Patents

Literature

35results about How to "Does not affect the construction period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

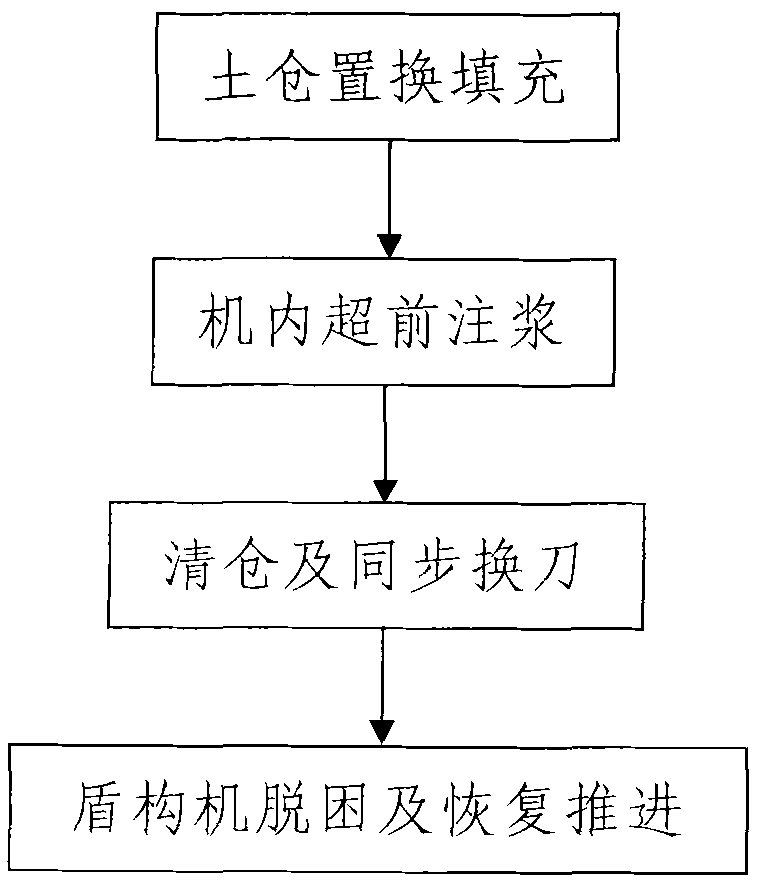

Method for exchanging tool of shield machine for tunnel construction

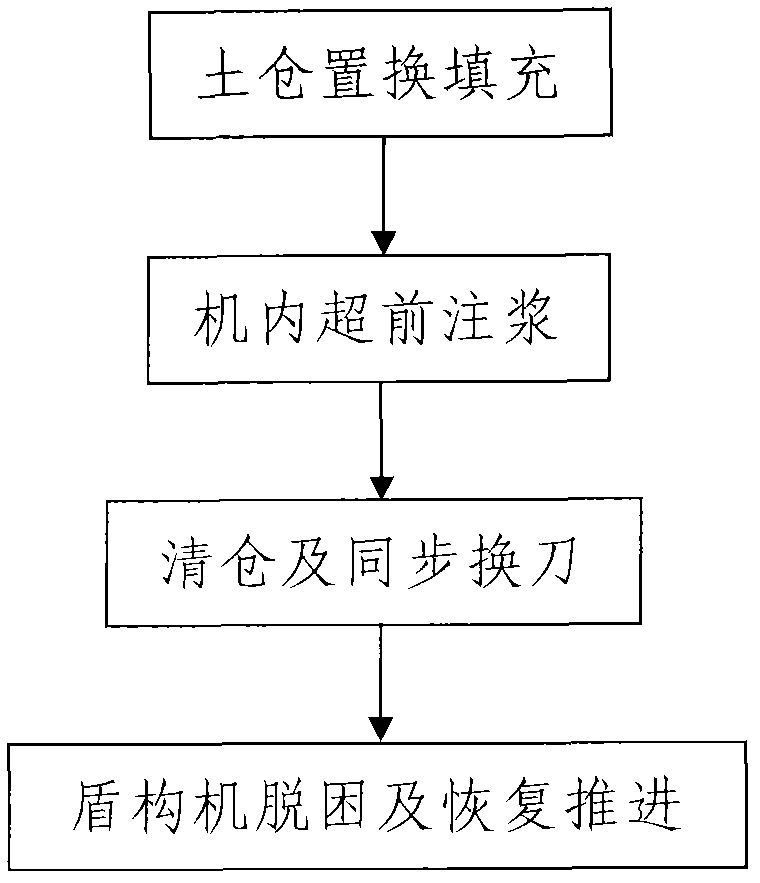

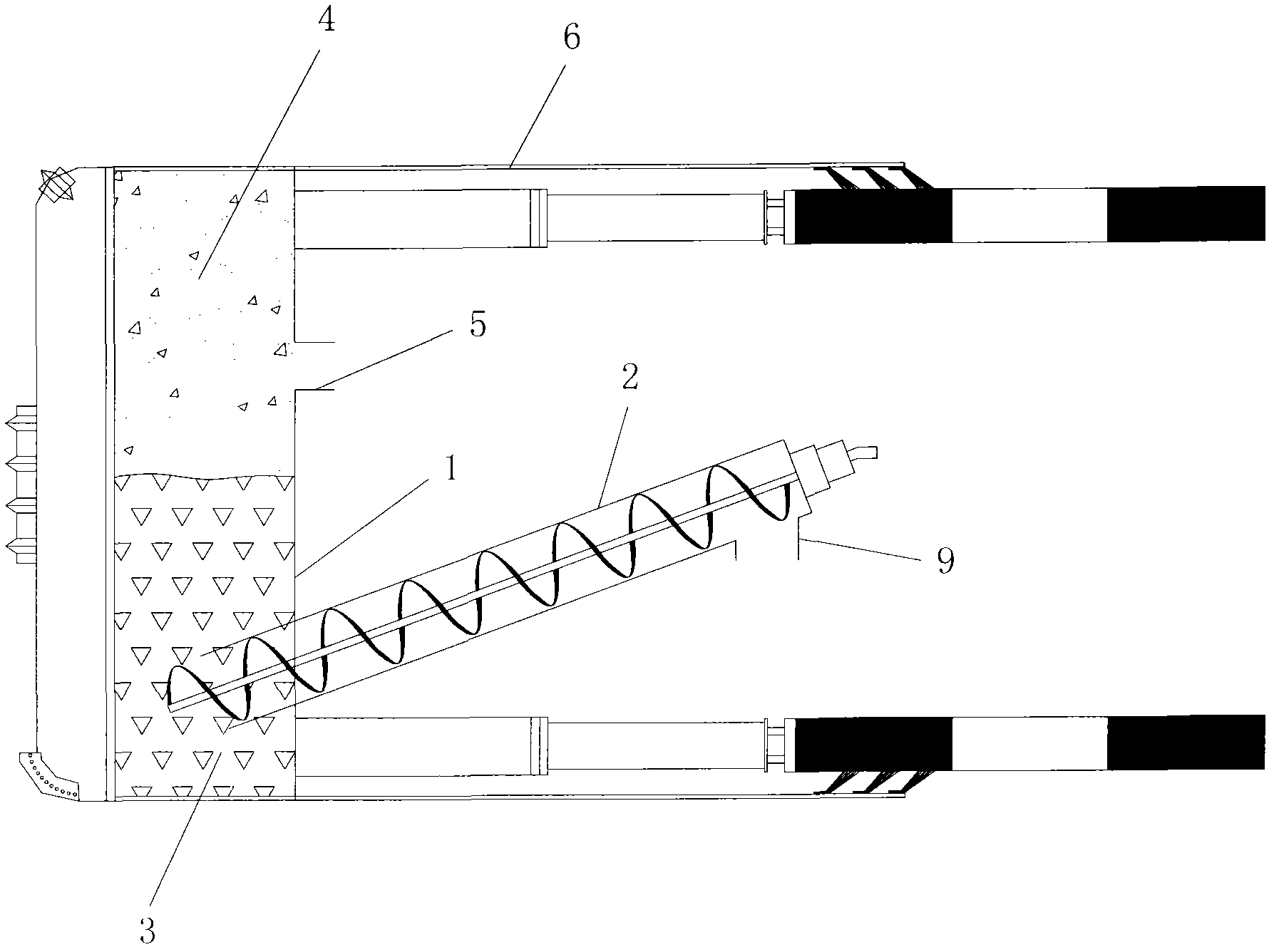

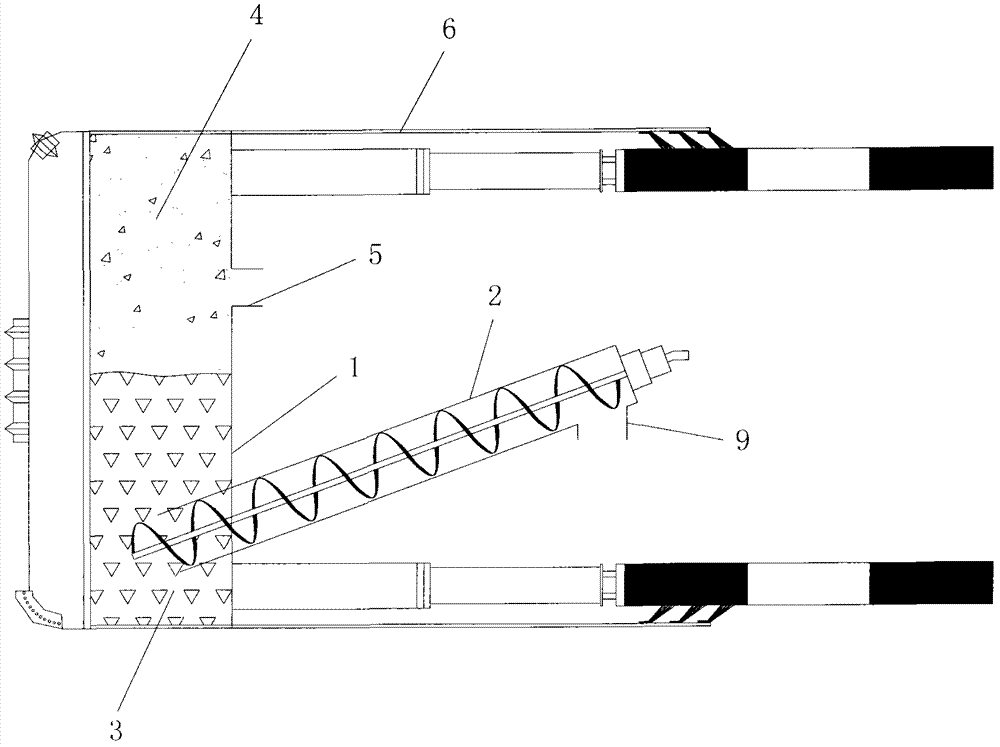

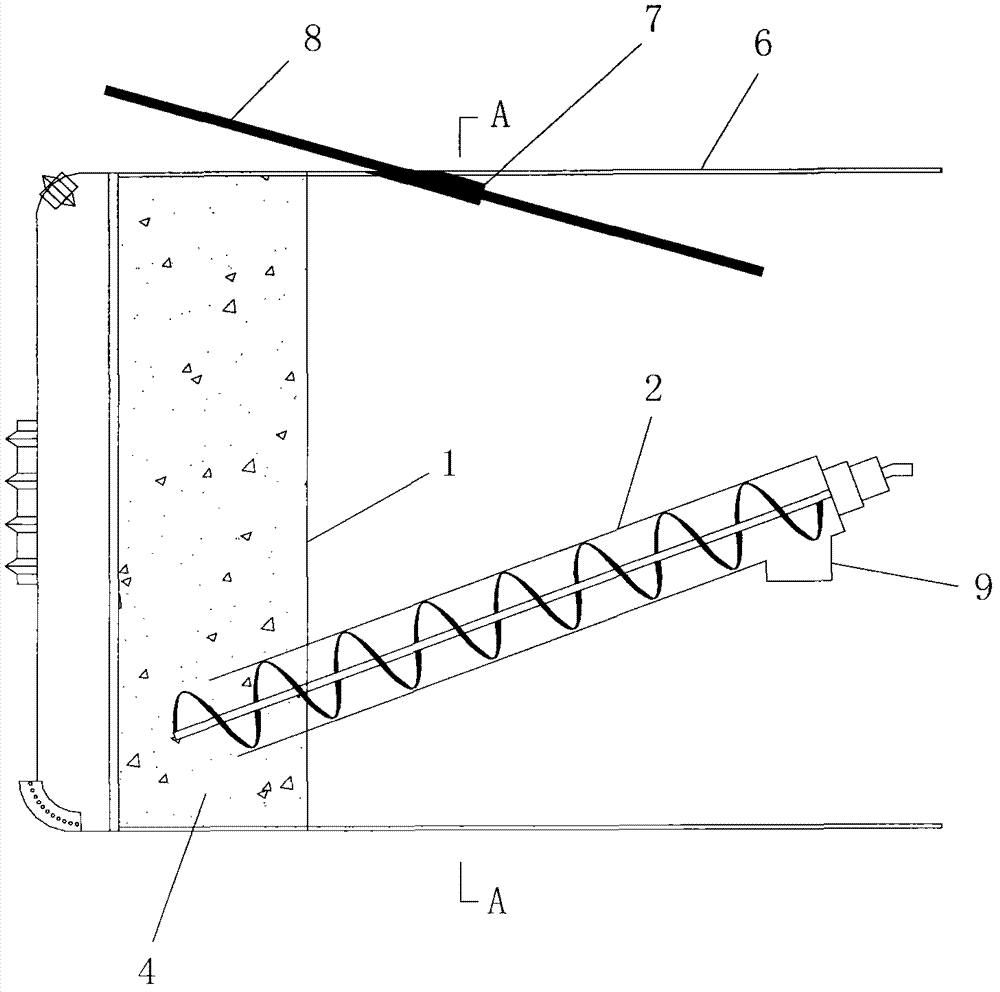

The invention discloses a method for exchanging a tool of a shield machine for tunnel construction, which comprises the steps of: (1) soil cabin replacement filling: performing the process of soil cabin replacement filling by using a spiral excavating machine and a slip casting system synchronously working with the spiral excavating machine; (2) advanced slip casting inside the machine: beating a plurality of slip casting pipes into the soil on the upper part of the shield machine from inner to outer inside the shield machine by respectively passing through a plurality of advanced geologic holes and then synchronously injecting cement paste into the soil on the upper part of the shield machine through the slip casting pipes by using a slip casting device till the cement paste cannot be injected any more; (3) cleaning cabin and exchanging tool synchronously: manually cleaning the cement plaster solidified inside the soil cabin and synchronously exchanging the tool mounted on the shield machine; and (4) getting rid of the difficult position of the shield machine and recovering the process. The method provided by the invention has the advantages of reasonable design, convenience for operation, low cost, high safety factor, good use effect and capable of solving the problem that the tool cannot be exchanged in the traditional tool exchanging mode under severe tool exchanging conditions.

Owner:URBAN RAIL TRANSIT ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

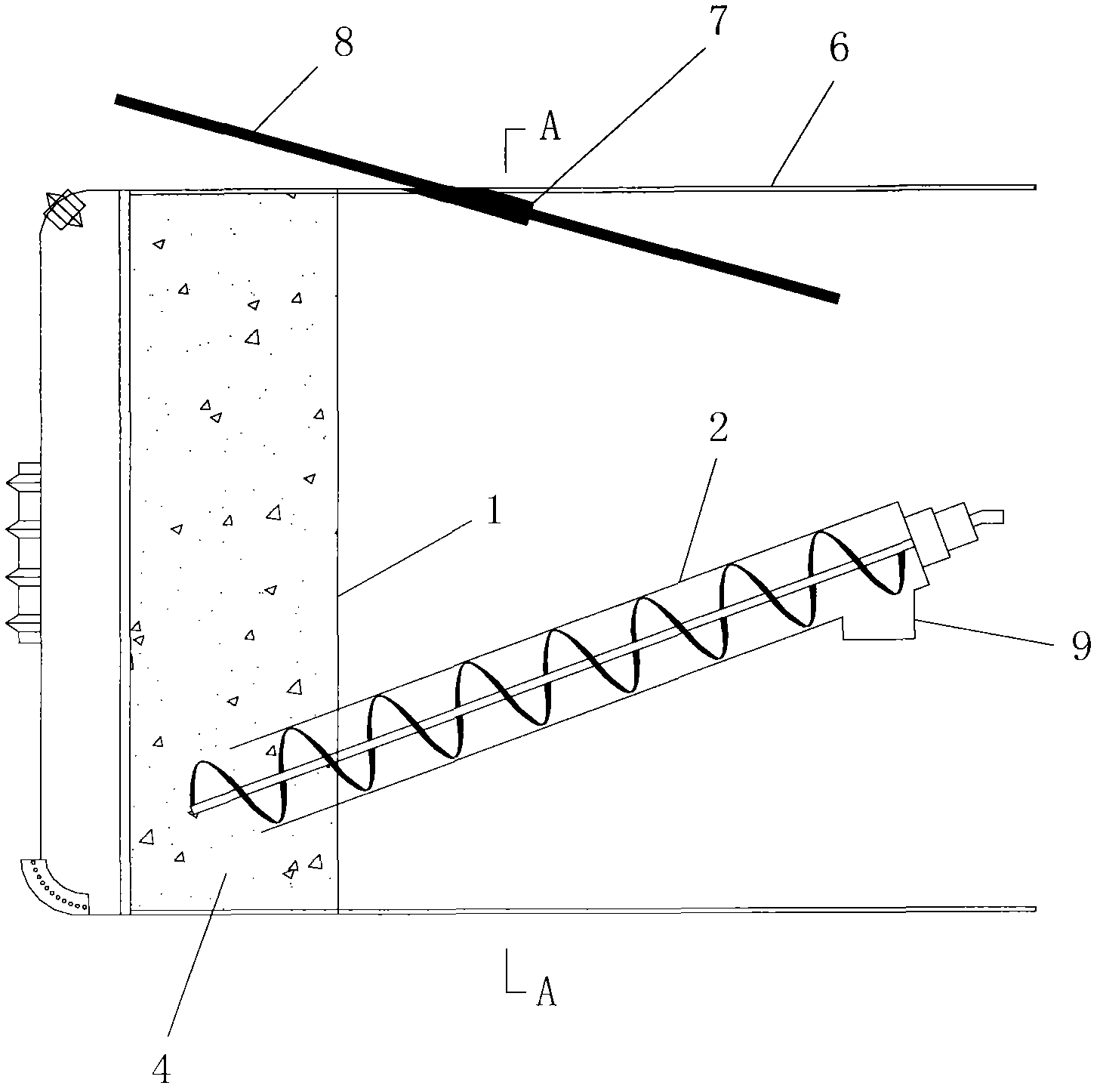

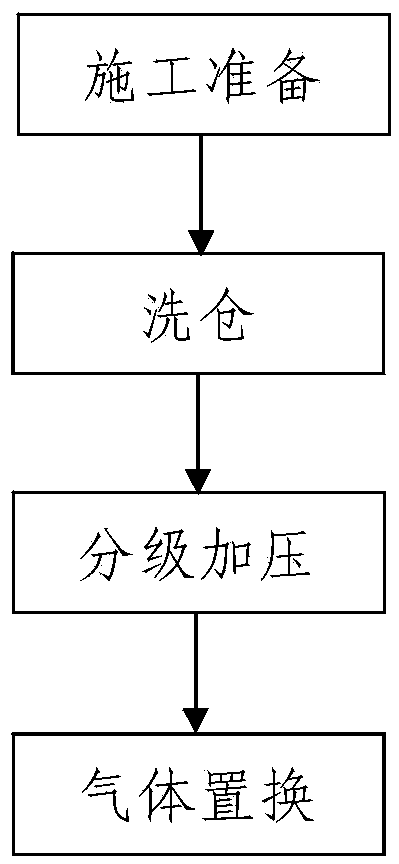

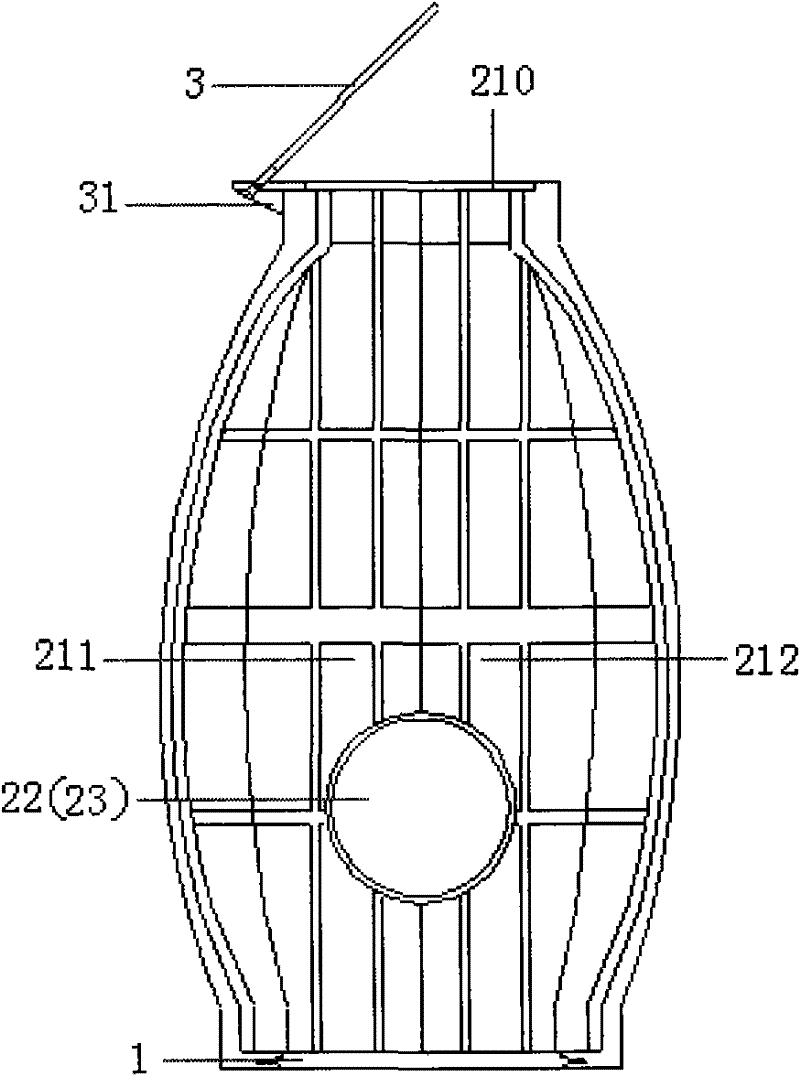

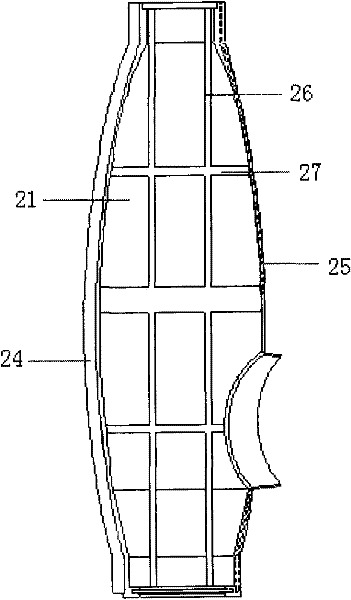

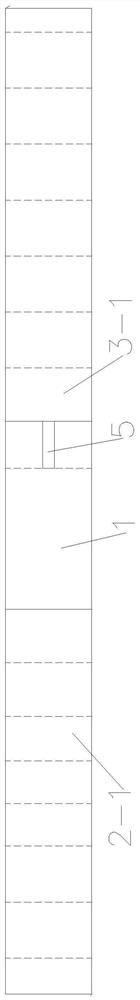

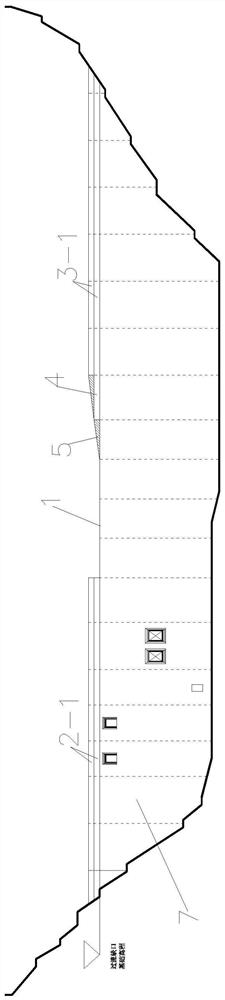

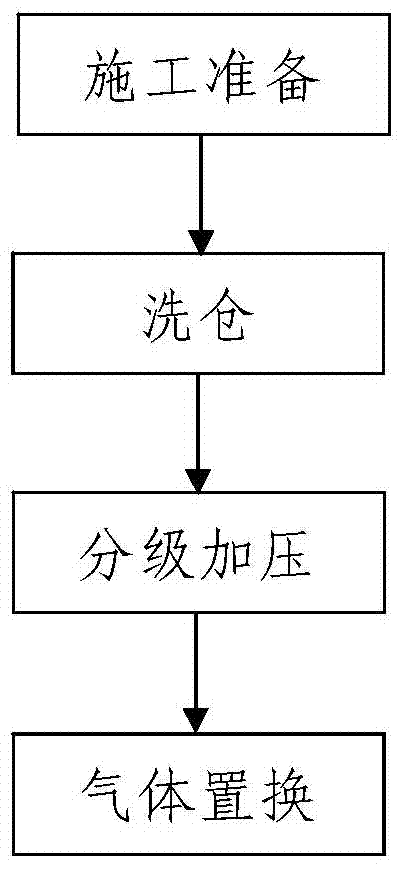

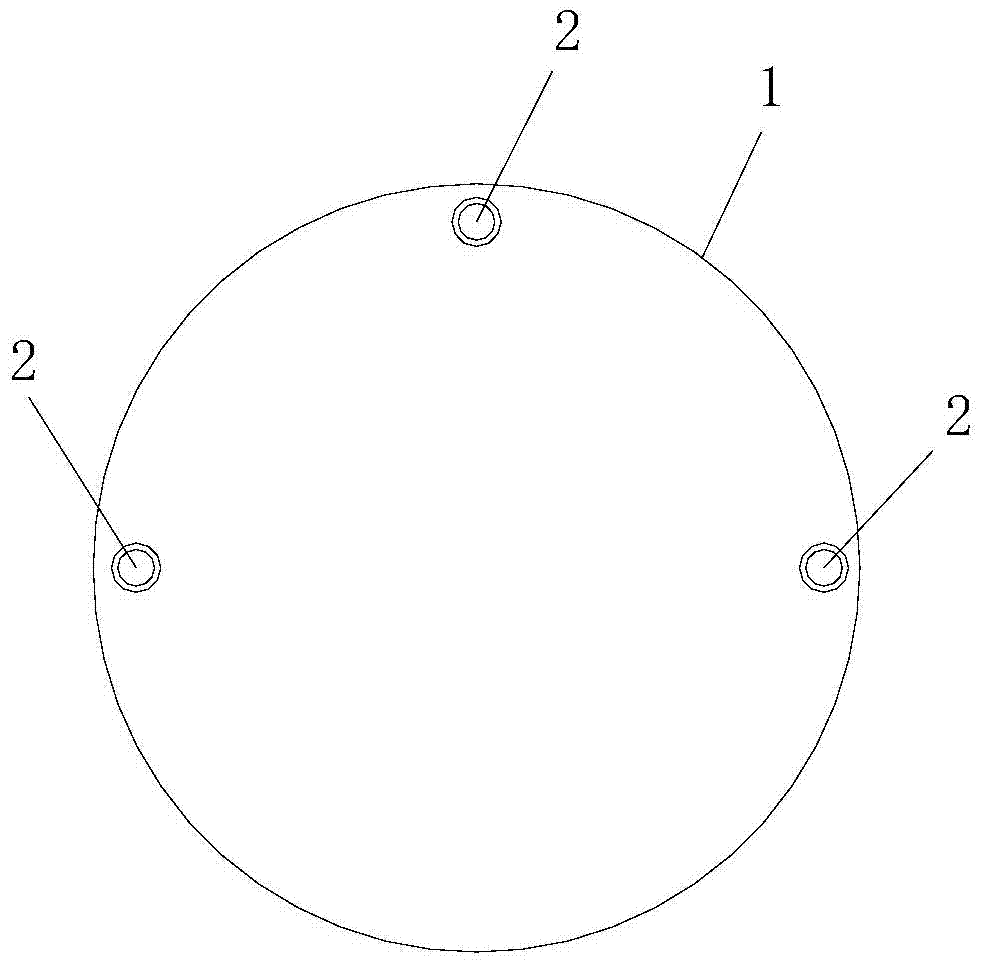

Tunnel face breast wall filter cake construction process for shield compressed air operations

The invention discloses a tunnel face breast wall filter cake construction process for shield compressed air operations. The process includes the steps of 1, preparing for construction, namely connecting an injection system with a plurality of injection holes through an injection pipeline, which are arranged on the outer wall of the upper middle of an earth bin of a shield machine in the peripheral direction; 2, cleaning the bin, namely cleaning the earth bin of the shield machine by a screw conveyer and the injection system; 3, performing graded pressurization, namely performing graded pressurization, including primary pressurization, secondary pressurization, tertiary pressurization and quaternary pressurization, on the inside of the earth bin by the injection system; 4, performing air replacement, namely shutting down the injection system, and replacing bentonite slurry inside the earth bin by air. The construction process is reasonable in design, simple to operate, low in input cost, high in safety coefficient and good in using effect; the practical problem that under the tool-changing severe conditions of loose stratum at the shutdown position of the shield machine, poor self-stabilization capacity of tunnel face earth and the like, existing common tool changing methods fail in changing tools is solved.

Owner:URBAN RAIL TRANSIT ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

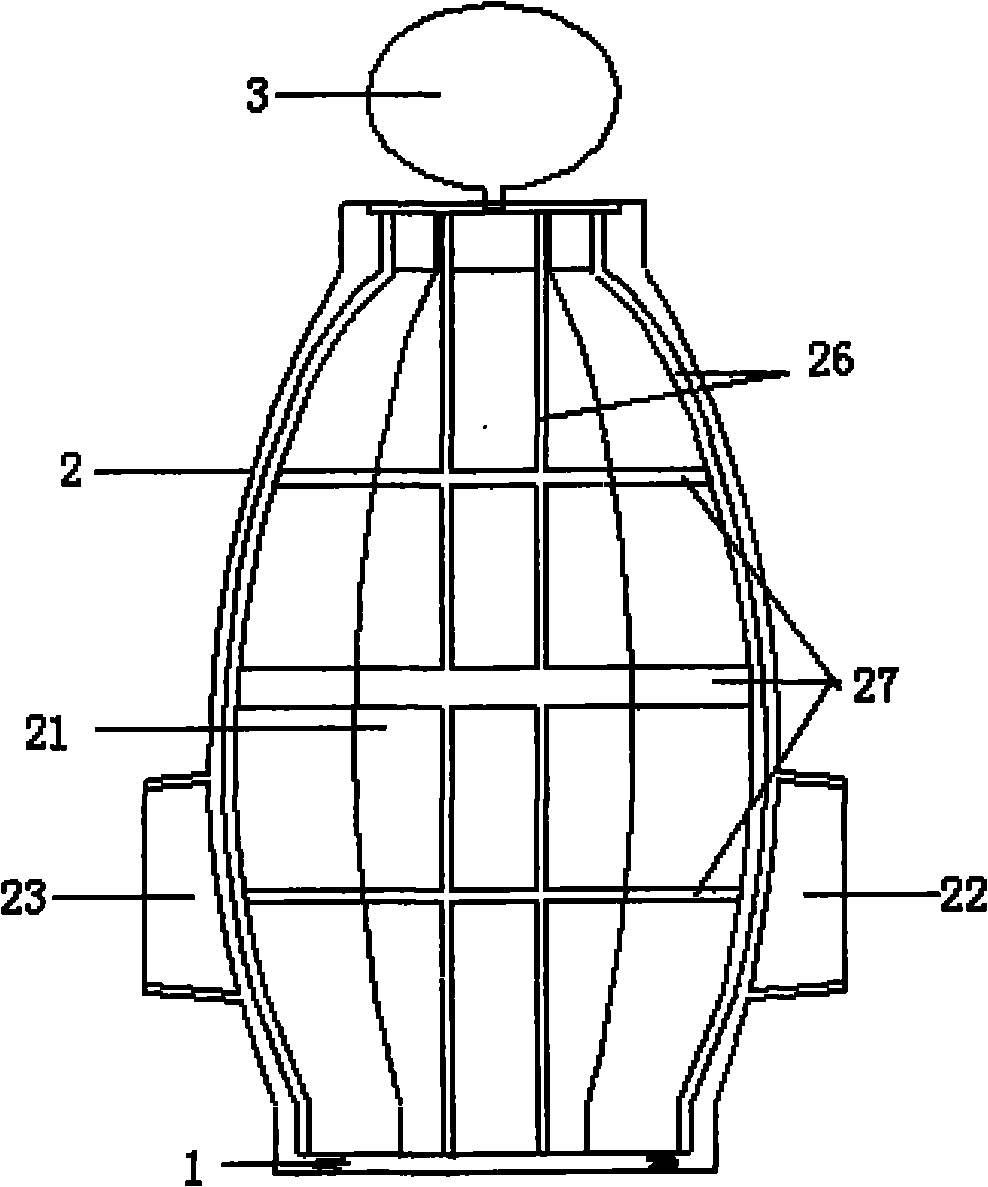

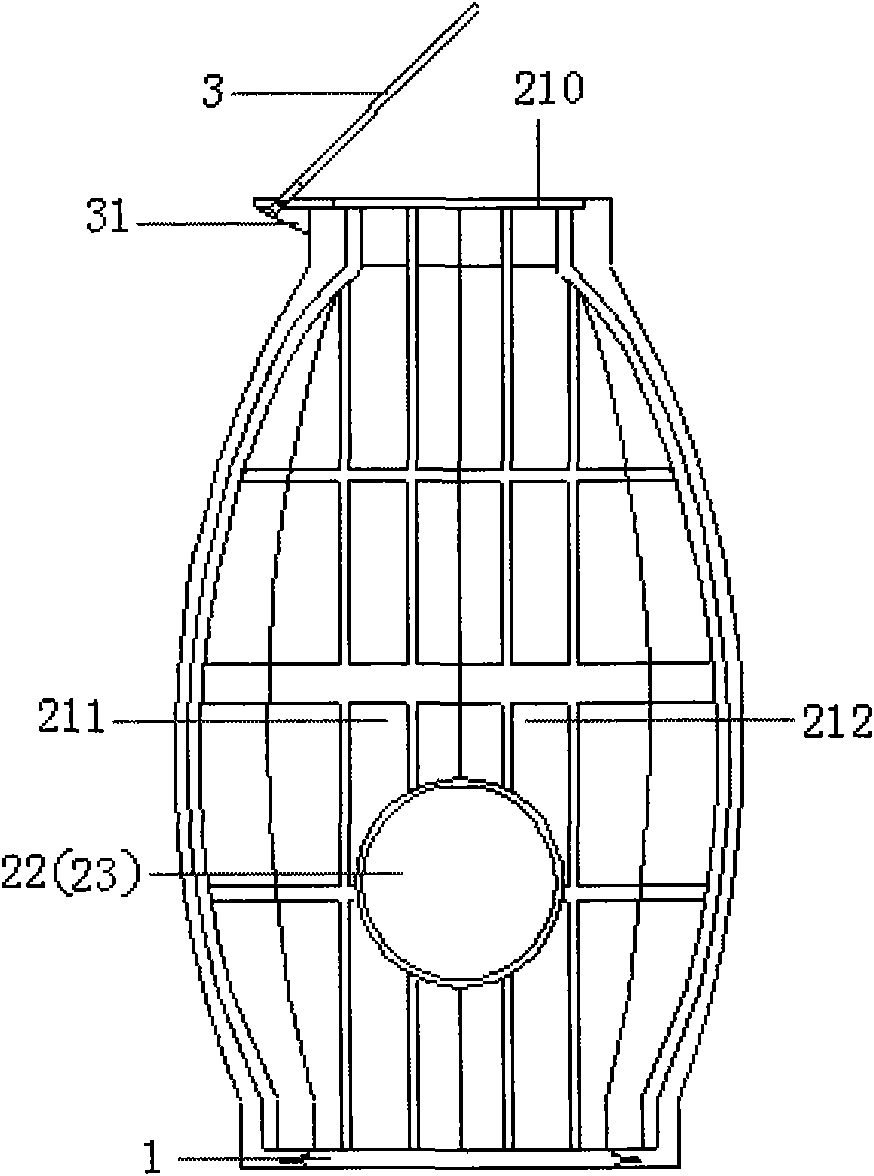

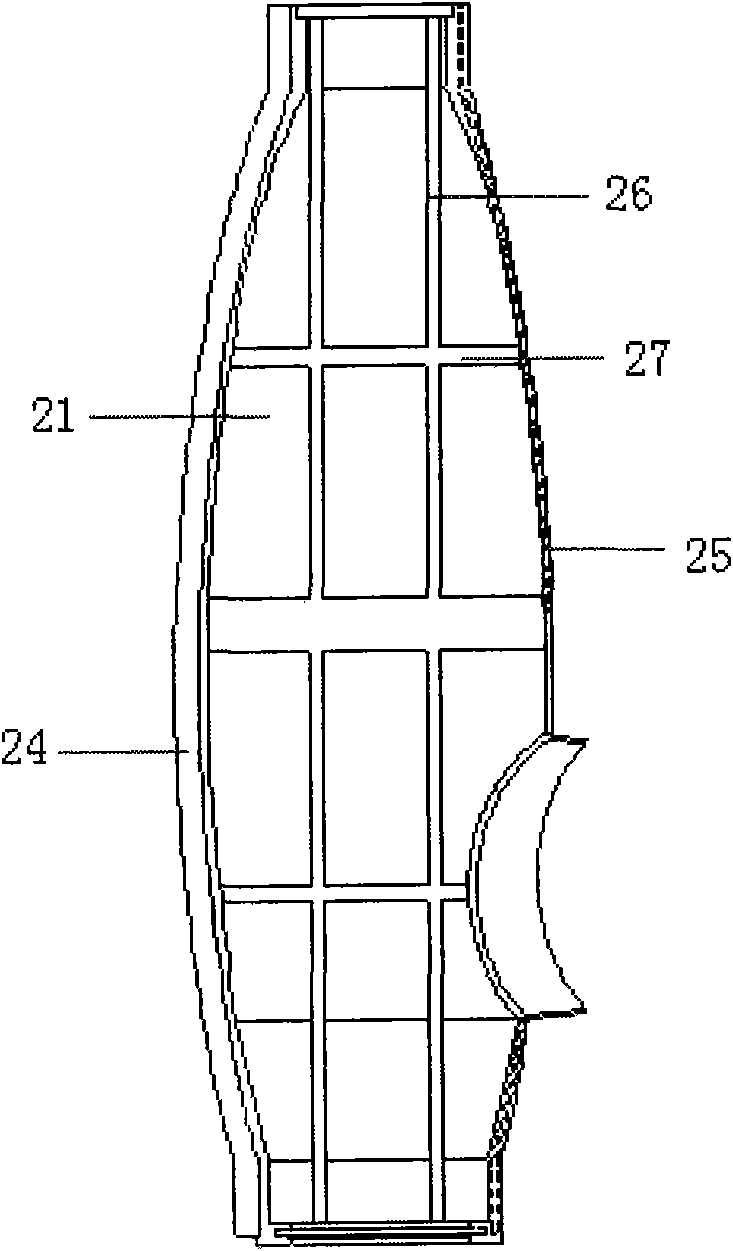

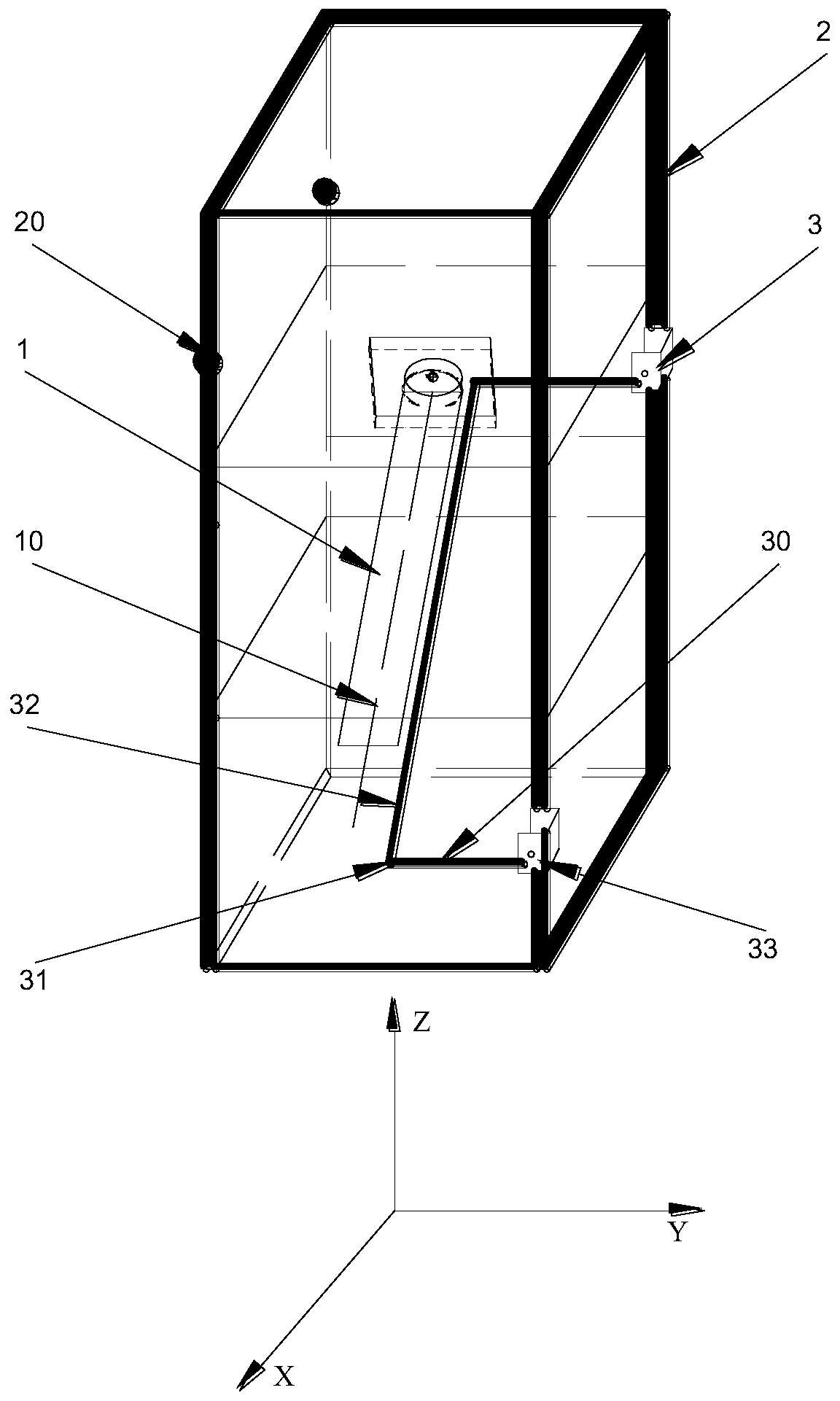

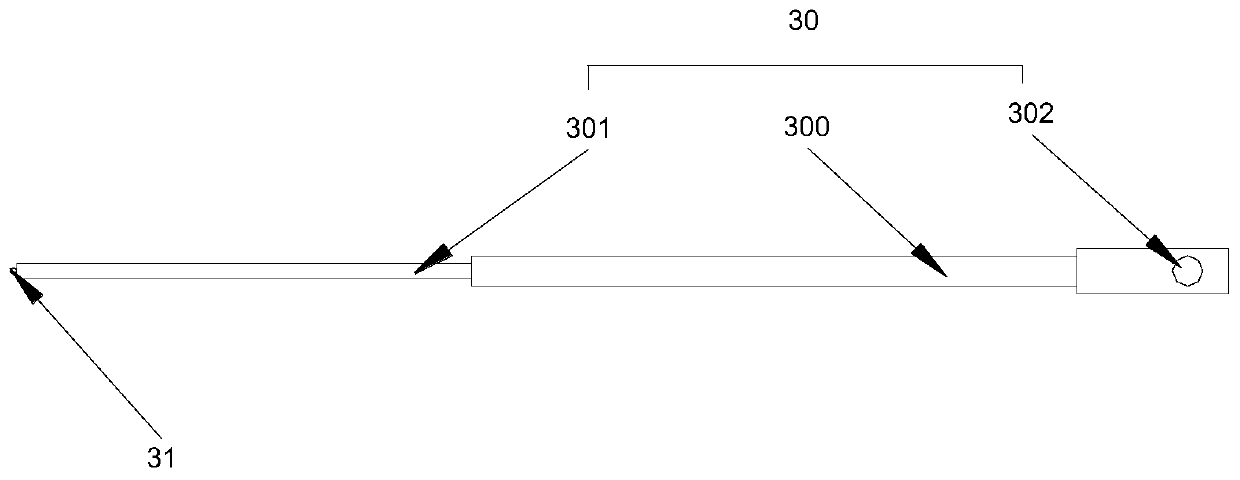

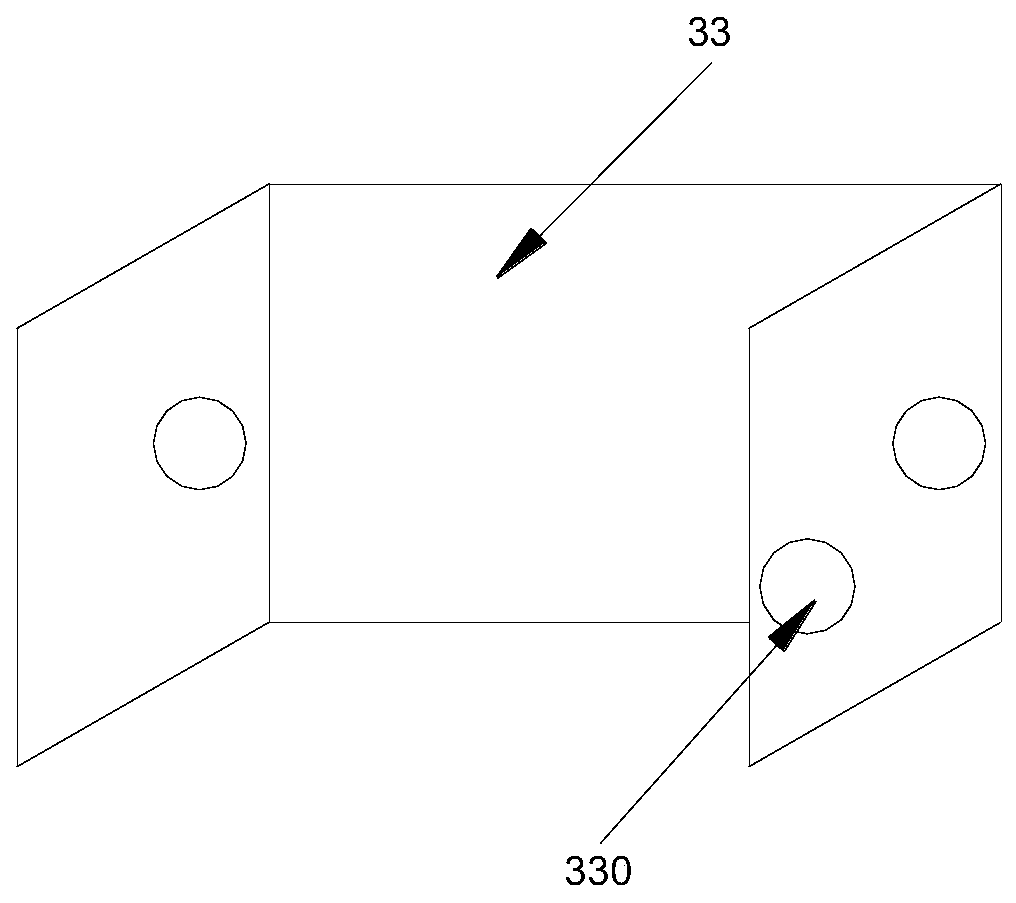

Tunnel surrounding rock scanning and observing system based on dual-shield TBM technology

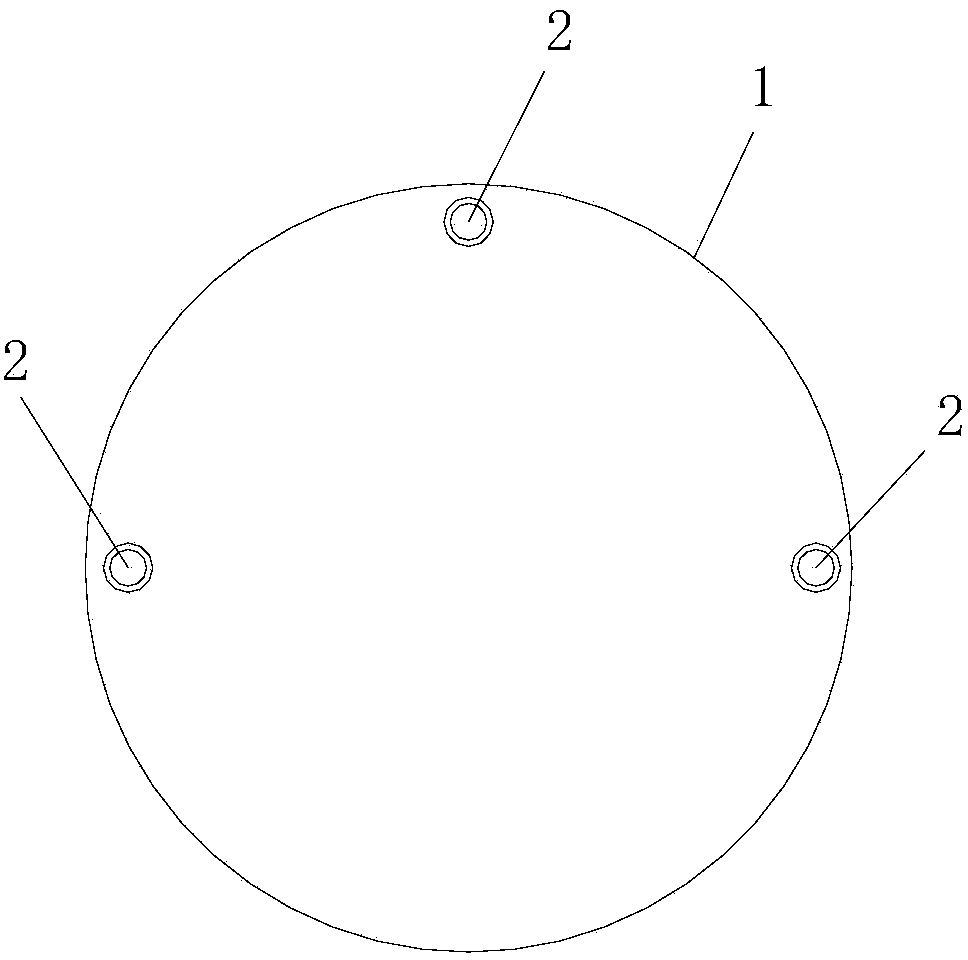

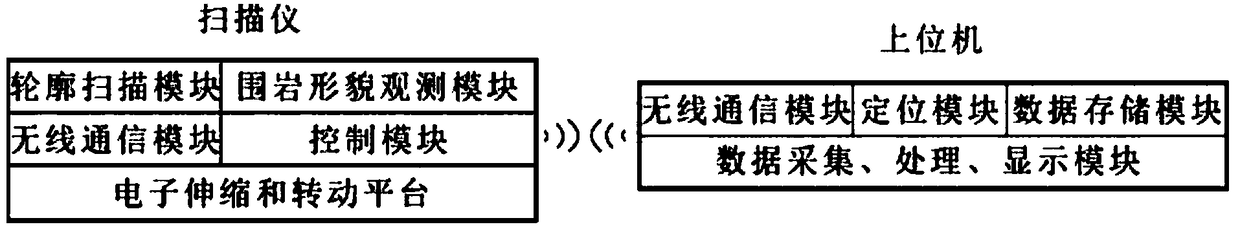

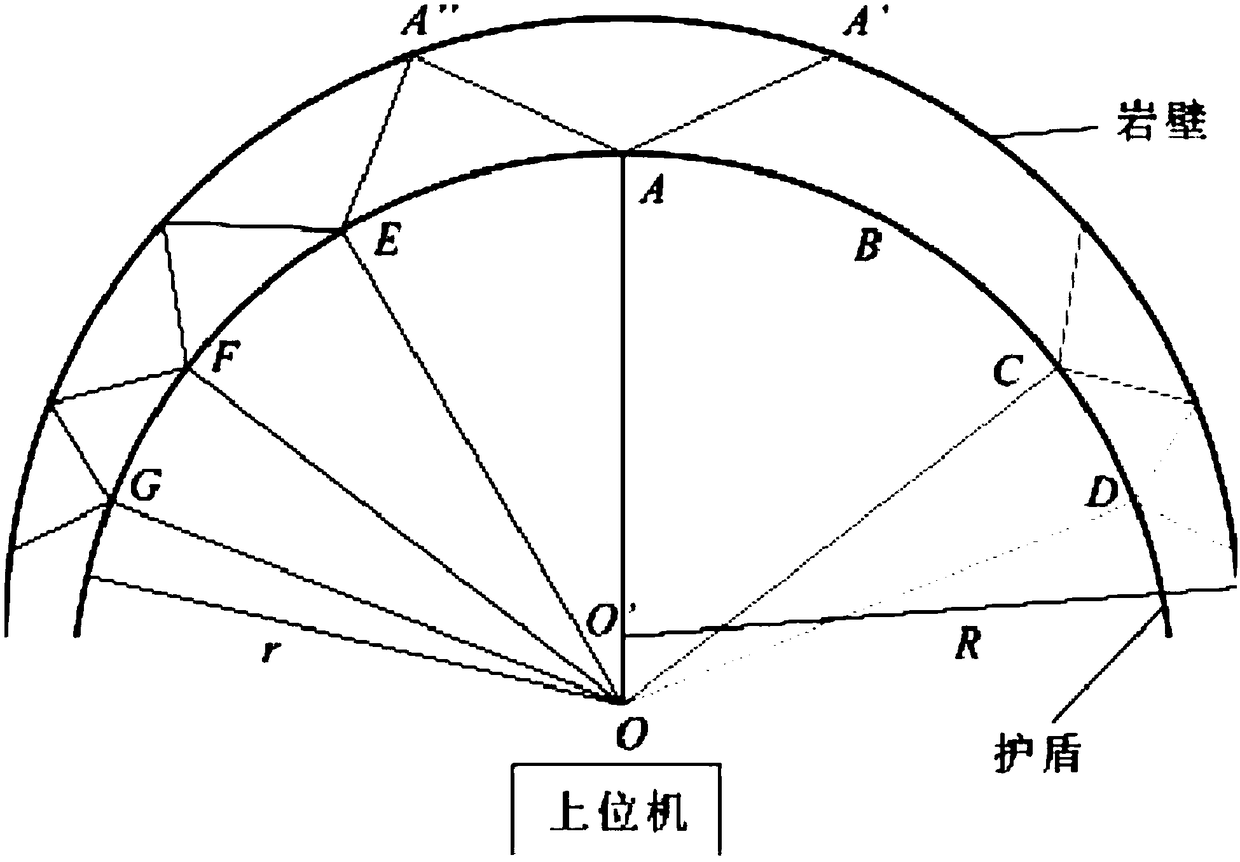

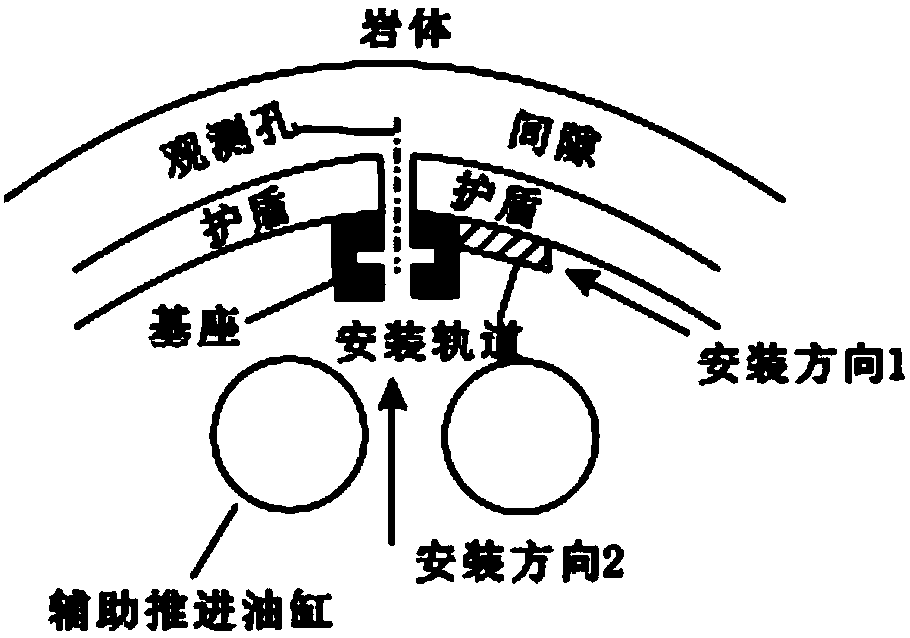

ActiveCN109186480AQuick installationEasy to installEarth material testingUsing optical meansMeasurement deviceGeomorphology

The invention discloses a tunnel surrounding rock scanning and observing system based on a dual-shield TBM technology. The system comprises multiple scanners and an upper computer; the upper computeris positioned at the axis of the shield of an auxiliary propulsion oil cylinder position; the scanner is installed at each observing hole of the shield of the cross section of the auxiliary propulsionoil cylinder. According to the system provided by the invention, the scanner is installed at the preset observing hole on the rear shield to achieve direct measurement; data is collected via multiplecoordinate systems and processed in a unified manner; a scanning system for propelling observation on the profile of the tunnel surrounding rock and rock appearance by accompanying tunneling similarto well logging during drilling is formed; drawing of a two-dimensional profilogram of the cross section of a tunnel, building of a three-dimensional model of the actual excavation face of the tunnel,surrounding rock appearance imaging of the cross section of the tunnel, and three-dimensional rock appearance imaging of the actual excavation face of the tunnel within a certain angle range of the top of the whole tunnel can be achieved; in addition, the scanners and the upper computer are installed in a modularized manner, and the internal different modularized measurement devices can be changed according to needs, to achieve more functions.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

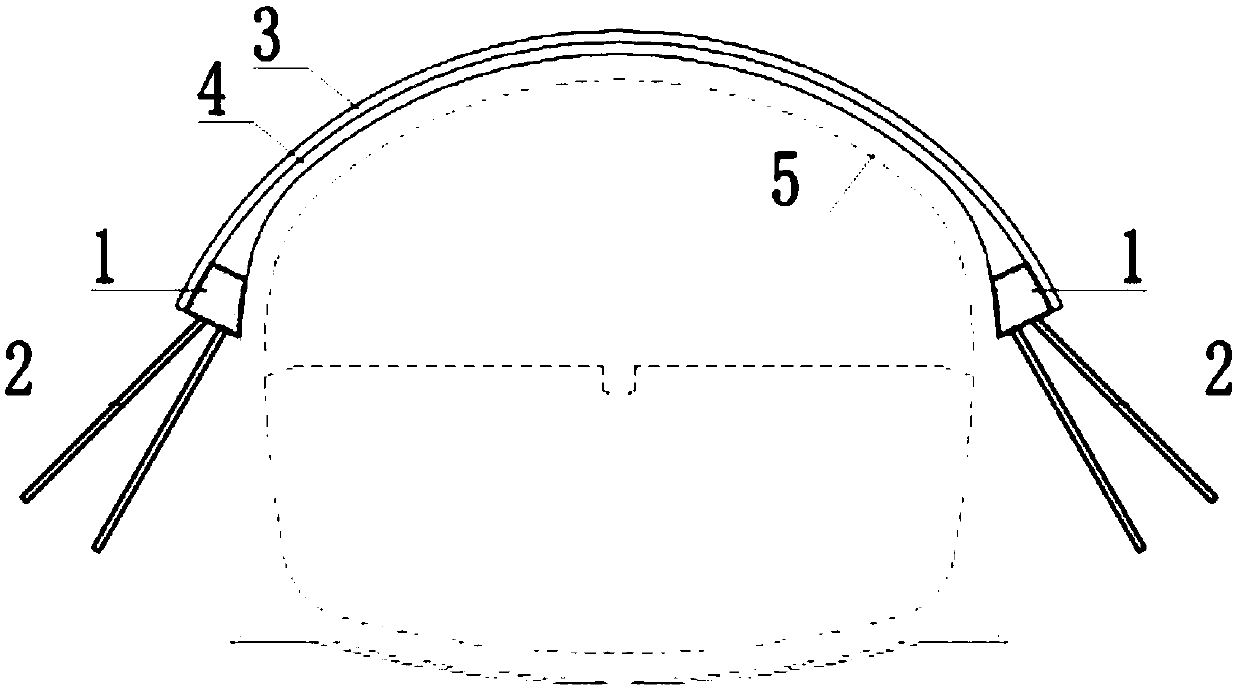

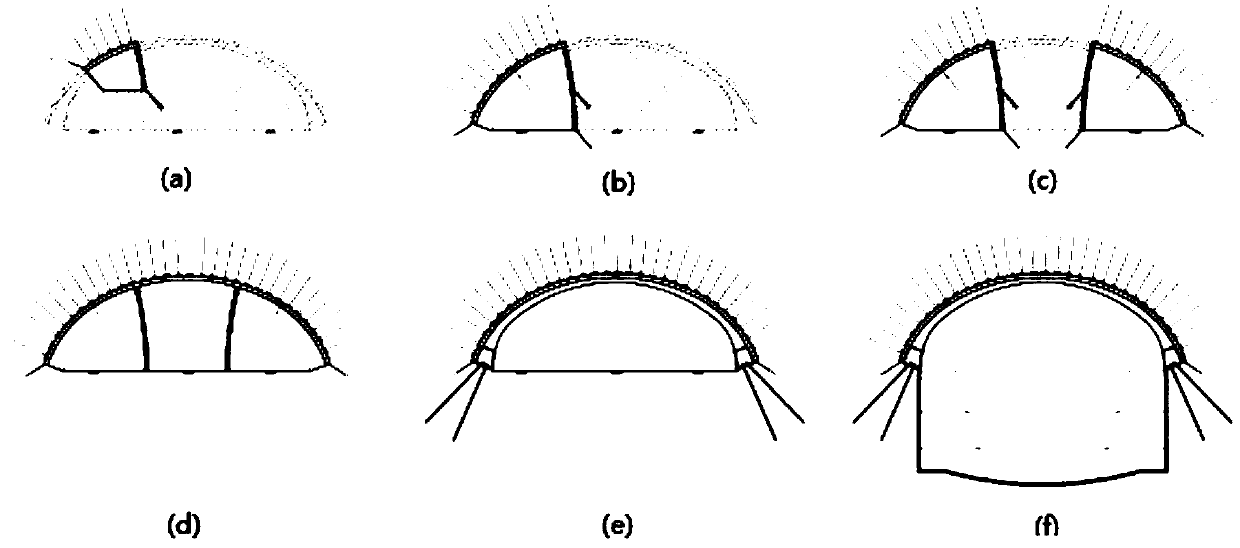

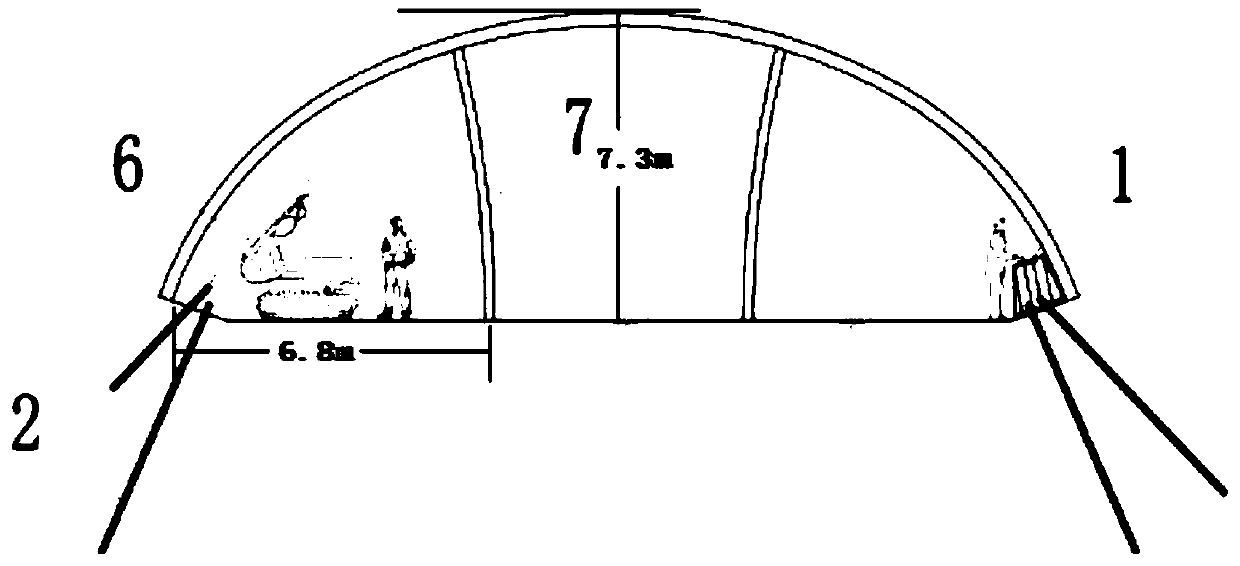

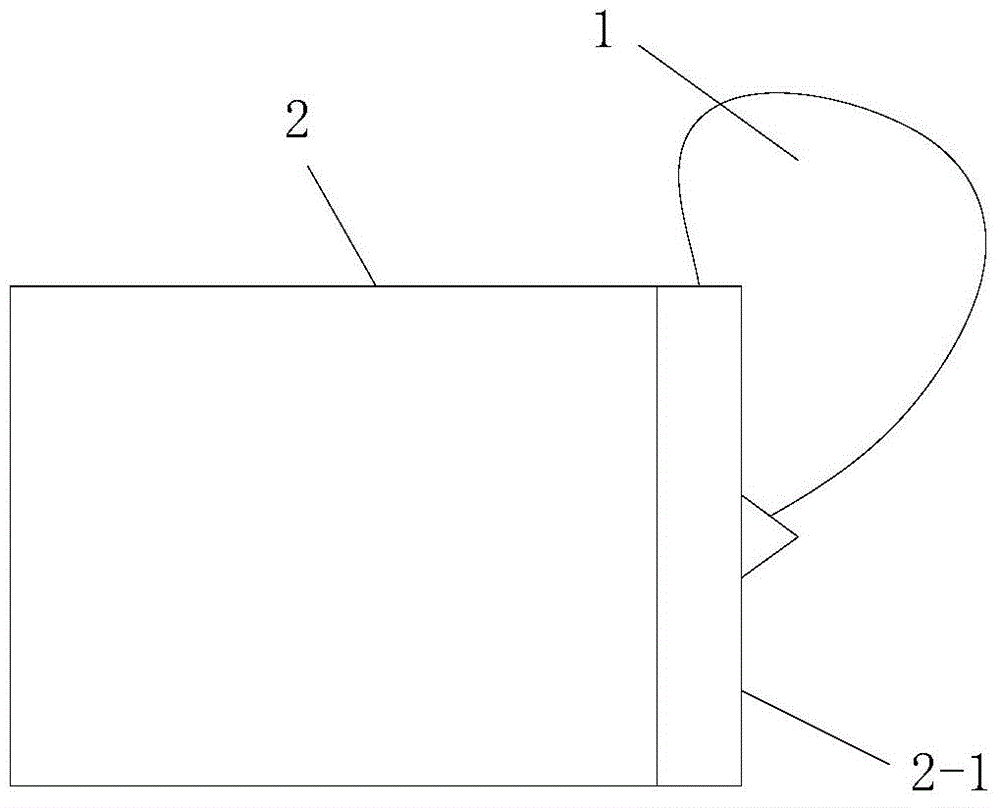

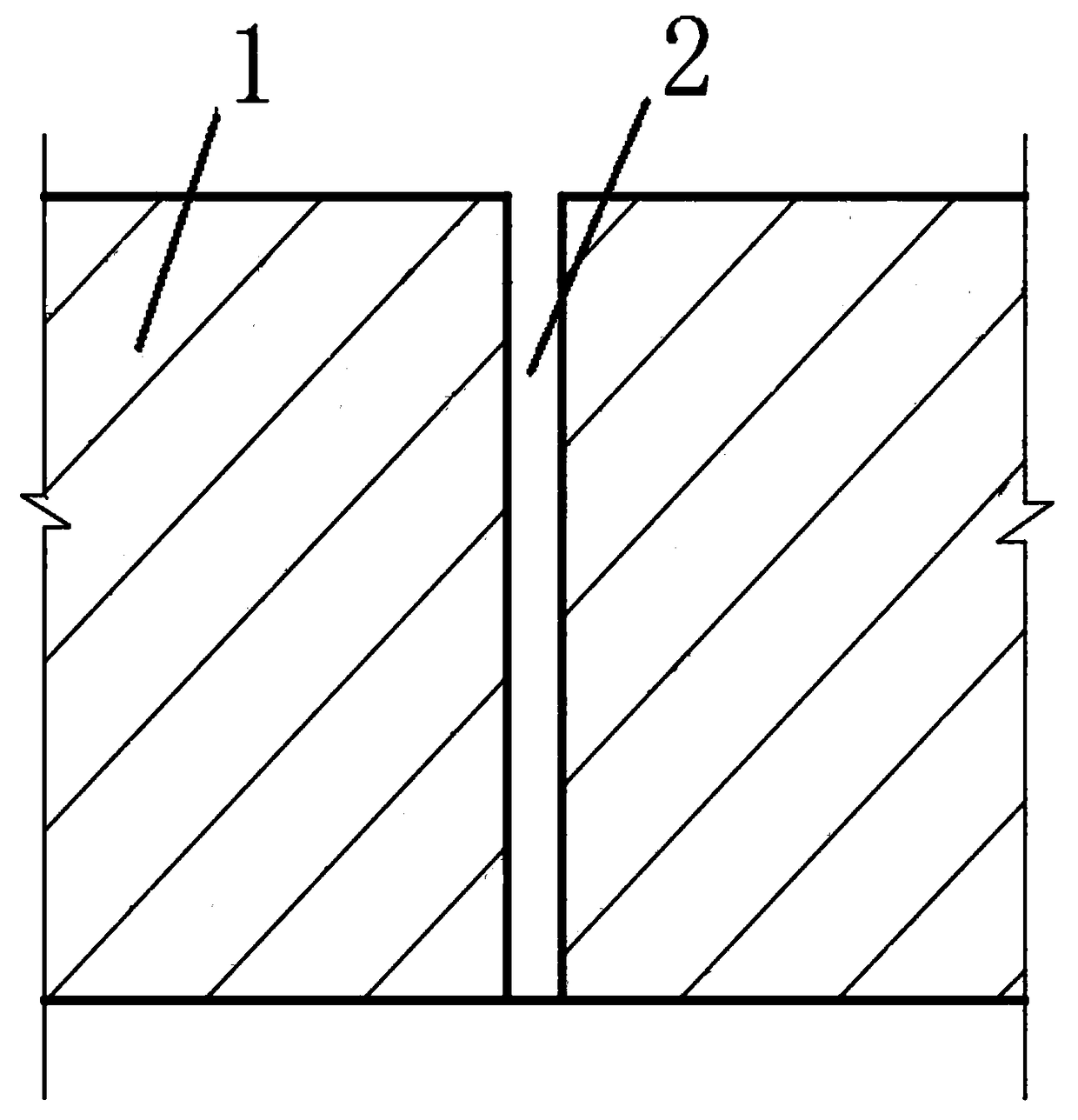

Reinforcement structure for arch-covering-method underground excavation subway station arch feet and construction method

PendingCN109538246AEasy to controlIncrease stiffnessUnderground chambersTunnel liningSubway stationStructural integrity

The invention discloses a reinforcement structure for arch-covering-method underground excavation subway station arch feet and a construction method. The reinforcement structure for the arch feet comprises two layers of arch cover supports, arch foot piles distributed at the arch feet of the left and right sides of subway station arch cover bodies and arch foot longitudinal beams, the arch foot longitudinal beams and the arch foot piles are integrally connected, and pile bodies of the arch foot piles are distributed along the tangent line of the arch feet; each arch foot pile is composed of asection steel framework and fine aggregate concrete which is poured into the section steel framework and pile holes. The reinforcement structure is a reinforcement system combining the arch foot pileswith the longitudinal beams, the longitudinal beams are connected with the arch foot piles and the first and second layers of arch cover supports, the structural integrity is good, the capacity of resisting local stress and deformation is high, and deep and thick smashed surrounding rock at the arch feet can be effectively reinforced and protected; in addition, according to the construction method of the reinforcement structure for the arch feet, the reinforcement range and implementation objects are flexibly selected, rock layers of the arch feet for supporting arch covers are smashed, the integrity influence cannot be caused, and the advantages of an arch-cover method in the aspects such as project cost, construction working period, implementation efficiency and mechanical operation cannot be influenced.

Owner:中铁科学研究院有限公司

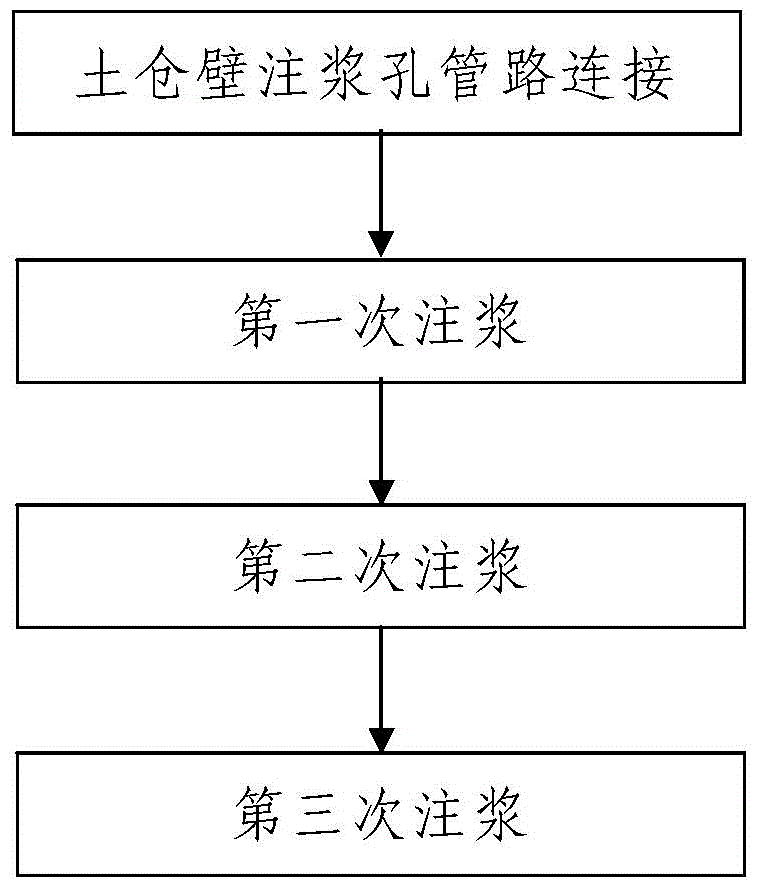

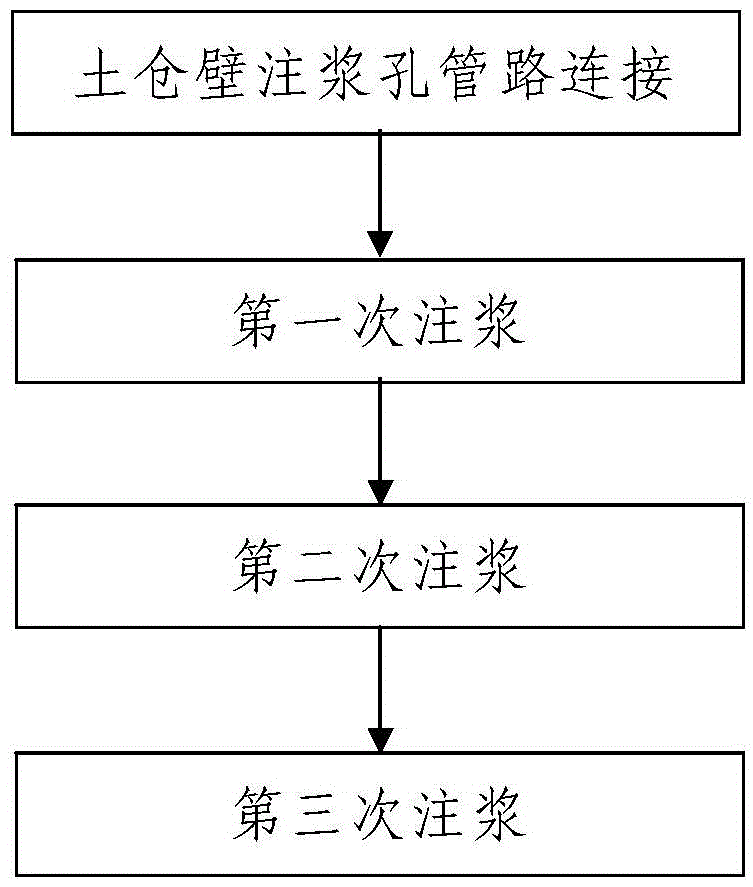

Tunnel face cavity processing method for shield tunnel construction

ActiveCN104481548AThe method steps are simpleLow input costUnderground chambersTunnel liningCement slurryShield tunnelling

The invention discloses a tunnel face cavity processing method for shield tunnel construction. The tunnel face cavity processing method for the shield tunnel construction includes steps that 1, primary grouting, to be specific, using a grouting system to fill first cement mortar to the lower part of the cavity from the top to bottom through a soil warehouse, wherein the first grouting size is composed of cement, bentonite, coal ash, sand and water according to the weight ratio of 45-55: 45-55: 180-220: 540-660: 360-440; 2, secondary grouting, to be specific, using the grouting system to fill second cement mortar to the middle of the cavity, wherein the second cement mortar is composed of cement, bentonite, coal ash, sand and water according to the weight ratio of 90-110: 68-82: 200-280: 540-660: 420-500; 3, tertiary grouting, to be specific, using the grouting system to fill cement slurry to the upper part of the cavity. The tunnel face cavity processing method for the shield tunnel construction is simple in steps, reasonable in design, easy and convenient to operate, low in invested cost, good in use effect and capable of solving the problems of a traditional grouting strengthening method.

Owner:URBAN RAIL TRANSIT ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

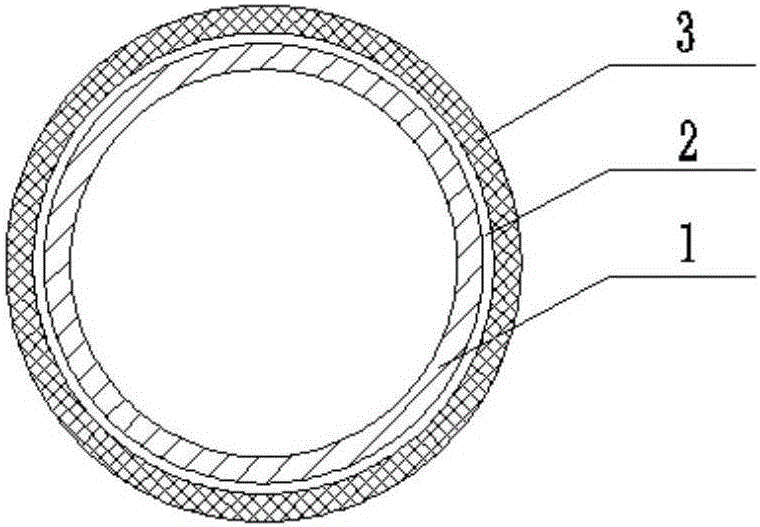

Directional drilling crossing pipeline outer coating structure and machining method thereof

InactiveCN106122678ASimple structureEasy to useLamination ancillary operationsLaminationEpoxySolvent free

The invention provides a directional drilling crossing pipeline outer coating structure and a machining method thereof. The directional drilling crossing pipeline outer coating structure is formed by wrapping the outer surface of a corrosion-resistant layer with a composite protection layer. The composite protection layer is made of pressure-resistant and friction-resistant composite materials formed by mixing resin, fibers and an additive, wherein the resin is photocuring composite resin, the fibers are made of epoxy glass reinforced plastic and / or dual-layer sintered epoxy powder, and the additive is a solvent-free epoxy abrasion-resistant coating. The composite protection layer has high mechanical damage resistance, and when directional drilling crossing encounters complex geological conditions and hard underground structures, damage to the corrosion-resistant layer can be avoided to the greatest extent. The directional drilling crossing pipeline outer coating structure can resist corrosion of a chemical solvent, the phenomenon that a thermal shrinkage sleeve is possibly disengaged in the construction process is completely avoided, and the effect of protecting a pipeline welding junction is greatly improved; and the curing time is short, construction is easy, the construction period is not affected, and the directional drilling crossing pipeline outer coating structure is not influenced by weather elements or field construction conditions, greatly saves manpower and material resources, is high in operability, is easy to implement and popularize, and has broad industrial application prospects.

Owner:SHAANXI YUYANG PETROLEUM TECH ENG CO LTD

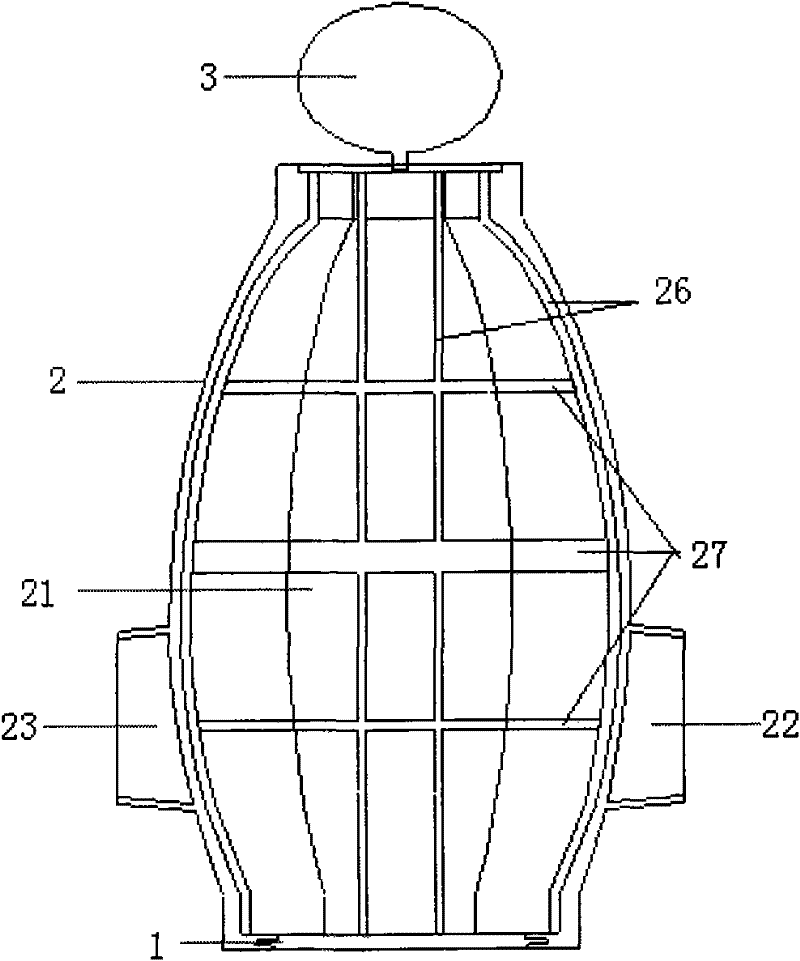

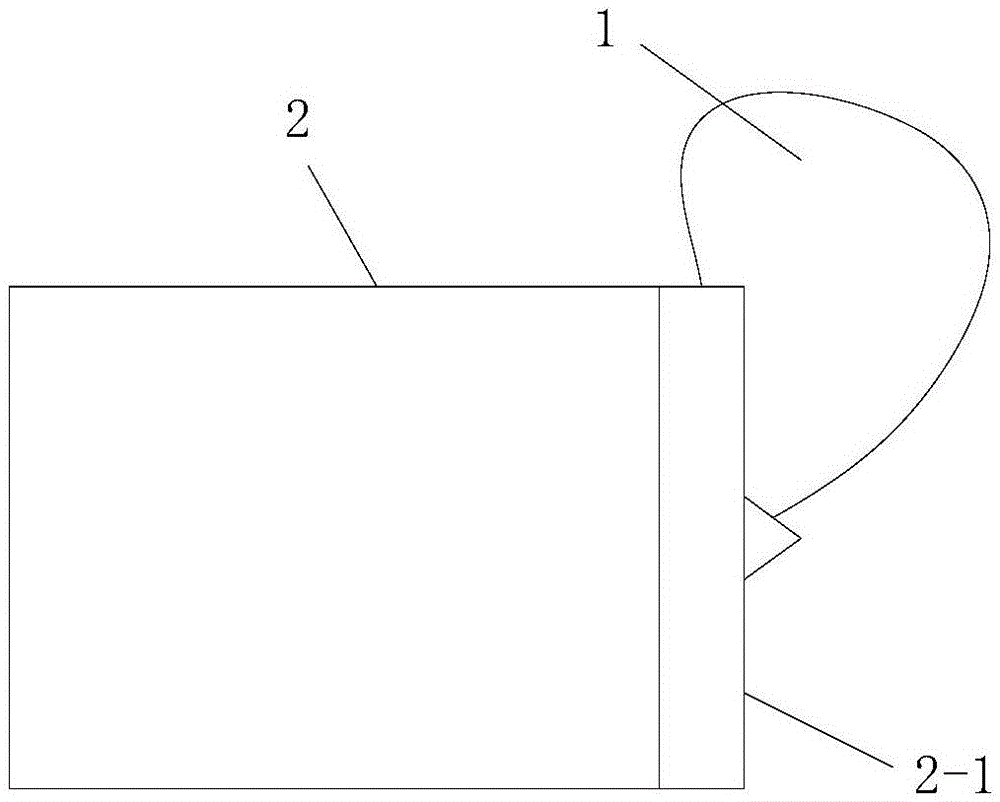

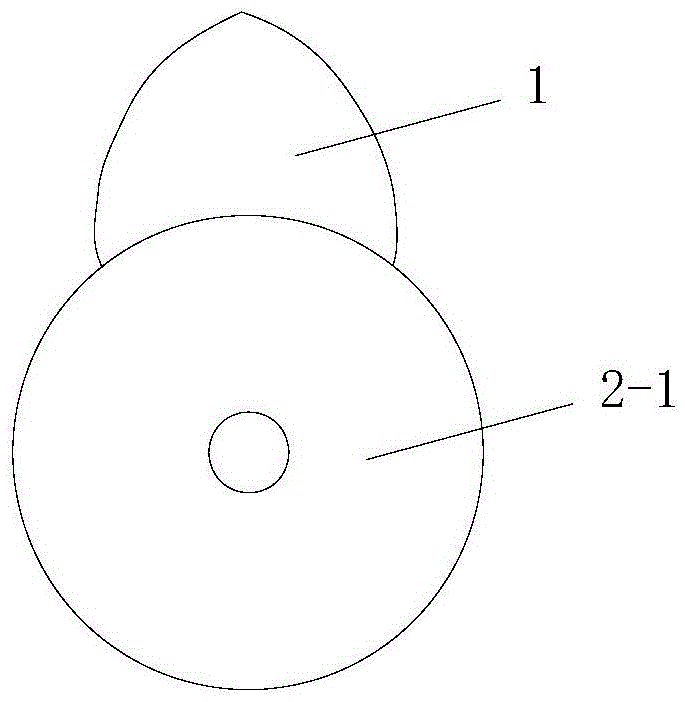

Spliced-type integrated inspection well

InactiveCN101838999AEasy constructionFast on-site installationArtificial islandsUnderwater structuresEngineeringUltimate tensile strength

The invention provides a splice-type integrated inspection well. The inspection well is an integrated piece which mainly consists of a chassis, a side wall and a cover plate, wherein the side wall is an integrated side wall formed by splicing a plurality of wall plates in the peripheral direction; and the bottom end of the side wall is spliced with the chassis, and the upper part of the side wall is connected with the cover plnate to form a sealed shape. When being applied to a project, the invention has the advantages of great convenience for construction, fast field installation, clean operational environment, no need of special maintenance and no influence on construction period; since the splicing structure of split-type components is reasonable and a convex edge is in interference with a groove, the invention has good sealing performance and can effectively prevent soil pollution caused by leakage of harmful substances contained in water body in the inspection well; and PVC plastic which is adopted as the materials for the split-type components in the invention has strength and toughness, is not easy to damage when being impacted by the water body, and has corrosion resistance, thereby the splice-type integrated inspection well almost needs not to be maintained, and saves labor.

Owner:金湖县九鼎塑胶制品有限公司

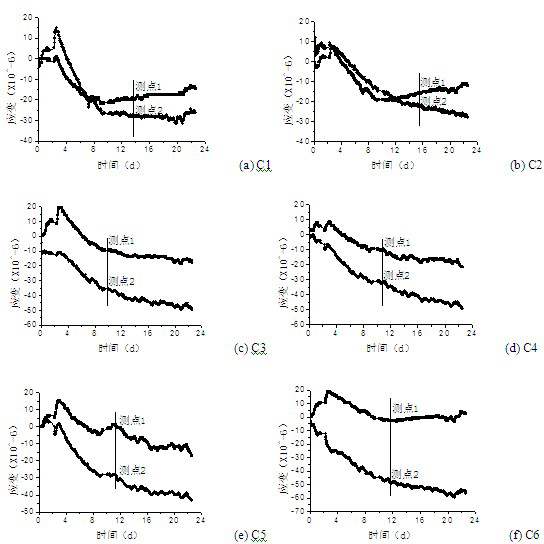

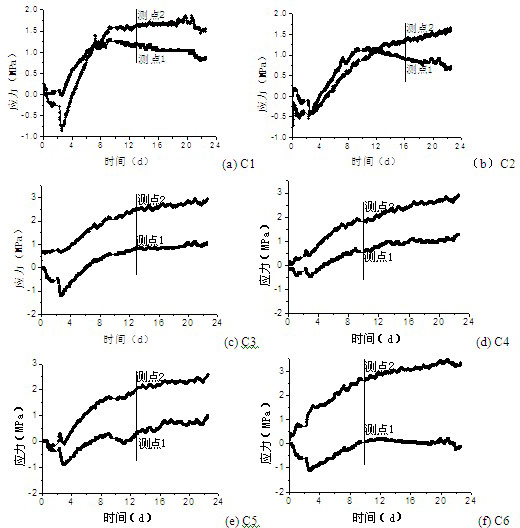

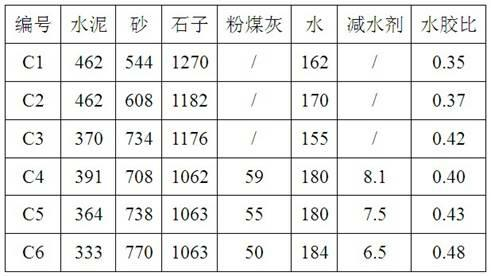

Method for rapidly evaluating crack resistance of cement-based material

InactiveCN102539656AAvoid after-the-fact fixesIncreased durabilityUsing mechanical meansMaterial testing goodsCrack resistanceMechanical property

The invention relates to a method for rapidly evaluating the crack resistance of the cement-based material, comprising the following steps: testing the crack resistance and the mechanical properties of the cement-based material to be evaluated, drawing an inner steel ring strain development curve which changes with time according to the obtained inner ring strain, calculating the circumferential tensile stress of the cement-based material, drawing a circumferential tensile stress curve which changes with time of the cement-based material, calculating the tensile strength which changes with time of the cement-based material according to the measured mechanical properties of the cement-based material, and evaluating the crack resistance of the cement-based material according to the circumferential tensile stress curve secant slope, the ratio of the circumferential tensile stress to the tensile strength of the cement-based material with the age of 14d and the ratio of the stress decrease value of the cement-based material at the first mutation age and in the first mutation period to the tensile strength of the cement-based material of the same age. The method is simple, practical, accurate and reliable. Due to the adoption of the method, the construction period of the building structure is not affected, the subsequent repair is avoided, the crack risk is reduced, the durability and the safety of the structure are improved, and the service life is prolonged.

Owner:福建省融旗建设工程有限公司 +1

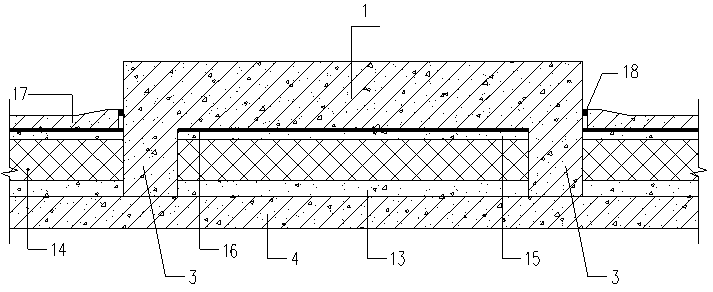

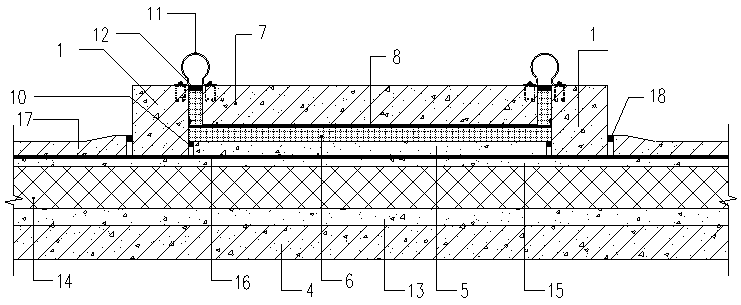

Vibration isolation roofing equipment foundation construction

InactiveCN110565883AImprove integrityIntegrity guaranteedRoof covering insulationsFoundation engineeringInsulation layerArchitectural engineering

The invention belongs to a vibration isolation roofing equipment foundation construction in the field of construction engineering vibration isolation. According to the technical scheme, a concrete constructional frame is placed flat on a roofing waterproof insulation layer, constructional columns are arranged at the corners of the concrete constructional frame, and column feet of the constructional columns are fixedly connected with a structural layer; a protective layer, an elastic cushion layer, a waterproof layer and a concrete slab floating building layer are successively laid from bottomto top on the space in the concrete constructional frame; and a connecting ring is arranged at the frame edge of the concrete constructional frame, one end of the connecting ring is connected with theframe edge, the other end of the connecting ring is connected with the top surface of the concrete slab floating building layer, and the finished surface is laid on the roofing waterproof insulationlayer outside the concrete constructional frame. According to the vibration isolation roofing equipment foundation construction, the problem of vibration isolation and waterproofing of a roofing equipment foundation is conveniently solved, building cold bridge formation is reduced, the effect of solid sound transmission on the building space under a roofing is lowered, the purposes of environmental protection and energy saving are achieved, and meanwhile, reasonable control and layout the heights and planes of buildings by architects are convenient.

Owner:SHANGHAI ARCHITECTURAL DESIGN & RES INST

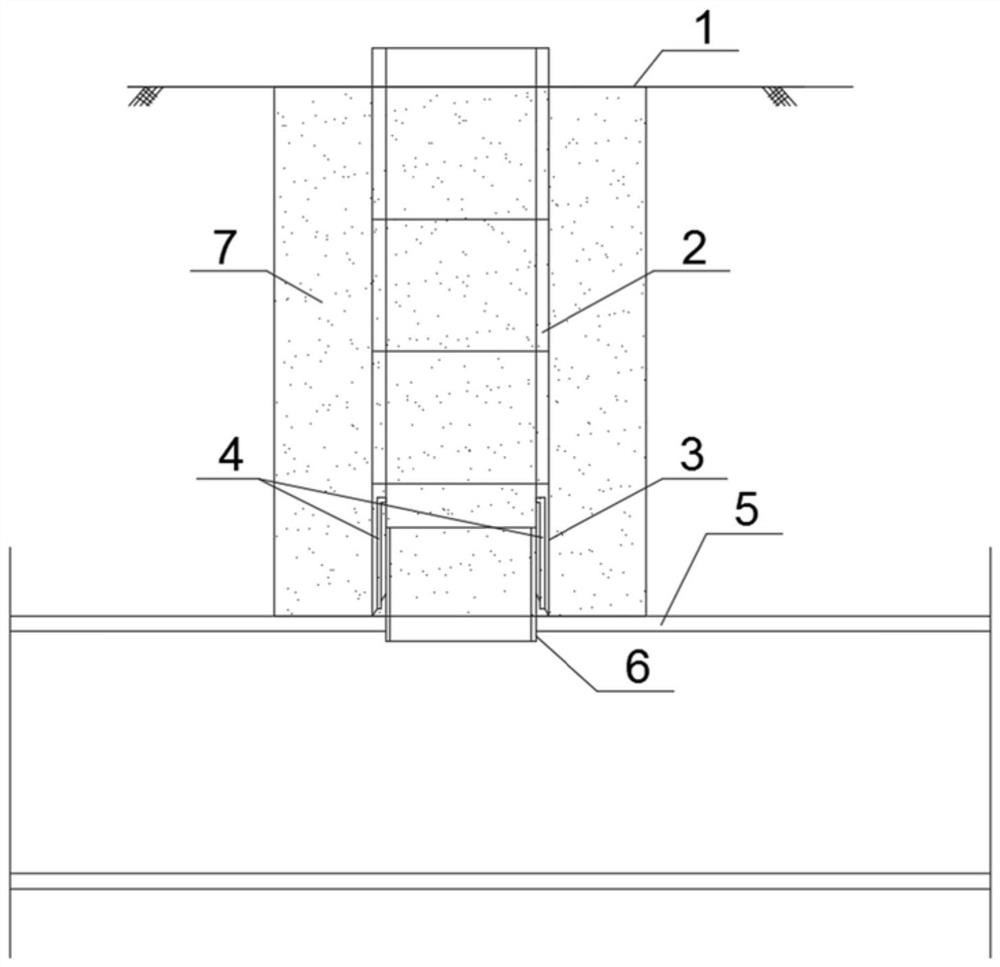

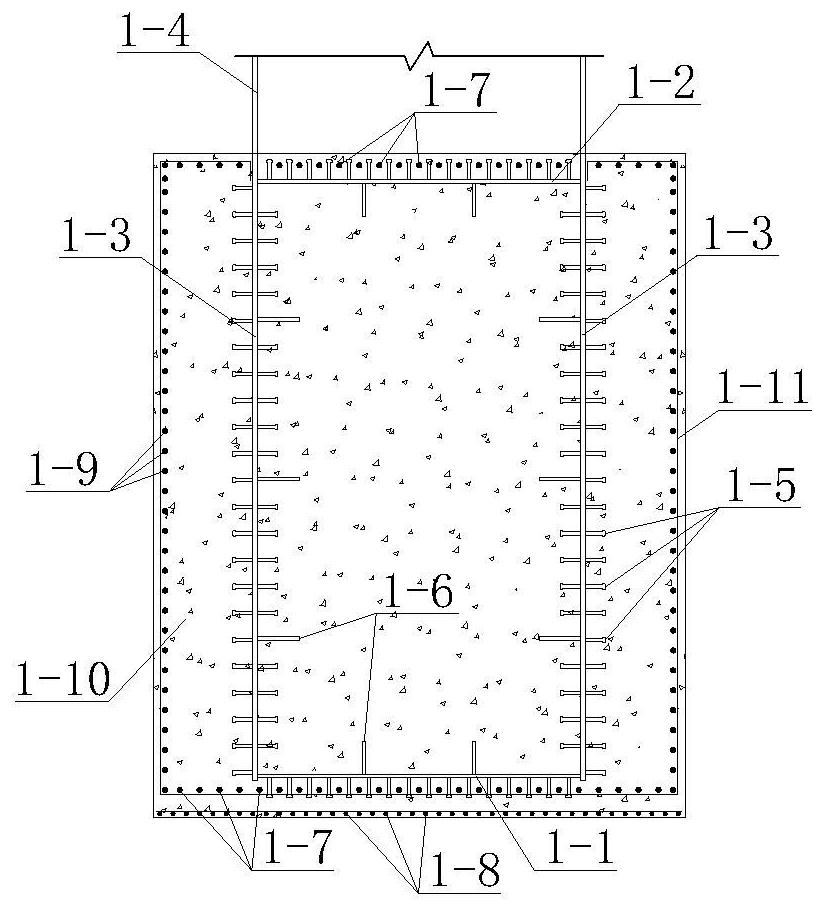

Construction method of support-free prefabricated assembly type shield tunnel air shaft structure

InactiveCN112727466AReduce the risk of excavationReduce wasteUnderground chambersTunnel/mines ventillationWater stopArchitectural engineering

The invention discloses a construction method of a support-free prefabricated assembly type shield tunnel air shaft structure. The method includes the steps that after shield tunneling is completed, high-pressure jet grouting piles are adopted to conduct reinforcement and water stop on soil in an air shaft construction range at a designed air shaft position, then the prefabricated air shaft structure is hoisted in place in sections, excavation is conducted in the air shaft structure, the air shaft structure gradually sinks by means of self weight, and excavation is performed until the excavation is performed above a constructed shield tunnel structure; and after reliable reinforcing and water stopping are conducted at a connecting position of a shield and the air shaft structure, holes are formed in the top of the shield tunnel structure in the air shaft structure, steel pipe pieces are adopted as pipe pieces for hole forming, then the steel pipe pieces of a shield tunnel are connected with the air shaft structure in a welded mode through steel sleeves, and the construction of the air shaft structure is completed. According to the construction method of the support-free prefabricated assembly type shield tunnel air shaft structure, an air shaft deep foundation pit supporting structure can be constructed, so that the safe, rapid, economical and environment-friendly construction purpose of a tunnel air shaft is achieved, and the method is suitable for construction of urban shield tunnel engineering.

Owner:绍兴市柯桥区轨道交通集团有限公司

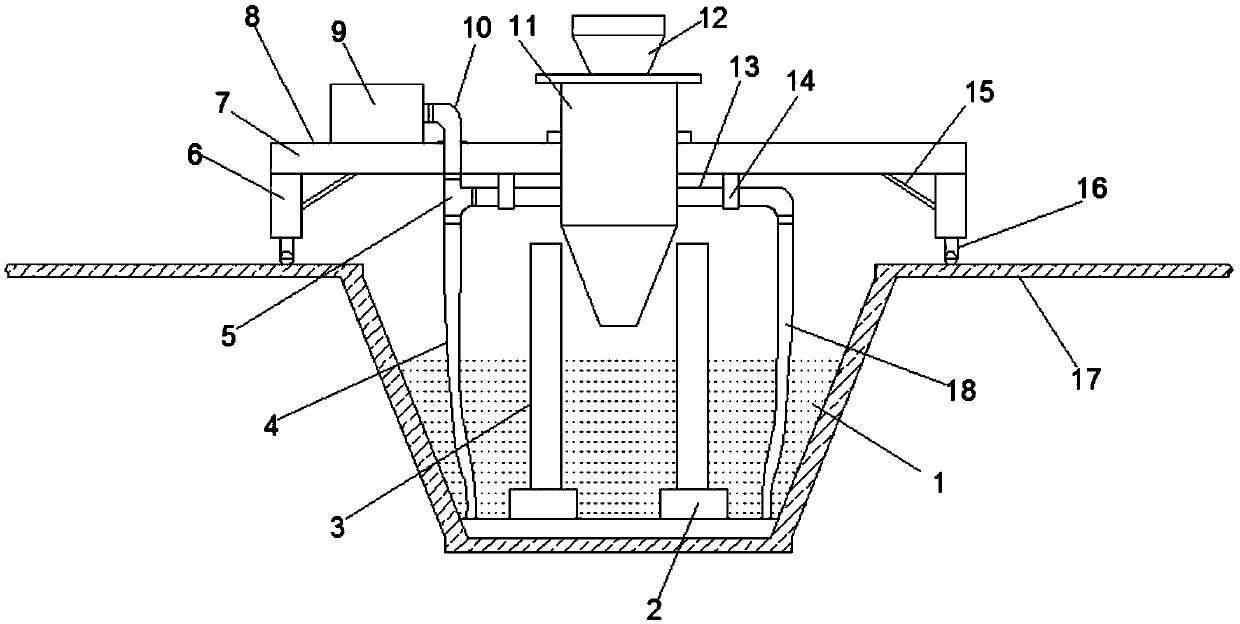

Civil engineering building backfilling device

PendingCN109537664AAvoid failureQuality improvementSoil-shifting machines/dredgersProtection layerBuilding construction

The invention discloses a civil engineering building backfilling device. The device comprises a foundation pit; a pair of bearing platforms are arranged at the bottom of the foundation pit, a frame column is arranged at the top end of each bearing platform in the height direction of the bearing platform, and a guide tool of the backfilling device is arranged above the foundation pit; and the guidetool comprises a horizontal frame, a funnel cavity and rolling wheels, wherein the funnel cavity is arranged at the center of the horizontal frame. The device has the beneficial effects that due to the arrangement of the guide tool, the defect of traditional soil throwing to backfill is overcome, the failure of a waterproof protection layer caused by earthwork impact is avoided, the quality and the efficiency of the backfilling soil are improved, the reworking is reduced, and the later plugging cost is reduced; in addition, water pumping pipes and a water pump are combined, the problem of water accumulation in the foundation pit area is solved, and meanwhile, the problem that due to the fact that the area of the backfilling area is narrow, a backfilling machine is inconvenient to pass through is solved; and the engineering is enabled to be carried out in a non-turbulent mode, the construction period is not affected, and the practicability is high.

Owner:安徽省人防建筑设计研究院

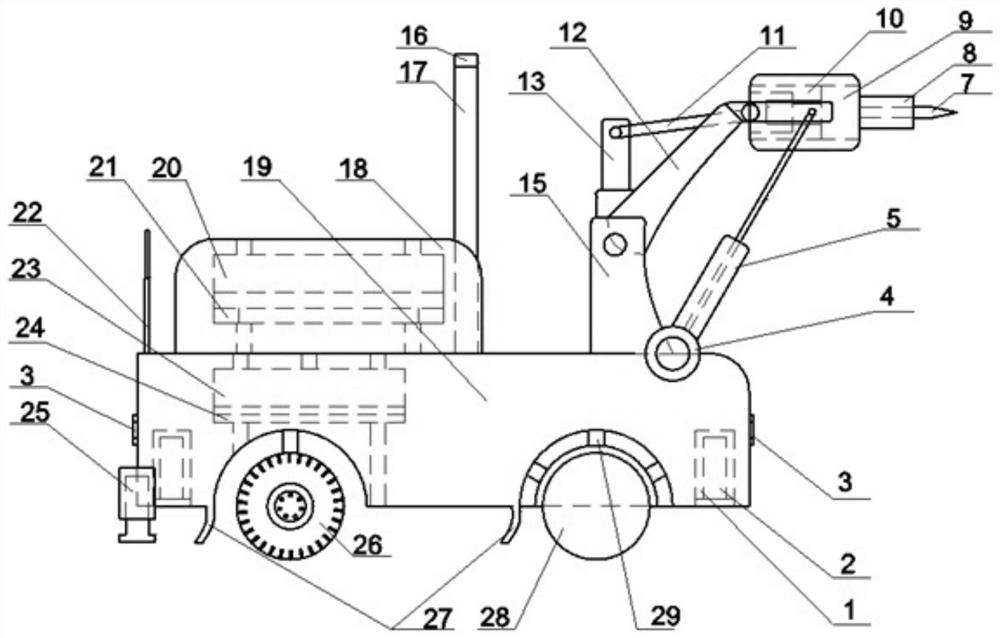

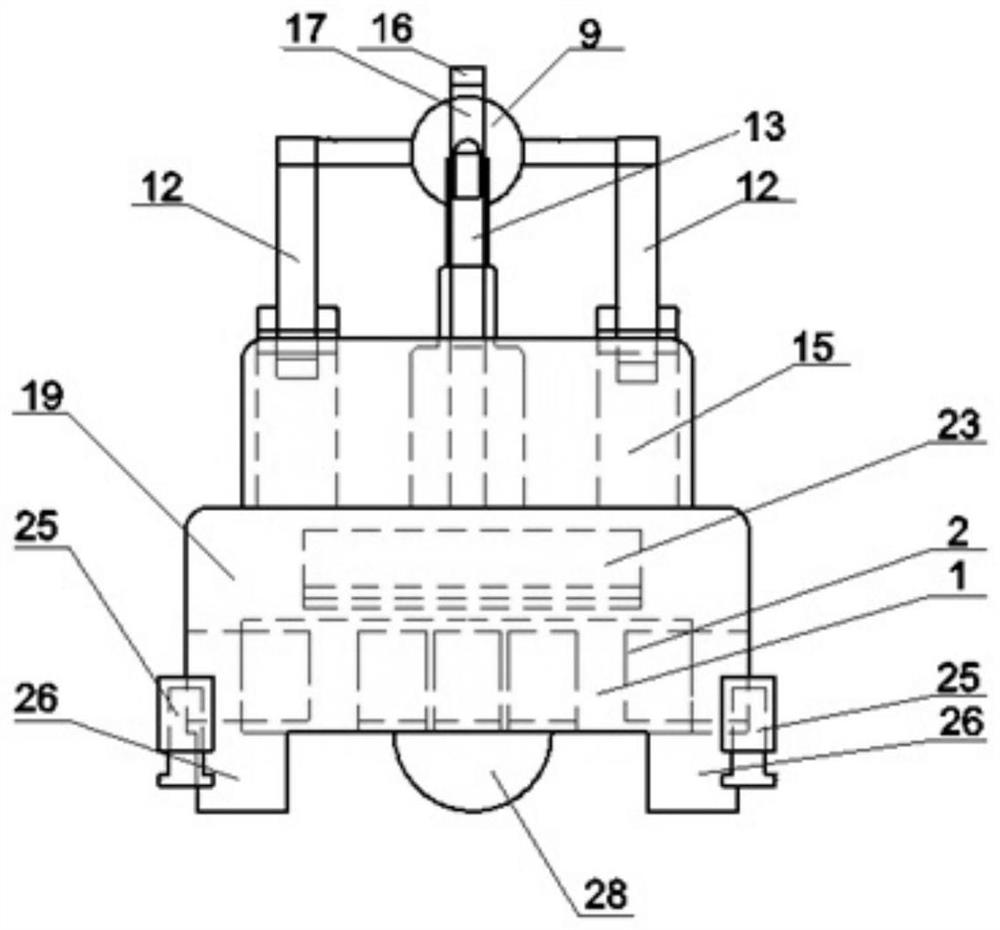

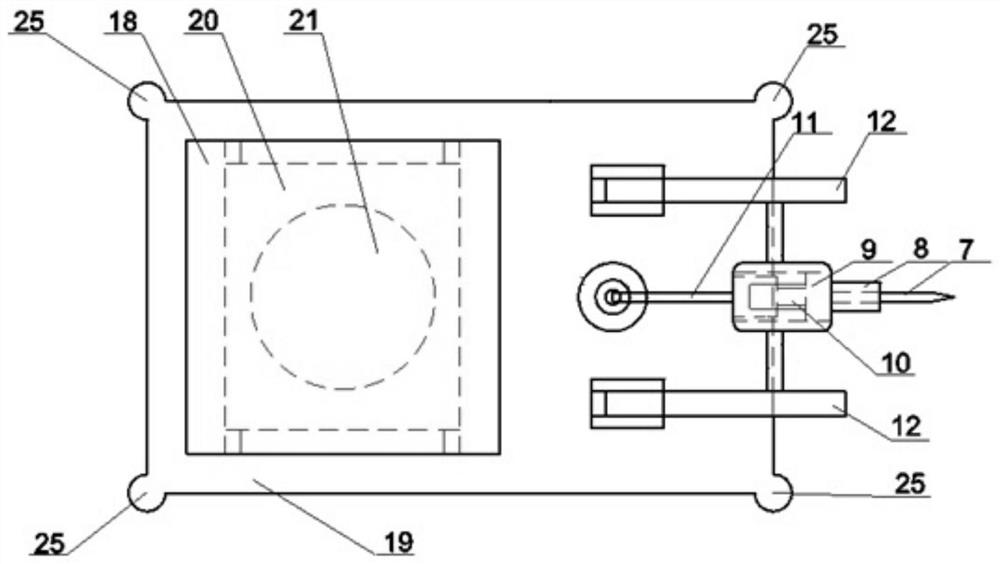

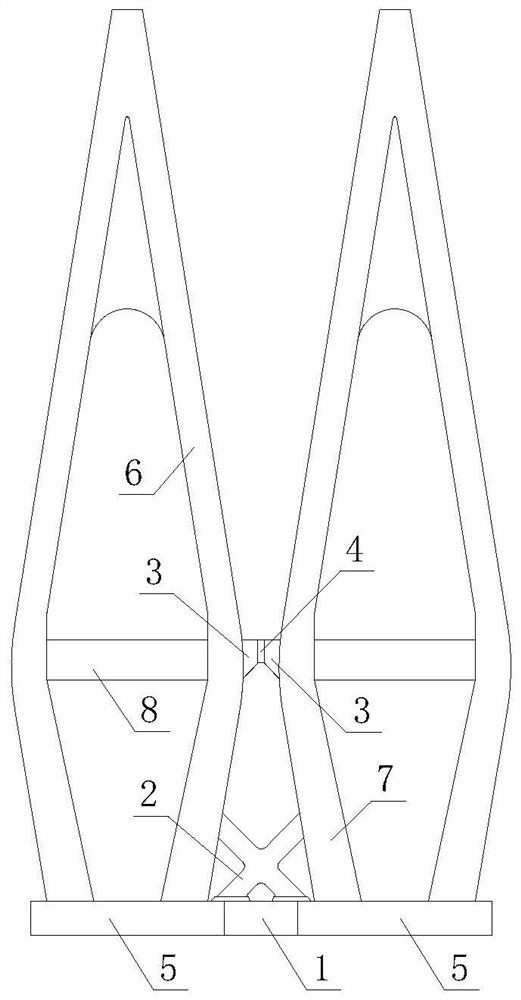

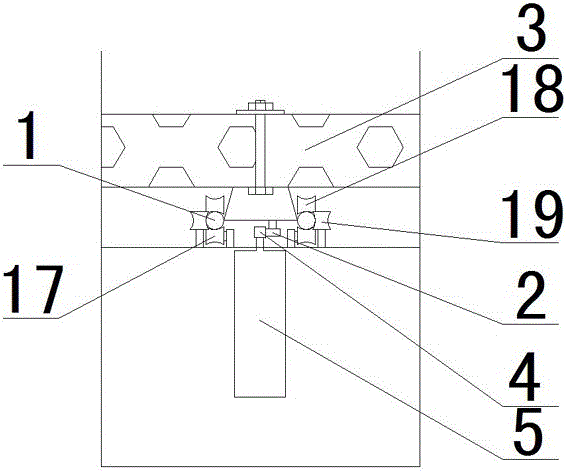

Mining intelligent drilling pressure relief device and using method thereof

PendingCN112196512AReduce pressure relief workloadEasy constructionSurveyMining devicesAutomatic controlCoal mining

The invention relates to a mining intelligent drilling pressure relief device and a using method thereof, and belongs to the technical field of coal mining equipment. The device comprises a machine body support, a control system, an identification sensing system and a drilling system, wherein the front end of the machine body support is connected with universal wheels through universal wheel supports, driving wheels are arranged on the two sides of the rear end of the machine body support respectively, the identification sensing system is arranged on the machine body support, the drilling system is arranged at the front end of the machine body support, the control system is arranged at the rear end of the machine body support, and the driving wheels are connected to the control system. According to the device, automatic control is carried out through the control system in the whole process, the pressure relief workload is effectively reduced, meanwhile, construction is facilitated, theconstruction speed is increased, and the construction period is not affected.

Owner:SHANDONG UNIV OF SCI & TECH

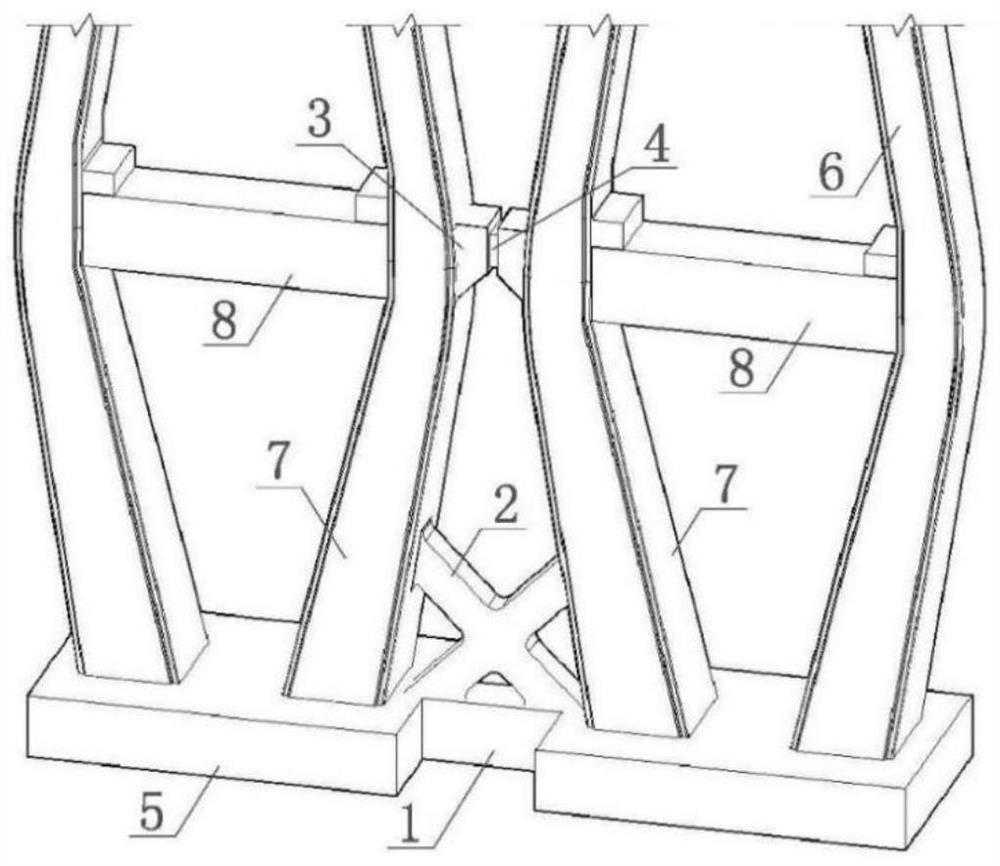

Novel energy dissipation and shock absorption type inter-tower connection structure of framing connected-tower cable-stayed bridge

PendingCN112853934AIncrease lateral stiffnessImprove lateral stabilityCable-stayed bridgeBridge structural detailsEarthquake resistanceArchitectural engineering

The invention relates to a novel energy dissipation and shock absorption inter-tower connection structure of a framing tower-connected cable-stayed bridge. The structure comprises bridge tower bearing platforms, bridge tower columns are fixed to the bridge tower bearing platforms, the bridge tower columns are divided into upper tower columns and lower tower columns through bridge tower cross beams arranged on the bridge tower columns, and the bottom ends of two bridge towers are connected through a combined structure bearing platform straining beam between the bridge tower bearing platforms; inter-tower steel box inclined struts are arranged between tower limbs of the lower tower columns, so that the two bridge towers form local connection; and steel corbels are installed on the tower columns at the positions of the bridge tower cross beams, and dampers are installed between the two bridge towers through the steel corbels. According to the framing tower connecting structure form provided by the invention, on the basis of not influencing the construction period of the bridge tower and not increasing the construction difficulty, the transverse bridge direction earthquake response of the bridge tower is greatly reduced, and the anti-seismic property, the safety and the economical efficiency of the bridge tower are greatly improved.

Owner:甘肃省交通规划勘察设计院股份有限公司

Track climbing type monolithic architecture construction scaffold

The invention relates to the field of construction and particularly relates to a track climbing type monolithic architecture construction scaffold which comprises a frame body and a rack bracket, wherein the rack bracket is fixed on a building wall through a bolt; the frame body is in slip connection with the rack bracket through a fixed pulley; a motor bracket is arranged on the frame body; an electromotor is arranged on the motor bracket; and a transmission shaft of the electromotor is provided with a transmission gear matched with a rack of the rack bracket. The scaffold provided by the invention is directly mounted for use along with the construction of the building main body, the scaffold lifting speed is increased, the construction period is shortened, and the production efficiency is improved; and moreover, the frame body has strong overall stability, the working range of people construction is widened, and the construction is facilitated.

Owner:天力博达科技有限公司 +1

Positioning adjustment device and method of main tower cable guiding pipe of cable-stayed bridge

PendingCN110241735AEasy to adjustDoes not affect the construction periodBridge structural detailsBridge erection/assemblyCable stayedTower

The invention discloses a positioning adjustment device and method of a main tower cable guiding pipe of a cable-stayed bridge. The positioning adjustment device comprises a stiff skeleton, a measuring assembly and a standard assembly; the stiff skeleton is internally provided with an anchoring area used for anchoring the cable guiding pipe, and a datum point is preset on the stiff skeleton; the measuring assembly is used for adjusting an inlet and an outlet of the cable guiding pipe into a preset elevation surface according to the relationship between coordinates of the datum point and preset coordinates of the inlet and the outlet of the cable guiding pipe, and the relative position relationship between the datum point and the inlet and the outlet of the cable guiding pipe; the standard assembly comprises two telescopic rods, one ends of the telescopic rods are rotatably connected to the stiff skeleton, and the other ends of the telescopic rods are provided with standard points; and the standard assembly is used for adjusting the two standard points to enable the connecting line of the two standard points to coincide with or to be parallel to the theoretical axis according to the relationship between the coordinates of the datum point and the preset coordinates of the inlet and the outlet of the cable guiding pipe, and the relative position relationship between the datum point and the standard points. The cable guiding pipe can be quickly and precisely adjusted to the theoretical position even under heavy fog and strong wind weather.

Owner:1ST ENG OF CHINA ZHONGTIE MAJORBRIDGE GROUP +1

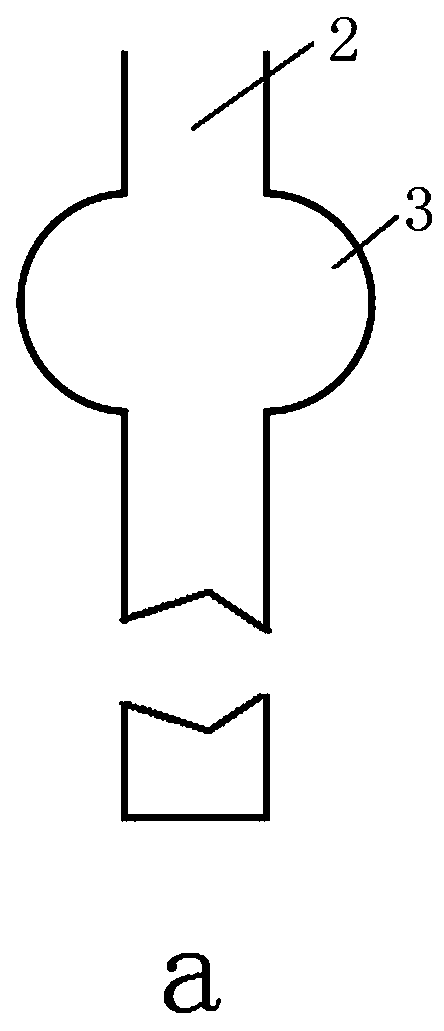

Underground construction deformation joint waterproof structure and construction method thereof

PendingCN108978731ASimple waterproof structureReliable functionArtificial islandsProtective foundationJoint spacesPrecast concrete

The invention discloses an underground construction deformation joint waterproof structure and a construction method thereof. The waterproof structure comprises a deformation joint, and an expansion cavity formed in the position 30 to 70 mm away from the top of the deformation joint, and the interior of the expansion cavity and deformation joint space above the expansion cavity are filled with a seal material with the waterproof effect; the construction method comprises the steps that firstly, a frame of a precast concrete wall is built, an expansion cavity mold in the corresponding shape is made, and the position of the preset expansion cavity is marked in the position, 30 to 70 mm away from the top o the deformation joint, in the reserved deformation joint; secondly, the expansion cavitymold is placed on the marked deformation joint and is used for supporting so as to form the expansion cavity; thirdly, concrete is poured into the frame for prefabrication molding, and after curing solidification, the expansion cavity mold and the frame are removed; fourthly, the position, below the expansion cavity, in a deformation joint hole is filled with a flexible filler, and a seal material with the waterproof effect is poured into the expansion cavity and the deformation joint space above the expansion cavity. The structure is simple, the function is reliable, the construction methodis simple, operation is easy, and the cost is low.

Owner:ZHENGZHOU UNIV

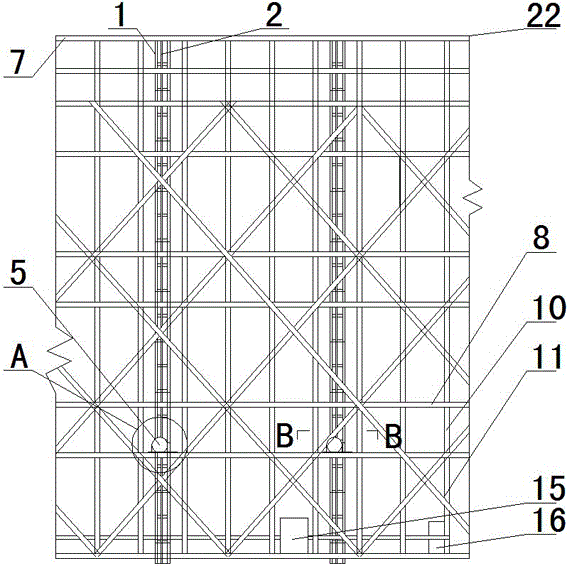

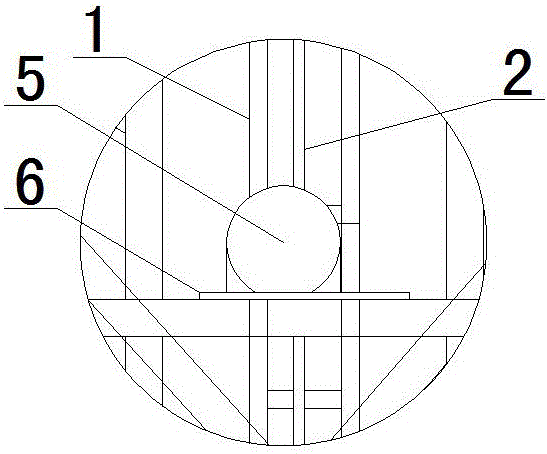

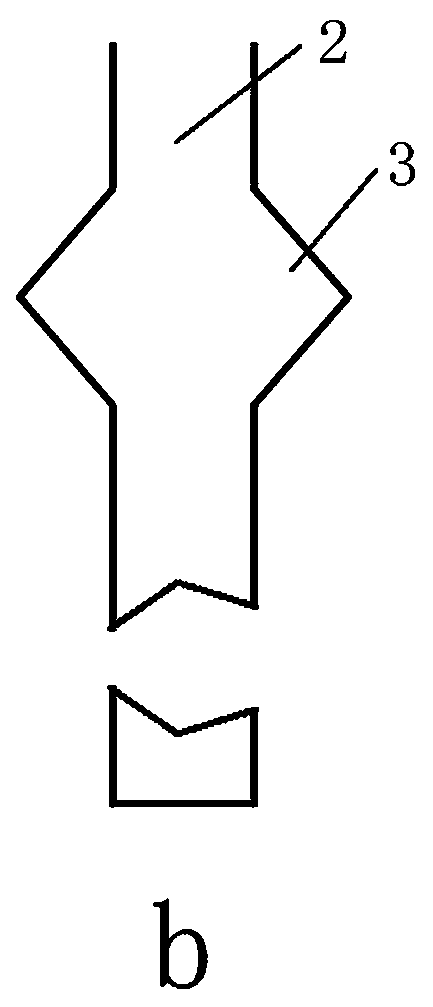

Occlusive pile construction method during encountering with deep layer underground obstacles

InactiveCN108385694ADoes not affect the construction periodImprove construction efficiencyExcavationsBulkheads/pilesBuilding construction

The invention relates to the technical field of foundation construction of building construction, and discloses an occlusive pile construction method during encountering with deep layer underground obstacles. The method comprises the following steps that site leveling and surface shallow layer old foundation cleaning are carried out; a guide wall is constructed; occlusive piles are constructed; the occlusive piles are of a continuous row pile structure composed of plain piles and complex piles which are occlusive and arranged at intervals, wherein the plain piles are A-sequence piles, and thecomplex piles are B-sequence piles; a casing oscillator is used for hole forming, in the construction process, when the deep layer underground obstacles appear, finished hole positions are subject tobackfill operation, construction of the next construction sequence hole position is continuously carried out, after the whole row of occlusive piles are constructed, or, after the plain piles on the two sides are finally set, in-position covering position construction is carried out, the deep layer underground obstacles are broken through a rotary digging machine or punching machine, hole formingis carried out again, and construction of a covering position pile is finished. The underground barriers are treated in situ, the key line duration is not affected, construction efficiency is high, accuracy is high, and the construction quality is easily controlled.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

Energy dissipation and shock absorption building with bound rubber beams

InactiveCN101839083AGuaranteed normal use of functional requirementsPlay a shock absorbing roleProtective buildings/sheltersLower gradeEngineering

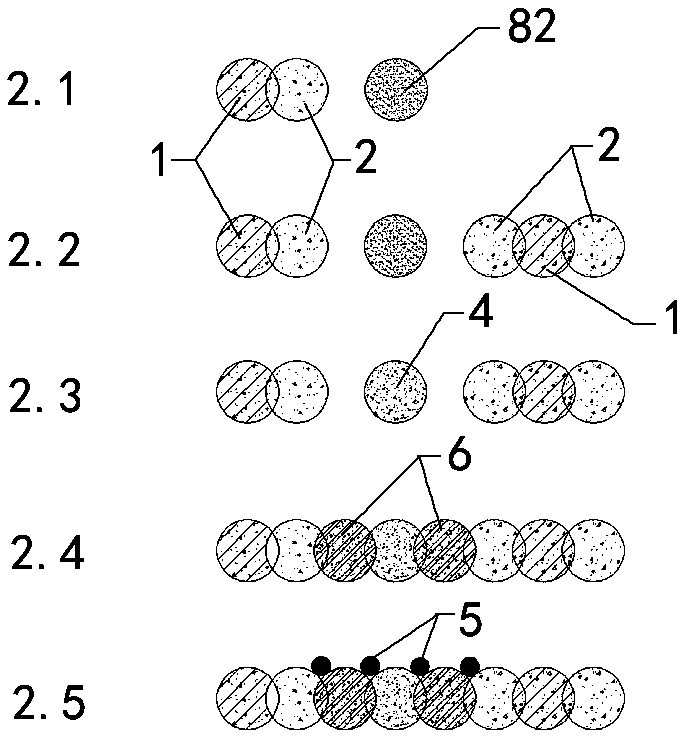

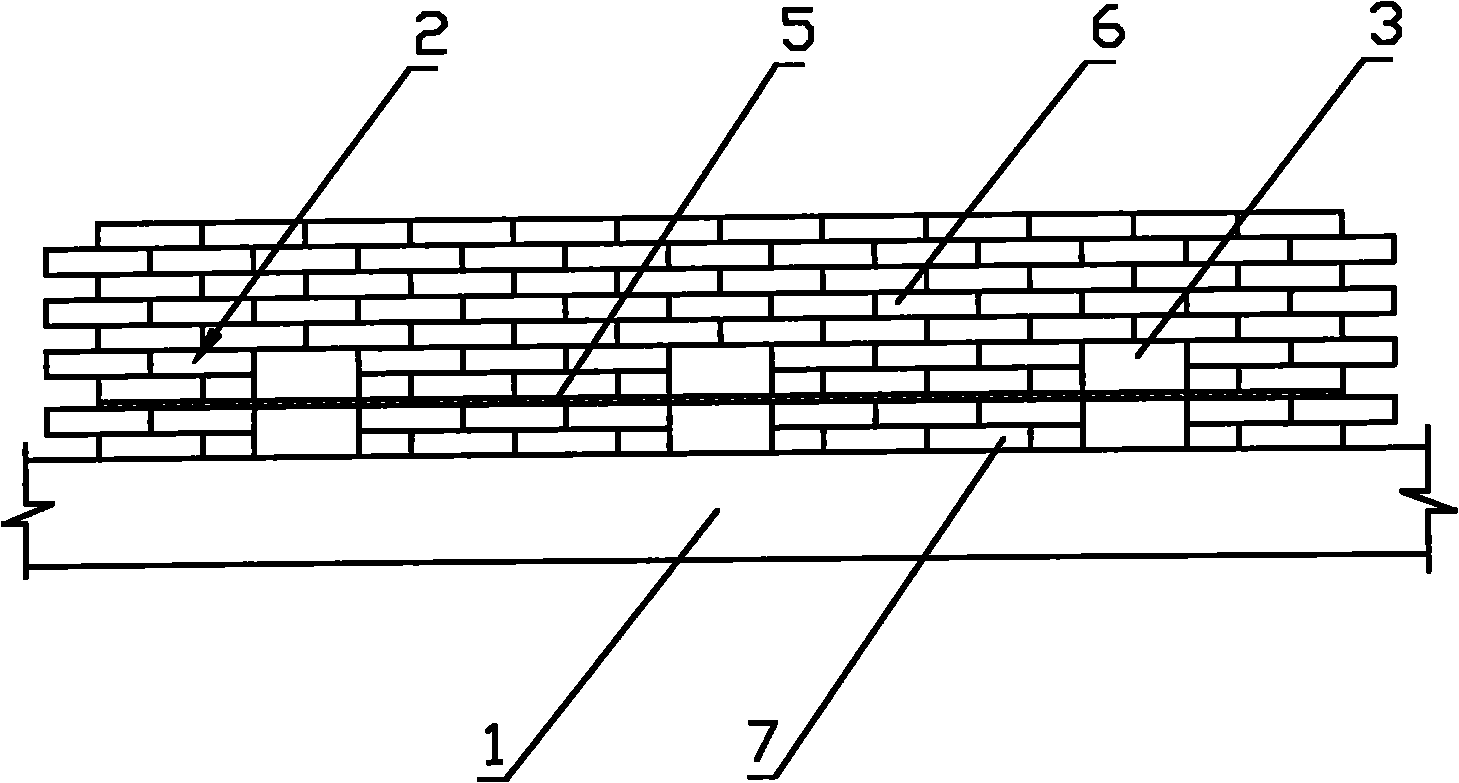

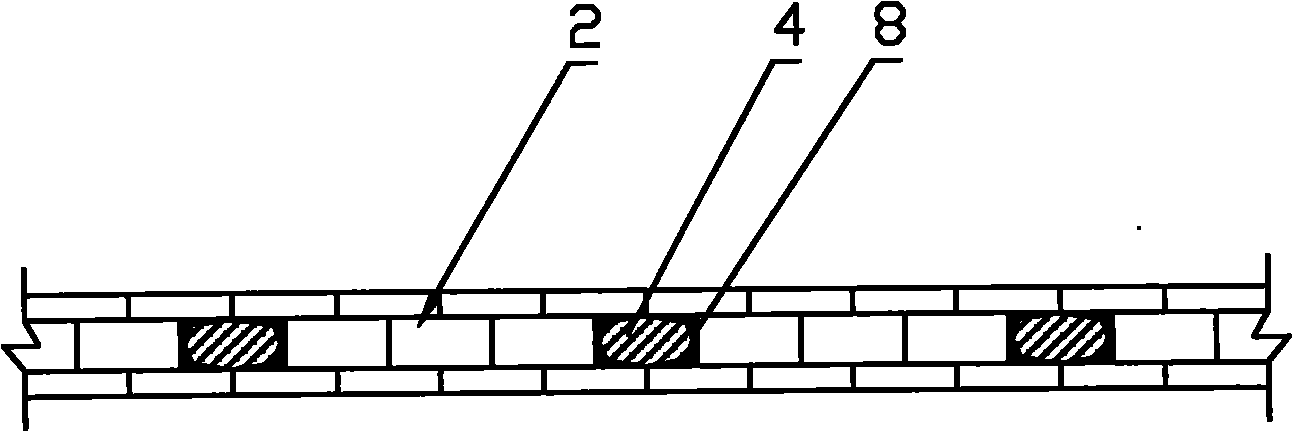

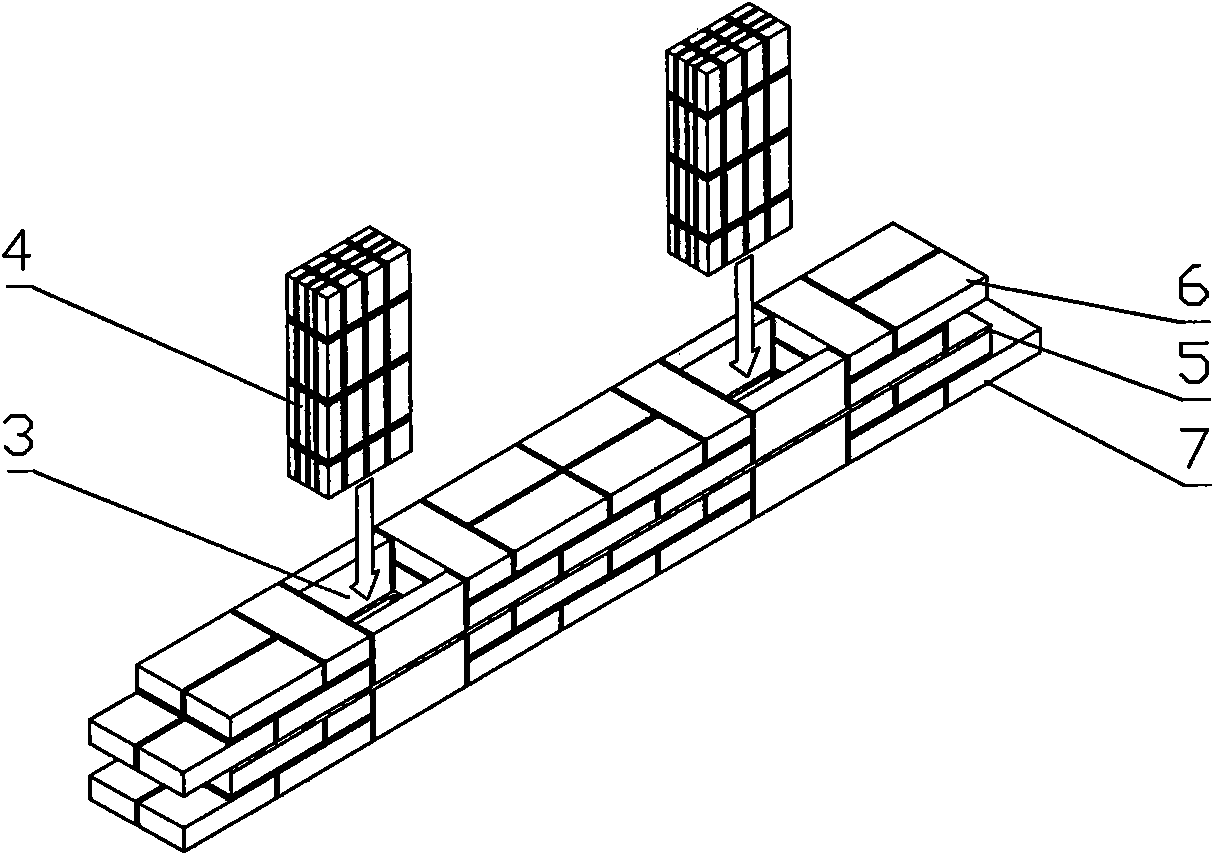

The invention discloses an energy dissipation and shock absorption building with bound rubber beams, comprising a diquanliang (DQL) and a wall body constructed on the DQL, wherein a plurality of rubber beam installation holes are arranged along the same horizontal height in the wall body at equal intervals, rubber beams are arranged in the rubber beam installation holes, the wall body is divided into an upper wall body and a lower wall body by a low grade cement mortar layer horizontally paved therein, and the low grade cement mortar layer is at the same horizontal height with the middle part of the rubber beams. The wall bodies are subjected to slippage in the low grade cement mortar layer and the built-in bound rubber beams are in elastic-plastic shear deformation under the action of a large earthquake, thus realizing dissipation of earthquake energy transmitted to an upper structure from a foundation, weakening the earthquake energy transmitted to the upper structure, and further playing a shock absorption role in the upper structure; the rubber beams can limit overlarge slippage in the earthquake and has a limit resetting function; and the building of the invention has simple construction, convenience in drawing materials, economical efficiency and effectiveness and environment-friendly drawn materials, and facilitates building construction in towns.

Owner:CHONGQING UNIV

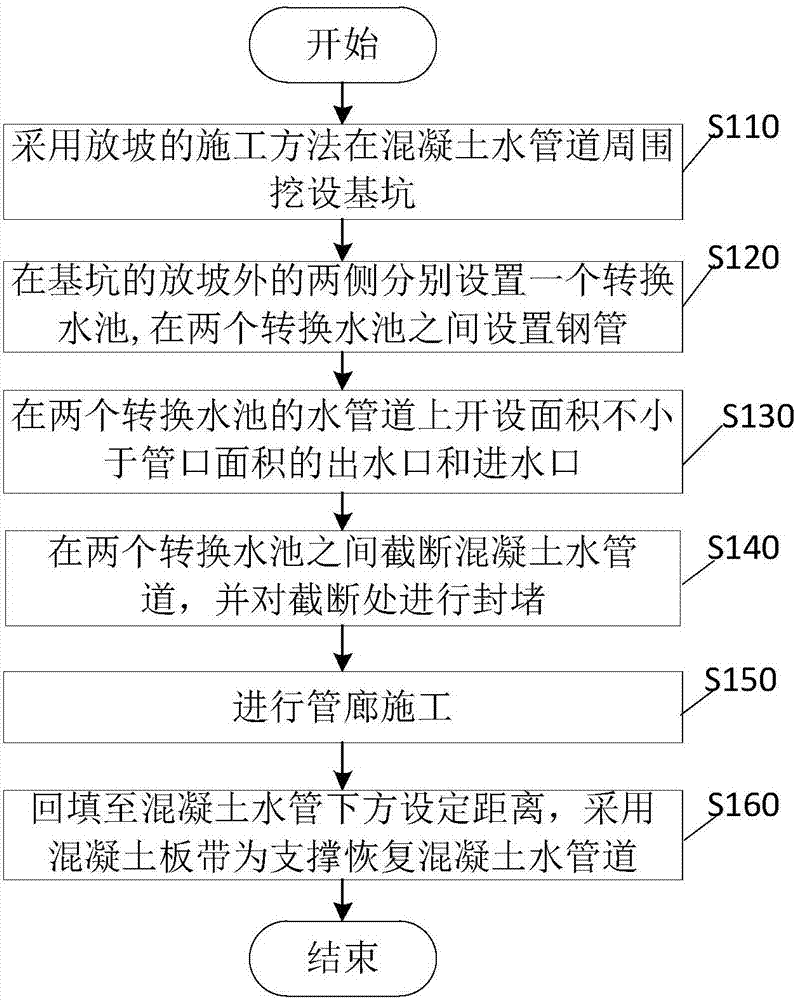

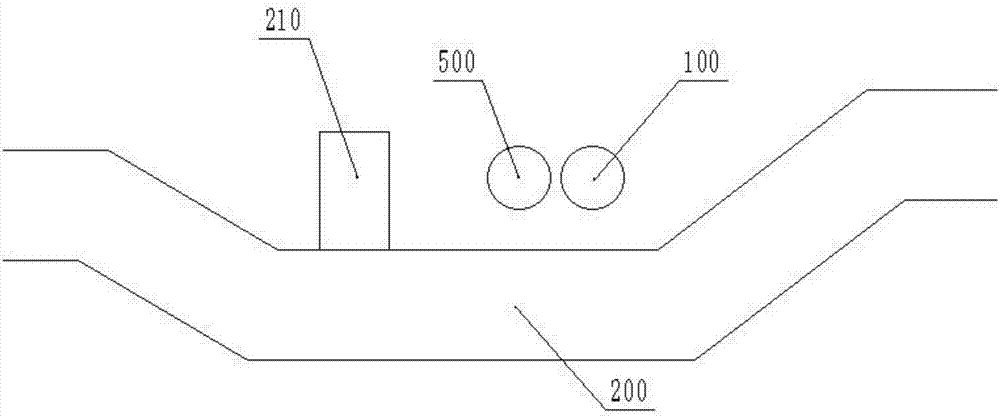

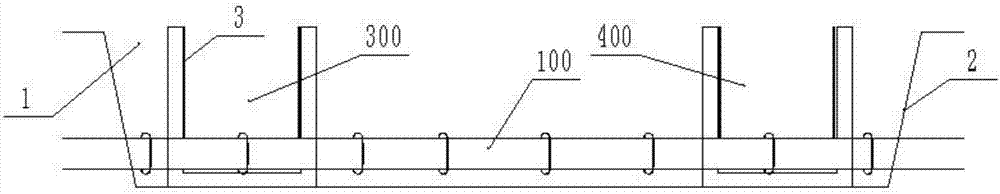

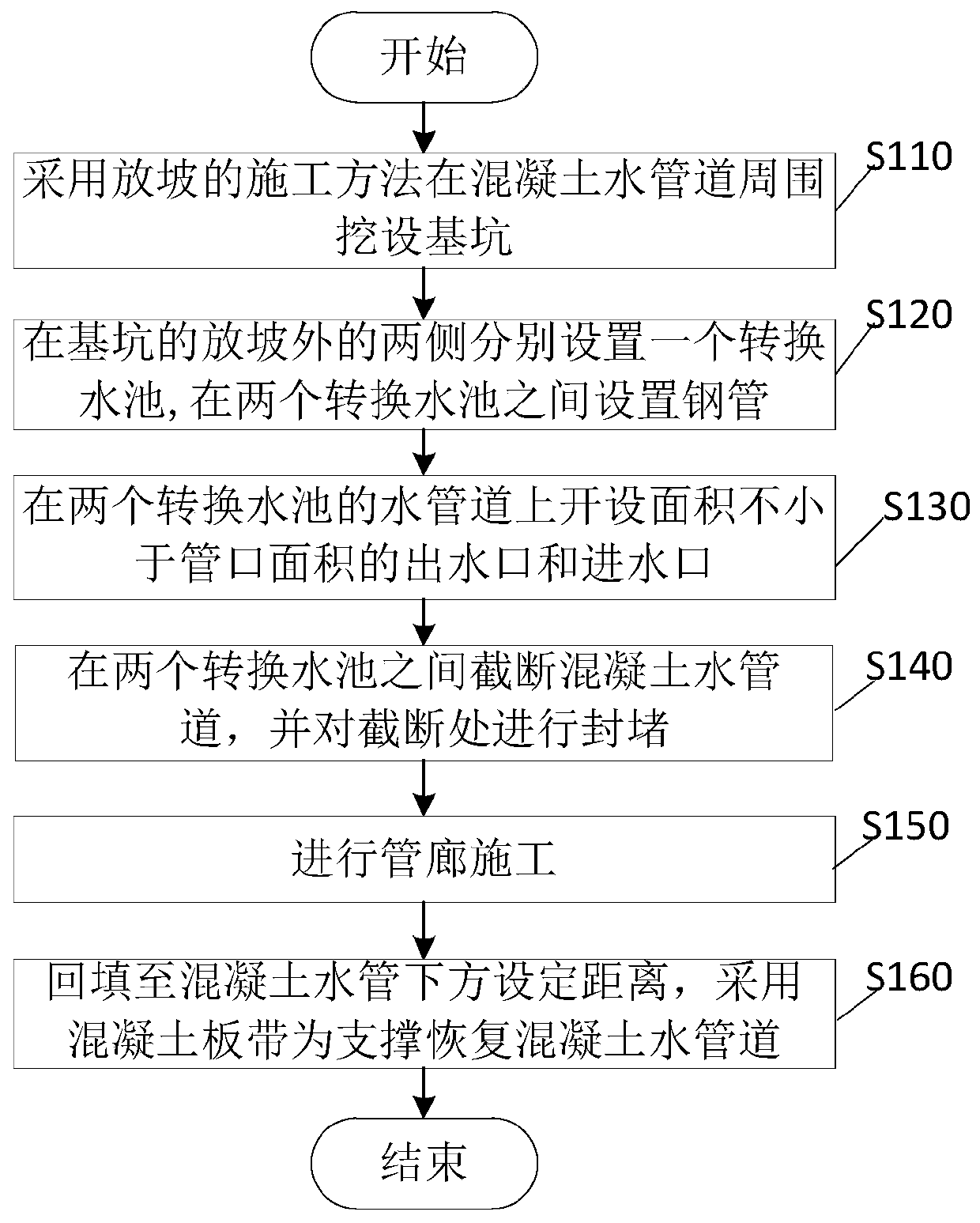

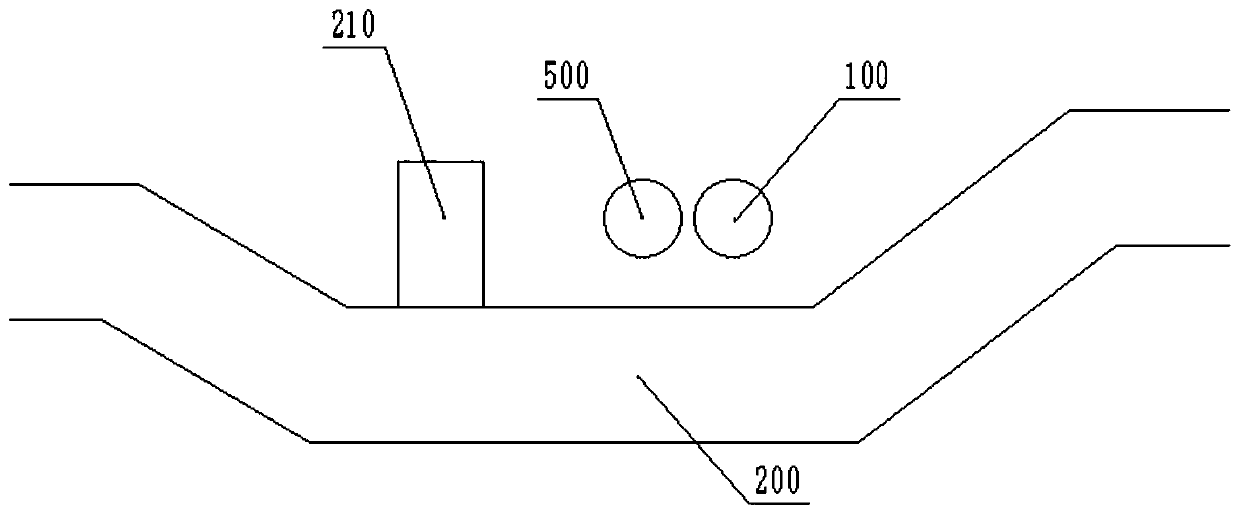

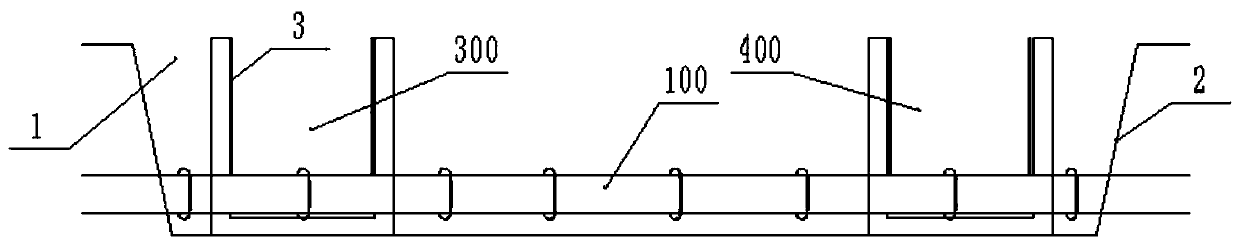

Construction method of underground pipe gallery passing through underground concrete water pipeline

ActiveCN107386320AReduce the amount of constructionLow costArtificial islandsUnderwater structuresSet distancePiping

Owner:CHINA HUAYE GROUP +1

Spliced-type integrated inspection well

InactiveCN101838999BEasy constructionFast on-site installationArtificial islandsUnderwater structuresUltimate tensile strengthToughness

Owner:金湖县九鼎塑胶制品有限公司

A method for treating voids in face of shield tunnel construction

ActiveCN104481548BThe method steps are simpleLow input costUnderground chambersTunnel liningCement slurryShield tunneling

The invention discloses a tunnel face cavity processing method for shield tunnel construction. The tunnel face cavity processing method for the shield tunnel construction includes steps that 1, primary grouting, to be specific, using a grouting system to fill first cement mortar to the lower part of the cavity from the top to bottom through a soil warehouse, wherein the first grouting size is composed of cement, bentonite, coal ash, sand and water according to the weight ratio of 45-55: 45-55: 180-220: 540-660: 360-440; 2, secondary grouting, to be specific, using the grouting system to fill second cement mortar to the middle of the cavity, wherein the second cement mortar is composed of cement, bentonite, coal ash, sand and water according to the weight ratio of 90-110: 68-82: 200-280: 540-660: 420-500; 3, tertiary grouting, to be specific, using the grouting system to fill cement slurry to the upper part of the cavity. The tunnel face cavity processing method for the shield tunnel construction is simple in steps, reasonable in design, easy and convenient to operate, low in invested cost, good in use effect and capable of solving the problems of a traditional grouting strengthening method.

Owner:URBAN RAIL TRANSIT ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

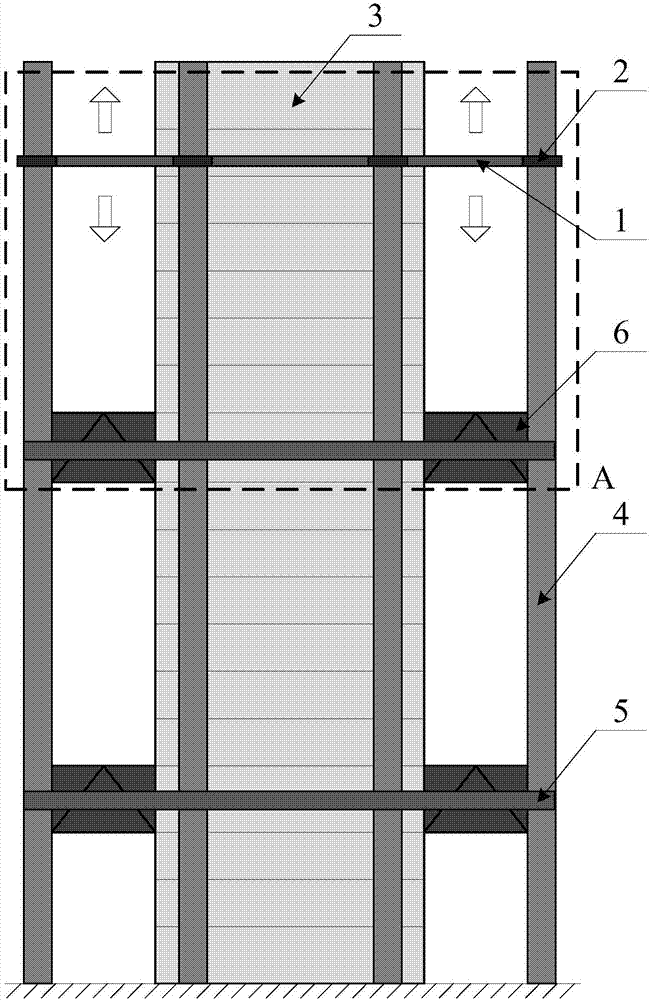

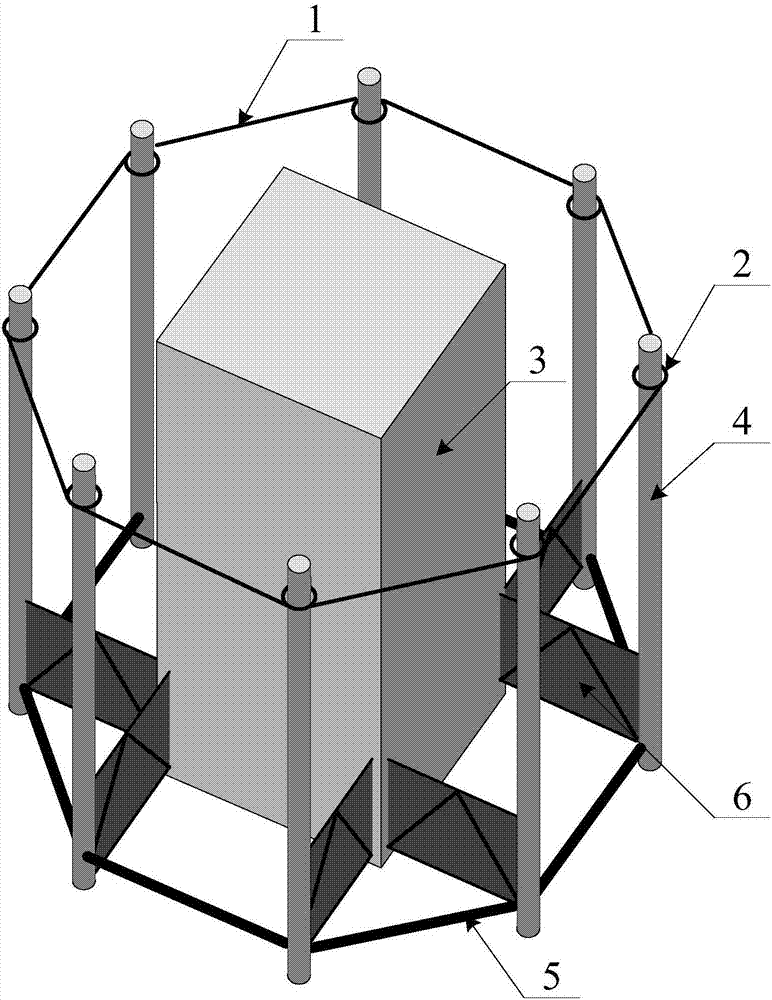

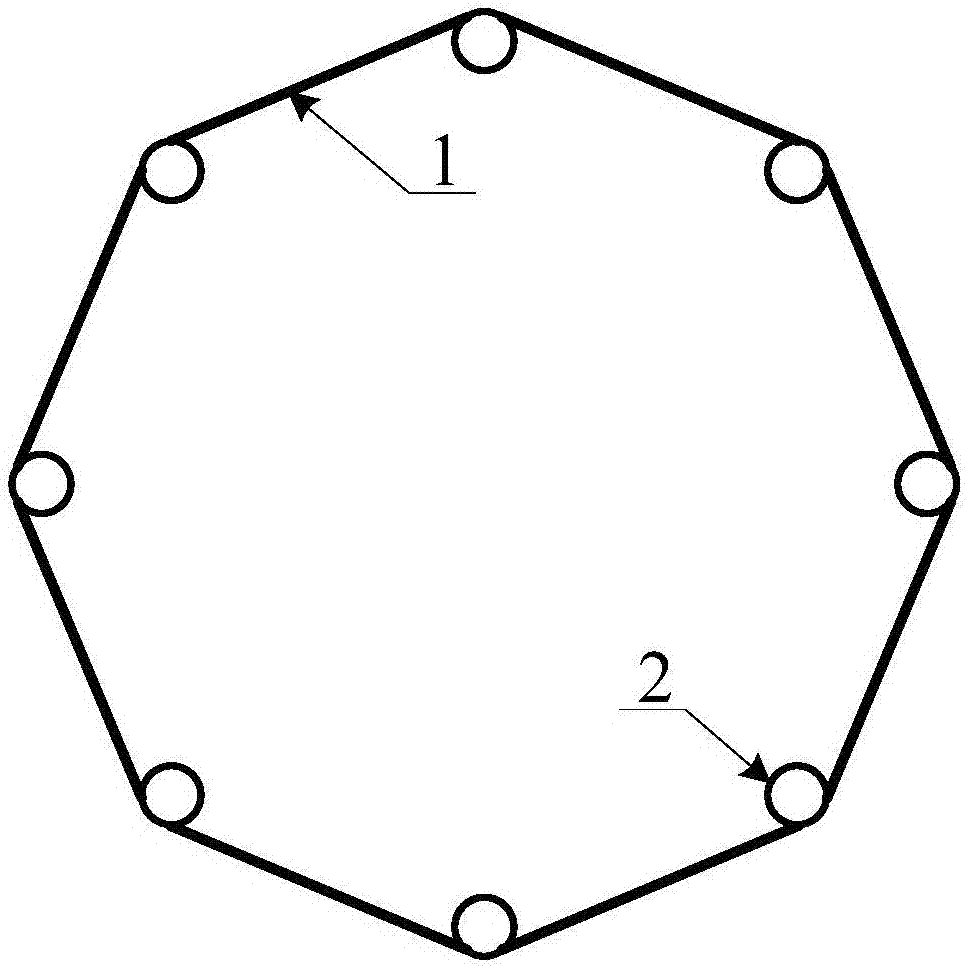

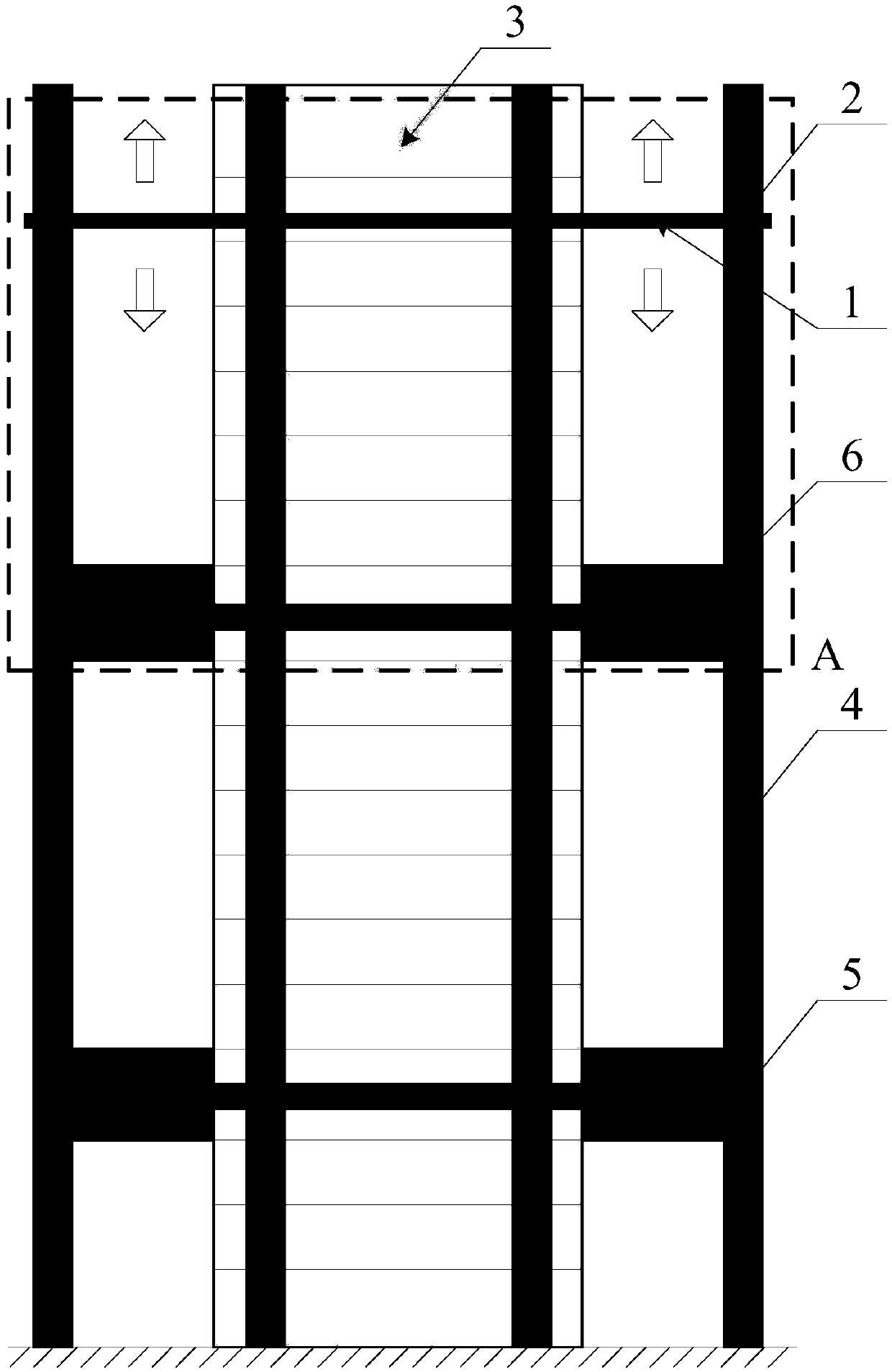

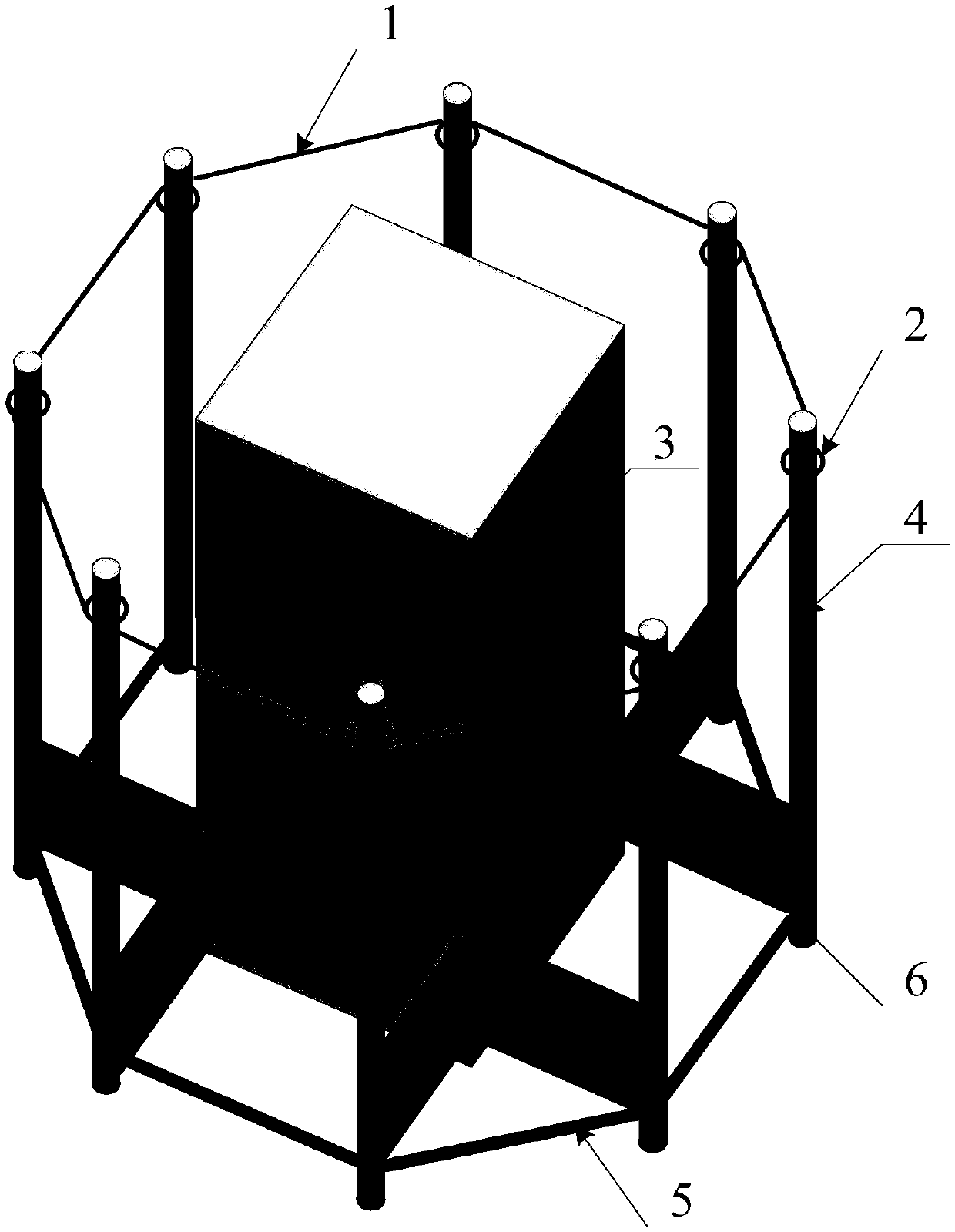

Slidable construction stable annular beam

The invention relates to a slidable construction stable annular beam applied in the process of high-rise and super high-rise framework core tube construction and belongs to the technical of structural projects. The slidable construction stable annular beam is composed of steel annular beams and fastening pieces. The steel annular beams are horizontally placed between adjacent framework columns, and the two ends of the steel annular beams are connected with the annular fastening pieces. The annular fastening pieces can be arranged on the peripheries of the framework columns in a sleeving mode and fixedly connected with the framework columns. The construction stable annular beam can slide in the height direction of a framework core tube structure system through the mode of locking and opening the fastening pieces. The slidable construction stable annular beam is constructed by full steel, the self weight is light, and site assembling and mounting are convenient and fast. The slidable construction stable annular beam only needs to be mounted at a time in the construction process of the same project. The stabilizing problem of the cantilever framework columns in the process of each construction step is solved through vertical sliding, and multiple times of disassembling and assembling are not needed. Disassembling, recycling and circular using are easy, therefore, the cost can be saved to the maximum extent, the construction period can be shortened to the maximum extent, and meanwhile the environment influence of the slidable construction stable annular beam is reduced to the maximum extent.

Owner:TSINGHUA UNIV +2

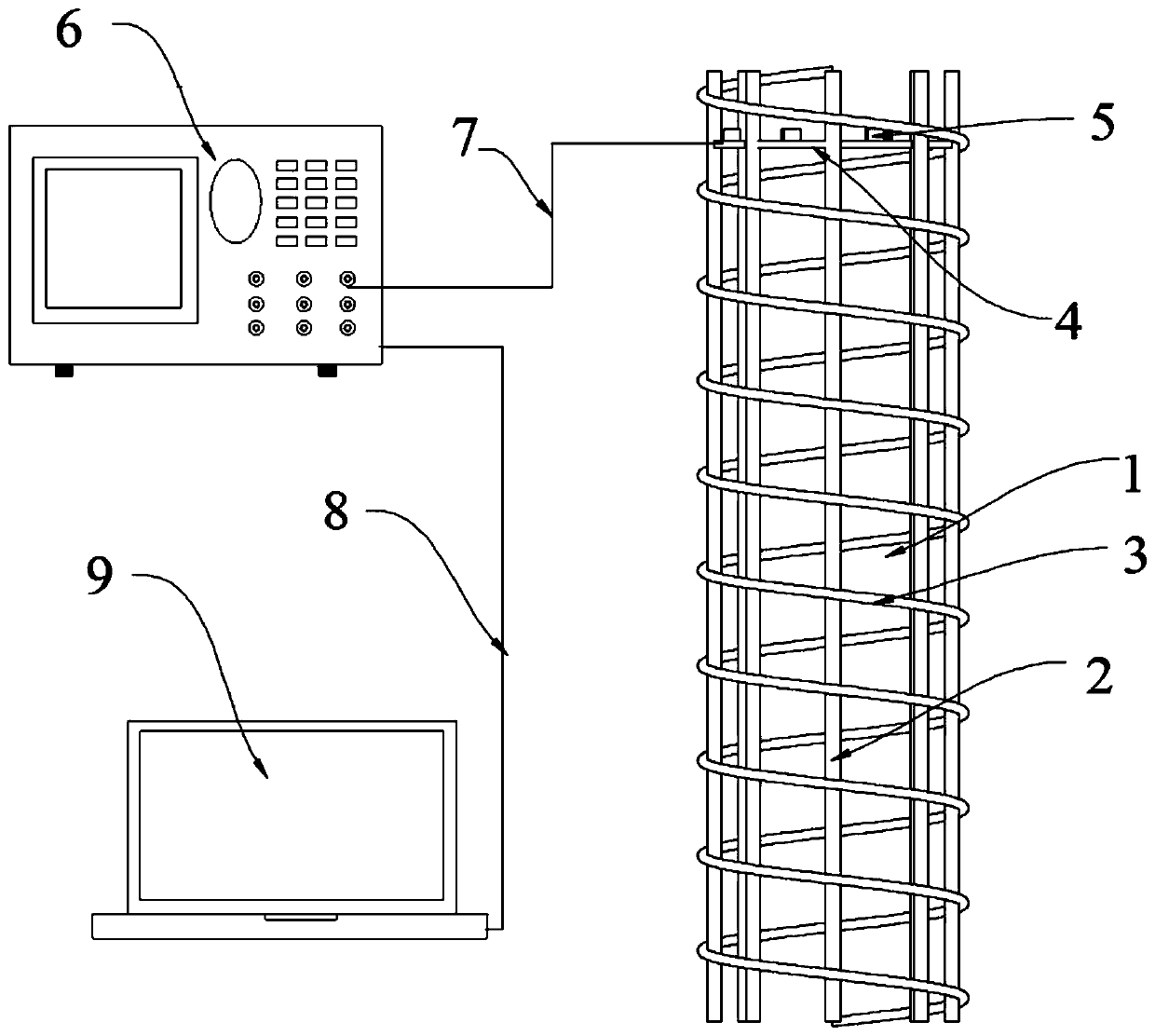

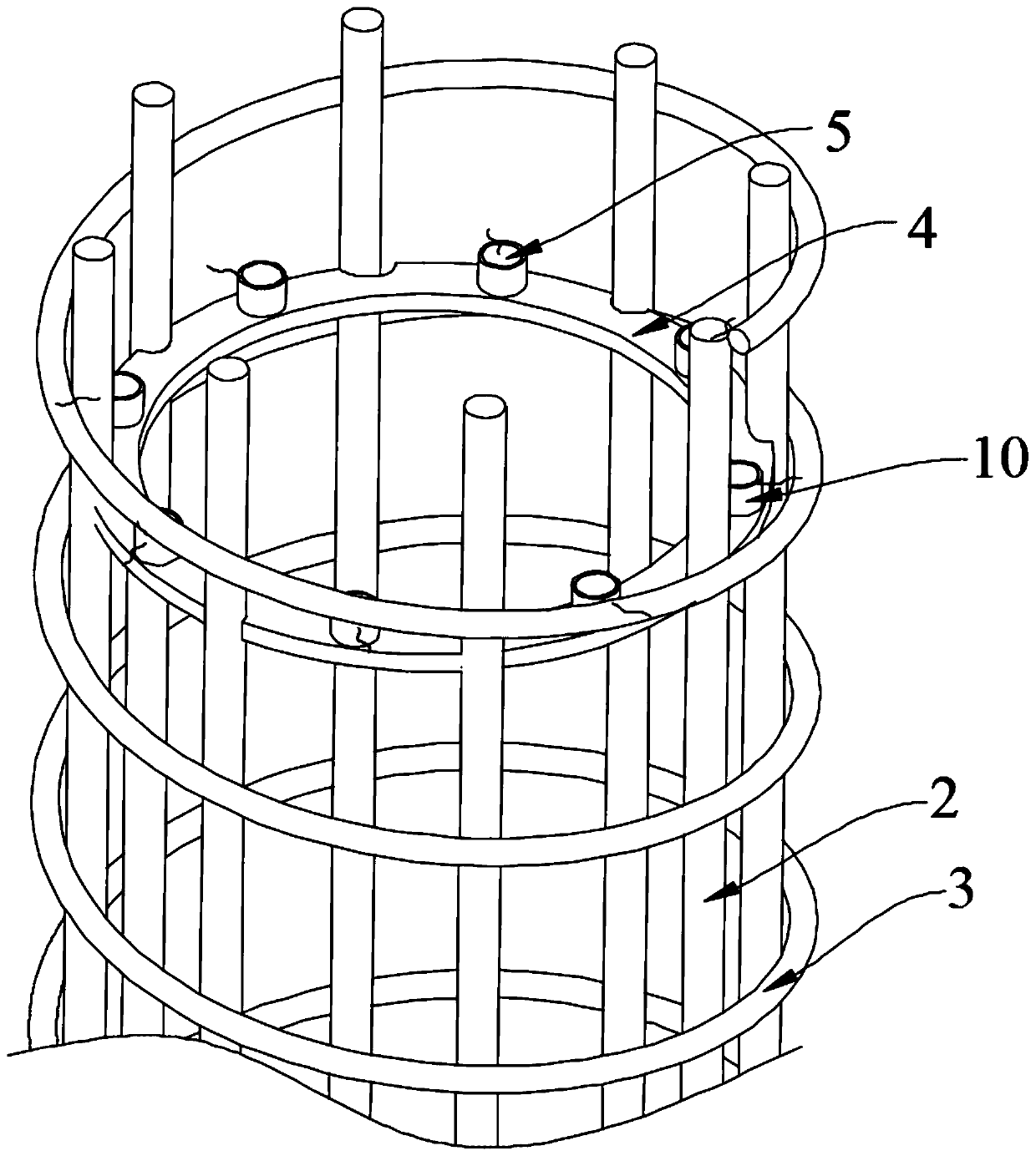

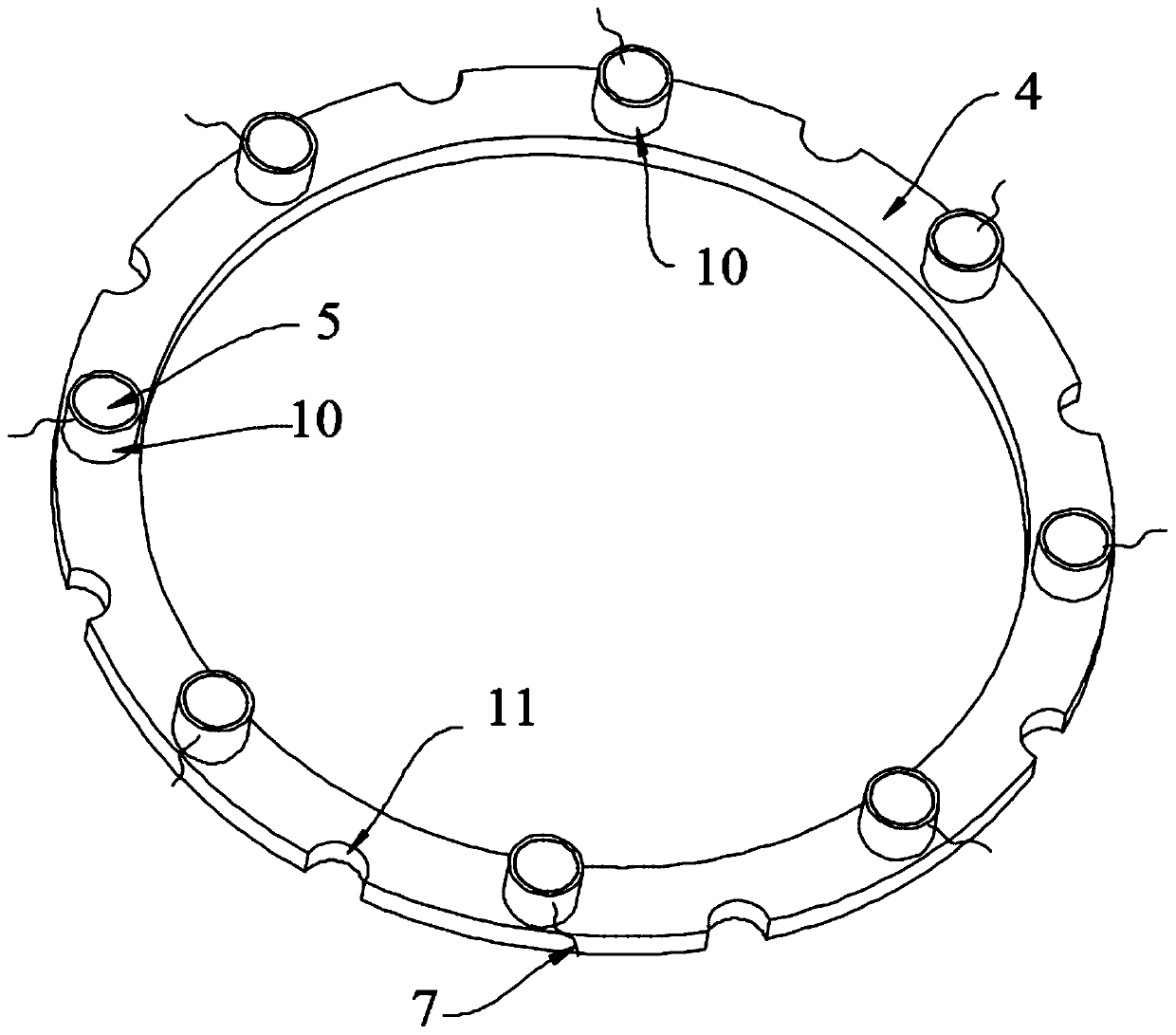

Cast-in-place concrete pile static load test unbalance loading monitoring method based on piezoelectric impedance frequency shift

ActiveCN111579355AEasy to installLow costMaterial strength using tensile/compressive forcesComputer terminalTest platform

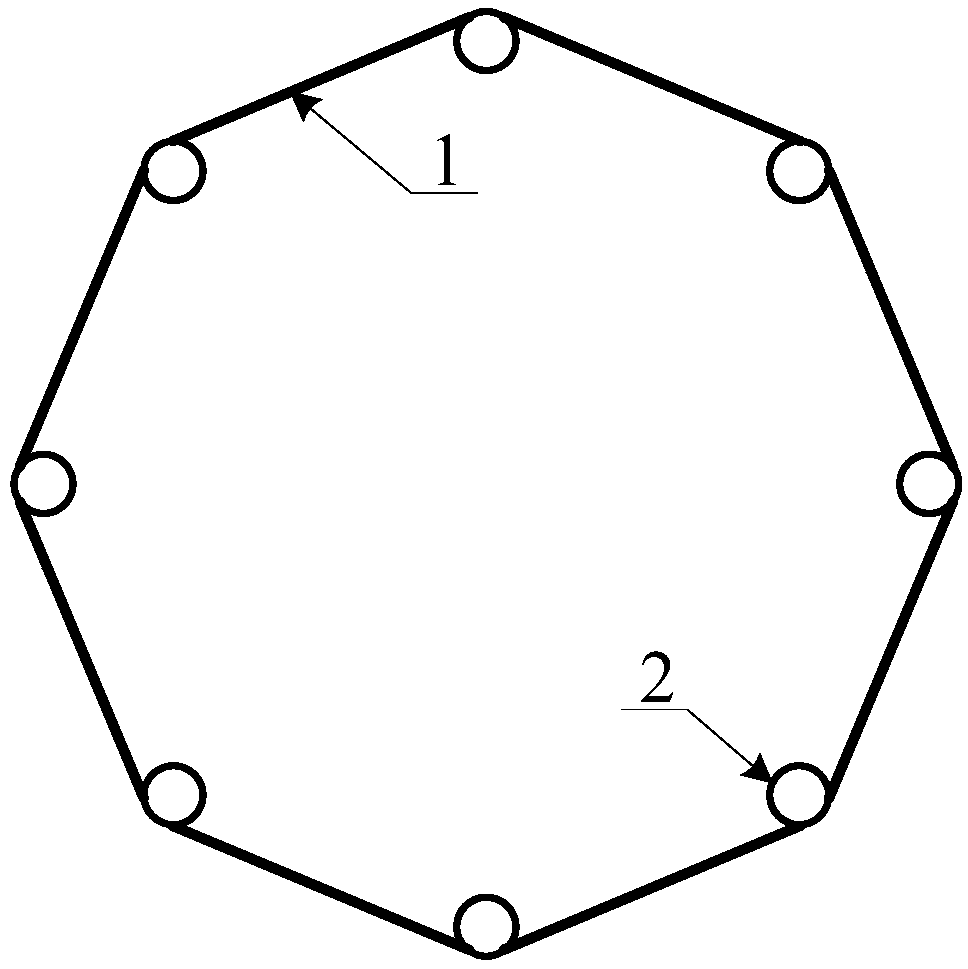

The invention discloses a cast-in-place concrete pile static load test unbalance loading monitoring method based on piezoelectric impedance frequency shift. In the pouring process of the cast-in-placeconcrete pile, a plurality of piezoelectric ceramic part sensors distributed in the circumferential direction are pre-buried in the top of the pile, the piezoelectric ceramic part sensors are led outof a pile body through cables to be connected with an impedance analyzer, the impedance analyzer is connected with a computer terminal, and the cast-in-place concrete pile is poured and maintained. Post-maintenance, static load test platform, a signal generator generates an excitation signal through a piezoelectric ceramic part sensor when not loaded, an electrical impedance signal received by the piezoelectric ceramic part sensor serves as a reference signal, load loading is conducted, electrical impedance signals of sensors at different loading stages are monitored and compared with the reference signal, and pile top section unbalance loading is judged according to the change of the electrical impedance signals. The cost is low, the monitoring and testing processes are synchronous, andthe monitoring accuracy can be ensured to the maximum extent.

Owner:湖北震泰建设工程质量检测有限责任公司

Method for exchanging tool of shield machine for tunnel construction

The invention discloses a method for exchanging a tool of a shield machine for tunnel construction, which comprises the steps of: (1) soil cabin replacement filling: performing the process of soil cabin replacement filling by using a spiral excavating machine and a slip casting system synchronously working with the spiral excavating machine; (2) advanced slip casting inside the machine: beating a plurality of slip casting pipes into the soil on the upper part of the shield machine from inner to outer inside the shield machine by respectively passing through a plurality of advanced geologic holes and then synchronously injecting cement paste into the soil on the upper part of the shield machine through the slip casting pipes by using a slip casting device till the cement paste cannot be injected any more; (3) cleaning cabin and exchanging tool synchronously: manually cleaning the cement plaster solidified inside the soil cabin and synchronously exchanging the tool mounted on the shield machine; and (4) getting rid of the difficult position of the shield machine and recovering the process. The method provided by the invention has the advantages of reasonable design, convenience for operation, low cost, high safety factor, good use effect and capable of solving the problem that the tool cannot be exchanged in the traditional tool exchanging mode under severe tool exchanging conditions.

Owner:URBAN RAIL TRANSIT ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

A Slidable Construction Stabilized Ring Beam

The invention relates to a slidable construction stable annular beam applied in the process of high-rise and super high-rise framework core tube construction and belongs to the technical of structural projects. The slidable construction stable annular beam is composed of steel annular beams and fastening pieces. The steel annular beams are horizontally placed between adjacent framework columns, and the two ends of the steel annular beams are connected with the annular fastening pieces. The annular fastening pieces can be arranged on the peripheries of the framework columns in a sleeving mode and fixedly connected with the framework columns. The construction stable annular beam can slide in the height direction of a framework core tube structure system through the mode of locking and opening the fastening pieces. The slidable construction stable annular beam is constructed by full steel, the self weight is light, and site assembling and mounting are convenient and fast. The slidable construction stable annular beam only needs to be mounted at a time in the construction process of the same project. The stabilizing problem of the cantilever framework columns in the process of each construction step is solved through vertical sliding, and multiple times of disassembling and assembling are not needed. Disassembling, recycling and circular using are easy, therefore, the cost can be saved to the maximum extent, the construction period can be shortened to the maximum extent, and meanwhile the environment influence of the slidable construction stable annular beam is reduced to the maximum extent.

Owner:TSINGHUA UNIV +2

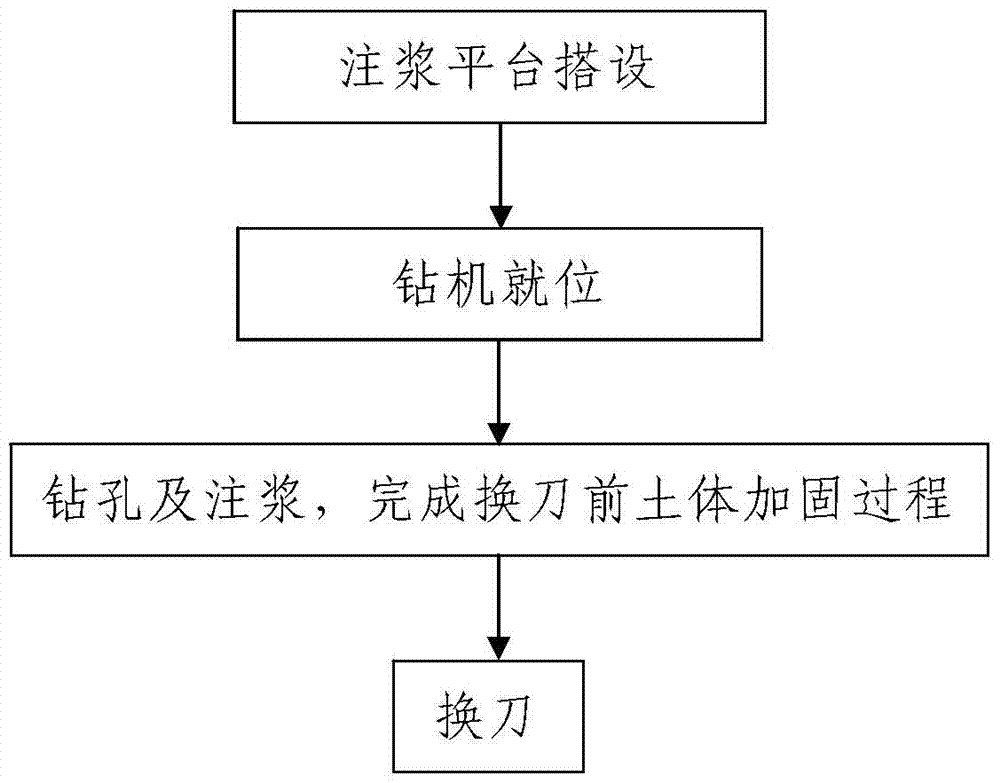

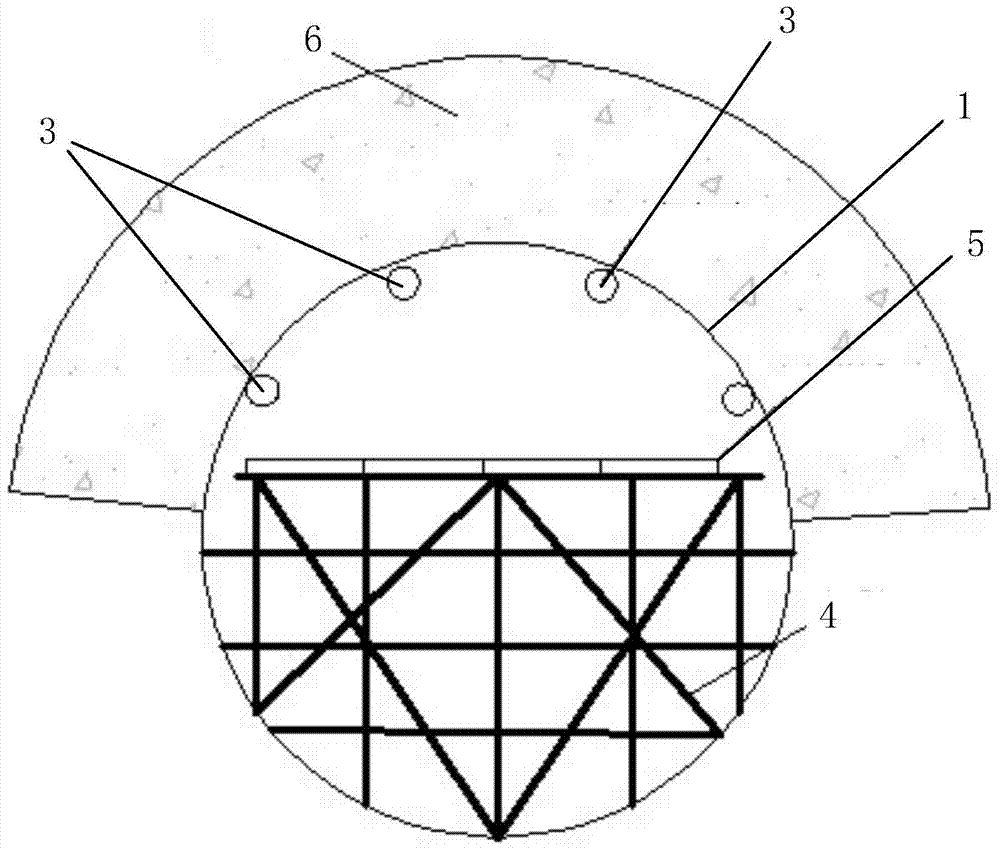

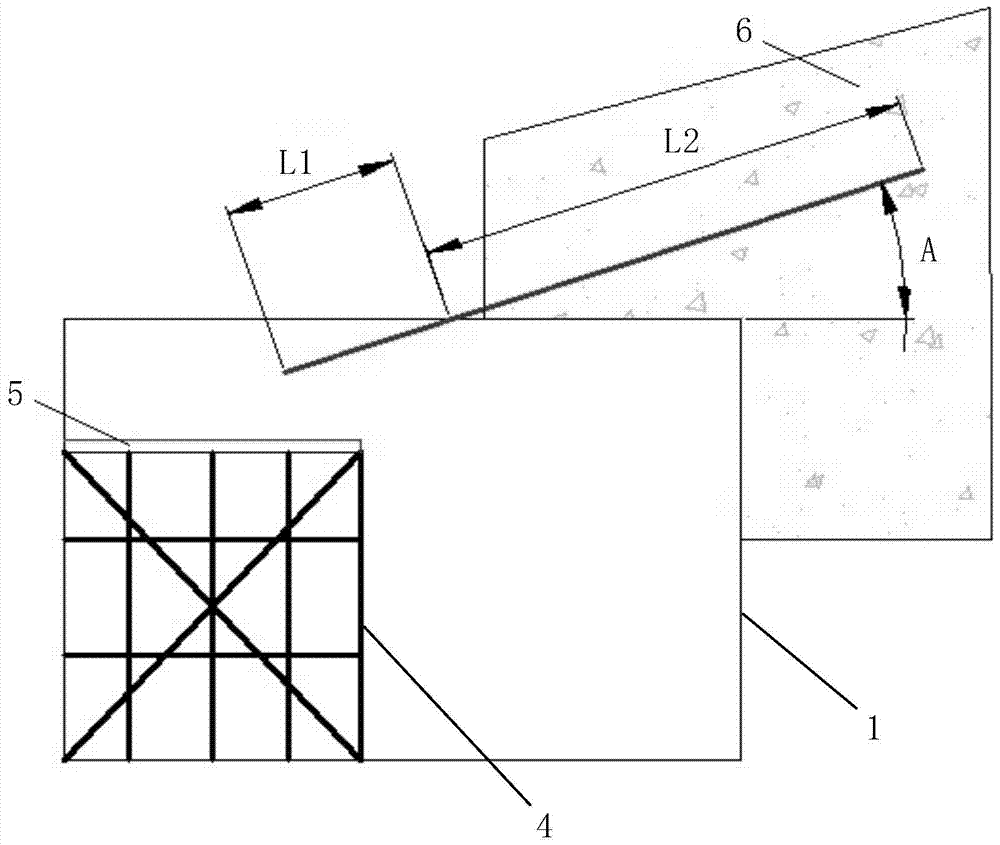

WSS Grouting Reinforcement Assisted Pneumatic Tool Change Method in Shield Tunnel

Owner:CHINA RAILWAY FIRST GRP CO LTD

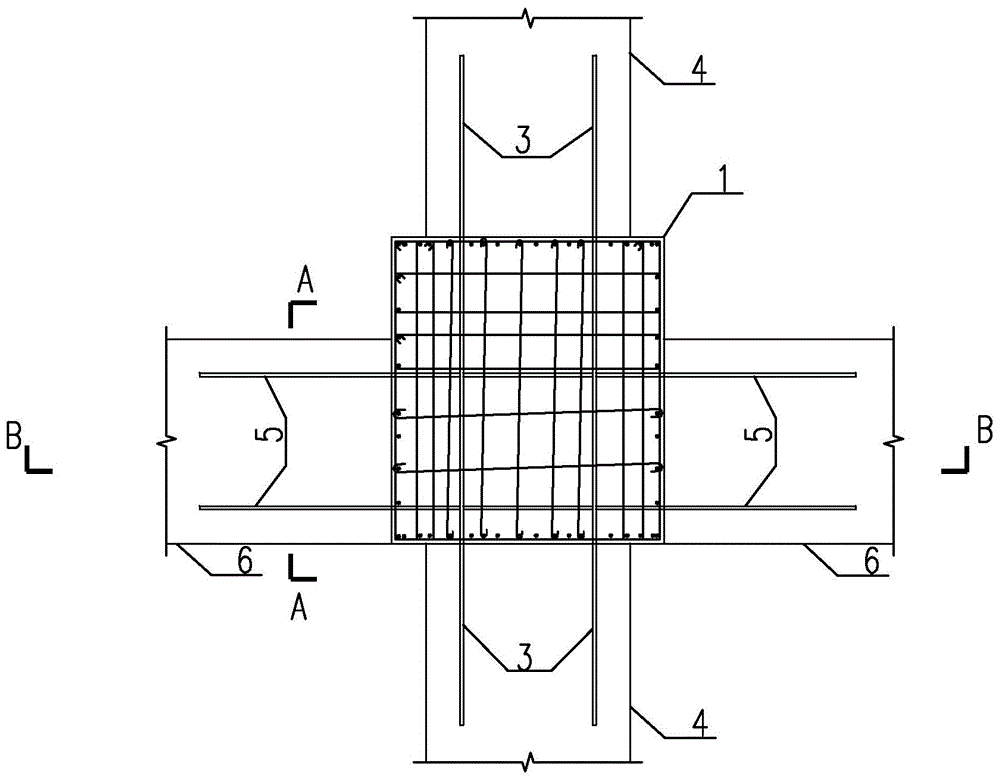

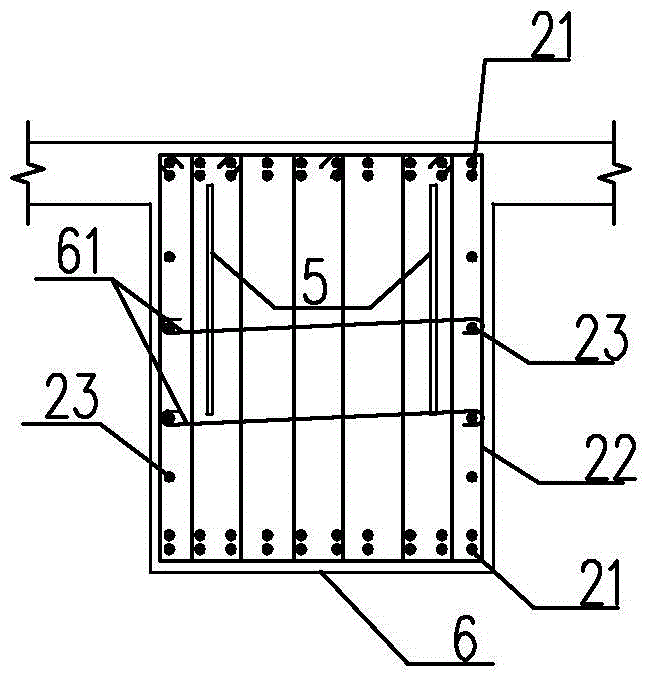

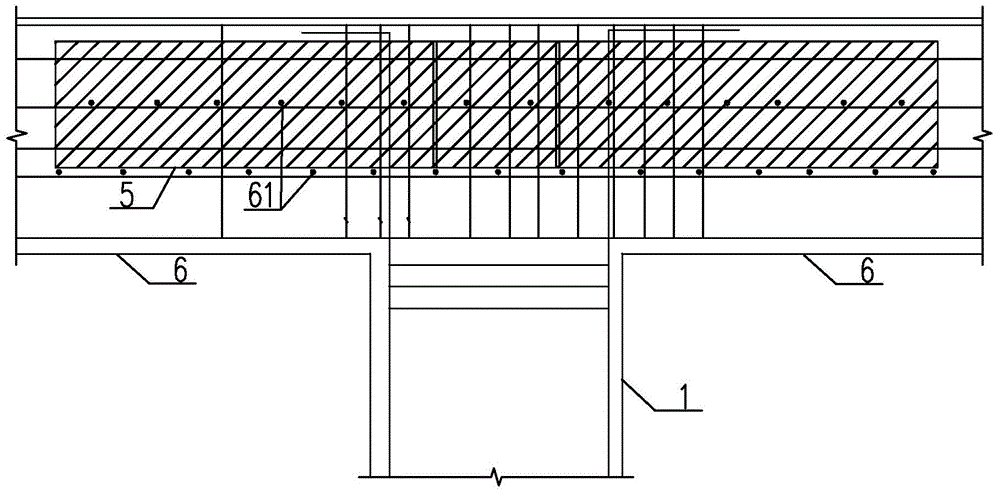

A Double Shear Plate Transfer Beam-Column Joint

ActiveCN103741816BIncreased shear capacityIncrease profitBuilding constructionsUltimate tensile strengthBeam column

The invention discloses a double shearing resistant plate transformation beam-column joint which comprises transformation column and concrete transformation beams. A pair of parallel shearing resistant steel plates are vertically arranged at the beam end of each concrete transformation beam along the length direction of the concrete transformation beam and mutually connected at the beam-column joint of the concrete transformation beam and the corresponding transformation column in a penetrating manner. The shearing resistant steel plates are additionally arranged at the ends of the concrete transformation beams, the shearing capacity of the sections of the transformation beams is improved, and requirements of the shear-compression ratio stipulated by specifications are met. Compared with conventional methods such as enlarging beam sections and concrete strength or using profile steel concrete sections, the use ratio of building space can be increased, structural weight is reduced, earthquake effect is decreased, construction cost is reduced, construction is simple, construction quality is ensured, and construction period cannot be affected.

Owner:广东省建科建筑设计院有限公司

A construction method for rapid silo-type roller compacted concrete dam with overflow gap concrete

ActiveCN111980028BEasy constructionFast constructionBarrages/weirsFoundation engineeringRoller-compacted concreteArchitectural engineering

The invention discloses a construction method of a roller-compacted concrete dam with overflowing notch concrete quickly put into storage, comprising the steps of: 1. constructing a foundation dam section; 2. constructing a transitional dam section; and 3. constructing a capping dam section. In the present invention, the conventional dam section and the transitional dam section RCC self-adaptive dam section are layered on the foundation dam section, and the transitional dam section RCC self-adaptive dam section is reconstructed to construct the transitional dam section RCC For the stepped dam section, the multi-layered RCC stepped dam section of the transitional dam section is connected successively to form a continuous construction channel for concrete transport vehicles. The gap is filled with roller compacted concrete into the warehouse, the construction period is short, the dam construction is convenient and fast, the construction efficiency is high, the construction quality is guaranteed, and the construction cost is saved.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

Construction Technology of Mud Membrane for Face of Shield Compression Operation

Owner:URBAN RAIL TRANSIT ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

Construction method of underground pipe gallery passing through underground concrete water pipe

ActiveCN107386320BGuaranteed anti-corrosion desiltingDoes not affect the construction periodArtificial islandsUnderwater structuresSludgeRoad surface

The invention provides a construction method of an underground pipe gallery through an underground concrete water pipeline. The construction method comprises the following steps that a foundation pit is excavated around the concrete water pipeline by adopting a sloping construction method; the external two sides of a slope are each provided with a conversion pool, a steel pipe is arranged between the two conversion pools, and the two ends of the steel pipe extend into the two conversion pools correspondingly; the portions, in the two conversion pools, of the concrete water pipeline are provided with a water inlet and a water outlet correspondingly; the concrete water pipeline is cut off between the two conversion pools, and cut-off openings are blocked; pipe gallery construction is conducted; and after pipe gallery construction, backfilling is conducted to the position below the concrete water pipeline by a set distance, a concrete plate belt with the thickness being the preset distance is arranged between the two conversion pools, the concrete water pipeline is recovered, the first conversion pool and the second conversion pool are dismounted, backfilling is conducted to a roadbed, and the road surface is constructed. According to the construction method, the steel pipe is adopted, after excavation of the pipe gallery is completed, the concrete water pipeline is recovered, and it is ensured that corrosion prevention and sludge removing of the concrete water pipeline after construction do not need to make a detour.

Owner:CHINA HUAYE GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com