Method for processing screw thread by digital control lathes and screw thread processing tool thereby

A thread processing and CNC lathe technology, applied in the direction of manufacturing tools, metal processing equipment, thread cutting auxiliary equipment, etc., can solve the problems of uneven thread profile, low processing efficiency, and thread scrapping, so as to reduce processing costs and improve utilization. efficiency, the effect of protecting the cutter head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

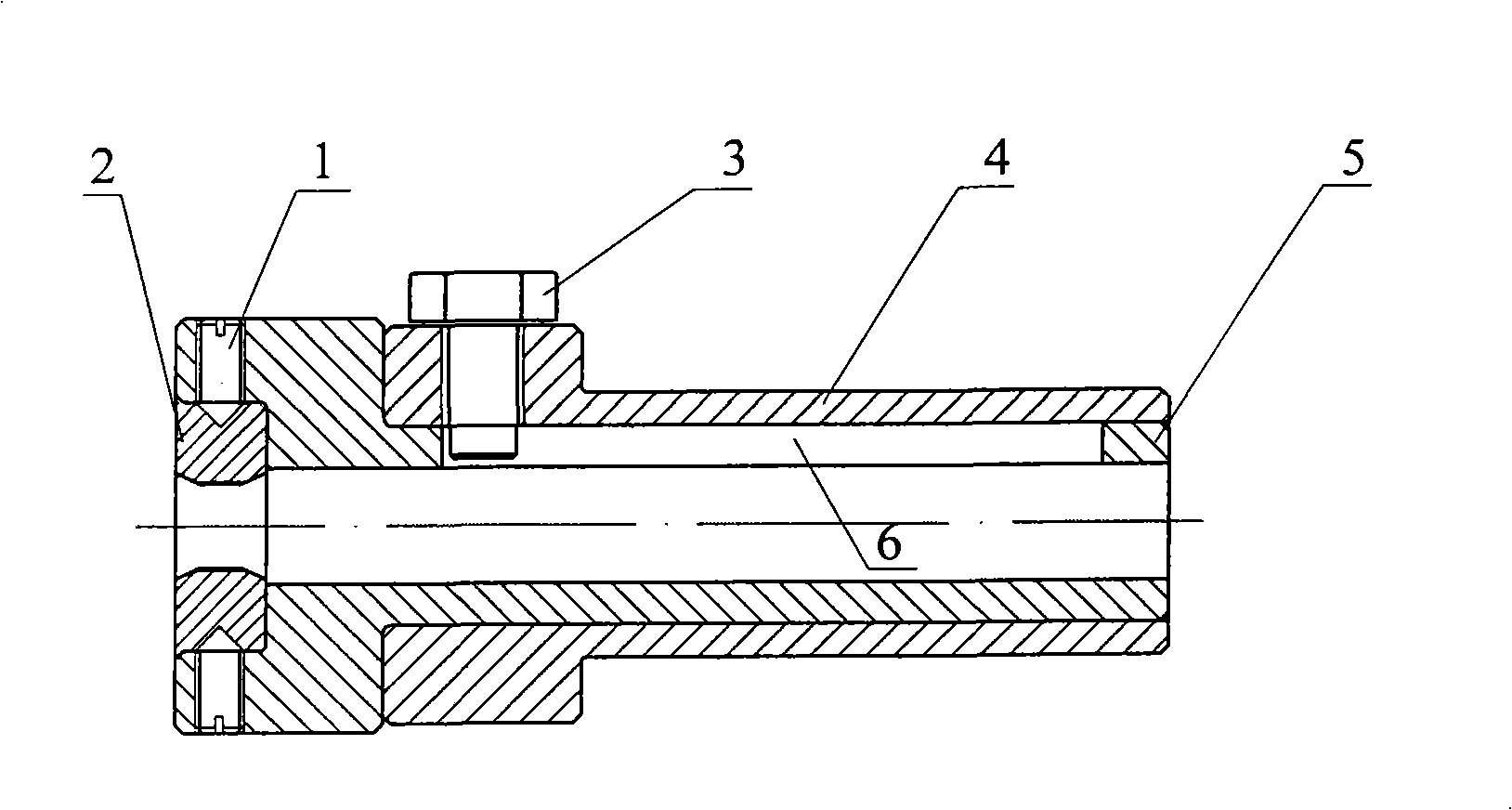

[0016] control figure 1 , The threading tool of this embodiment is mainly composed of a die 2, a tool body 4 and a sleeve 5. The tool body 4 is sleeved on the outside of the sleeve 5 , and the two can move axially relative to each other. The die 2 is clamped on the front end of the sleeve 5 through the set screw 1 . A guide groove 6 is arranged on the peripheral side of the sleeve 5 along its axial direction, and a guide screw 3 is screwed along the radial direction on the peripheral side of the tool body, and the screw extends into the guide groove 6 on the sleeve to make the tool body 4 The screw 3 screwed on it moves axially along the guide groove 6 relative to the sleeve and cannot be rotated relative to it.

[0017] CNC lathe and figure 1 The threading tool shown is for continuous processing of thin and long threaded parts:

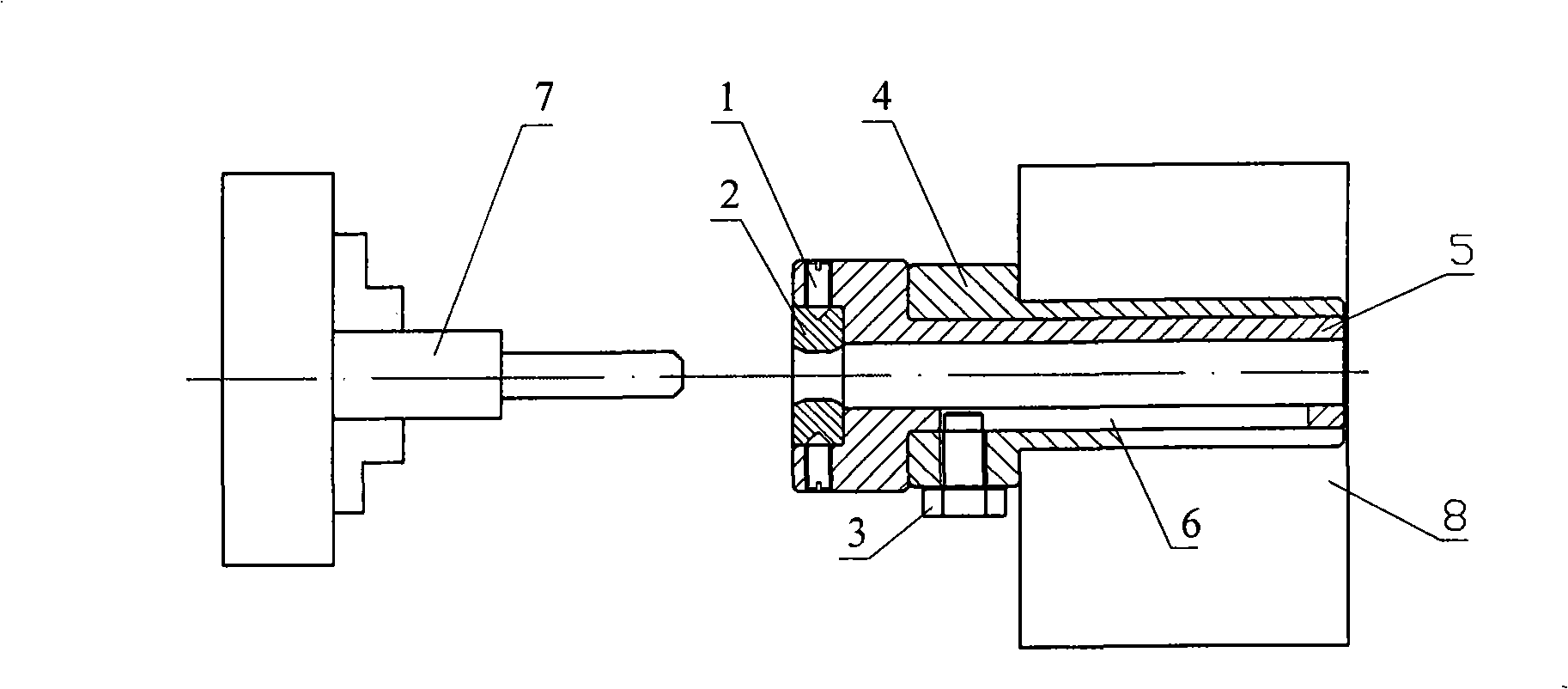

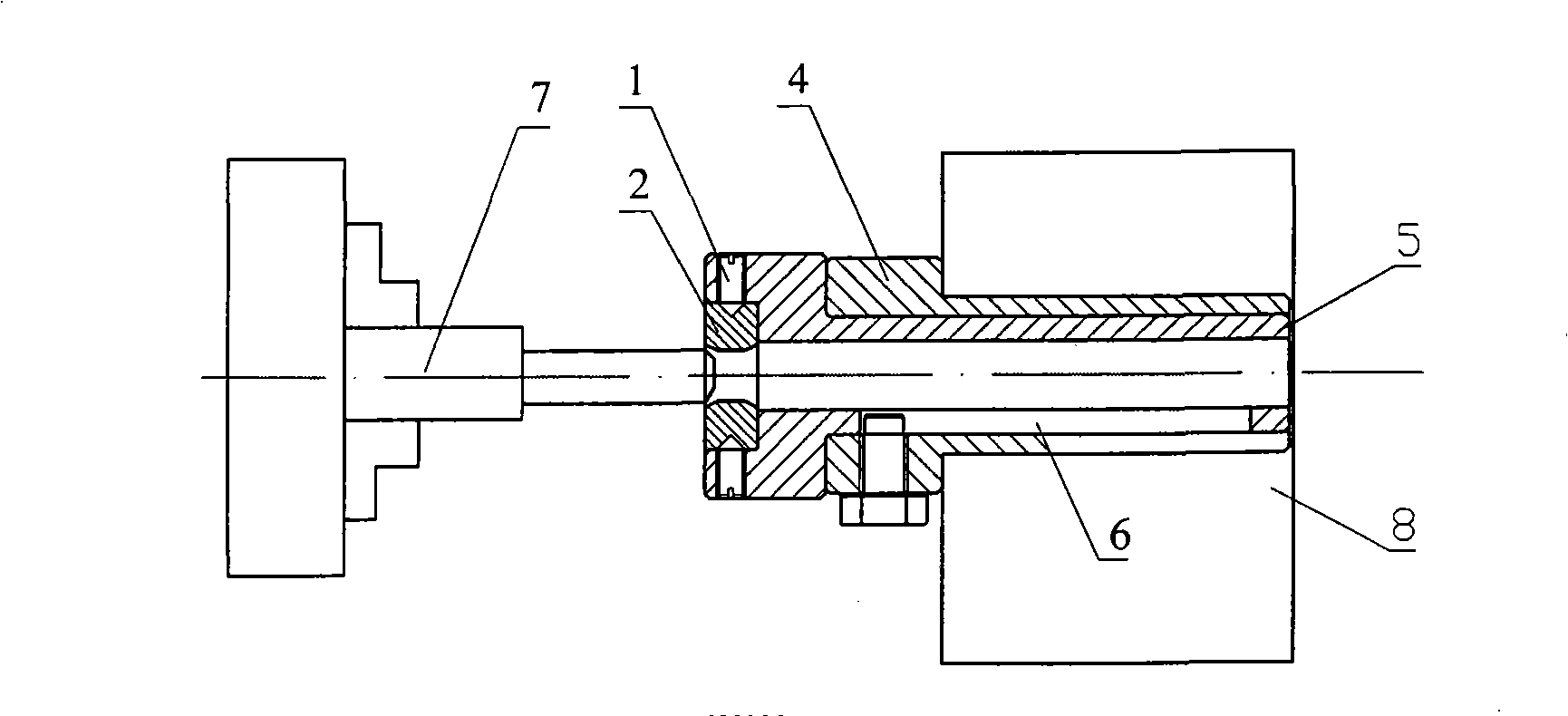

[0018] control figure 2 ,Will figure 1 The thread processing tool shown is clamped on the cutter head 8 of the CNC lathe and is pressed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com