Construction method of support-free prefabricated assembly type shield tunnel air shaft structure

A technology of shield tunneling and construction method, which is applied in mine/tunnel ventilation, tunnel, tunnel lining and other directions, and can solve the problems of non-protrusion, limited mileage, long construction period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

[0029] In a preferred embodiment of the present invention, a construction method for the air shaft structure of an unsupported prefabricated and assembled shield tunnel is provided, the purpose of which is to avoid pouring concrete at the construction site and instead adopt the form of prefabricated and assembled shield tunneling Construction of the air shaft structure of the tunnel.

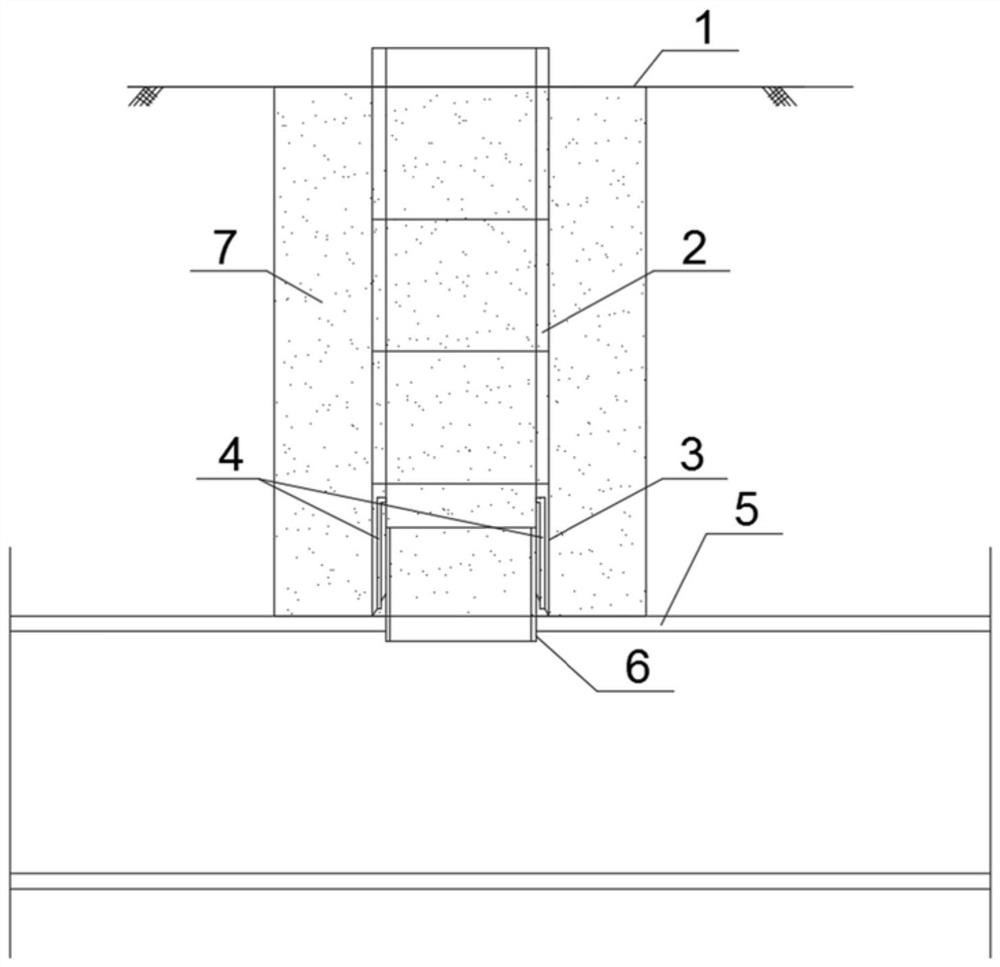

[0030] Such as figure 1 As shown, the air shaft structure is assembled by multiple sections of prefabricated pipe joints. The prefabricated pipe joints can be designed and determined according to the cross-sectional size of the air shaft and the depth of the air shaft. It is process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com