Numerical control system with cutter changing function and numerical control method of numerical control system

A technology of numerical control and numerical control device, applied in the direction of digital control, electrical program control, manufacturing tools, etc., can solve the problems of reduced tool change efficiency, increased machine tool cost, and increased processing time, so as to increase production capacity and improve changeover. Tool efficiency and the effect of reducing tool change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

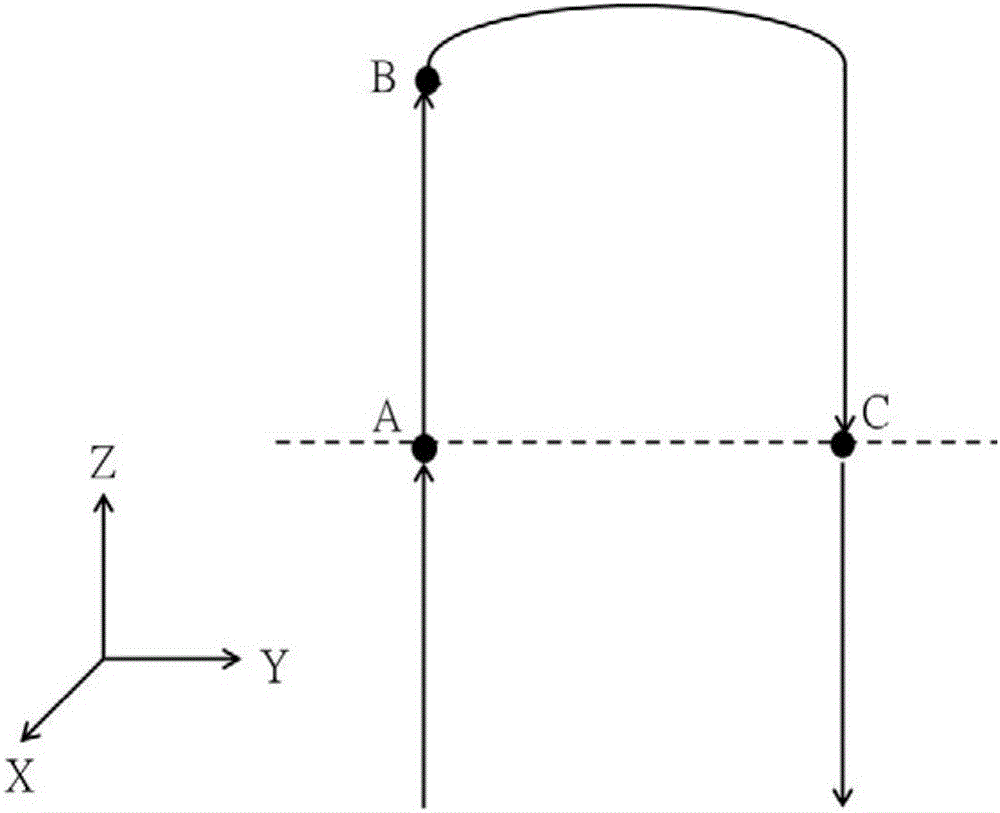

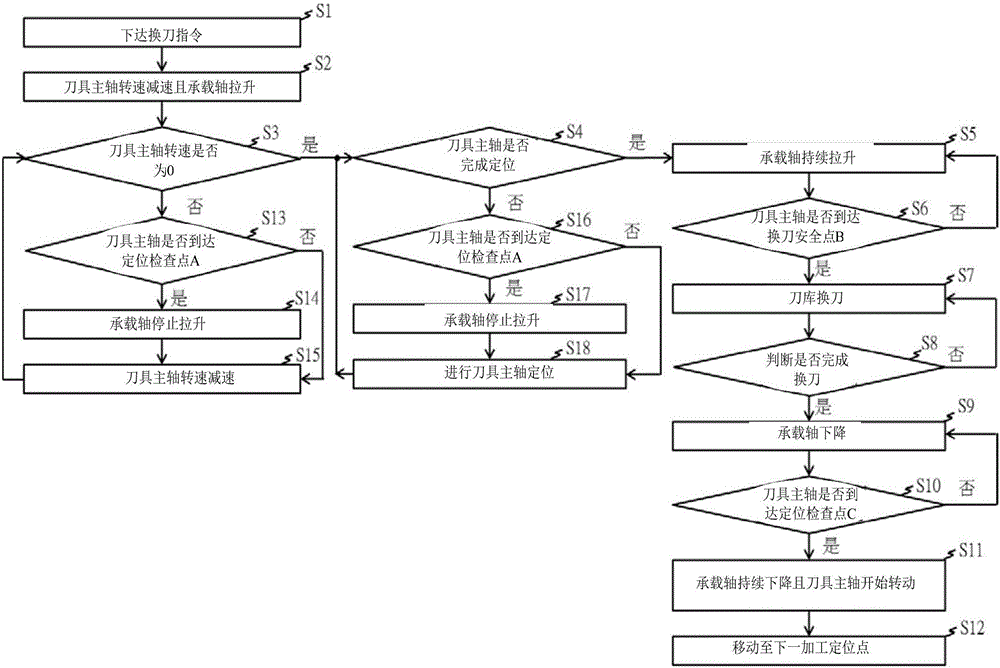

[0036] The present invention designs a numerical control system with a tool change function. The detector detects the rotation angle of the tool spindle, and the numerical control device generates a judgment signal after judging the rotation speed, position and rotation angle of the tool spindle. The numerical control device according to Judging the signal to plan the speed and rotation angle of the tool spindle and the position of the bearing shaft for tool change. When the numerical control system performs tool change, it can decide whether to stop the vertical pulling according to the actual movement of the tool, thus reducing the tool change time. The purpose of increasing production capacity and improving tool change efficiency.

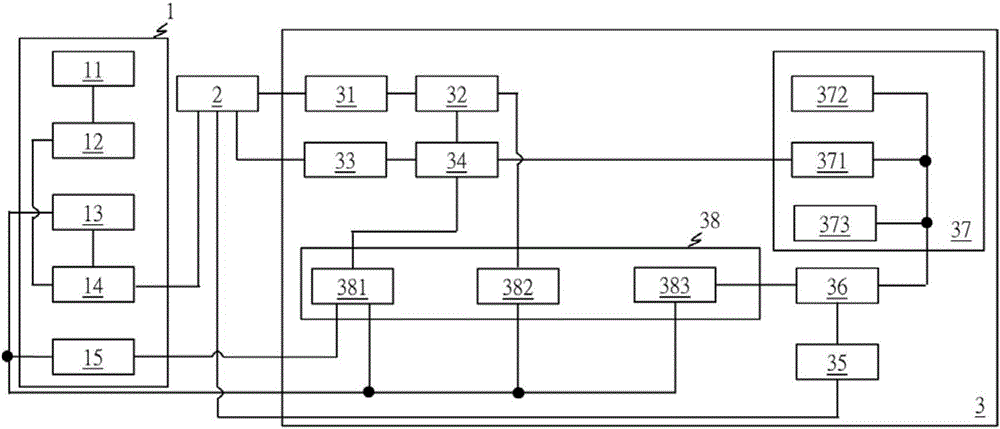

[0037] like figure 1As shown, the numerical control system with tool change function includes a numerical control device 1, a driving device 2 and a processing device 3, the driving device 2 has a first end, a second end, a third end and a fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com