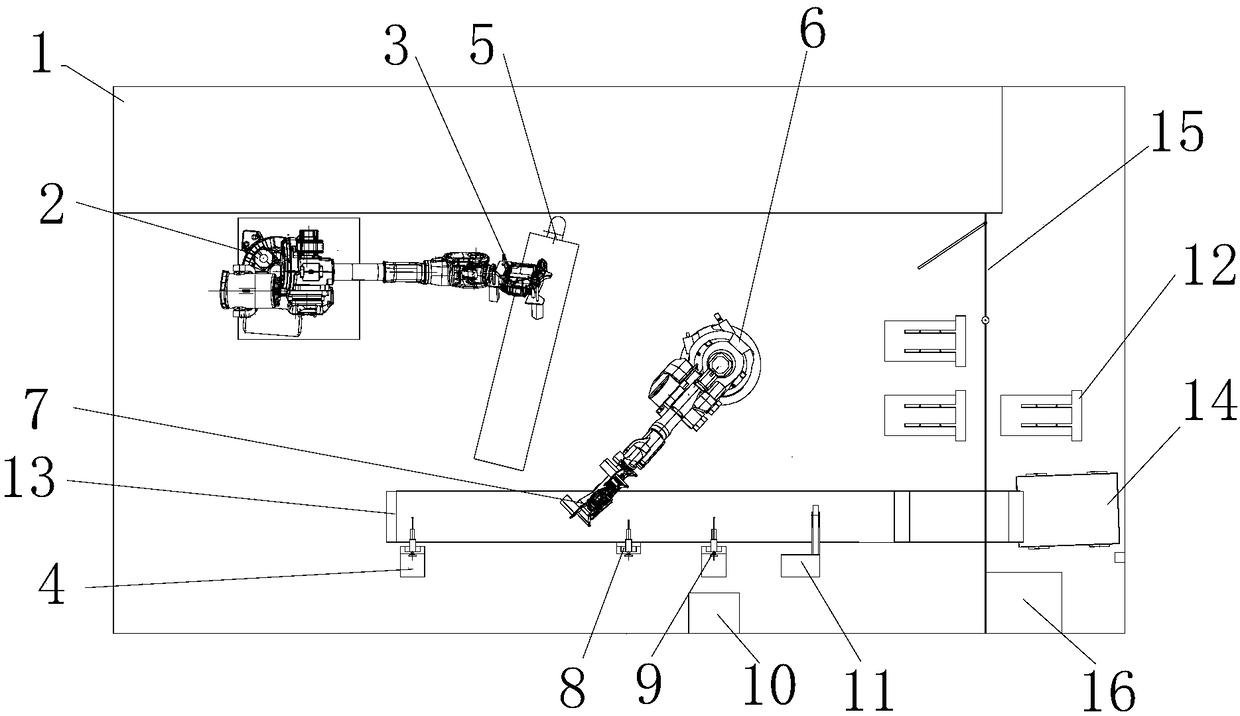

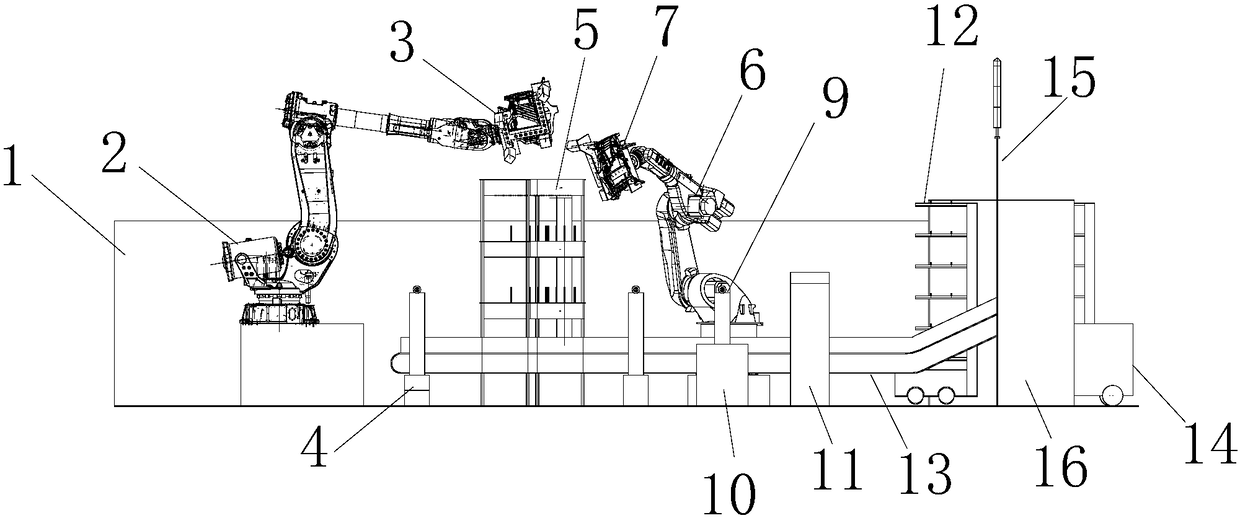

[0037] Examples see eg figure 1 , figure 2 As shown, this flexible production automatic line for industrial robots to process automobile engine end caps includes an end cap retrieving cooling system and a machining system; the end cap retrieving cooling system is arranged on one side of the die-casting machine 1 to take A chamfering milling machine 4 and a double-layer cooling frame 5 are set at the center of the robot 2, and the end of the reclaiming robot 2 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com