A construction method of underground diaphragm wall combined with prefabrication and cast-in-place

A technology of underground diaphragm wall and construction method, which is applied in infrastructure engineering, artificial island, sheet pile wall, etc. The risk of digging, improving the bearing capacity, and ensuring the effect of verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further described below, but protection scope of the present invention is not limited thereto:

[0036] First, the structure of the prefabricated materials and auxiliary devices used in the construction of the prefabricated cast-in-place underground diaphragm wall involved in the embodiment of the present invention will be described. Sectional prefabricated walls; auxiliary devices include jacking positioning frame and wall brushing device, specifically:

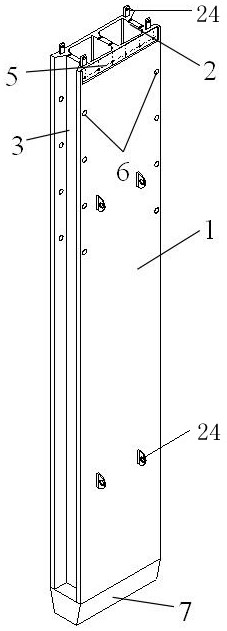

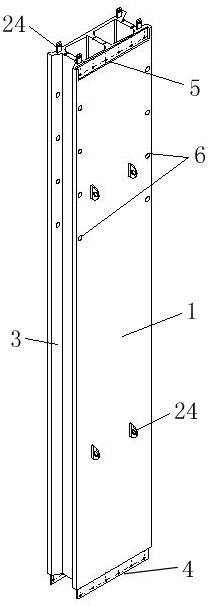

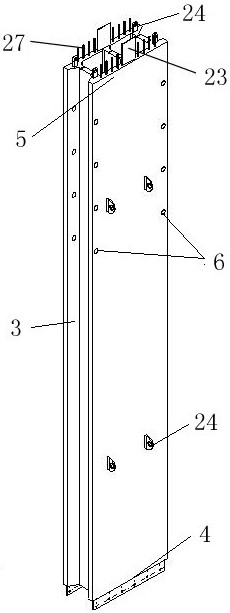

[0037] Such as Figure 1-3 As shown, the prefabricated walls of the present invention are all pre-tensioned prestressed walls, the length of the prefabricated walls is 10-16m, preferably 12-15m, the width is 2m, and the width is 2-4cm smaller than the design width. The prefabricated wall includes a hollow square main body 1, the inner axial direction of the square main body 1 is provided with 1-2 square through long holes 2, the side of the square main body 1 is provided with trapezoidal groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com