Patents

Literature

48results about How to "Decentralization smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

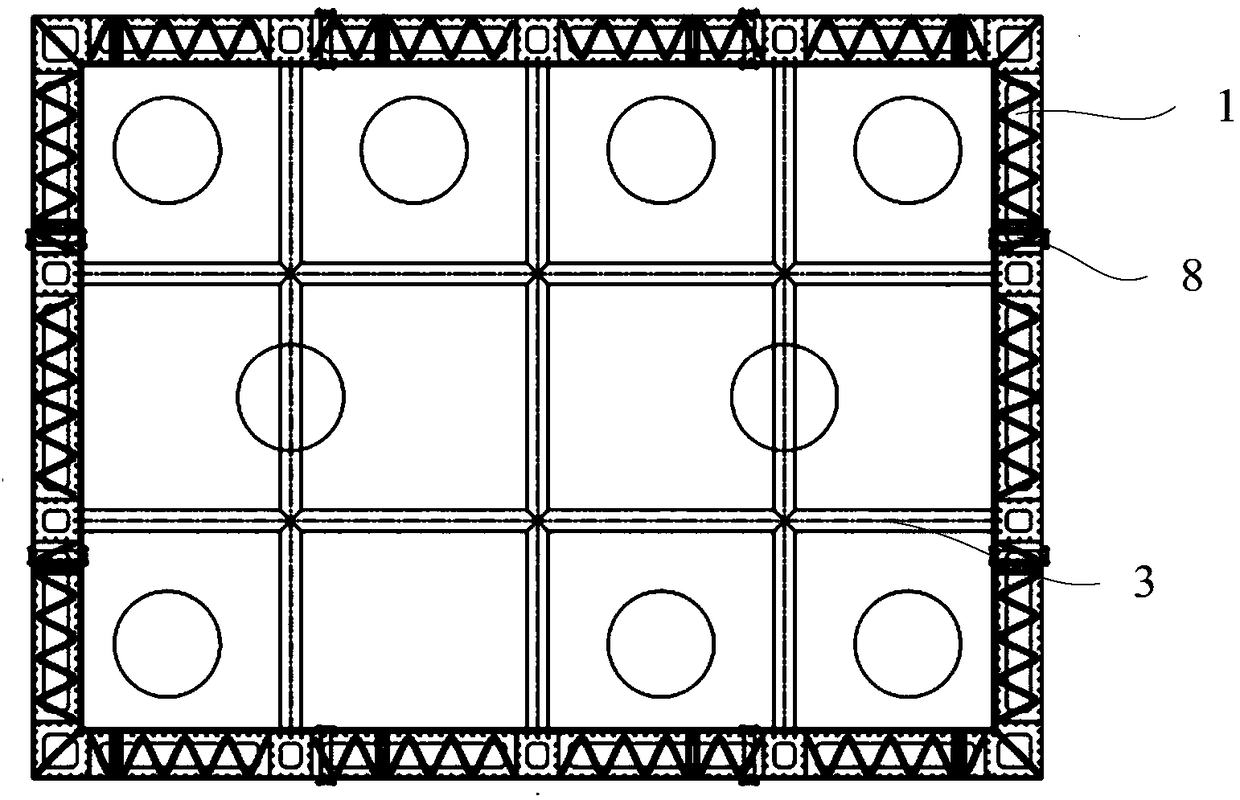

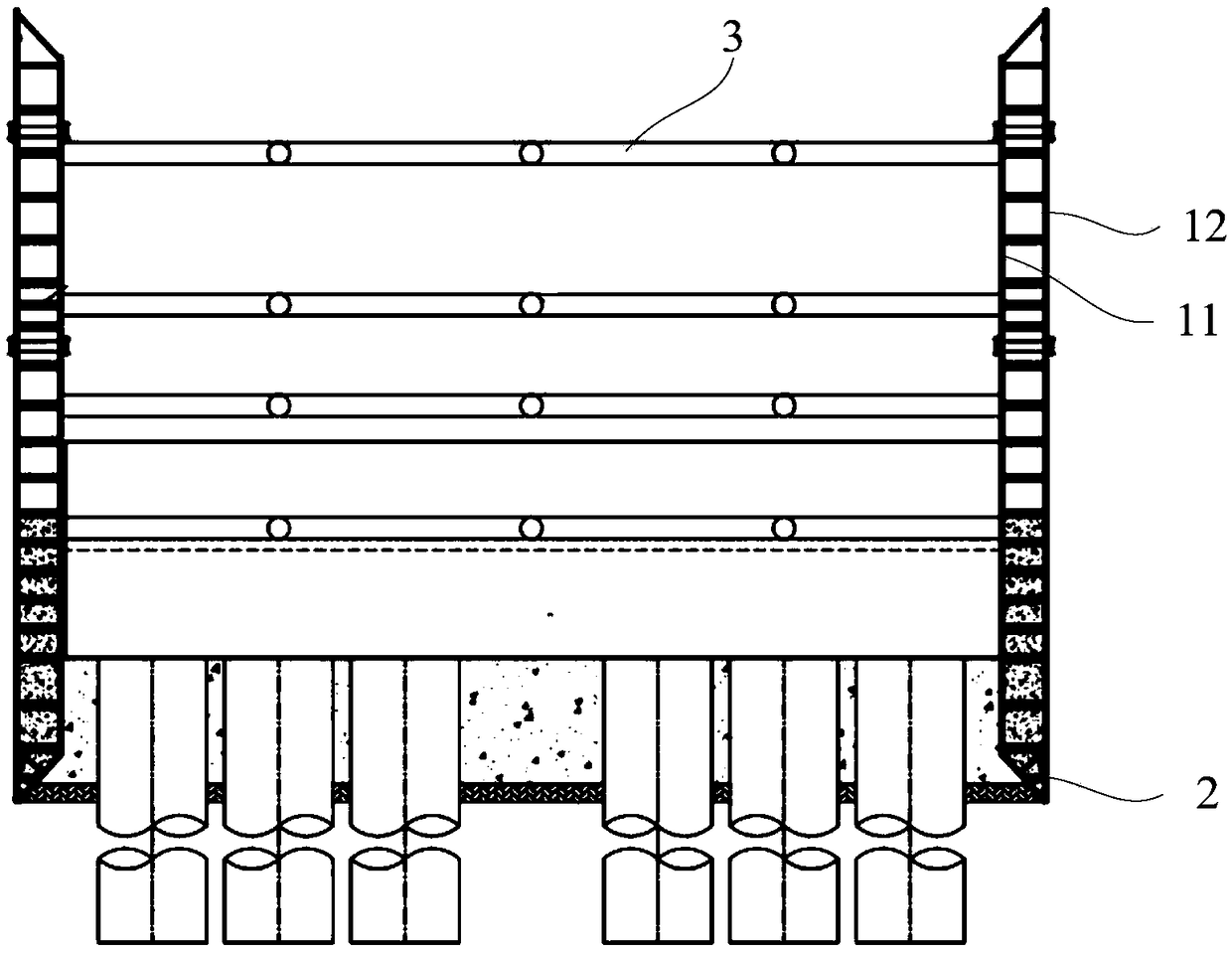

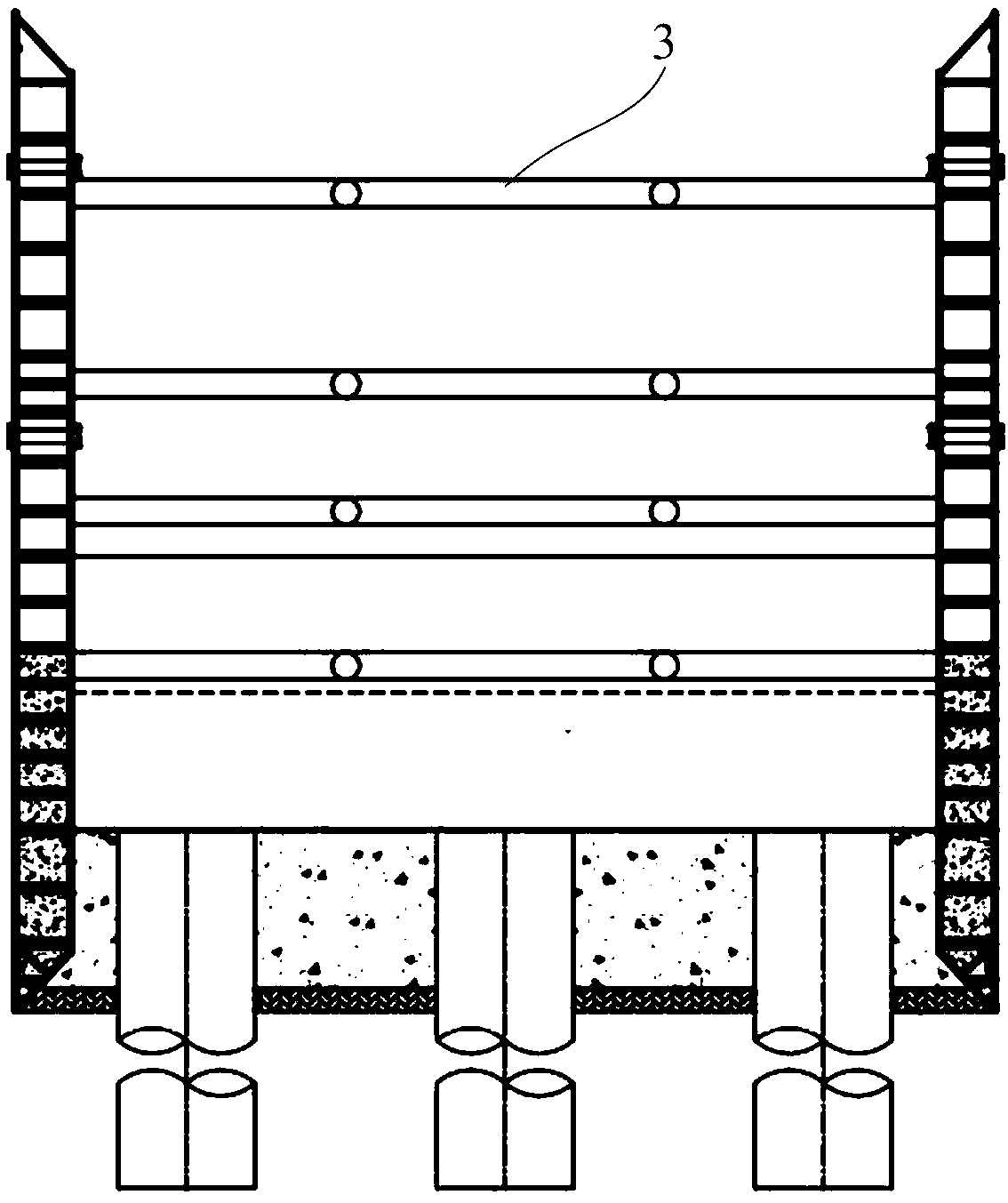

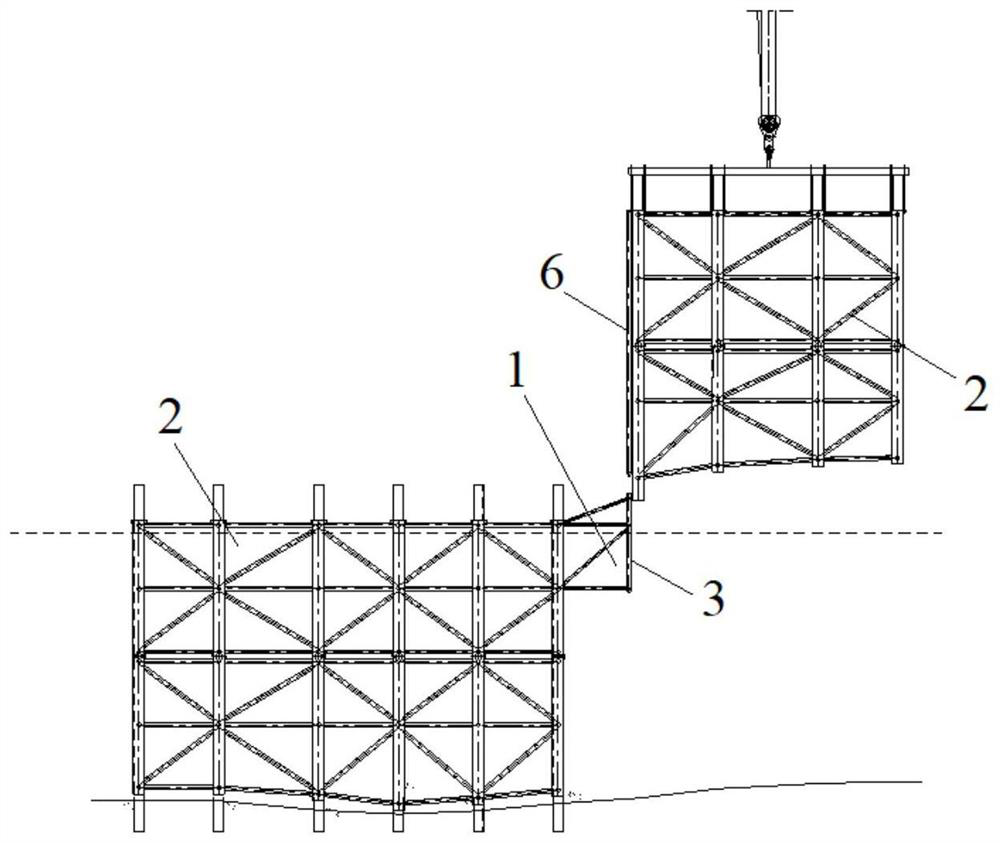

Prefabricated bearing platform mounting method

ActiveCN103362068ASmall construction impactImprove construction stabilityFoundation engineeringBridge erection/assemblyCofferdamWater flow

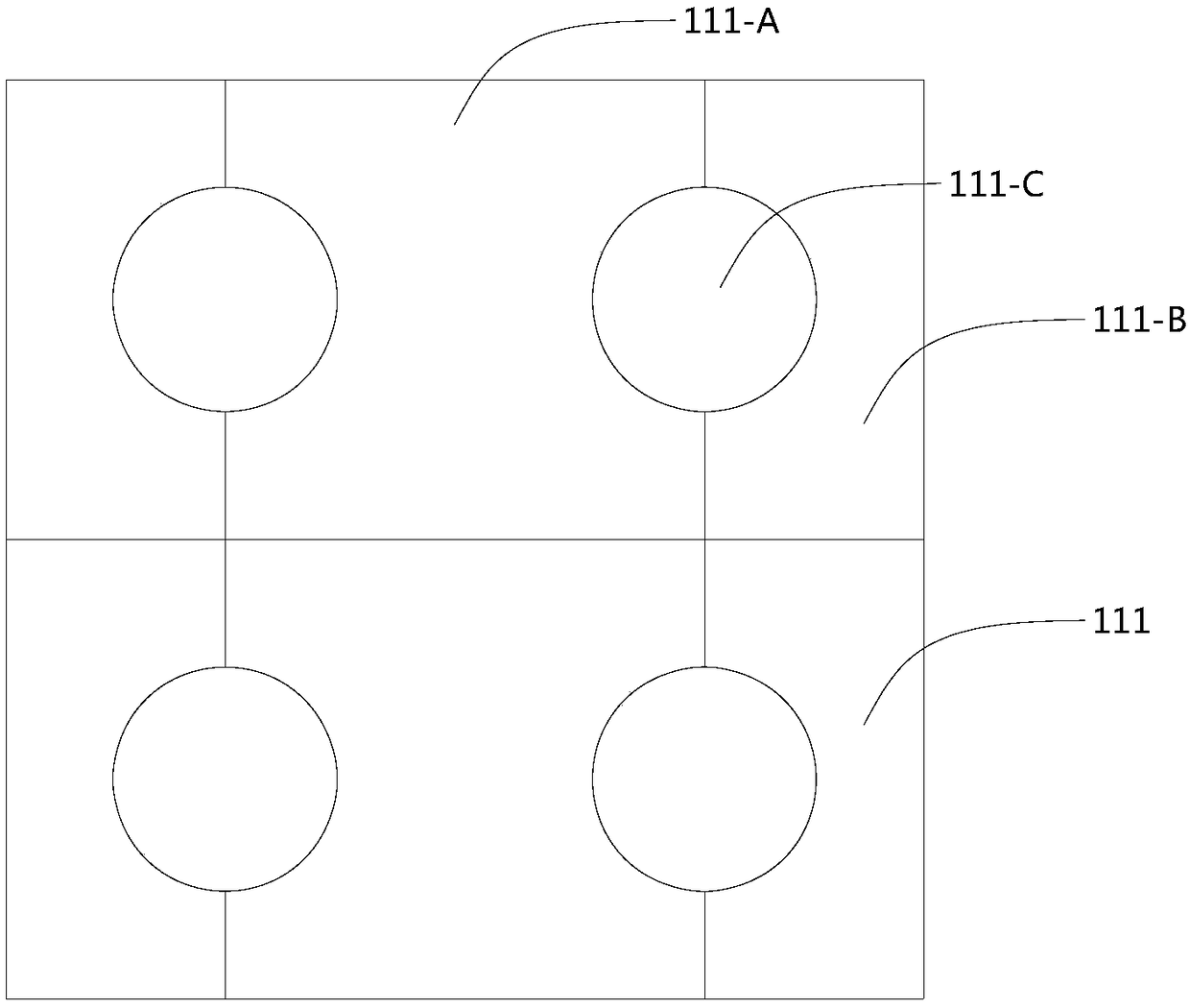

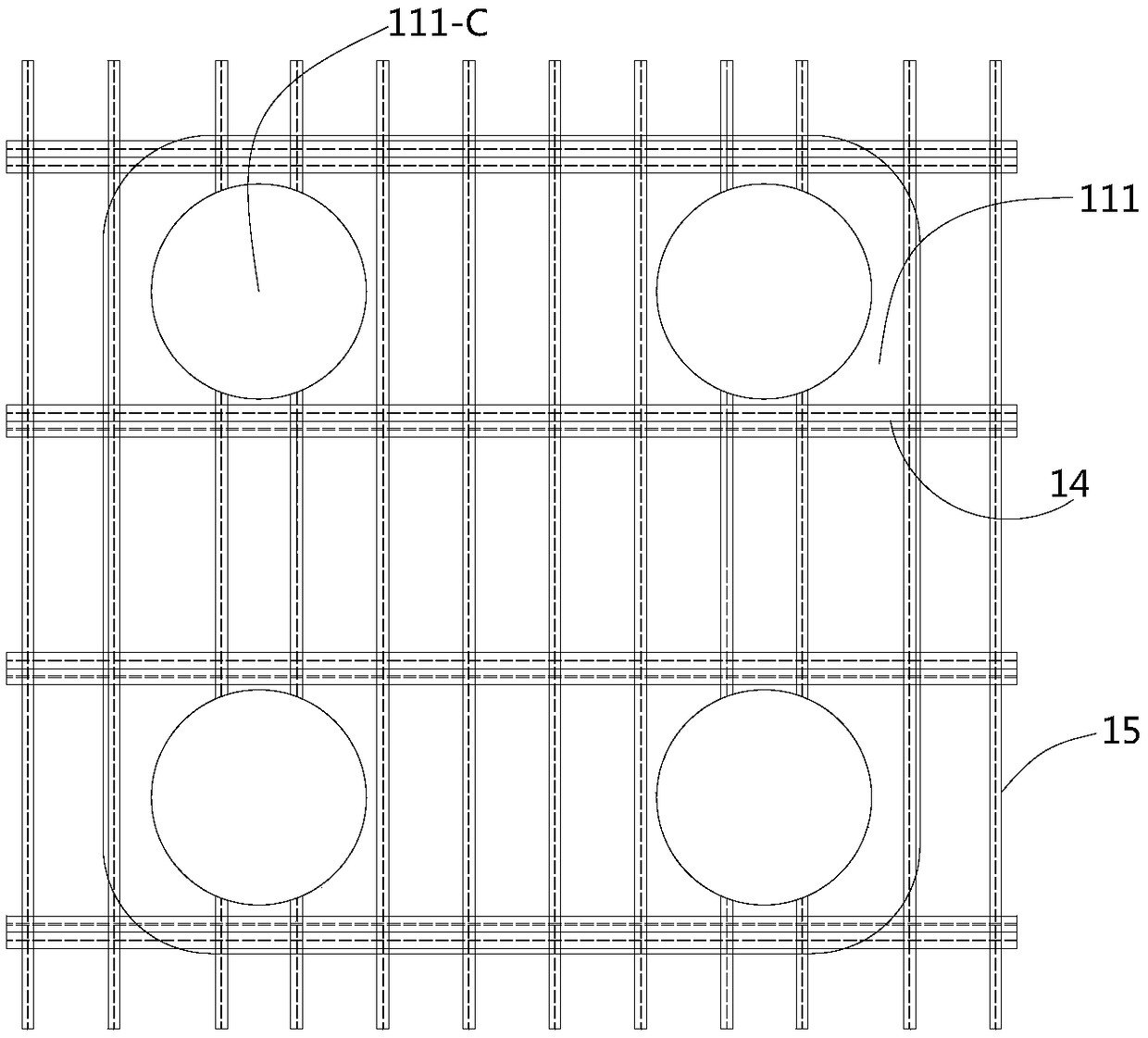

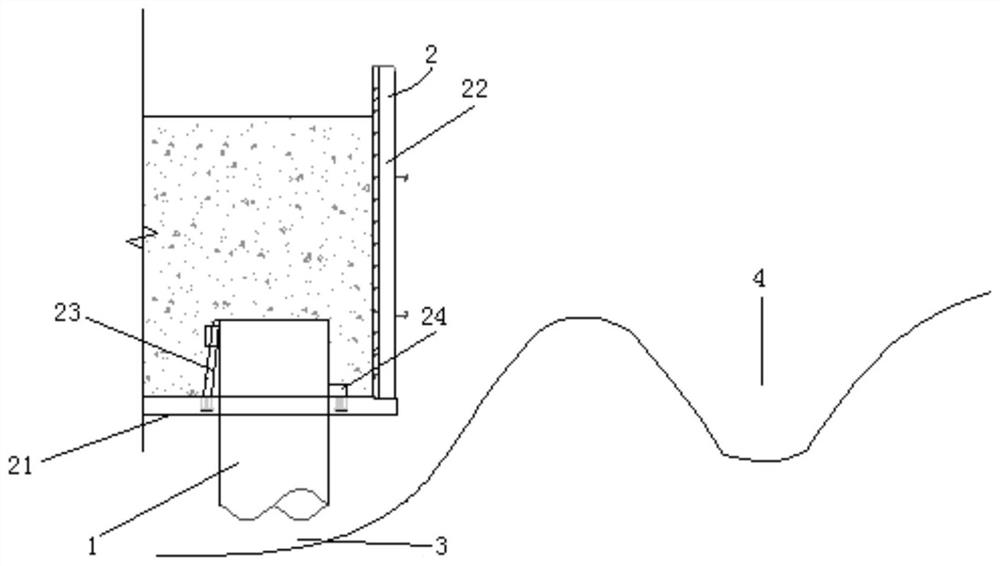

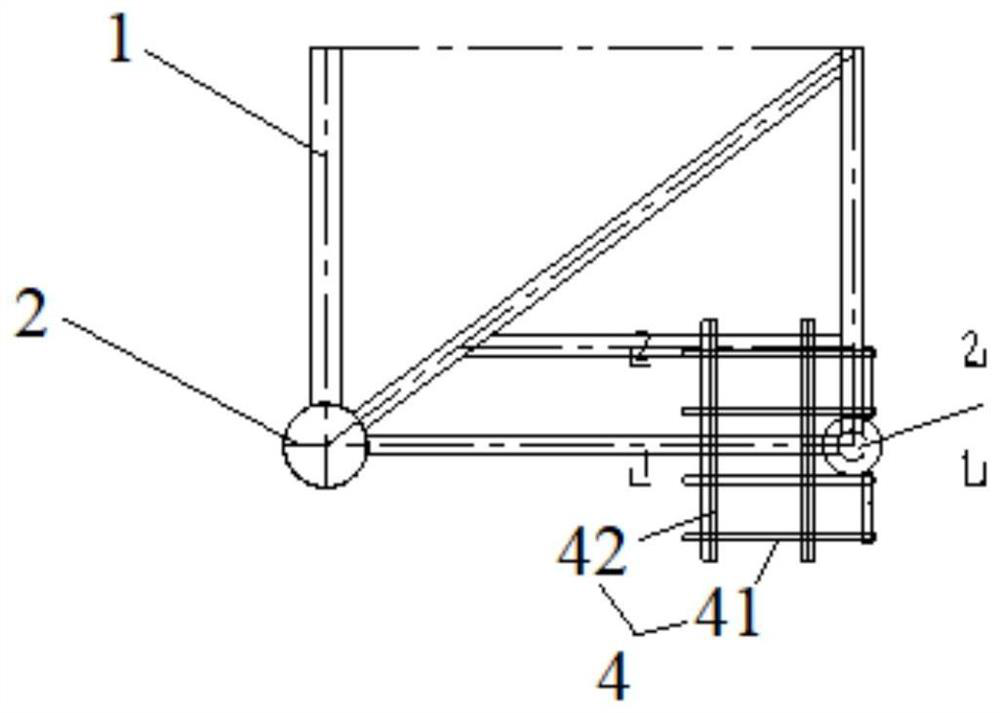

The invention discloses a prefabricated bearing platform mounting method and relates to the field of bridge construction. The prefabricated bearing platform mounting method comprises the following steps that a bearing platform and bottom pier bodies are prefabricated in a prefabrication field, and steel pile hole positions are reserved in the bearing platform; the bearing platform is lifted to a pile site by a large floating crane; a pile top guiding device is pre-mounted on steel piles in the pile site before the bearing platform is lifted; after the bearing platform is lifted down and is in place, a carrying pole is arranged on a pile top longitudinal direction adjusting position in a hanging manner, and the horizontal plane of the bearing platform is regulated as required; and the pouring of bottom-sealing concrete of a steel cylinder cofferdam, the water pumping, the binding of reserved hole steel reinforcing bars, and the pouring of reserved hole concrete at non-lifting points and lifting points are sequentially finished, and the steel cylinder cofferdam is detached, so that the mounting of the prefabricated bearing platform is finished. According to the prefabricated bearing platform mounting method disclosed by the invention, a small steel cylinder cofferdam replaces a large bearing platform steel cofferdam, so that the steel material can be effectively saved, the on-water operation time is shortened, and the construction cost is reduced; and meanwhile, the influence of water flow to the construction of the bearing platform is reduced, and the construction quality of the bearing platform is ensured.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

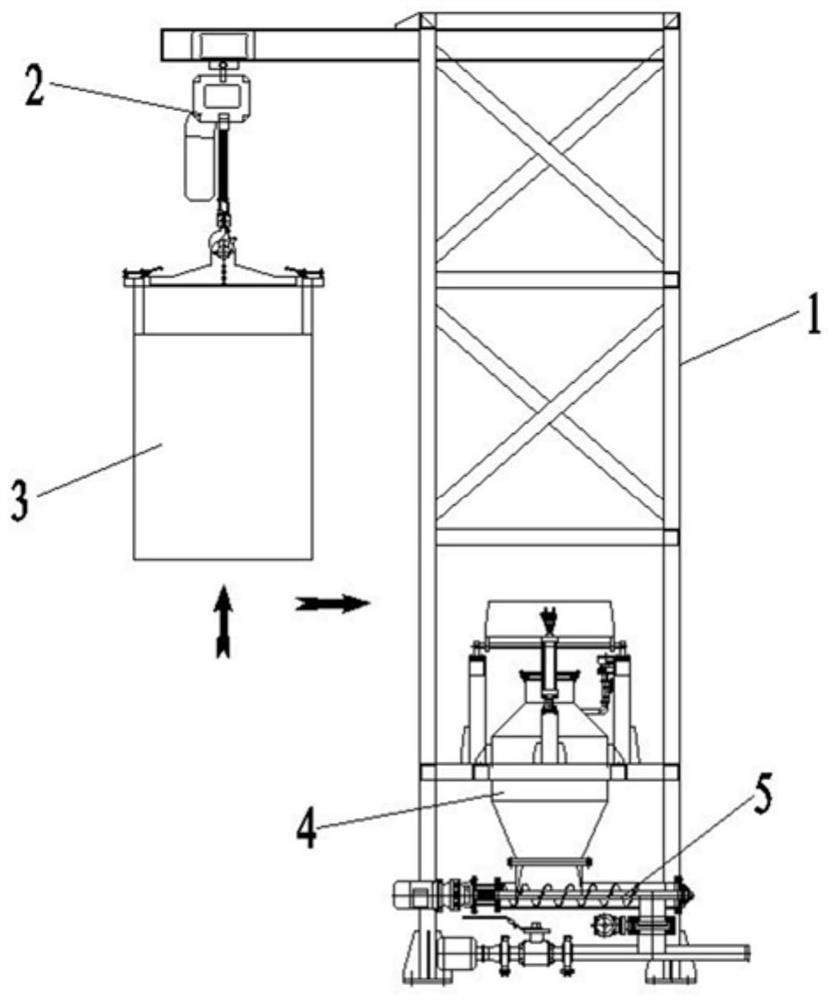

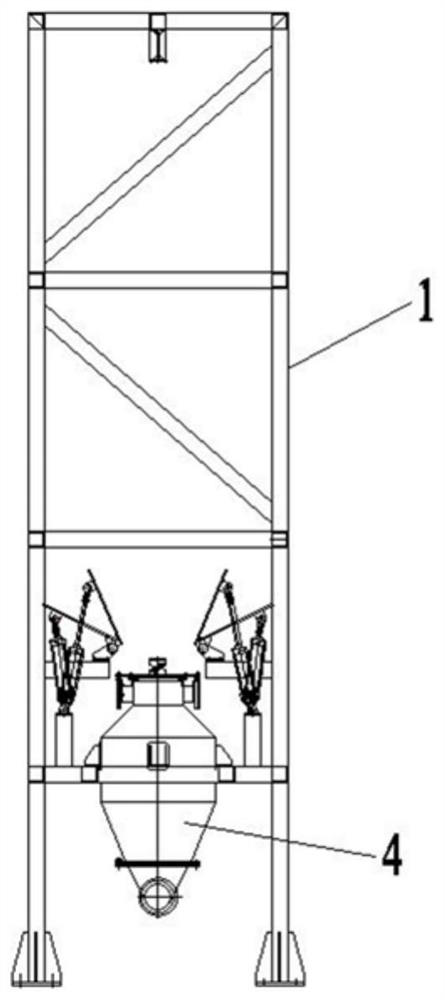

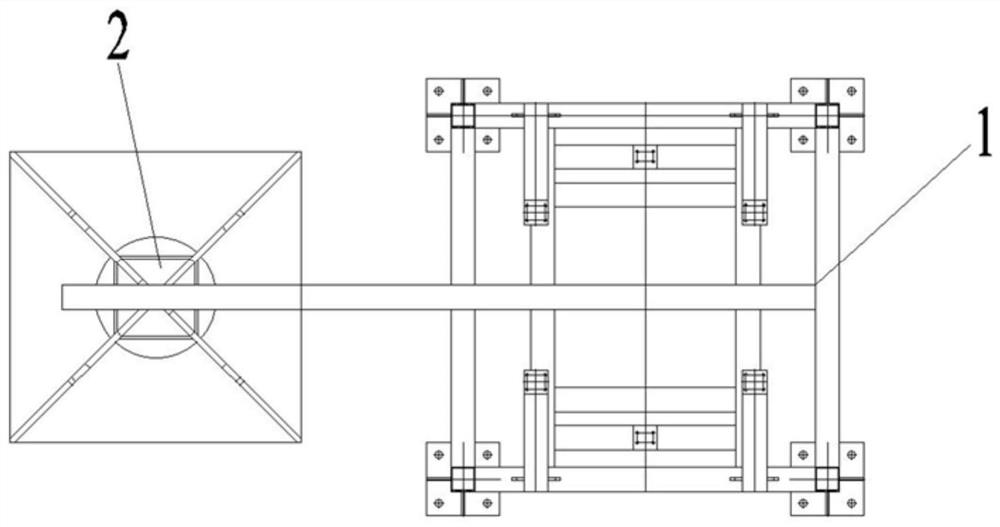

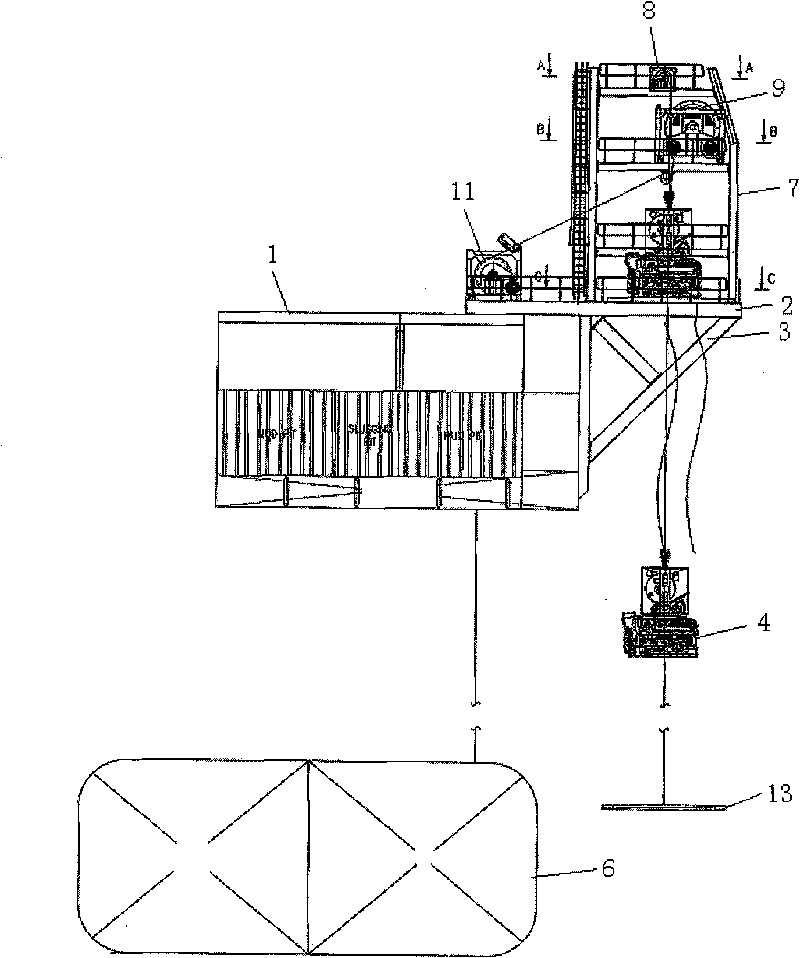

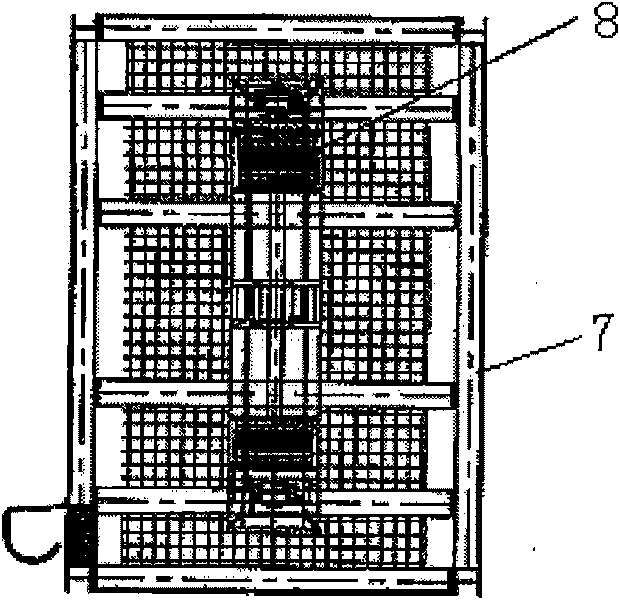

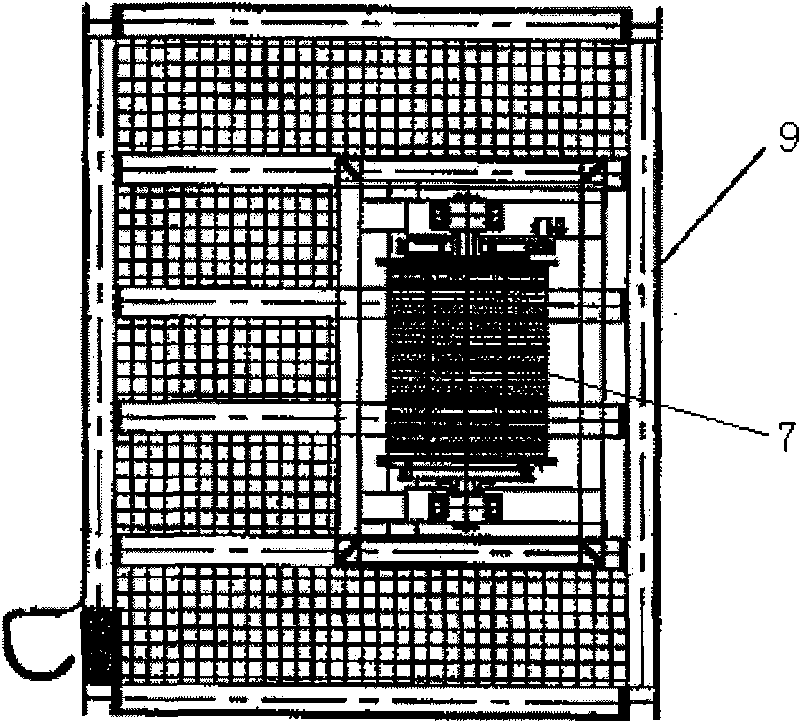

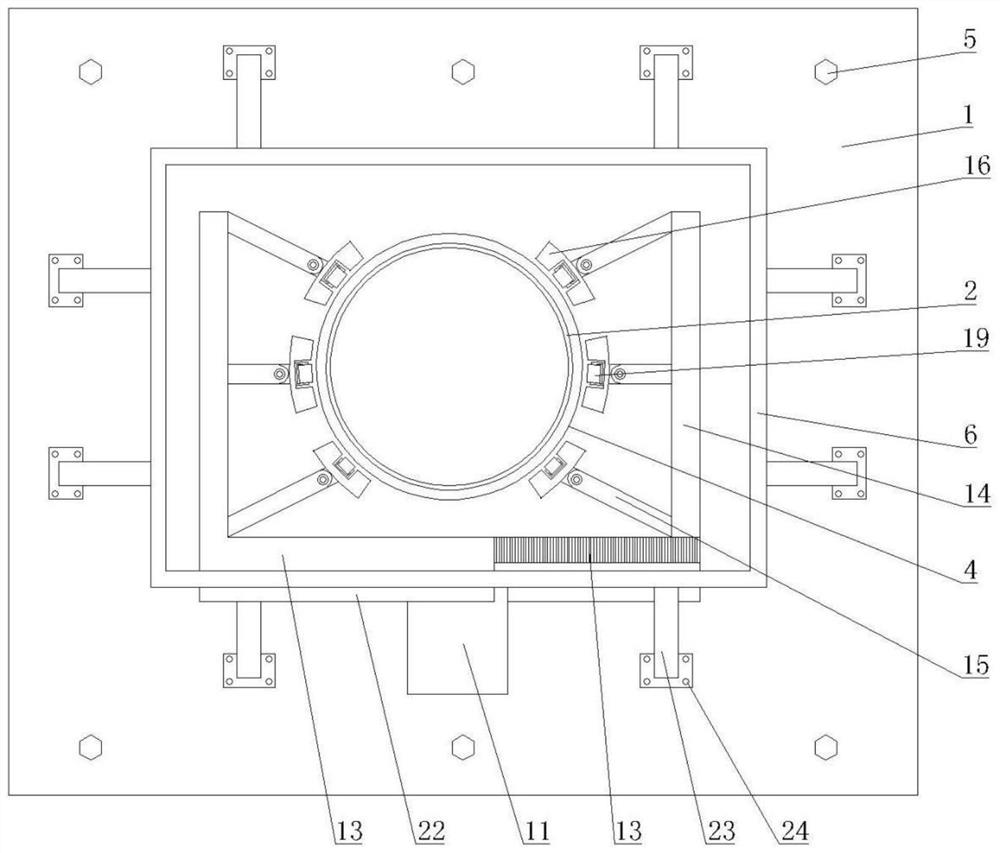

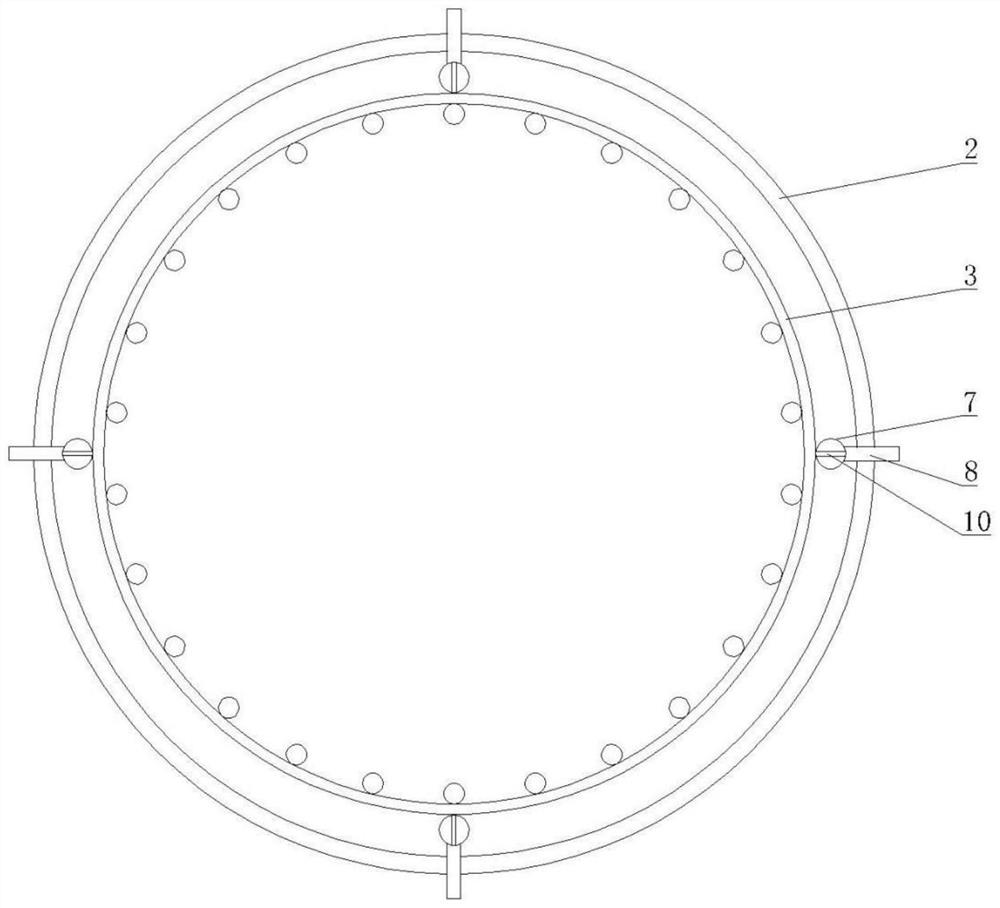

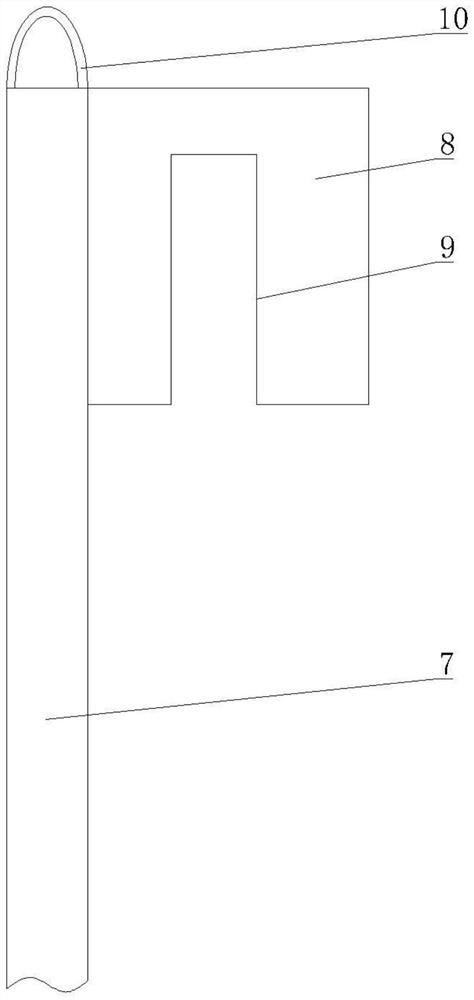

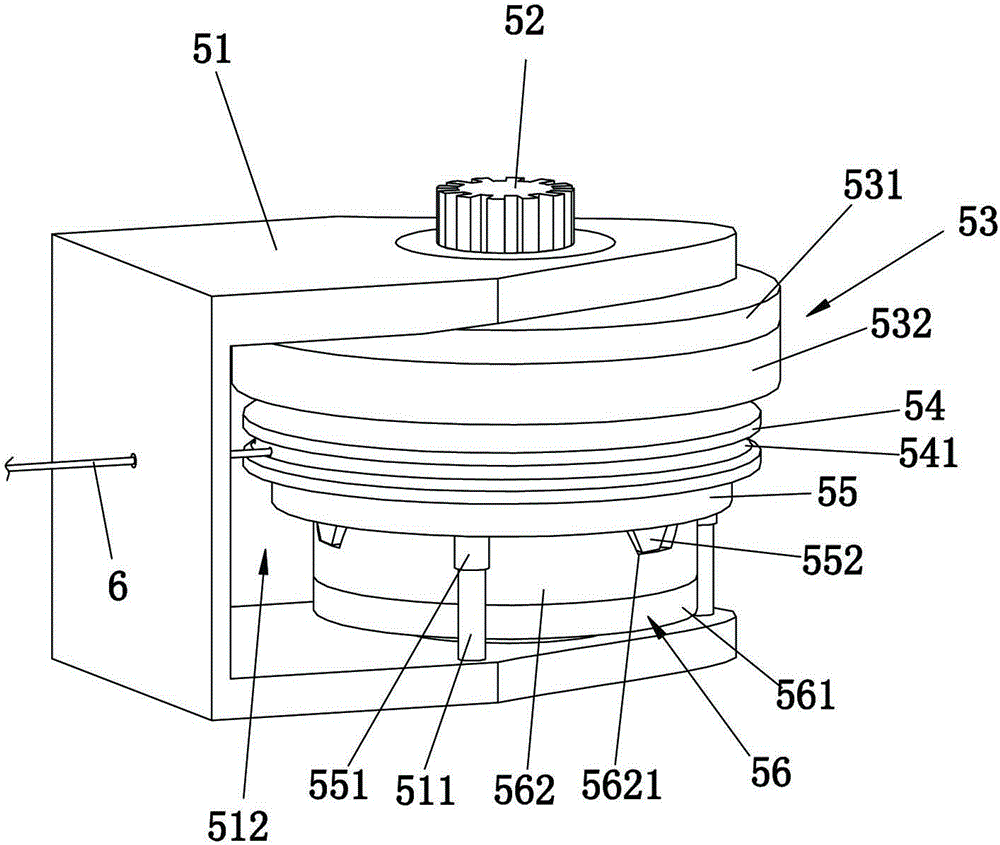

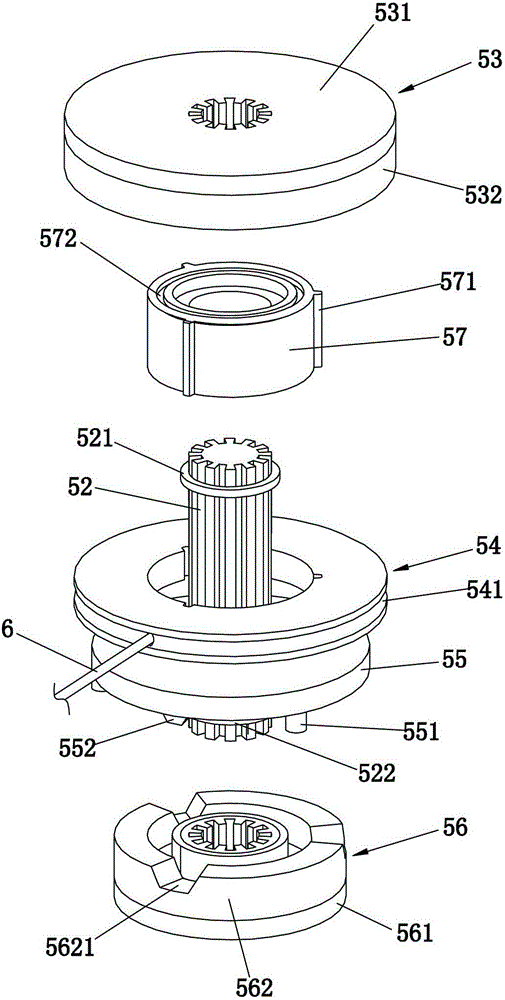

Ton bag breaking machine

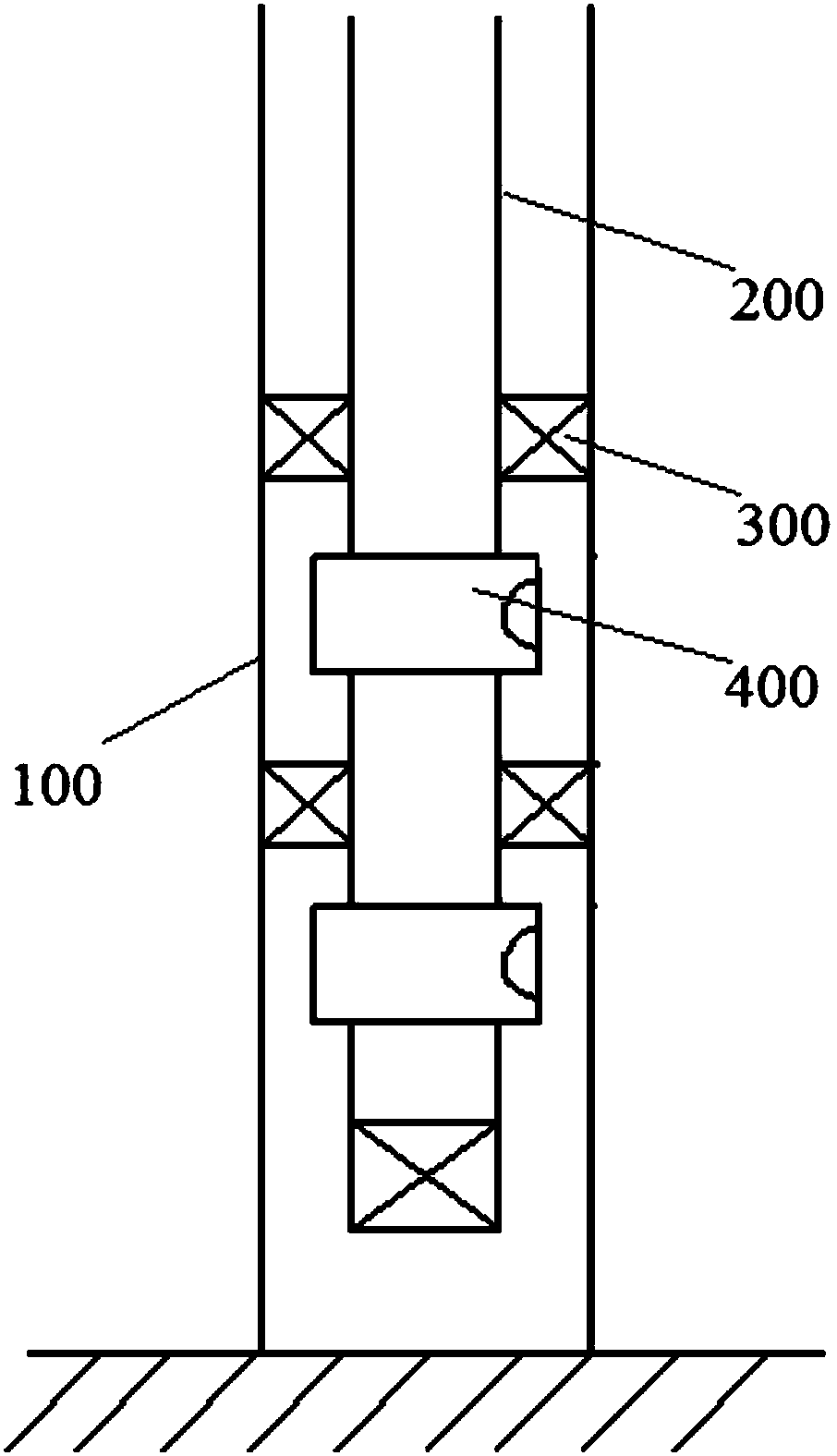

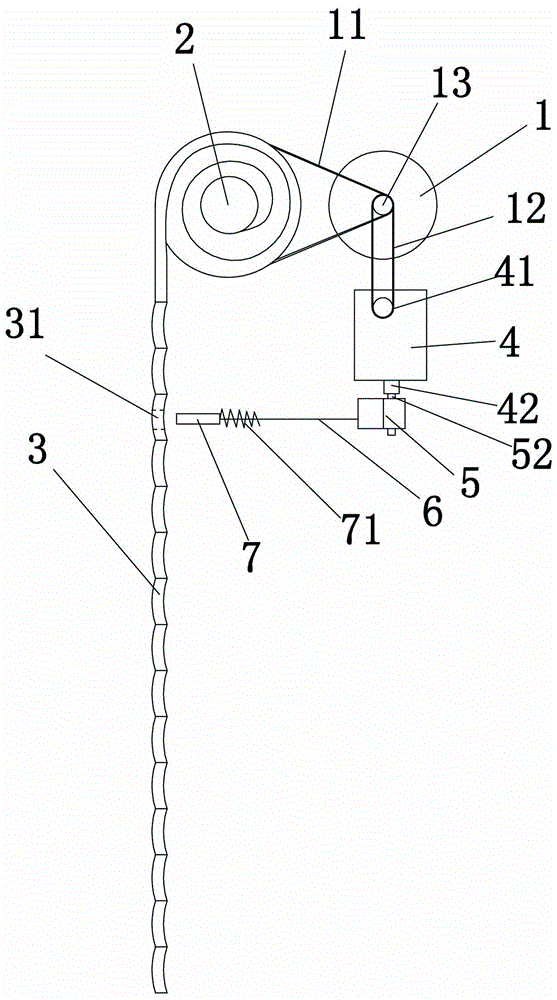

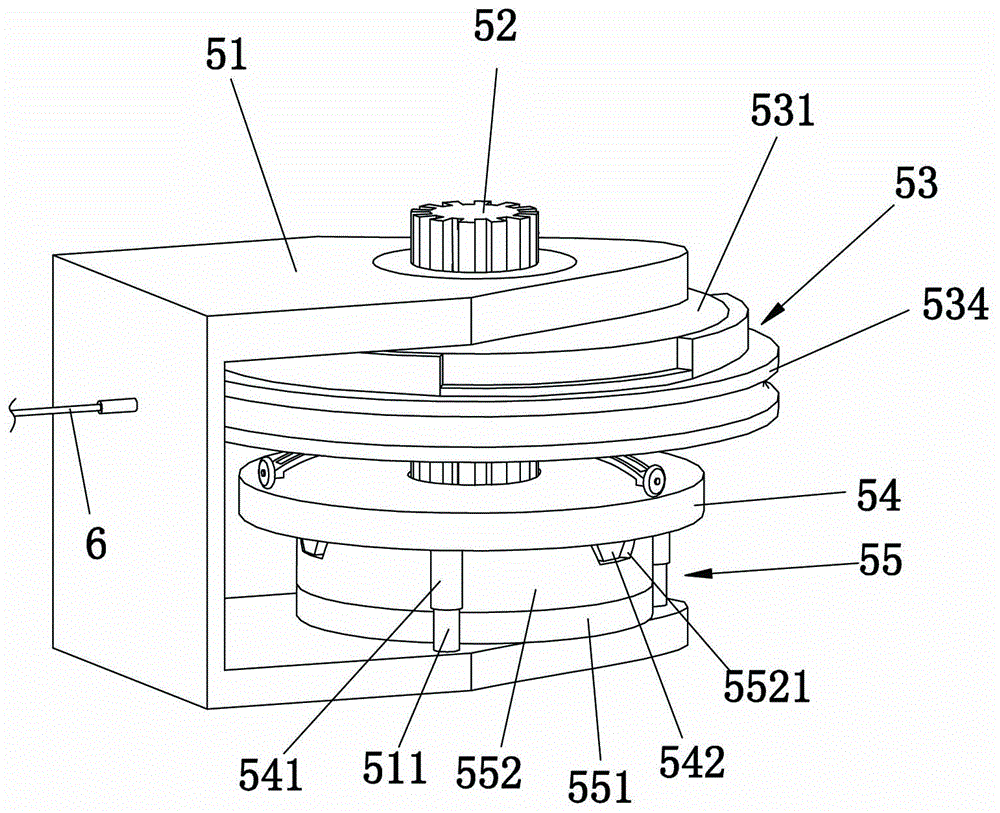

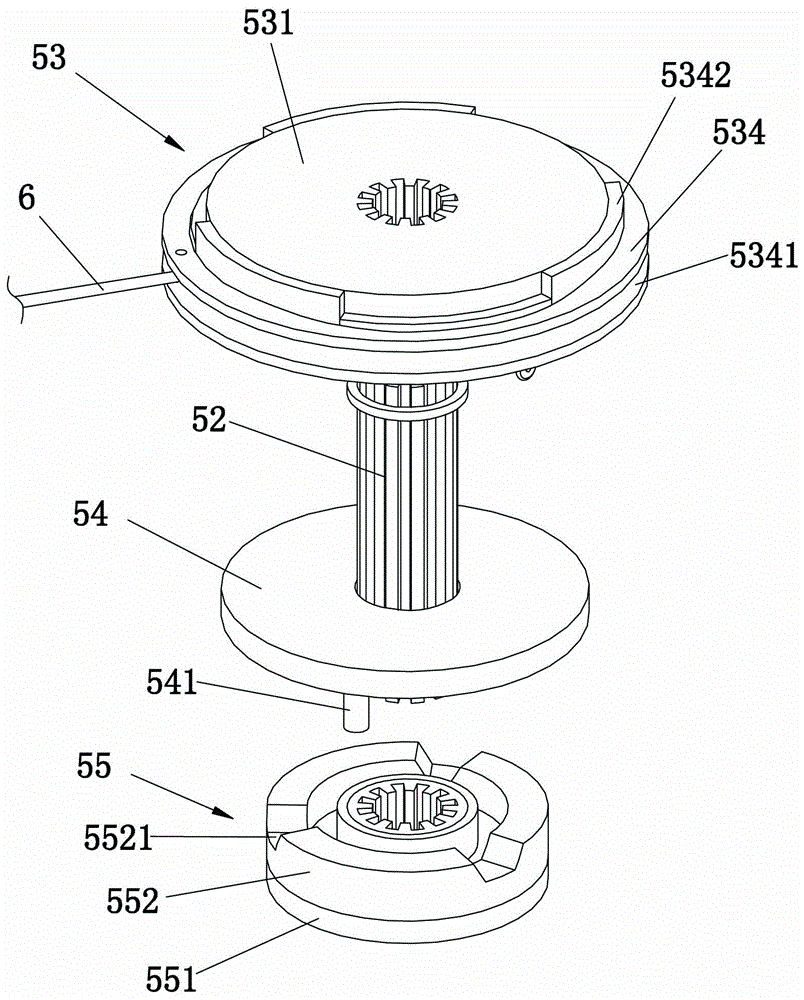

PendingCN111792137AEliminate easy aggregatesDecentralization smoothlyLarge containersBulk conveyorsImpellerStructural engineering

The invention relates to a ton bag breaking machine, comprising a main frame body, a suspension mechanism, a transition bin, a beating mechanism, a breaking arch mechanism and a negative-pressure pipe. A support structure is provided in the main frame body; the suspension mechanism is assembled at the top of the main frame body, and is used for suspending a ton bag onto the support structure; thebeating mechanism is fixed at the support structure, and comprises multiple beating units peripherally arranged at intervals, and each beating unit is used for beating the side edge position of the ton bag; the transition bin is fixed at the bottom of the support structure; a pressing mechanism is provided at the top of the transition bin; the breaking arch mechanism and the negative-pressure pipeare both mounted at the bottom of the transition bin; the breaking arch mechanism comprises a rotation impeller extending into the bottom of the transition bin; and the negative-pressure pipe is usedfor implementing negative-pressure conveying of powder. By adopting the ton bag breaking machine of the invention, the conditions of accumulation and bridging of the powder in the transition bin areprevented, and the condition of easy aggregation at the right-angled corner of the ton bag is also eliminated.

Owner:上海富昶环保科技有限公司

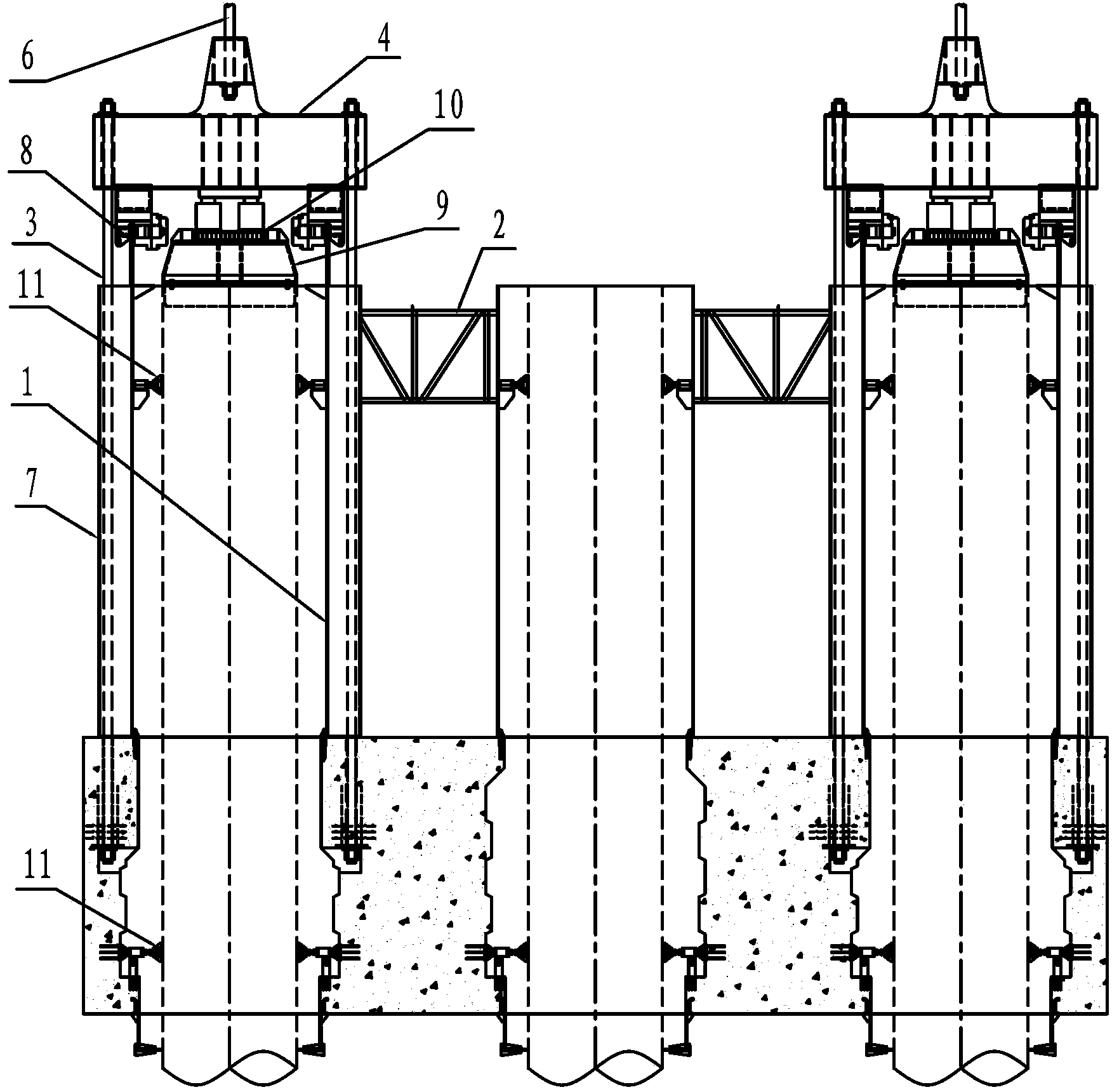

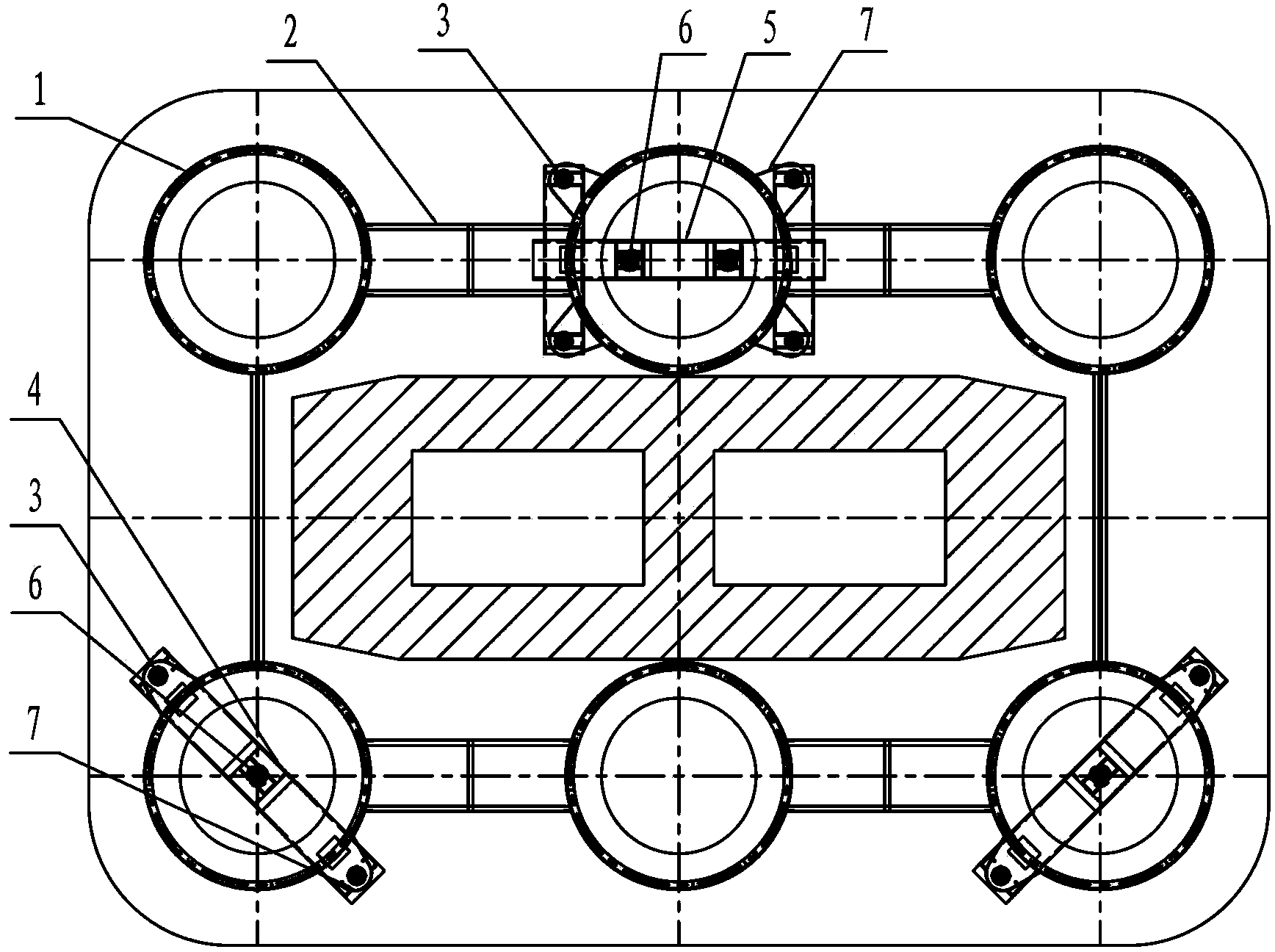

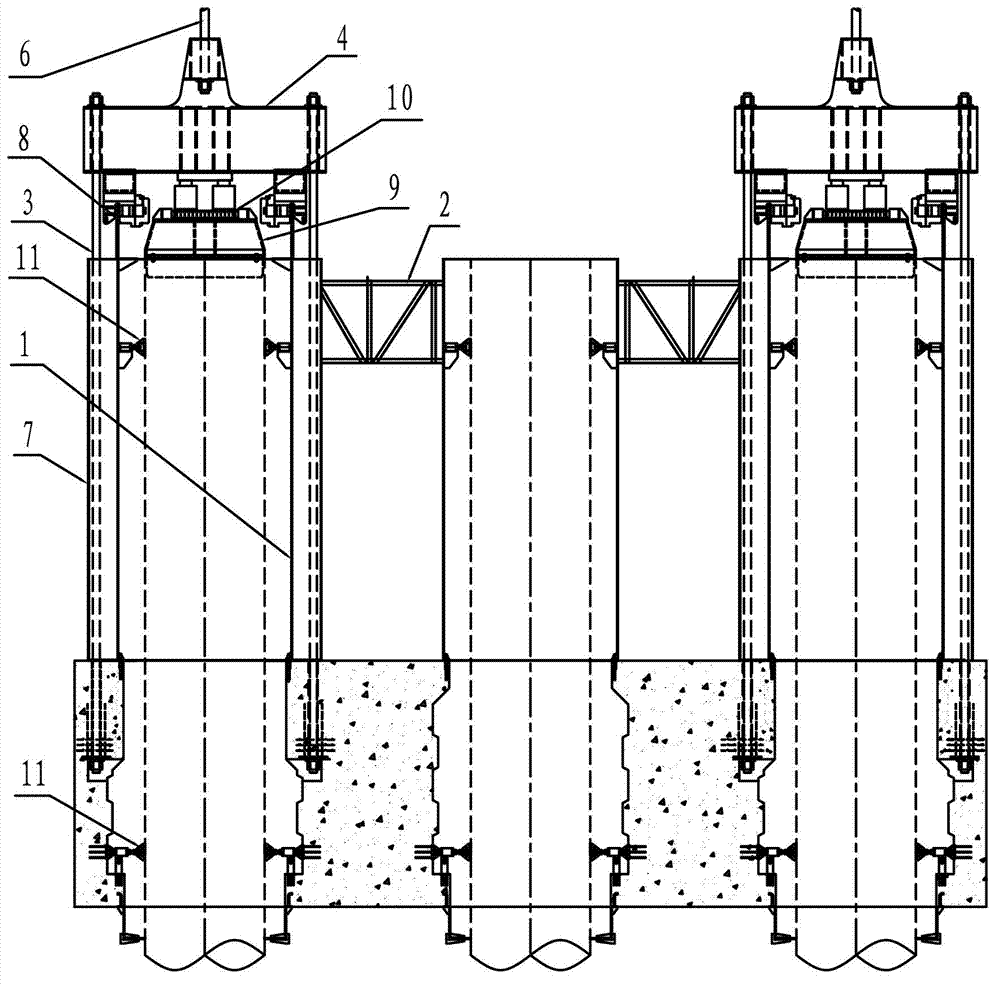

Underwater robot platform of semisubmersible drilling platform

The invention relates to an underwater robot platform of a semisubmersible drilling platform, which is characterized in that: the underwater robot platform comprises two bases arranged at a position of a left side and a position of a right side of a main deck, one part of the base is fixed on the main deck, while the other part extends out of the main deck; a lowering window is arranged in the middle of an extension end of the base, a support is arranged on the upper part of the extension end of the base; the support is divided into three layers, and two guide rope winches, a umbilical winch and a sliding seat cushion are arranged on the support in return from top to down; a fixing end of the base is provided with a wave compensation winch and a hydraulic power station; the two guide rope winches are connected with a weight block through a steel wire rope, the umbilical winch is connected with the underwater robot through a cable, and the wave compensation winch rounds pulleys fixed on the support and the underwater robot in turn through the cable; and the sliding seat cushion is arranged on the upper part of the lowering window. The underwater robot platform not only enables the underwater robot to be lowered smoothly in bade environment, but also has wider selectivity for the underwater robot.

Owner:CHINA NAT OFFSHORE OIL CORP +1

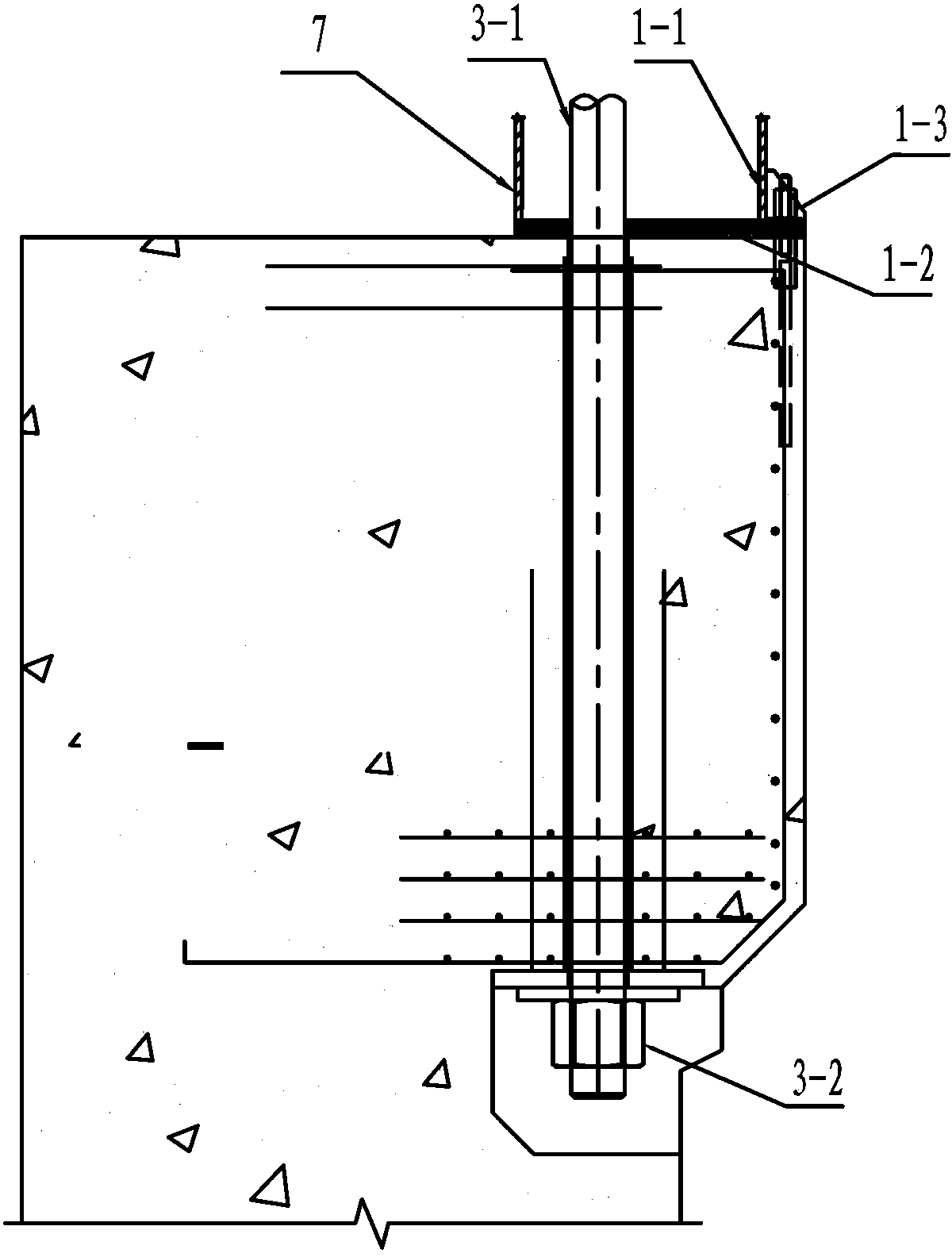

Double-wall cofferdam and pier body construction method

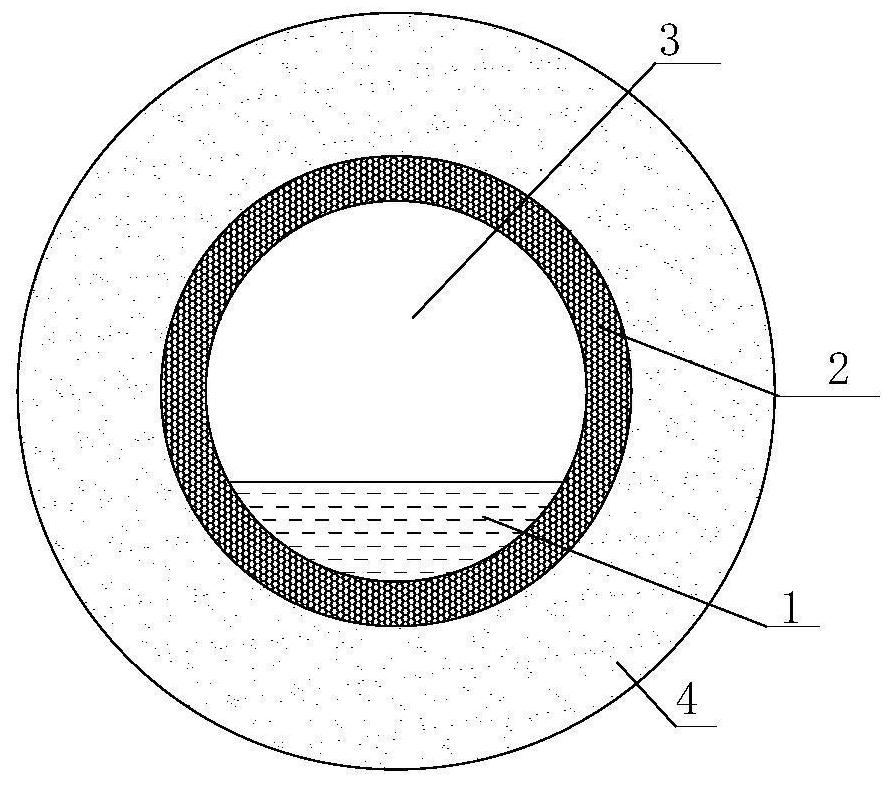

PendingCN109371997AImprove stabilityGood water stop effectFoundation engineeringDouble walledSurface plate

The invention relates to the technical field of bridge construction, in particular to a double-wall cofferdam and a pier body construction method utilizing the double-wall cofferdam. The double-wall cofferdam comprises at least one section of double-wall cofferdam unit. The double-wall cofferdam unit comprises a wall body, a cutting edge, an inner supporting rod and a guiding mechanism. The cutting edge is arranged at the bottom end of the wall body. The inner supporting rod is horizontally located in an inner surface plate of the wall body, and is connected with the inner panel of the wall body. The guide mechanism comprises a connecting rod and a guide plate, and the guide plate is connected with the inner panel of the wall body through the connecting rod, the bending degree of the guideplate is matched with the curvature of the outer wall surface of a protection tube of a drilling pile, and a distance is formed between the guide plate and the outer wall surface of the protection tube. The inner supporting rod can enhance the stability of the double-wall cofferdam. The guide plate can guide and locate the lowering process of the double-wall cofferdam. Therefore, the double-wallcofferdam has the advantages that the structure strength is improved, stability is high, water stopping effect is good, structural design is reasonable, the structure is not required to be adjusted for multiple times in the construction process, and the smooth proceeding of engineering is guaranteed.

Owner:CHINA RAILWAY SIXTH GROUP +1

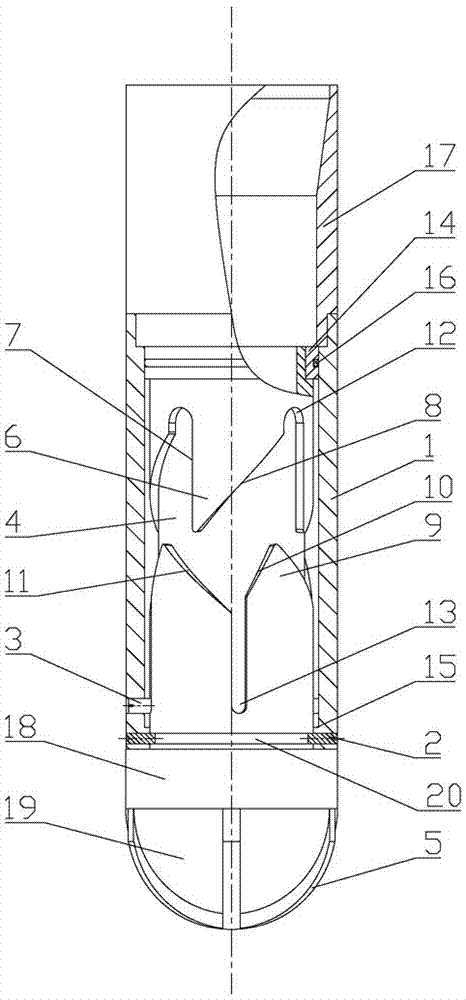

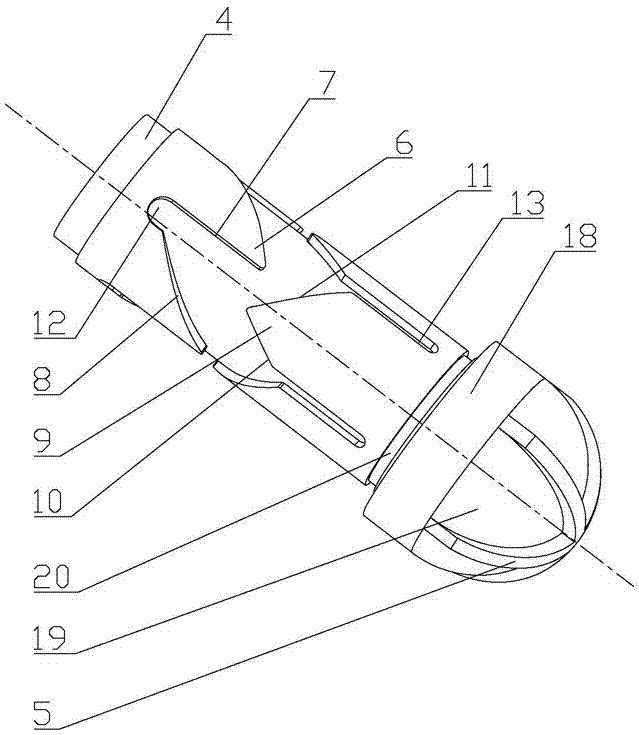

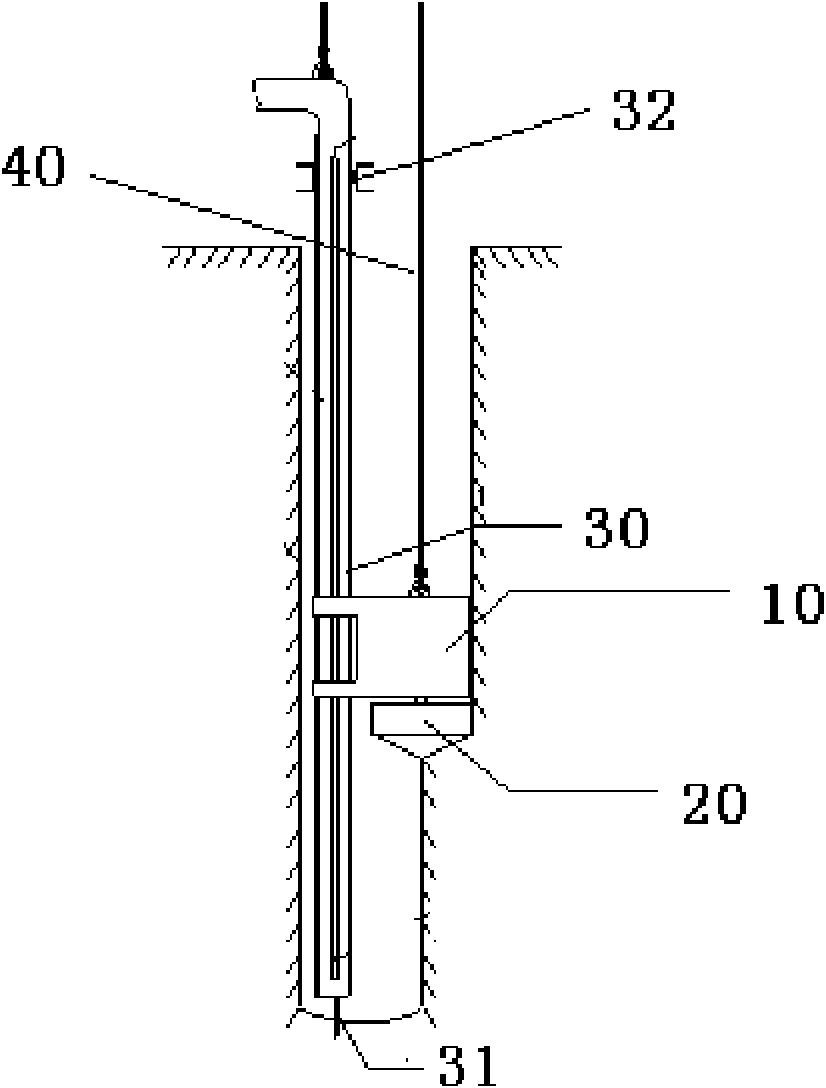

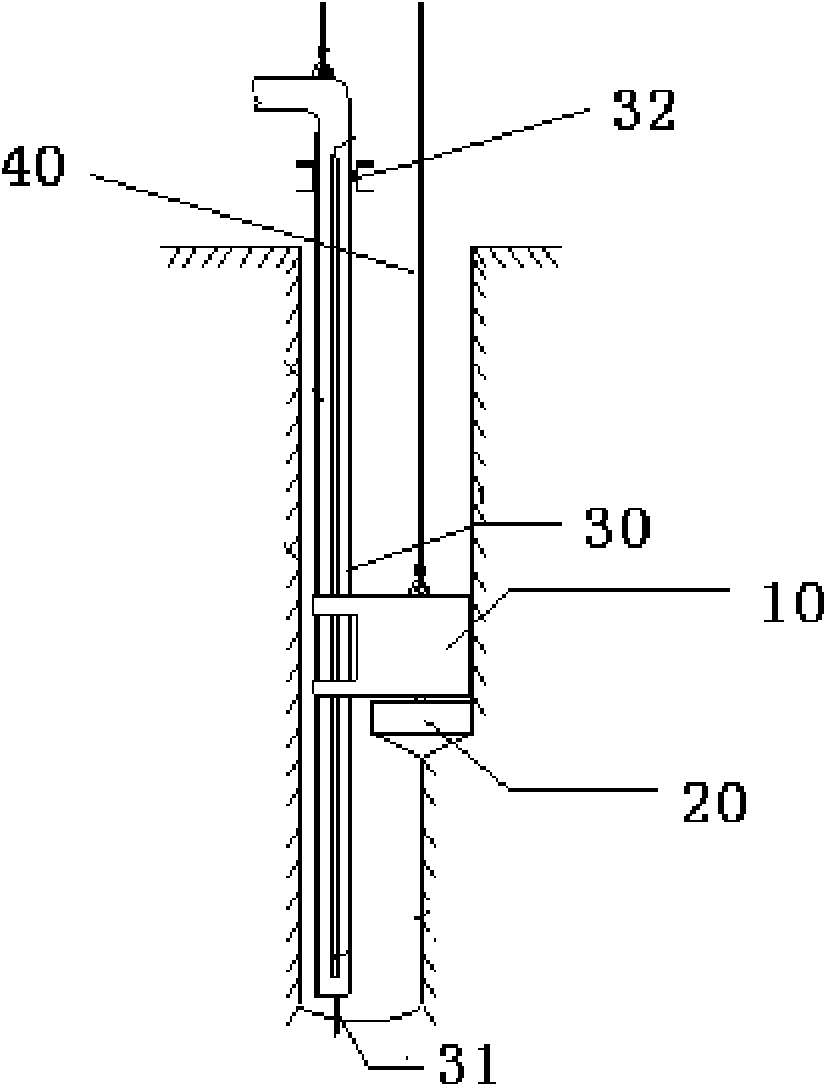

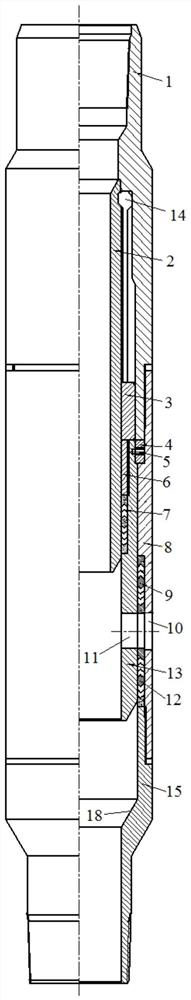

Rotary guiding shoe assembly capable of repairing borehole

PendingCN107227938AReasonable structureReduce contact areaDrilling rodsDrilling casingsWell cementingMechanics

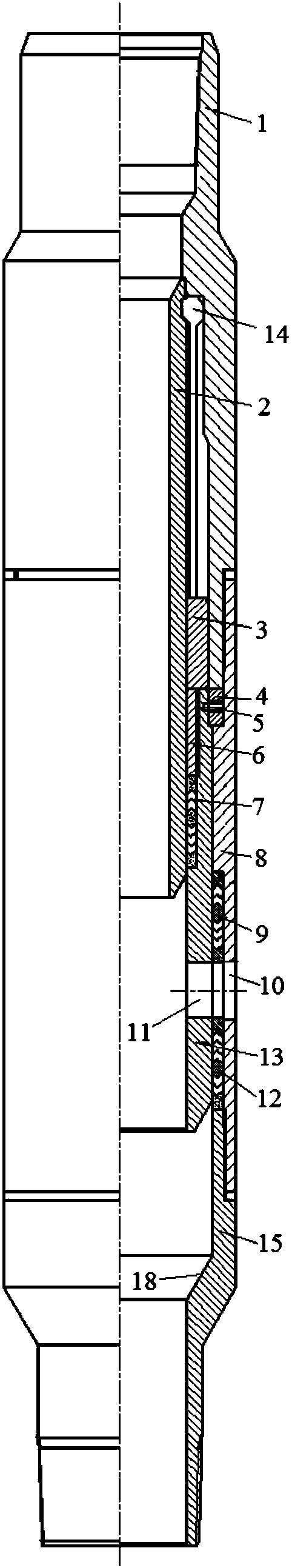

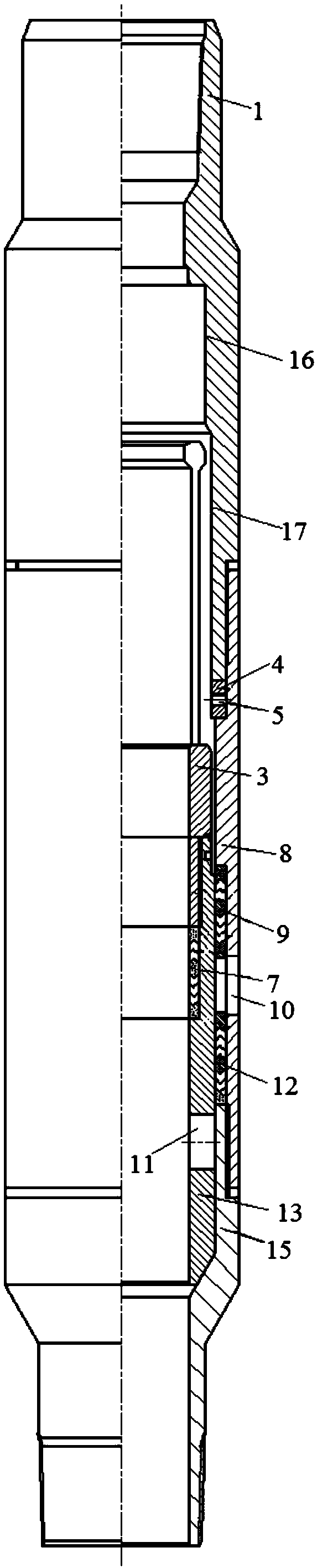

The invention relates to the technical field of oilfield well cementation and completion operation equipment, and provides a rotary guiding shoe assembly capable of repairing a borehole. The rotary guiding shoe assembly capable of repairing the borehole comprises a guiding shoe body, an outer barrel, a shearing pin and guiding pins, wherein the guiding shoe body comprises an inner barrel and a guiding shoe head; the bottom end of the inner barrel and the top end of the guiding shoe head are fixed together; the inner barrel is inserted in the outer barrel; the inner barrel and the outer barrel are mounted together in a limited manner through the shearing pin; a groove type rotary guiding track capable of rotating through change of movement of the guiding pins is arranged on the outer wall of the inner barrel; at least guiding pins of which the inner ends are clamped in the groove type rotary guiding track are fixedly mounted on the outer barrel. A scraping blade capable of rotating along with the inner barrel is added on the outer side of the guiding she head, multiple necks and irregular boreholes can be further repaired in a rotating process, the area of a part, which is in contact with a well wall, of the guiding shoe head is reduced, the passing ability is improved, therefore, smooth descending of a pipe string is ensured, and the circumstance that well cementation construction is affected due to jamming of the pipe string is avoided. The rotary guiding shoe assembly capable of repairing the borehole has the characteristics of simplicity in operation, convenience in use, and capability of saving time and labor.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

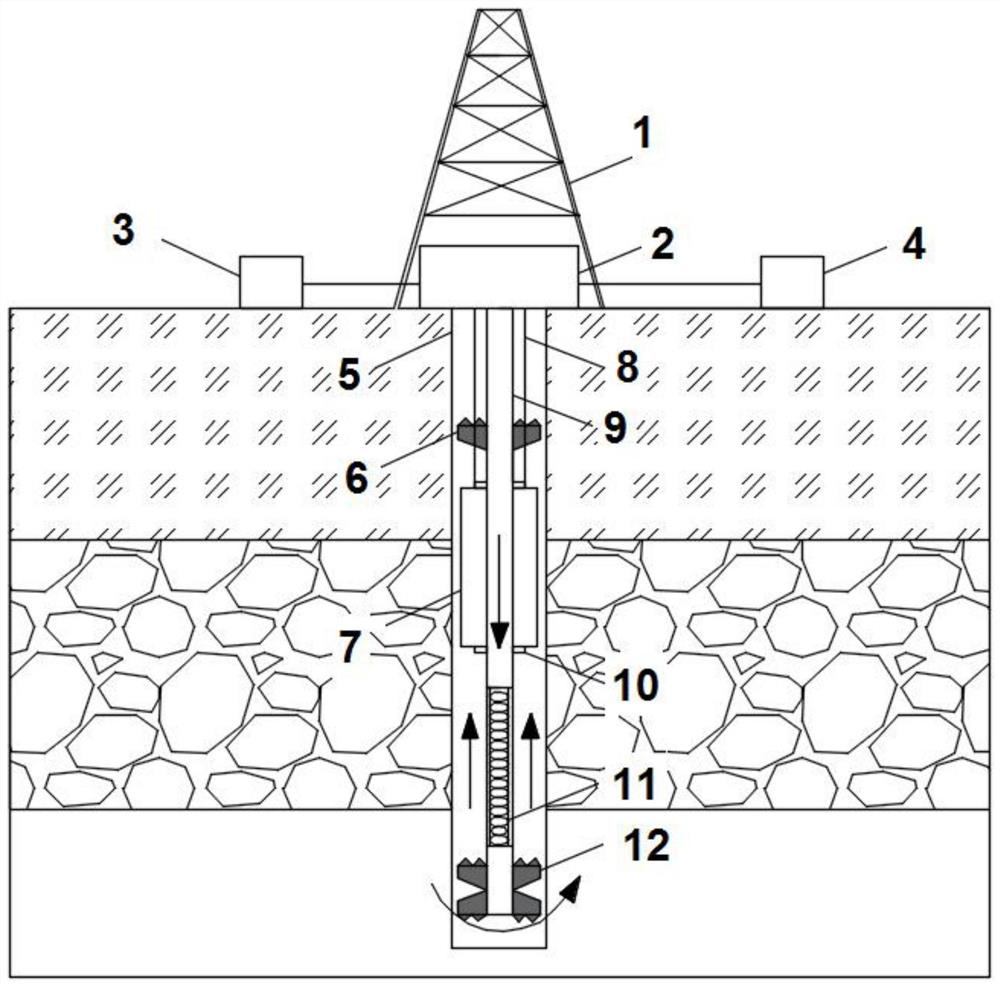

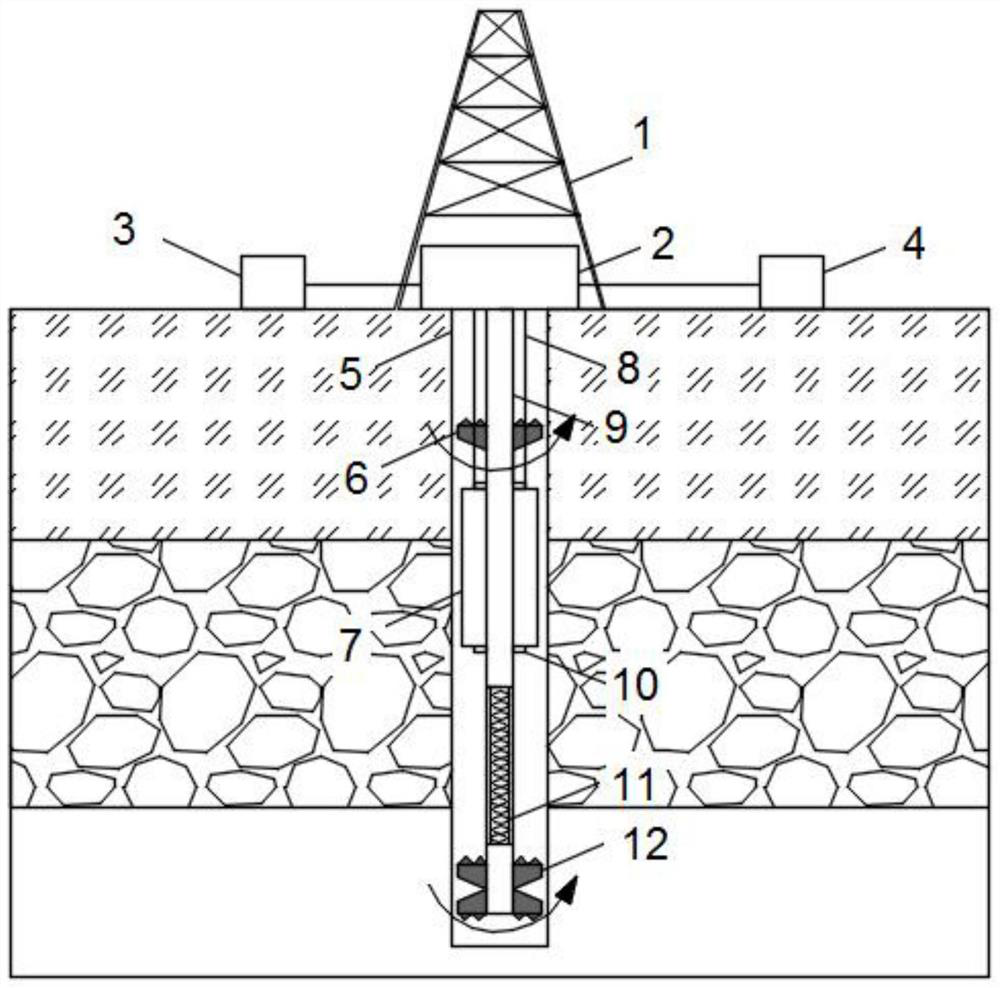

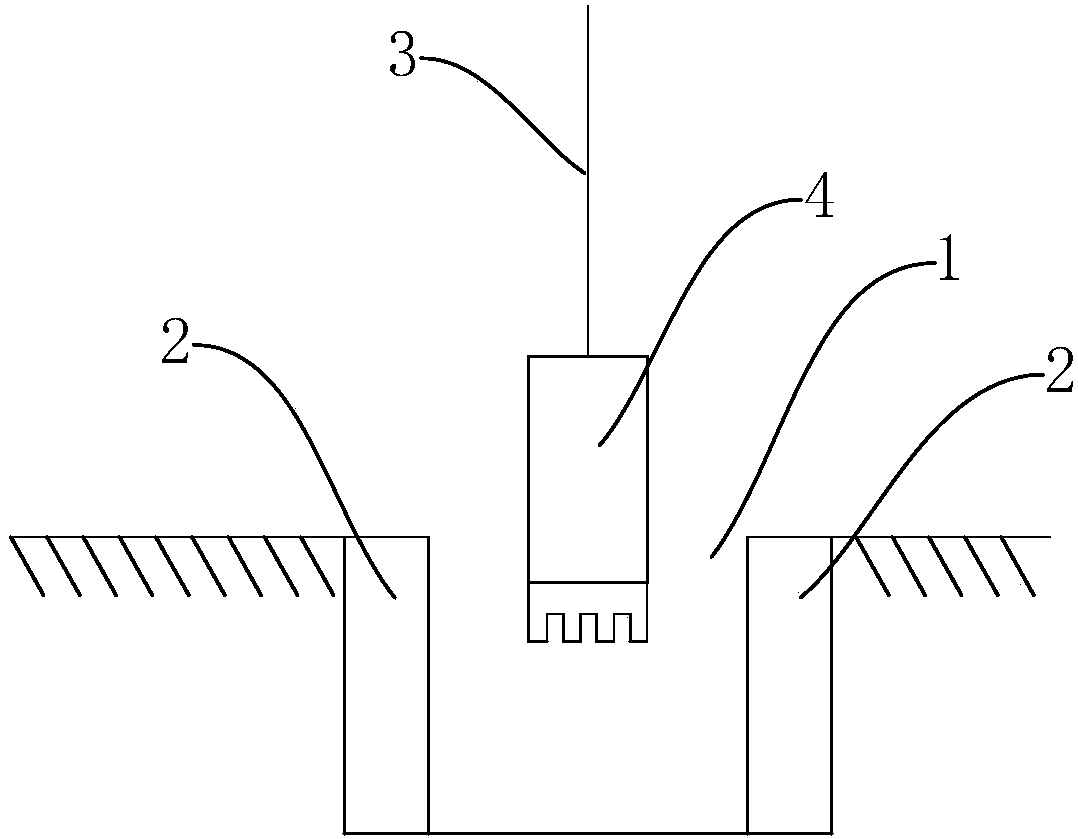

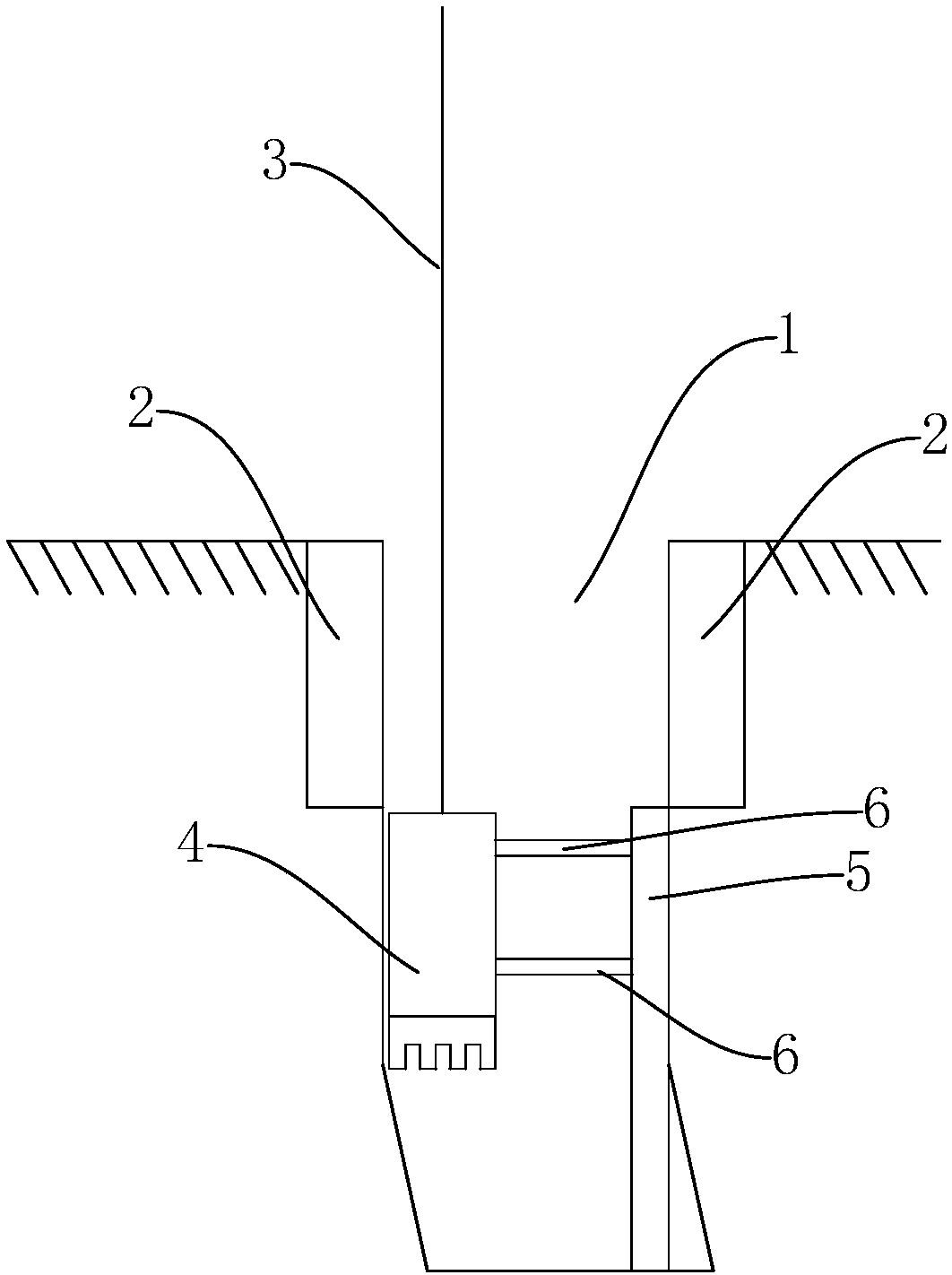

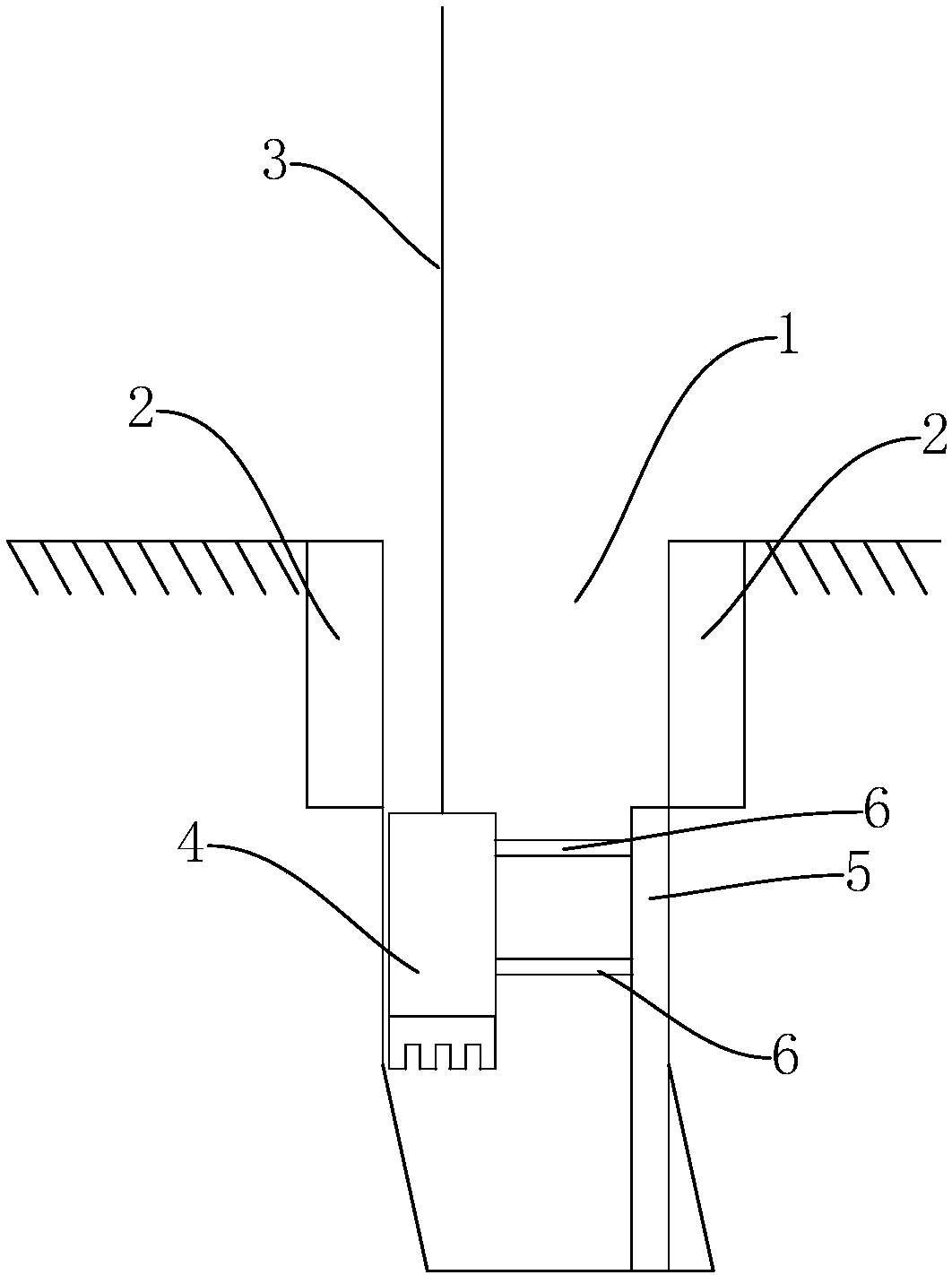

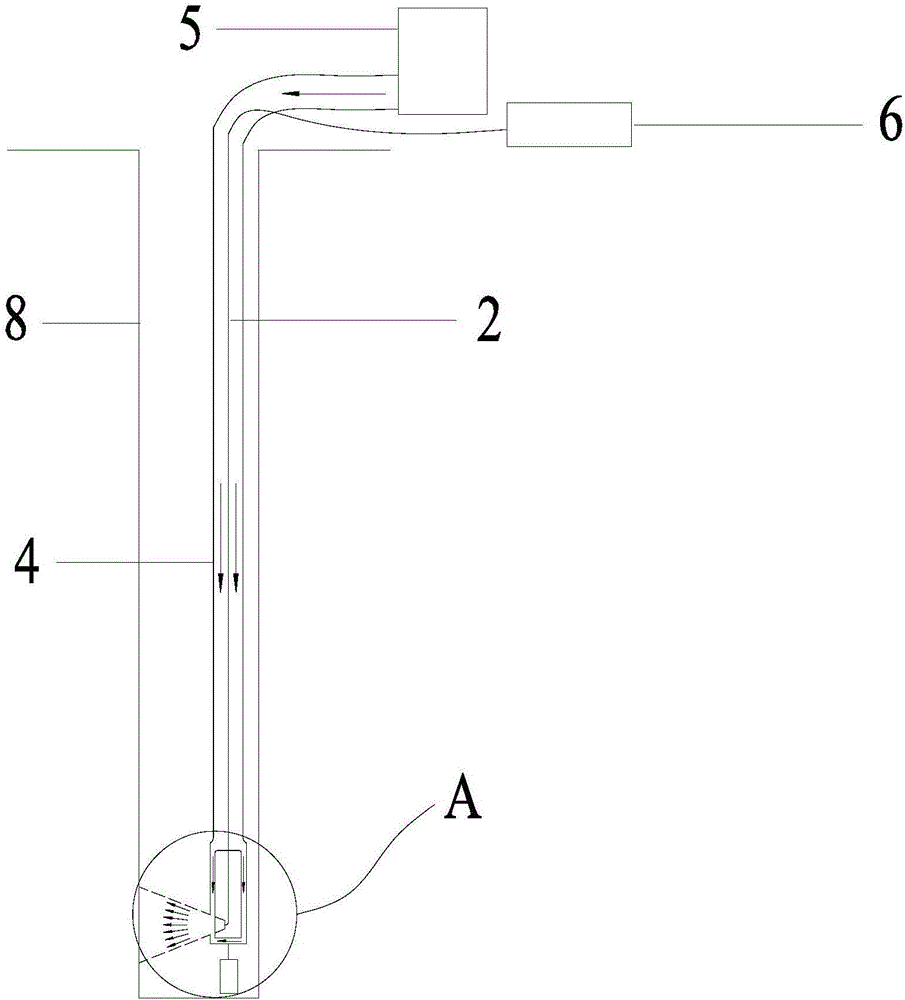

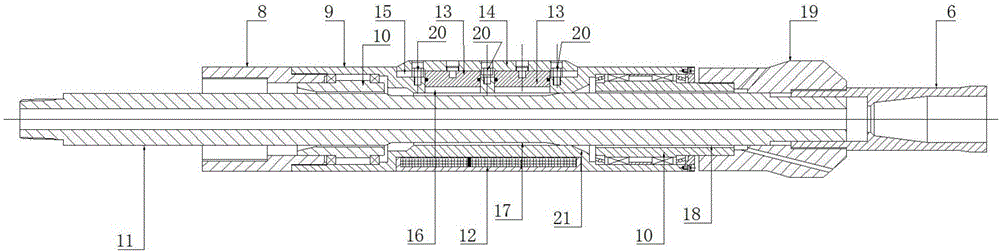

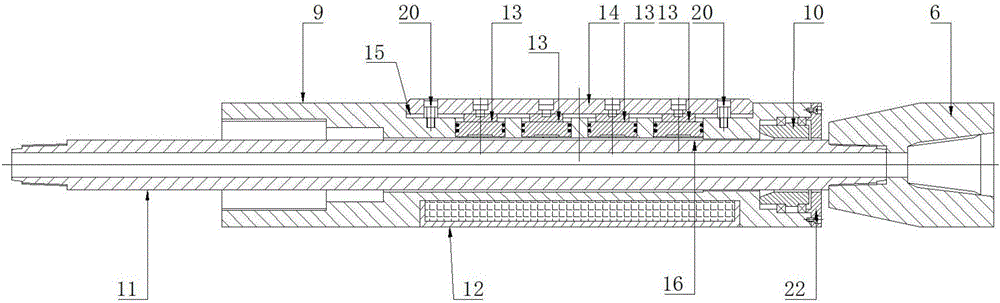

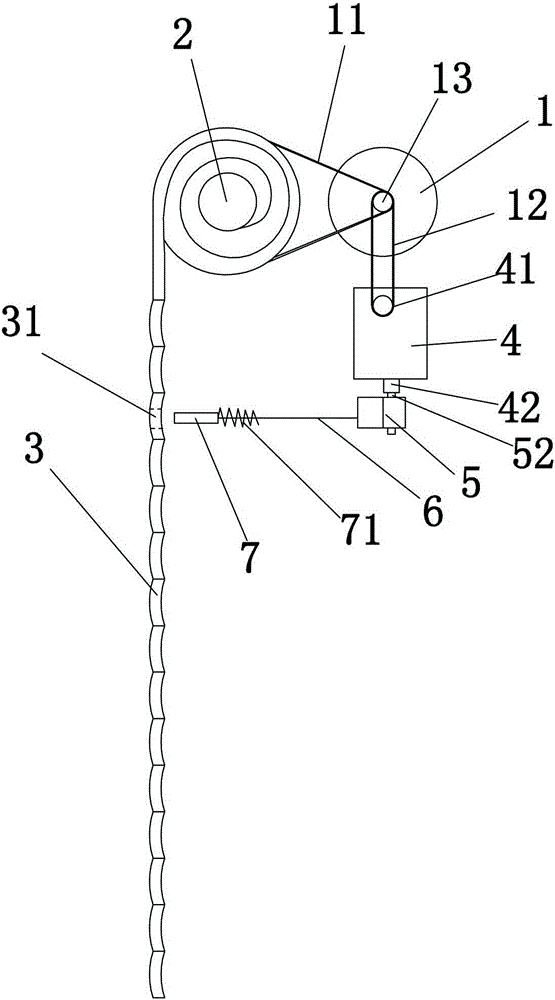

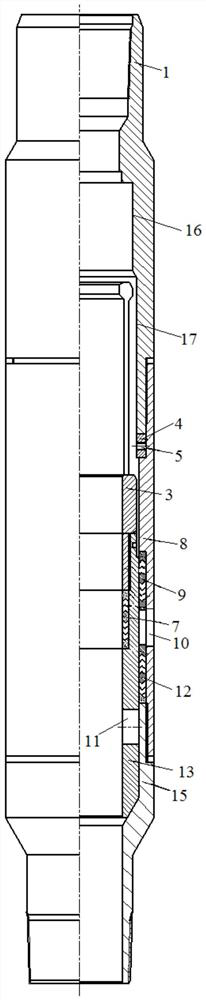

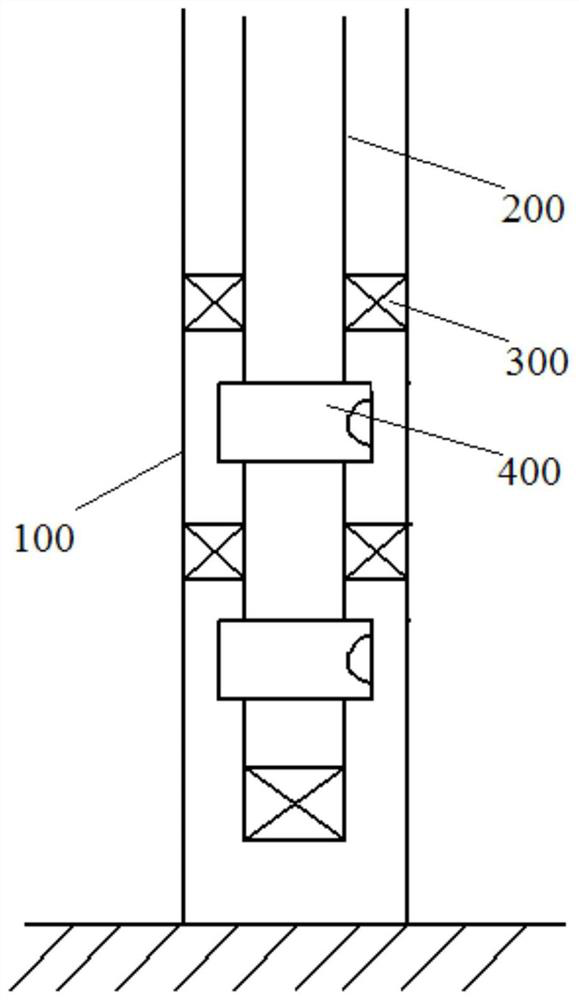

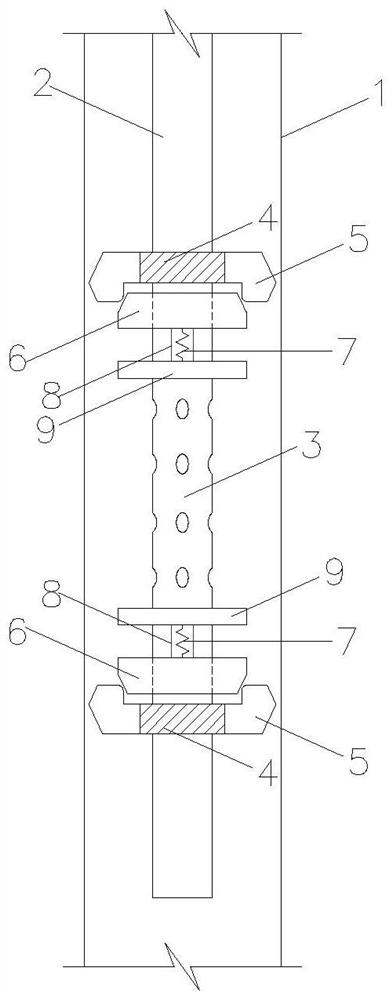

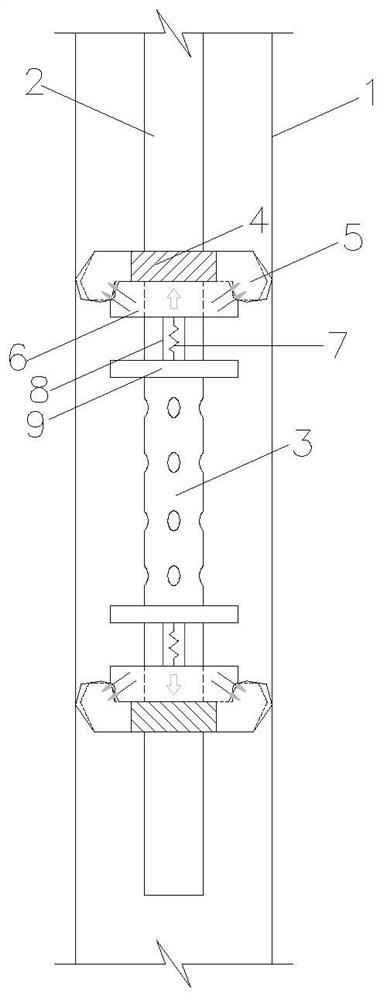

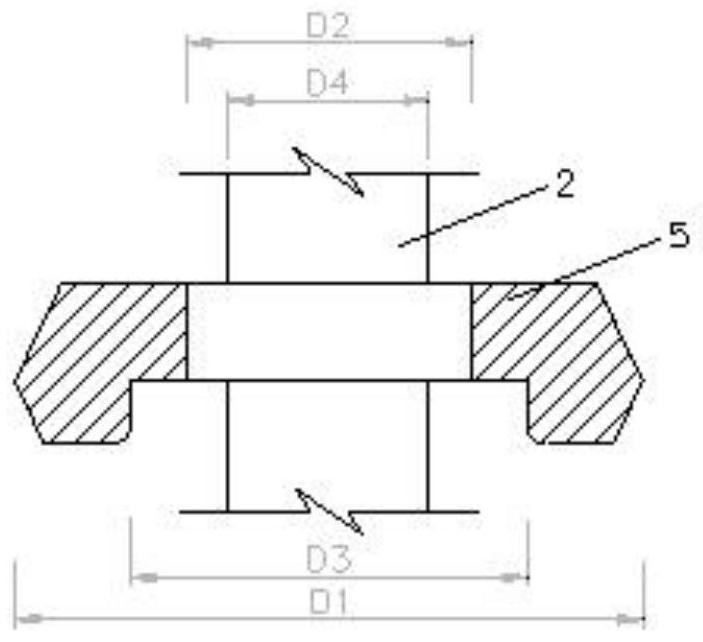

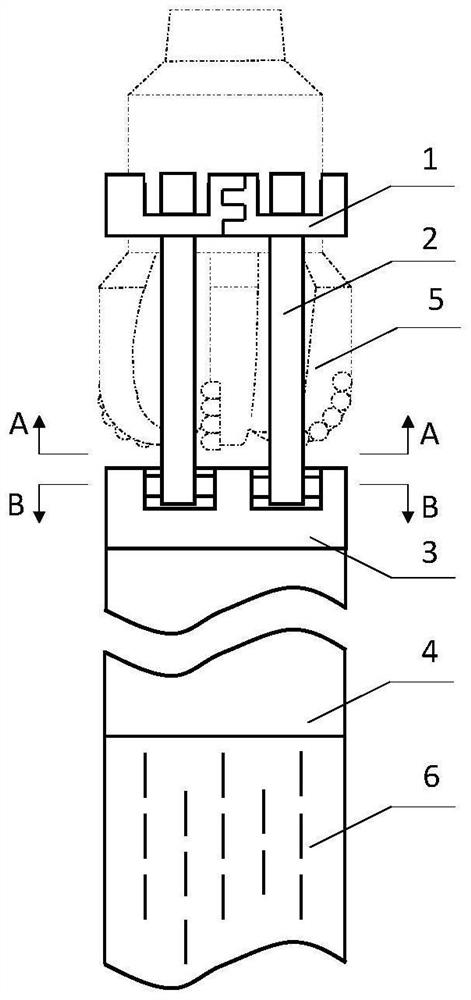

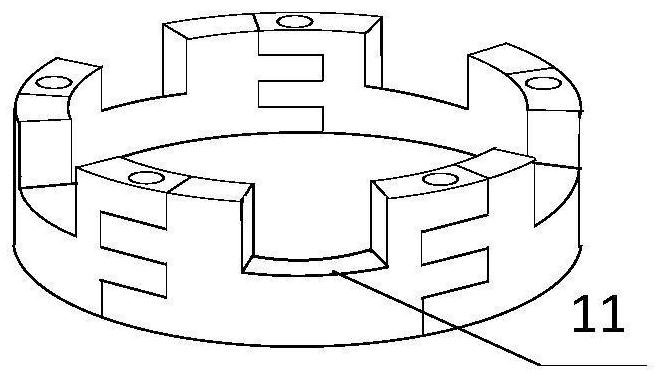

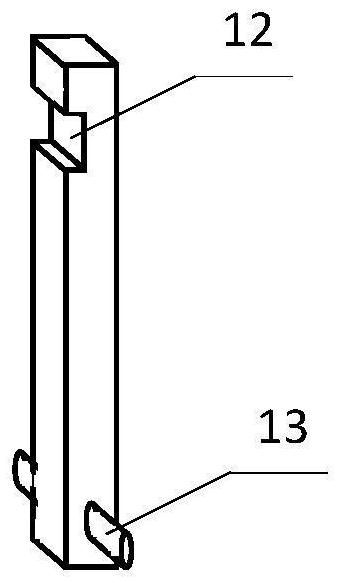

Deep well measuring instrument conveying device and method

ActiveCN112112592APrevent rotationDecentralization smoothlySurveyDrilling rodsWell loggingMeasuring instrument

The invention discloses a deep well measuring instrument conveying device and method. The conveying device comprises a well logging assembly or at least two well logging assemblies connected in series, a drill rod, a screw drill and a front guide drill bit, wherein the well logging assembly is composed of inverted well drill bits, instrument working cabins and instrument working cabin fixing devices. The method for conveying an underground measuring instrument comprises the steps of lowering and lifting. The rotation power of the front guide drill bit is provided by the upper screw drill, blocked rock blocks encountered in the lowering process are crushed, the instrument working cabins are prevented from rotating in the lowering process, and smooth lowering is guaranteed. The underground measuring instrument is integrated in the instrument working cabins, the multiple instrument working cabins can be installed at the same time, and simultaneous measurement is conducted on well sectionsof different depths. The upper portion of each instrument working cabin fixing device is in threaded connection with one inverted well drill bit, the whole conveying device is driven by a drilling machine to slowly rotate during lifting, the drill bits slowly rotate, the collapsed rock blocks are cut and crushed, and the instrument working cabins are rapidly lifted out of trouble.

Owner:JILIN UNIV

Grooving perpendicularity control process of super-deep underground diaphragm wall

ActiveCN103397659AShorten construction timeDecentralization smoothlyArtificial islandsFoundation testingSlurry wallEngineering

The invention discloses a grooving perpendicularity control process of a super-deep underground diaphragm wall. A groove is formed by using a hydraulic grab through excavation, two sections of guide walls are arranged according to the width of the groove before excavation, the distance between the two sections of guide walls is equal to the width of the groove, the guide walls extend to underground for an appointed depth from the ground, the hydraulic grab is hung by using a steel rope to ensure that the hydraulic grab excavates between the two sections of guide walls. The grooving perpendicularity control process is characterized in that when the depth of the groove is less than 5-15m in a grooving process, the distances between the two sections of guide walls and the steel rope are measured by using a measuring ruler, the perpendicularity accords with the requirement if the distances between the steel rope and the two sections of guide walls are equal or the difference between the distances from the steel rope to the two sections of guide walls does not exceed 30cm, the excavation is carried out continuously; after the depth of the groove is more than 5-15m, when the excavation is carried out for a certain depth, the perpendicularity of the wall of the groove is measured by adopting an ultrasonic wall measuring apparatus, and the tunneling is carried out continuously if the perpendicularity of the side wall meets the requirement. The grooving perpendicularity control process of the super-deep underground diaphragm wall, disclosed by the invention, is capable of controlling the grooving perpendicularity of the underground diaphragm wall with a construction depth of exceeding 60m to be within 1 / 1000, and ensuring that an ultra-long reinforcement cage with I-beam joints at two ends is smoothly put in a design depth so that the construction time of the super-deep underground diaphragm wall is shortened.

Owner:SHANGHAI YUANFANG GROUNDWORK ENG

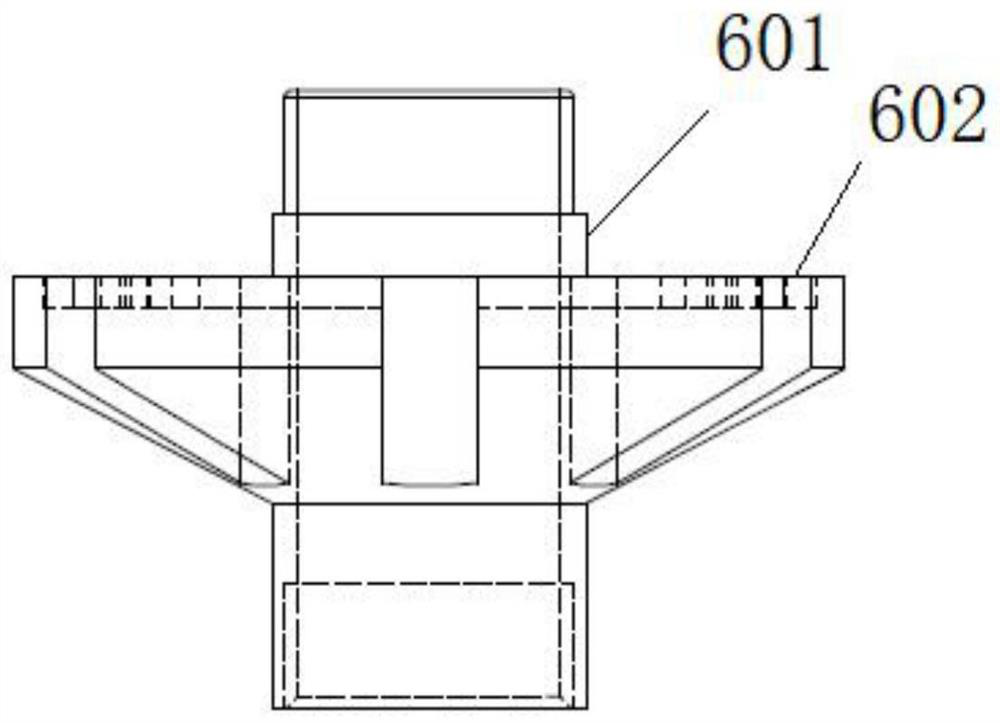

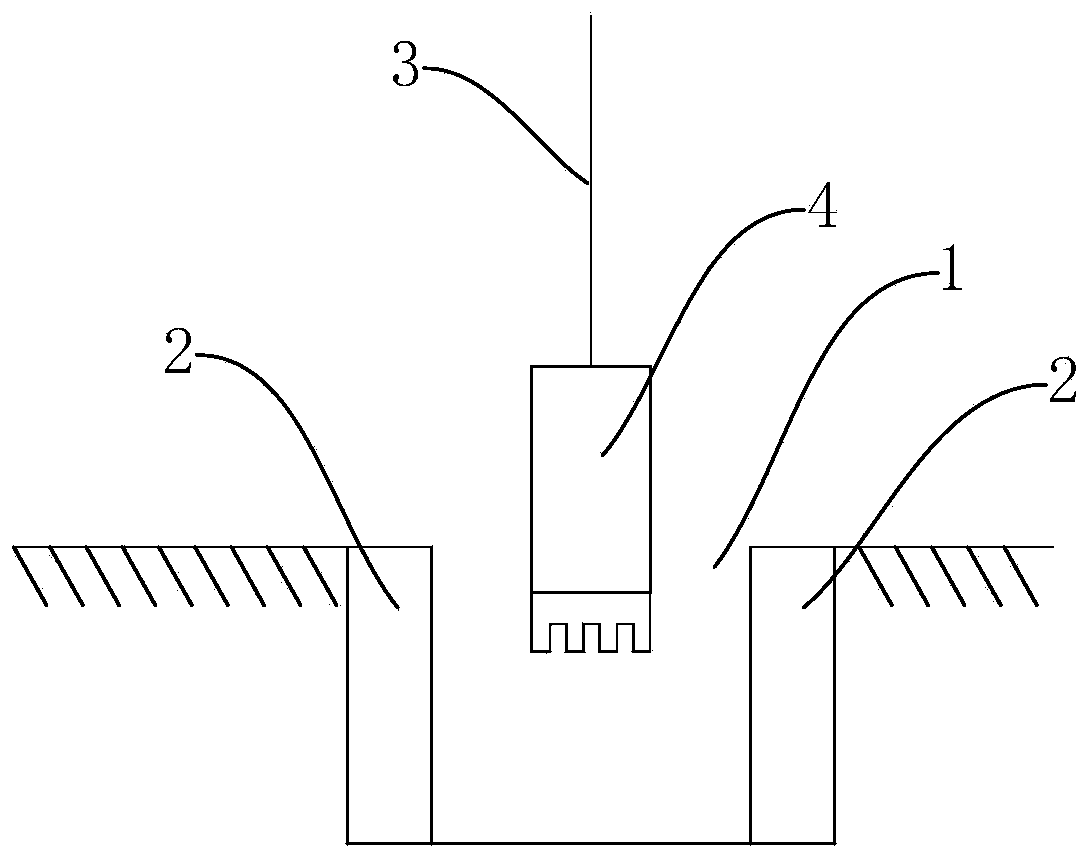

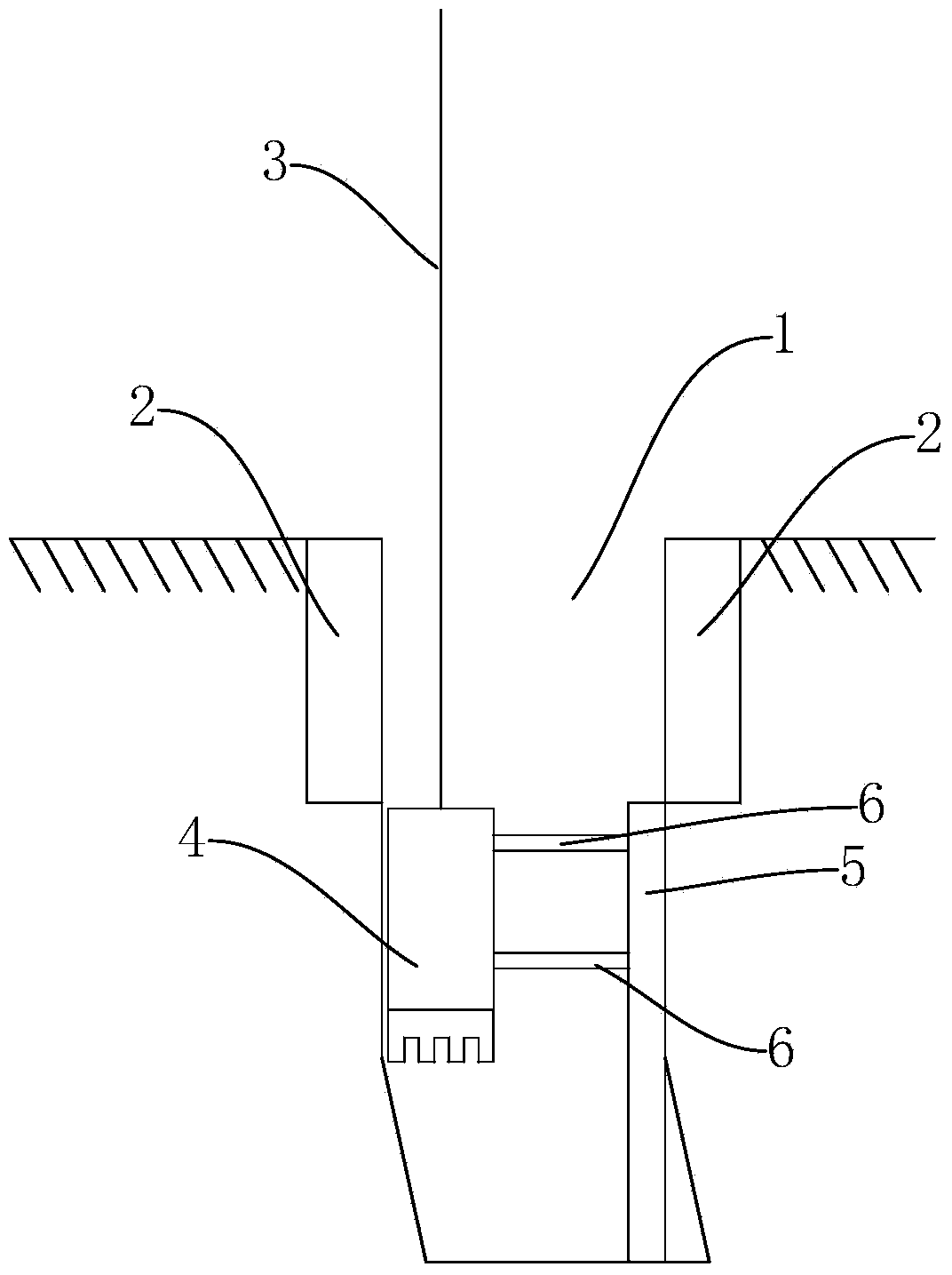

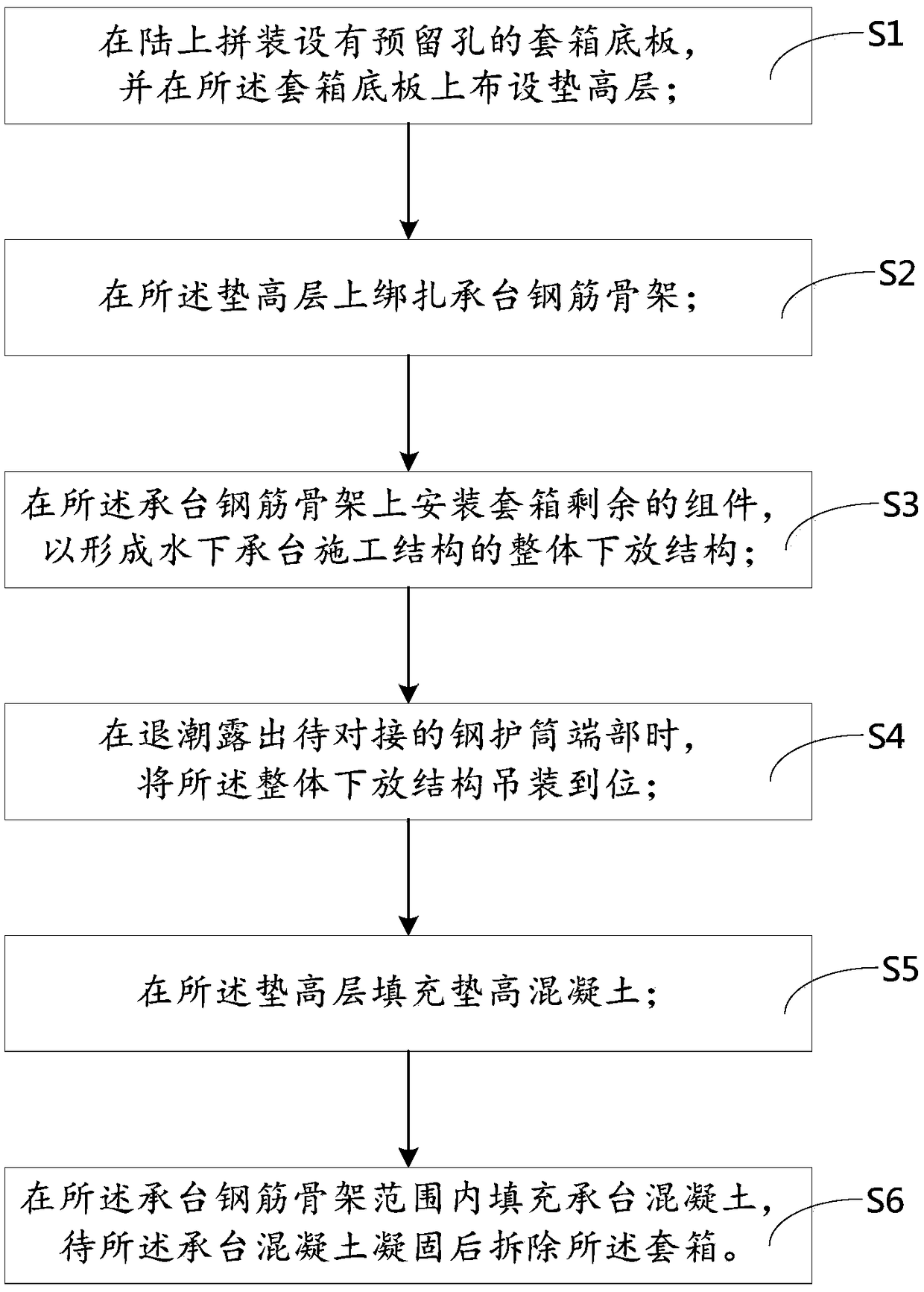

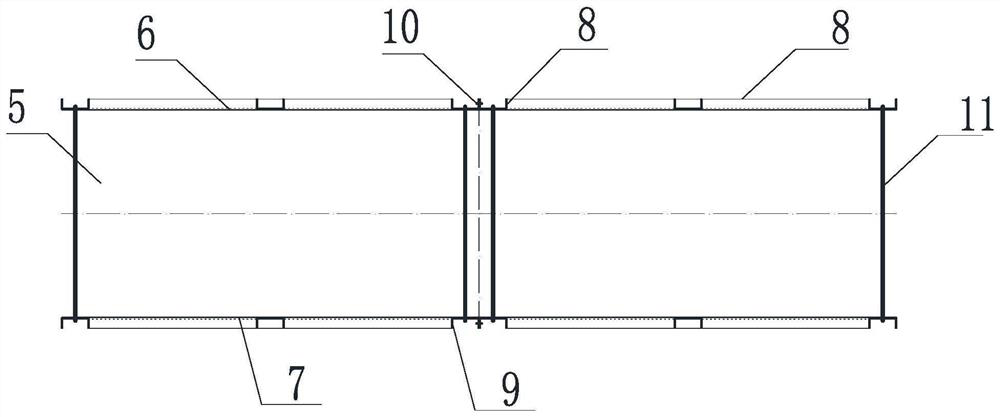

Constructing method of constructing structure of underwater bearing platform

The invention discloses a constructing method of a constructing structure of an underwater bearing platform. The method includes the steps that a pouring jacket bottom plate with reserved holes formedis assembled on land, and a blocking-up layer is arranged on the pouring jacket bottom plate; a bearing platform reinforcement cage is bound on the blocking-up layer; remaining assemblies of a pouring jacket are mounted on the bearing platform reinforcement cage so as to form a whole lowering structure of the constructing structure of the underwater bearing platform; when the end of a to-be-butted steel protecting barrel is exposed during tide falling, the whole lowering structure is lifted in place; blocking-up concrete is filled at the blocking-up layer; and bearing platform concrete is filled in the range of the bearing platform reinforcement cage, and after the bearing platform concrete is solidified, the pouring jacket is removed. According to the constructing method, by pre-assembling the whole lowering structure and lowering the whole lowering structure during tide falling, the hydrologic conditions can be effectively used for constructing, the construction period is shortened,structures like sealing concrete are saved, resources are saved, and costs are reduced; and the conflict problem between the bearing platform reinforcement cage and protecting barrel steel bars are avoided through the method of connecting the steel bars, and the fact that the lowering process is carried out smoothly is ensured.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

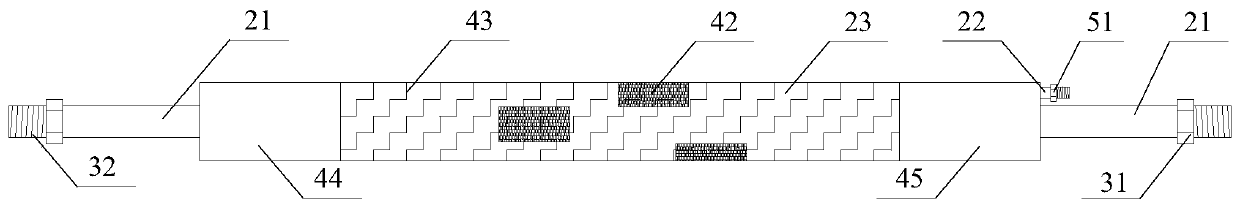

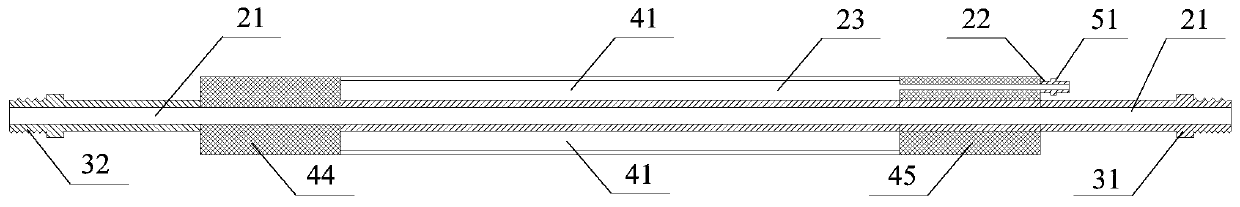

Electric ignition layered gas injection valve and layered electric ignition pipe column

ActiveCN108590577ADecentralization smoothlyLow costFluid removalWell/borehole valve arrangementsElectricityEngineering

The invention discloses an electric ignition layered gas injection valve and a layered electric ignition pipe column. The electric ignition layered gas injection valve comprises an outer pipe extending lengthwise, an inner pipe and a liner pipe. A first gas outlet hole is formed in the outer pipe; the inner pipe is slidably sleeved with the outer pipe, connected with the outer pipe through a shearpin, and a second gas outlet hole is formed in the inner pipe; the inner pipe is positioned on the first position where the second gas outlet hole and the first gas outlet hole communicate by the shear pin; the liner pipe is sleeved with the inner pipe; when the inner pipe is located on the first position, the liner pipe can drive the inner pipe to move to the second position under pushing of anelectric ignition device; and when the inner pipe is located on the second position, the second gas outlet hole does not communicate with the first gas outlet hole, and the liner pipe and the inner pipe are separated. According to the electric ignition layered gas injection valve and the layered electric ignition pipe column, a plurality of oil layers can be ignited in the fireflooding process.

Owner:PETROCHINA CO LTD

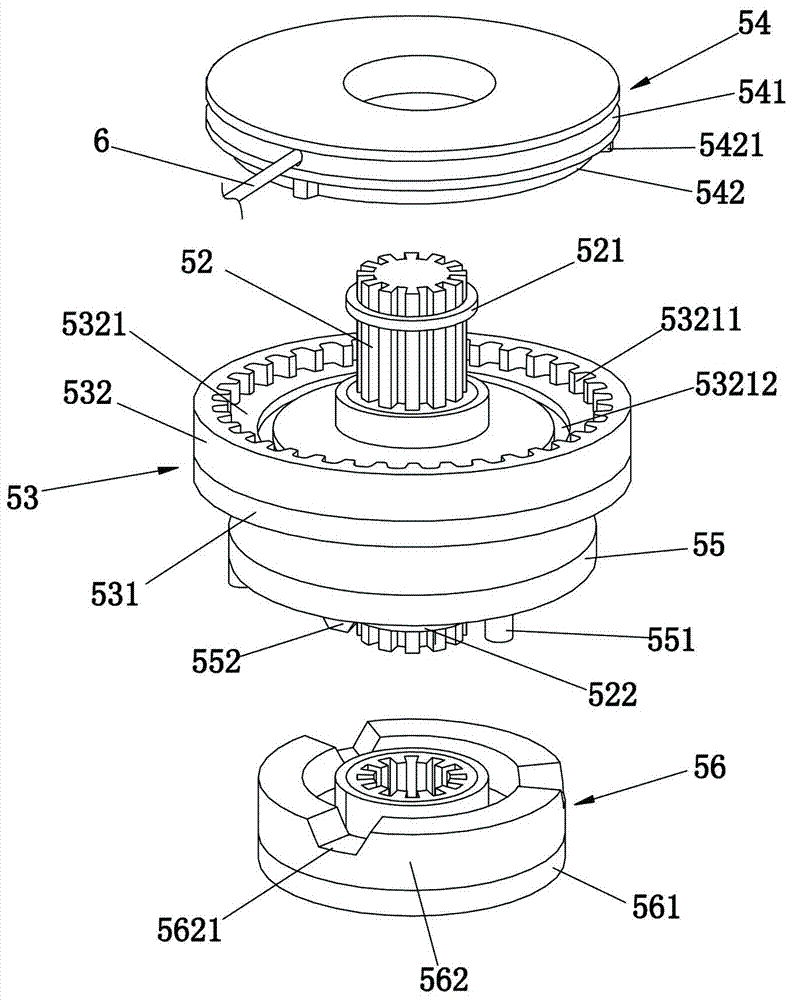

Work method of roller shutter door lock

ActiveCN105888523AEasy to operateNot easy to forgetDoor/window protective devicesNon-mechanical controlsCircular discMotor drive

Owner:蔡为达

Ultradeep underground continuous trenching construction method

InactiveCN109972679AShorten construction timeDecentralization smoothlyMechanical machines/dredgersBulkheads/pilesSlurry wallRebar

The invention discloses an ultradeep underground continuous trenching construction method. The ultradeep underground continuous trenching construction method is characterized in that during a trenching process, when the depth of a trench is smaller than 10 meters, the distance between a guide wall and a steel wire rope for hoisting a hydraulic grab is measured by utilizing a go-no-go gauge; if thedistance between the steel wire rope and the two sections of guide walls meets the measuring requirement of the go-no-go gauge, the perpendicularity meets requirements, and excavation is continued; and after the depth of the trench is larger than 10 meters, measurement is performed by adopting an ultrasonic gauge after a certain depth is excavated; and if the perpendicularity of a side wall meetsrequirements, excavation is continued. By adopting the ultradeep underground continuous trenching construction method, the final trenching perpendicularity of an underground continuous wall with a construction depth exceeding 60 meters can be controlled within 1 / 1000; an ultralong steel rib cage of which two ends are provided with I-steel connectors can be launched to a designed depth; and the construction time of ultradeep underground continuous walls is shortened.

Owner:SHANGHAI YUANFANG GROUNDWORK ENG

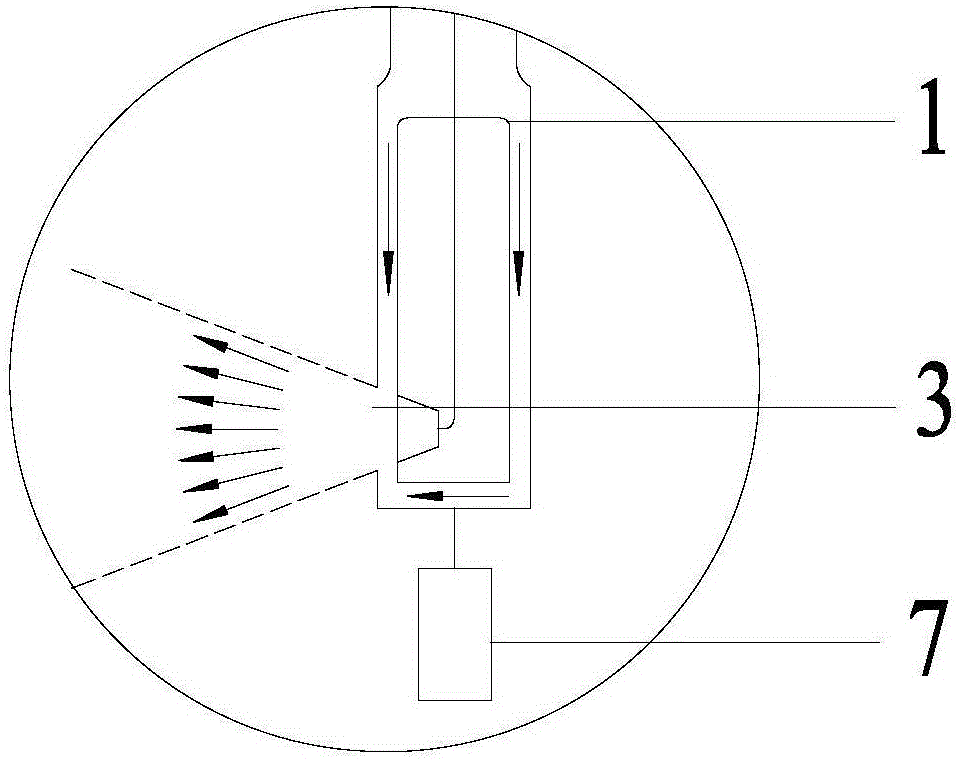

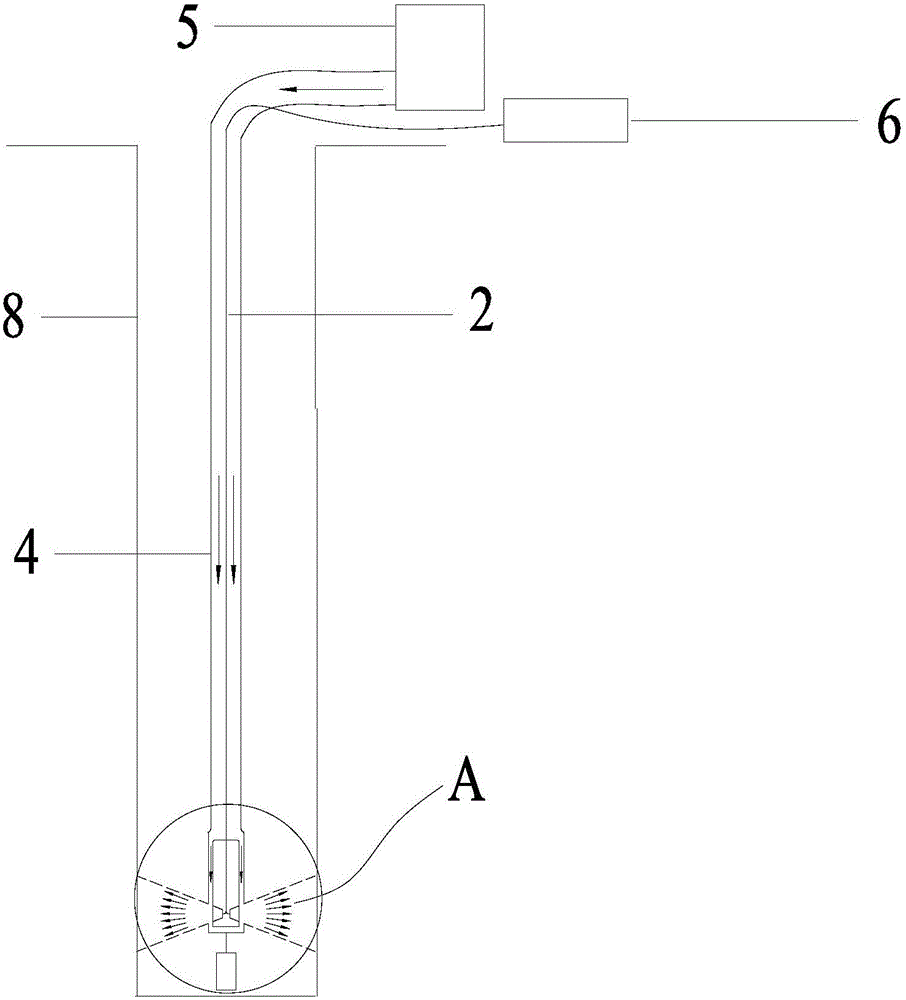

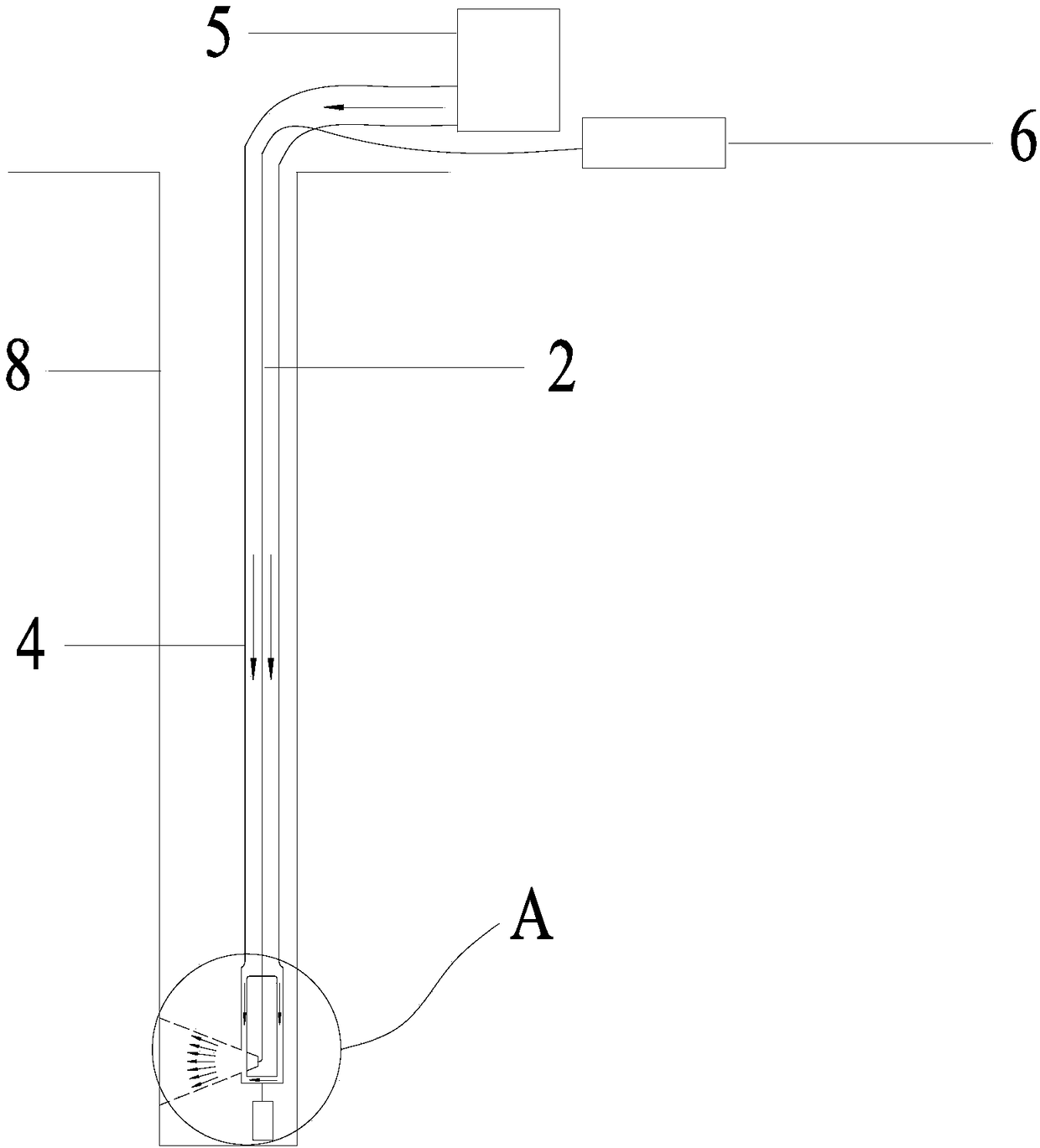

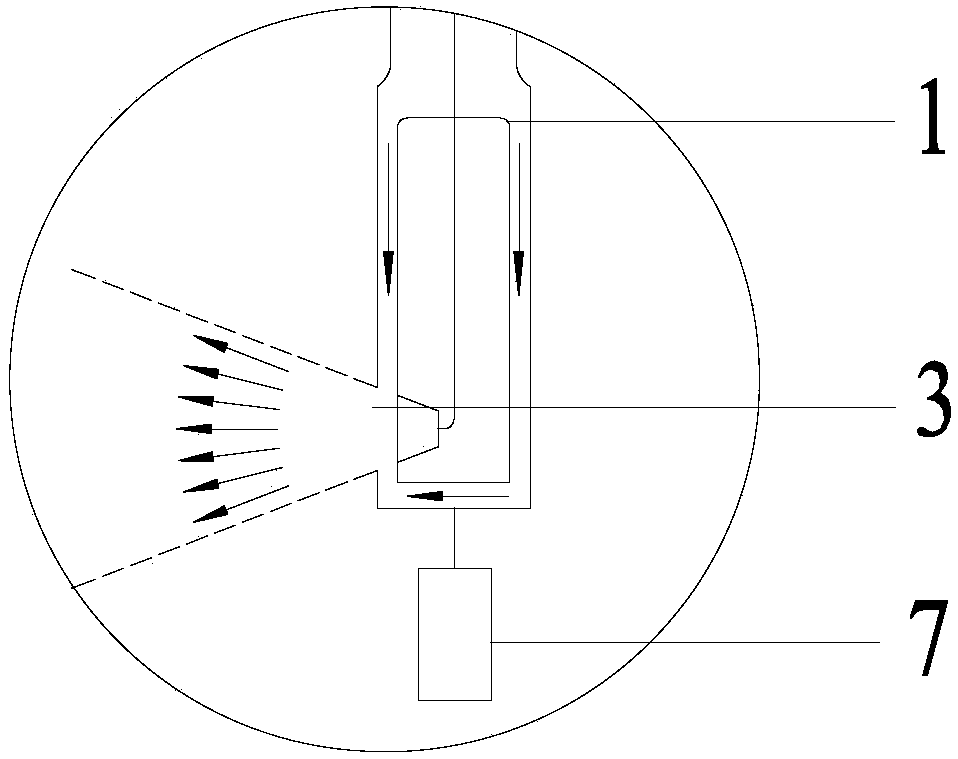

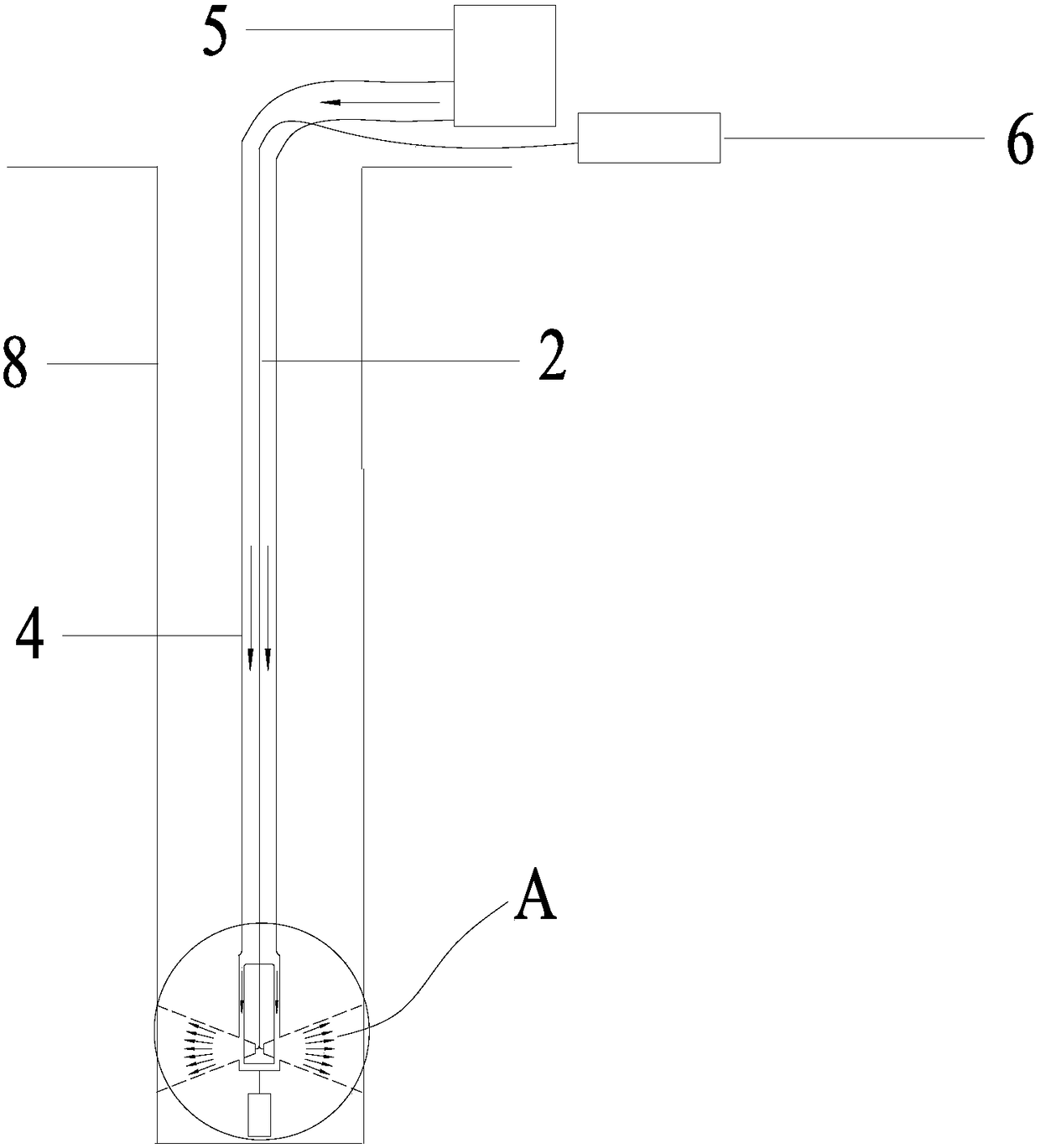

High temperature blast hole temperature measuring device and high temperature blast hole temperature measuring method

ActiveCN105784122AEvaluate the cooling effect of water injectionHigh speedRadiation pyrometryWater vaporAir pump

The invention discloses a high temperature blast hole temperature measuring device and a high temperature blast hole temperature measuring method. The device comprises an infrared temperature sensor, a cable, an air purge device, a heat-resisting pipe, an air pump, a display instrument and a weight. One end of the heat-resisting pipe is connected to the air pump and the other end is connected to the air purge device. The infrared temperature sensor is fixed in the air purge device. An infrared emission port position of the infrared temperature sensor corresponds to a purge port position of the air purge device. One end of the cable is connected to the display instrument and the other end passes through the heat-resisting pipe and then is connected to the infrared temperature sensor. The weight is fixed below the air purge device. In the invention, the infrared temperature sensor is used to increase temperature measurement response time; hole wall temperatures with different depths of a blast hole can be rapidly scanned and measured; through the air pump, air is continuously filled in the heat-resisting pipe so as to cool the cable and the infrared temperature sensor; and through the air purge device, dust or water vapor in the blast hole can be blown away and then the hole wall temperatures of the blast hole can be measured.

Owner:HONGDA MINING IND

Rectangular cast-in-place pile slotting combined drilling rig

InactiveCN102493762AGood pile typeGood effectEarth drilling toolsDrill bitsDrill bitStructural engineering

The invention discloses a rectangular cats-in-place pile slotting combined drilling rig. The drilling rig comprises an under water rig, a cage type combined drill which is arranged at the lower end of the under water rig, and a spray guide pipe which is arranged on one side of the under water rig; the spray guide pipe is connected with a rack; and the upper end of the under water rig is connected with the rack through a steel rope. According to the drilling rig, the cage type combined drill cuts a soil body from top to bottom, holes are formed primarily by using slot correction devices of the fixed under water rig, and the all-section overlapped slot position correction is performed by using a special rectangular section smasher, so the hole forming of a rectangular cast-in-place pile is finished well. A reinforcement cage can be placed smoothly, a section is excavated after construction, and a pile has a good shape. A spray guide pipe process air lift reverse circulation deslagging method is adopted, and an obvious deslagging effect and a slurry changing effect are achieved; and pile verticality is 1 / 300 required by the design.

Owner:CHINA STATE CONSTR HARBOR CONSTR

Radiation hole guide drilling equipment and process

ActiveCN106639876AImprove drilling accuracyMaintain stabilityDrilling rodsConstructionsDouble tubeDrilling machines

The invention discloses radiation hole guide drilling equipment and process. The radiation hole guide drilling equipment comprises a guide instrument, a guide drilling machine and double-layer drill rod. The guide drilling machine is provided with a double rotary power head. The double-layer drill rod comprises an outer drill rod on the outer layer and an inner drill rod on the inner layer. The outer drill rod and the inner drill rod are connected with two power output connectors of the double rotary power head correspondingly. The radiation hole guide drilling equipment further comprises a double pipe guide joint and a guide drill bit. The double pipe guide joint comprises an outer pipe and an inner pipe. One end of the outer pipe is connected with the outer drill rod. One end of the inner pipe is connected with the inner drill rod. The outer pipe is provided with a probe bin internally provided with a probe communicating with the guide instrument. The guide drill bit is connected to the other end of the inner pipe. According to the drilling process conducted through the radiation hole guide drilling equipment, deflecting is conducted through the outer drill rod in the double-layer drill rod during drilling, drilling is conducted through the inner drill rod, and the drilling precision is high. Reverse circulation drilling is conducted through the double-layer drill rod, thus the space between the outer drill rod and the hole wall is filled with under-pressure drilling fluid, and the stability of the sandy gravel well wall can be maintained effectively.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +4

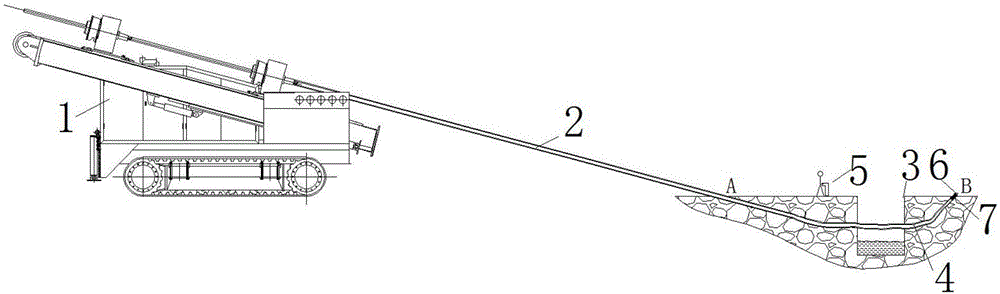

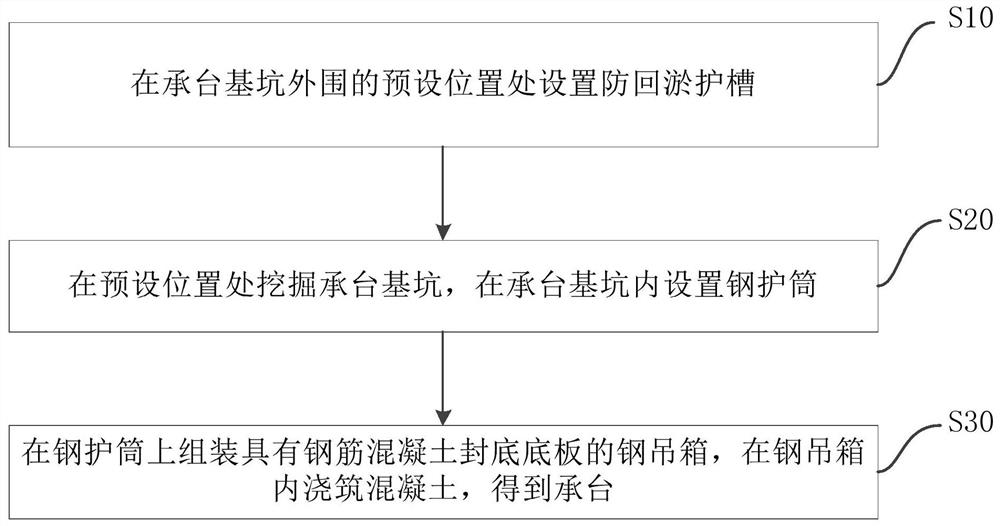

Construction method and cofferdam structure of underwater bearing platform

PendingCN111894025AMeet the construction spaceAnti-siltingFoundation engineeringReinforced concreteCofferdam

The invention relates to a construction method and cofferdam structure of an underwater bearing platform. The construction method comprises the steps that an anti-back-silting protection groove is formed in a preset position of the periphery of a foundation pit of the bearing platform; the foundation pit of the bearing platform is excavated at a preset position, and a steel casing is arranged in the foundation pit; and a steel hanging box with a reinforced concrete bottom sealing bottom plate is assembled on the steel casing, concrete is poured into the steel hanging box, and the bearing platform is obtained. The anti-back-silting protection groove is formed in the periphery of the foundation pit so that the situation that back silting of a riverbed occurs after the foundation pit of the bearing platform is excavated in place can be prevented; silt in the anti-back-silting protection groove is cleared away regularly so that the depth of the foundation pit can meet the requirement of aconstruction space of the steel hanging box; and in the rising and falling tide process, the flow plastic slit flows back to the anti-back-silting protection groove firstly in the flow plastic slit backflow process, and the silt in the anti-back-silting protection groove is cleared away regularly, so that the silt is prevented from flowing back into the foundation pit, therefore the space requirement for constructing a pouring jacket in the foundation pit is met, and it is guaranteed that the pouring jacket can be constructed smoothly.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD

Grout injector

PendingCN110055969ADecentralization smoothlyIncrease frictionFoundation engineeringHigh pressureGrout

The invention provides a grout injector. The grout injector comprises a penetrating steel pipe, a gas feeding pipe and an elastic sleeve pipe; a grout injecting connector is arranged at the upper endof the penetrating steel pipe, and a high-pressure nozzle connector used for being connected with a high-pressure nozzle is arranged at the lower end of the penetrating steel pipe; the elastic sleevepipe is arranged on the outer side of the penetrating steel pipe in a sleeving mode, and the lower end of the elastic sleeve pipe is fixed to the penetrating steel pipe; a gas hollow cavity is formedin the middle of the elastic sleeve pipe; anti-sliding patches are arranged on the outer side of the elastic sleeve pipe; and the gas feeding pipe is arranged at the upper end of the elastic sleeve pipe, a gas feeding connector is arranged at the upper end of the gas feeding pipe, and the gas hollow cavity of the elastic sleeve pipe is connected with the lower end of the gas feeding pipe. The grout injector can be applied to improve the grout injecting effect of the grout injector.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

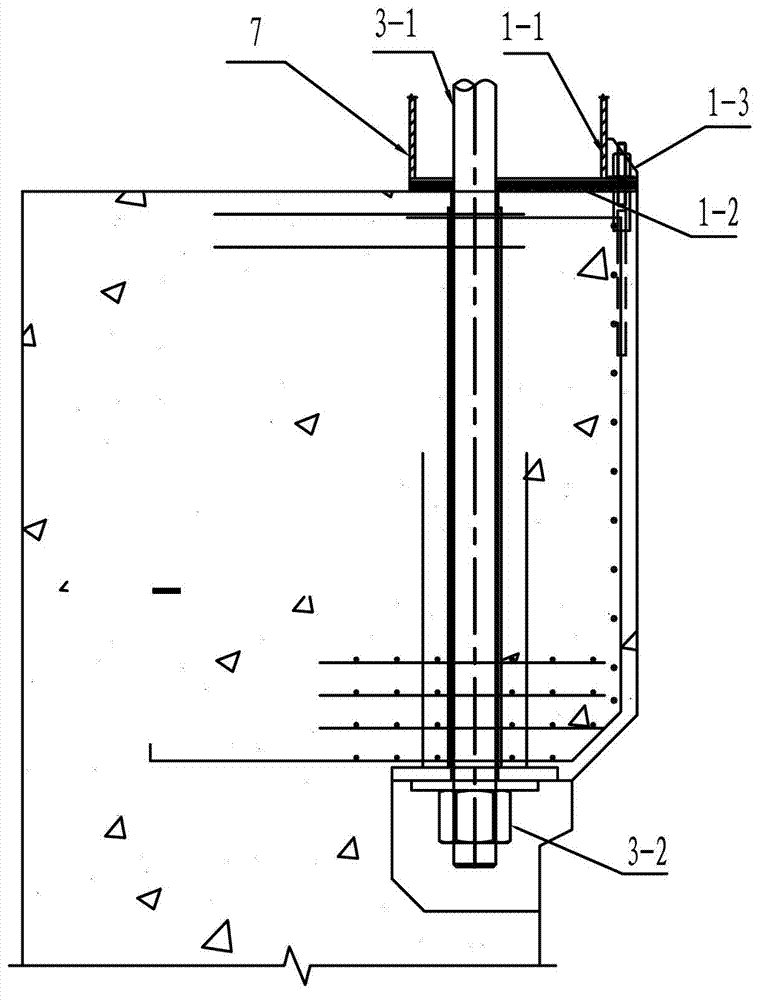

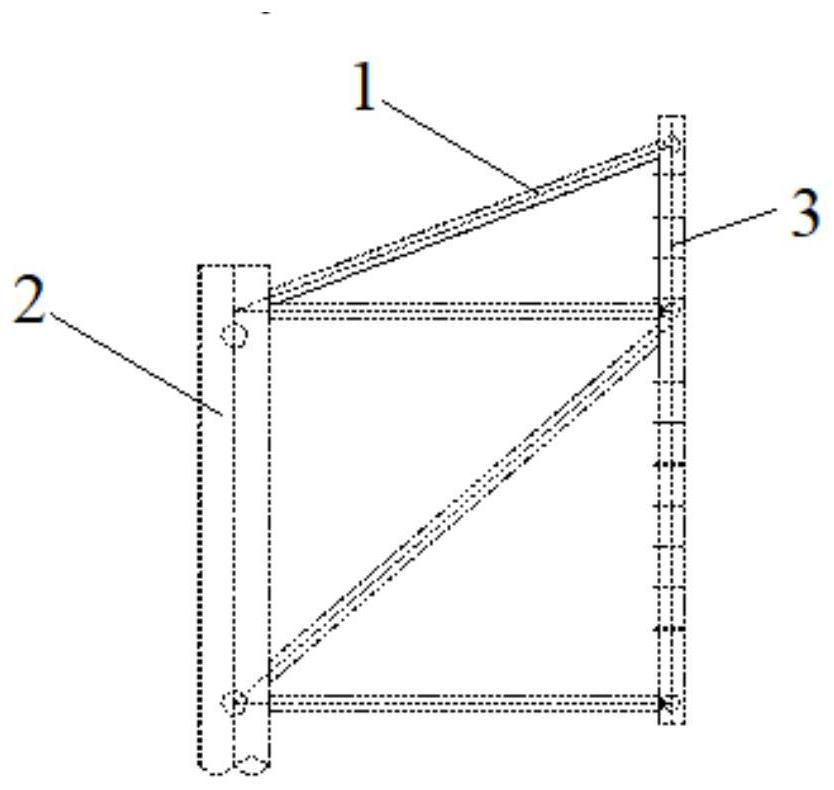

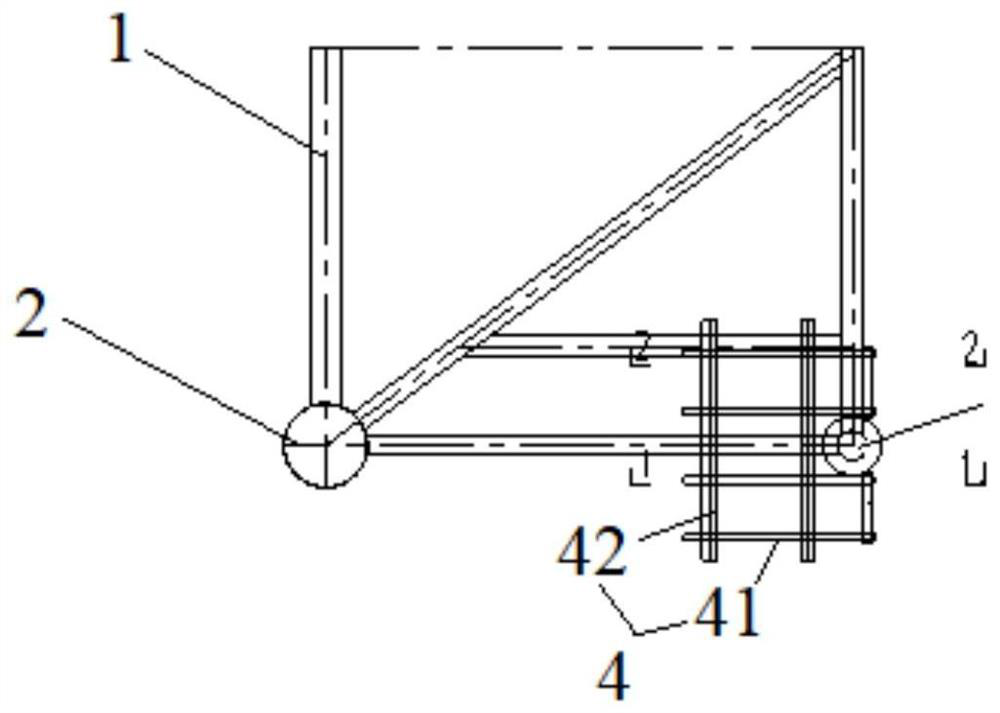

Building pile foundation positioning device

The invention relates to a building pile foundation positioning device which comprises a bottom plate and a through hole which is formed in the bottom plate and allows a pile casing and a reinforcement cage to penetrate through, the bottom plate is fixed to the ground through a plurality of first bolts, and the building pile foundation positioning device is characterized in that a surrounding plate surrounding the through hole is arranged on the bottom plate, and a positioning mechanism is arranged in the surrounding plate; a plurality of guiding and positioning steel pipes are movably arranged on the pile casing, and the inner sides of the guiding and positioning steel pipes can abut against the outer wall of the reinforcement cage. According to the building pile foundation positioning device, positioning is more accurate in the lowering process of the pile casing and the reinforcement cage.

Owner:WENZHOU POLYTECHNIC

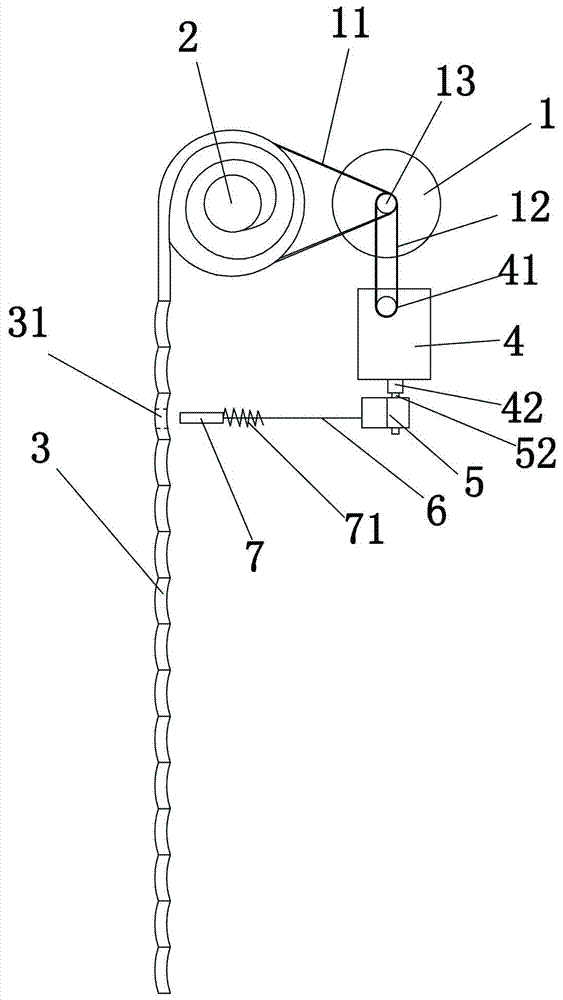

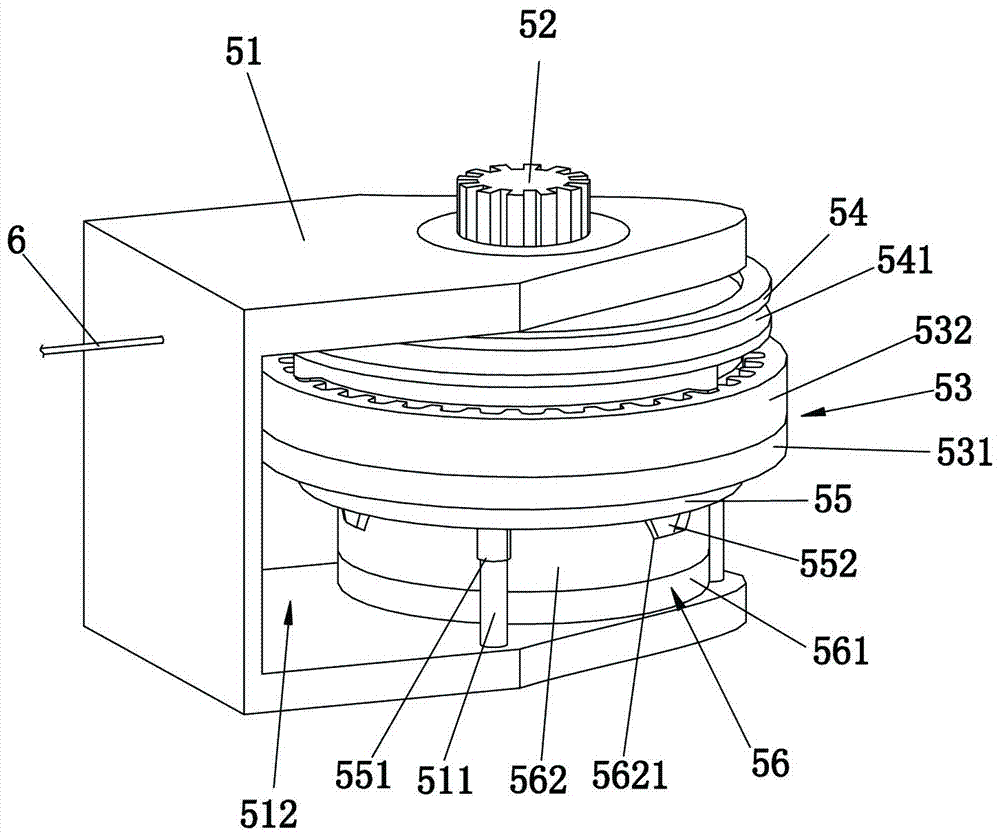

Door lock of roller shutter door and working principle of door lock

ActiveCN105201301AEasy to operateNot easy to forgetDoor/window protective devicesNon-mechanical controlsMotor drivePulp and paper industry

The invention discloses a door lock of a roller shutter door and a working principle of the door lock and relates to the technical field of roller shutter doors. The door lock of the roller shutter door comprises a lock cylinder, a spring, a pull cord, a separation and reunion device and a motor, wherein the spring drives the lock cylinder to move toward the roller shutter door and locks the roller shutter door, one end of the pull cord is connected with the lock cylinder, and the other end of the pull cord is connected with the separation and reunion device; the motor drives the separation and reunion device to roll up the pull cord, so that the lock cylinder is separated from the roller shutter door and unlocks the roller shutter door; after the motor stops, the spring stretches the pull cord which is rolled by the separation and reunion device, and the lock cylinder is driven to move toward the roller shutter door and lock the roller shutter door. The door lock has the advantages that no additional operation is needed for unlocking or locking the roller shutter door, the roller shutter door only needs to be ascended or descended normally, the roller shutter door unlocking or locking operation can be completed automatically through the door lock of the roller shutter door, operation is simple, and the antitheft effect is good.

Owner:蔡为达

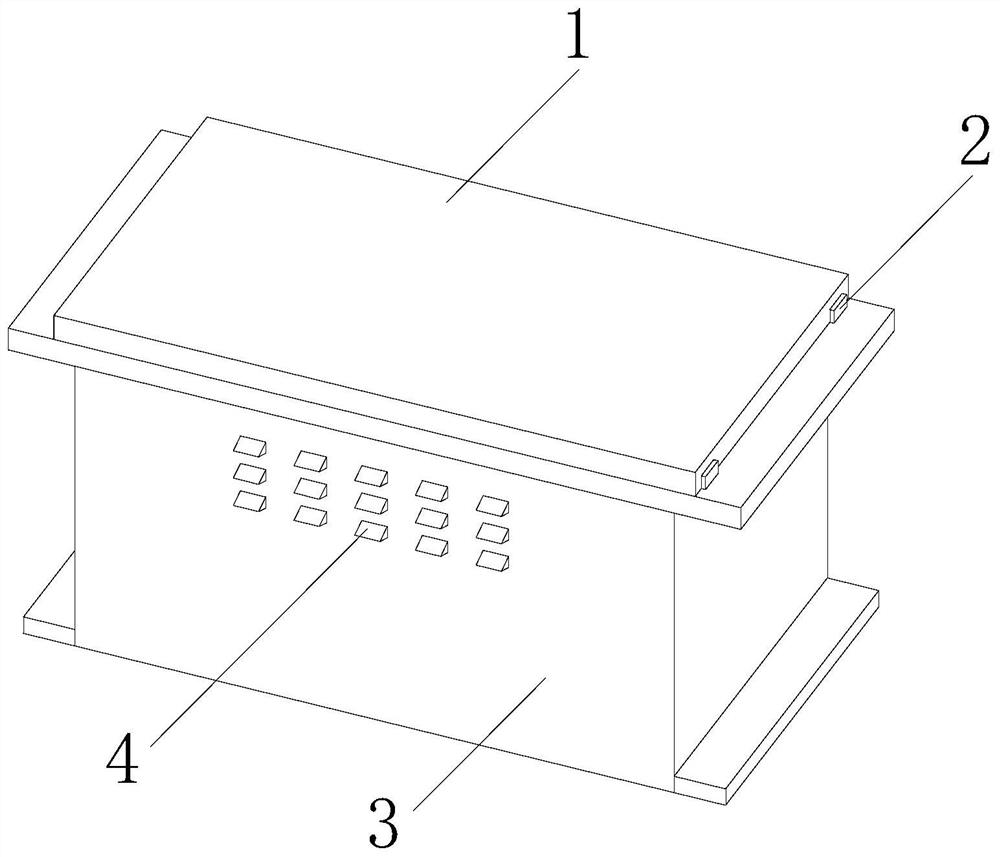

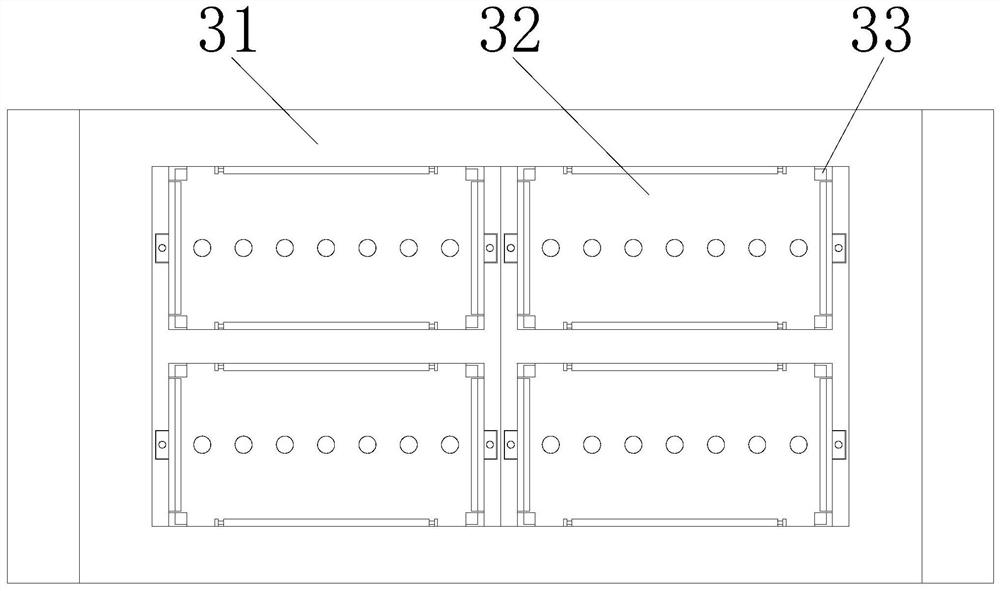

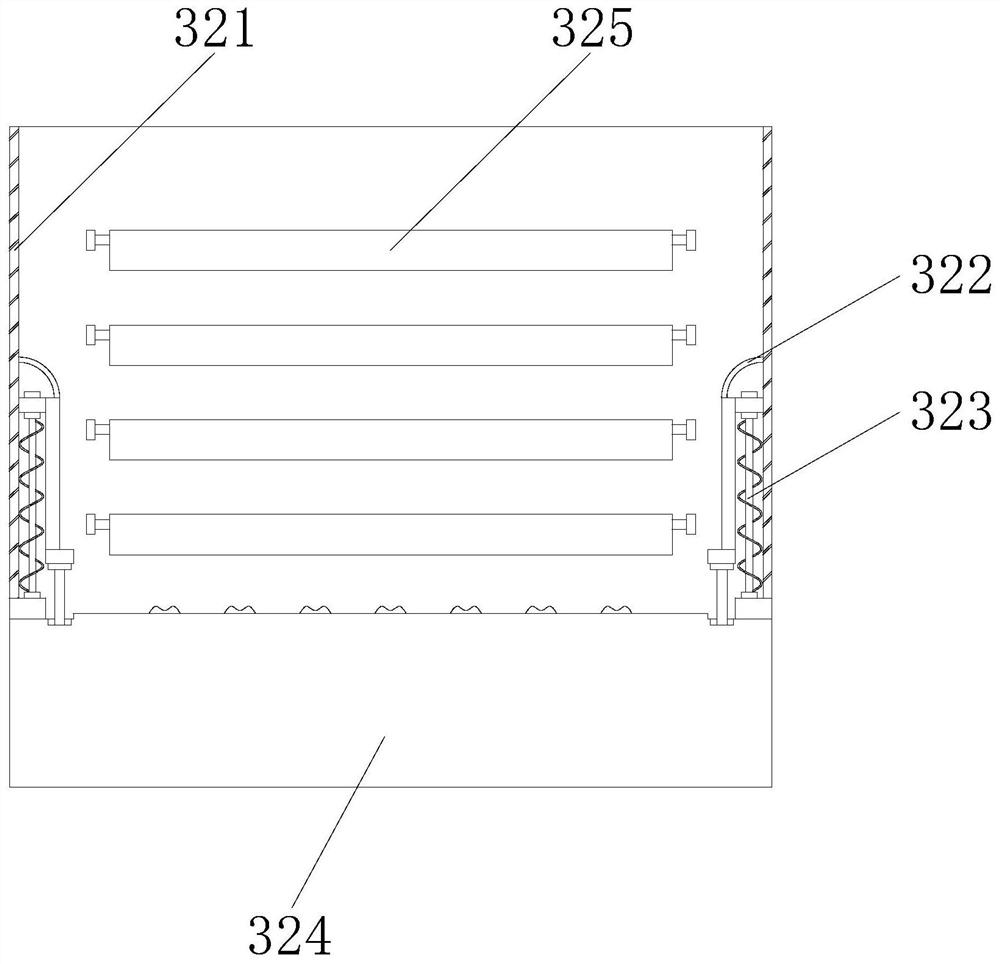

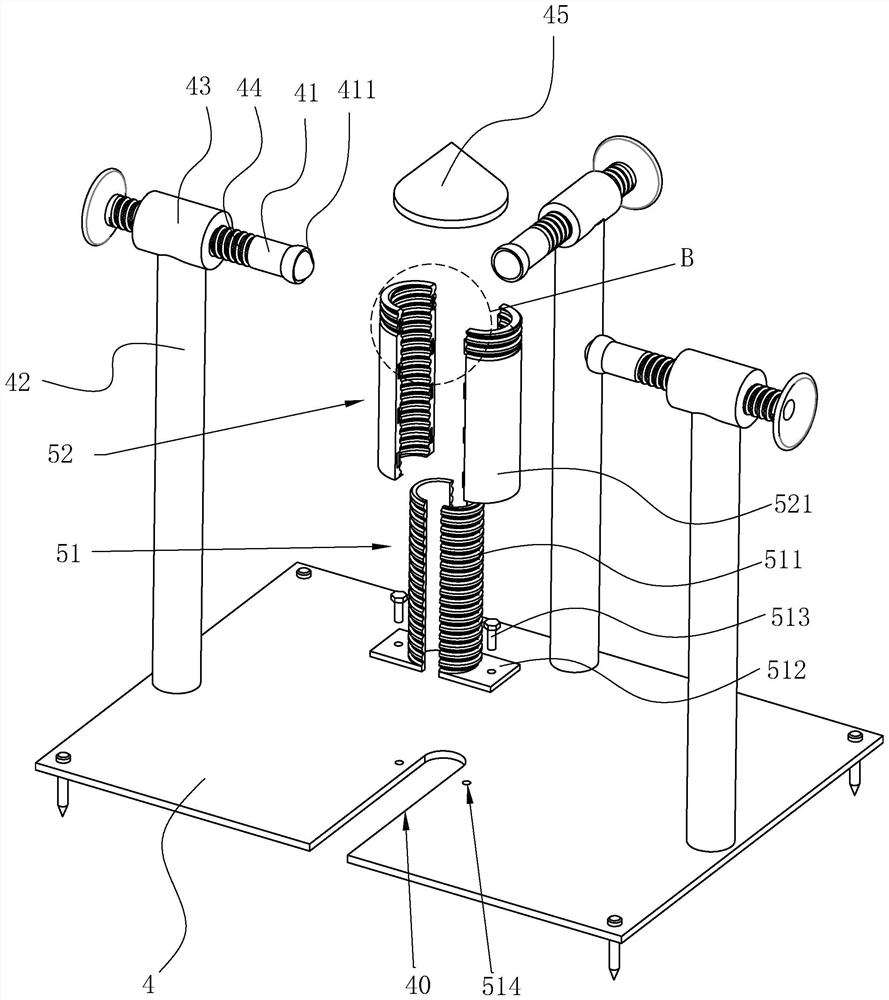

Capacitor element protection box

InactiveCN112863865ADecentralization smoothlyAvoid shakingNon-rotating vibration suppressionCapacitorsClassical mechanicsMechanical engineering

The invention discloses a capacitor element protection box which structurally comprises a top cover, a sliding rod, a placement box and heat dissipation holes, the lower end of the top cover is in sliding connection with the sliding rod, the sliding rod is fixedly installed at the top of the placement box, a square capacitor abuts against a bottom supporting plate, meanwhile, a swing plate swings in an arc shape, it is ensured that the square capacitor is smoother when the square capacitor is lowered, and the square capacitor is prevented from colliding with the inside of a placing groove; a downward pressing rod is pressed downwards in a conduction air pipe, an air thin film is bulged under air pressure, the bulged air thin film buffers and supports the bottom of the square capacitor which is put down, and the surfaces of the two sides of the right-angle end of the square capacitor abut against rubber blocks; and then the bottom of the right-angle end of the square capacitor presses a lower pressing plate, at the moment, a linkage plate drives a sliding block at the lower end to slide stably on a guide rod, buffering is conducted through a compression spring, the effect of buffering and supporting the bottom of the right-angle end of the square capacitor is achieved, and shaking and collision of the bottom of the right-angle end of the square capacitor are avoided.

Owner:乐志胜

Installation method of prefabricated platform

ActiveCN103362068BSmall construction impactImprove construction stabilityFoundation engineeringBridge erection/assemblyWater flowCofferdam

The invention discloses a prefabricated bearing platform mounting method and relates to the field of bridge construction. The prefabricated bearing platform mounting method comprises the following steps that a bearing platform and bottom pier bodies are prefabricated in a prefabrication field, and steel pile hole positions are reserved in the bearing platform; the bearing platform is lifted to a pile site by a large floating crane; a pile top guiding device is pre-mounted on steel piles in the pile site before the bearing platform is lifted; after the bearing platform is lifted down and is in place, a carrying pole is arranged on a pile top longitudinal direction adjusting position in a hanging manner, and the horizontal plane of the bearing platform is regulated as required; and the pouring of bottom-sealing concrete of a steel cylinder cofferdam, the water pumping, the binding of reserved hole steel reinforcing bars, and the pouring of reserved hole concrete at non-lifting points and lifting points are sequentially finished, and the steel cylinder cofferdam is detached, so that the mounting of the prefabricated bearing platform is finished. According to the prefabricated bearing platform mounting method disclosed by the invention, a small steel cylinder cofferdam replaces a large bearing platform steel cofferdam, so that the steel material can be effectively saved, the on-water operation time is shortened, and the construction cost is reduced; and meanwhile, the influence of water flow to the construction of the bearing platform is reduced, and the construction quality of the bearing platform is ensured.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Electric ignition stratified gas injection valve and stratified electric ignition string

ActiveCN108590577BDecentralization smoothlyLow costFluid removalWell/borehole valve arrangementsEngineeringElectric ignition

Owner:PETROCHINA CO LTD

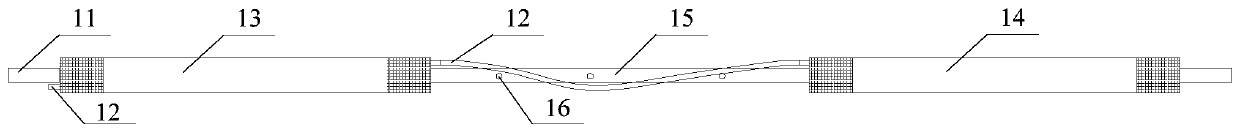

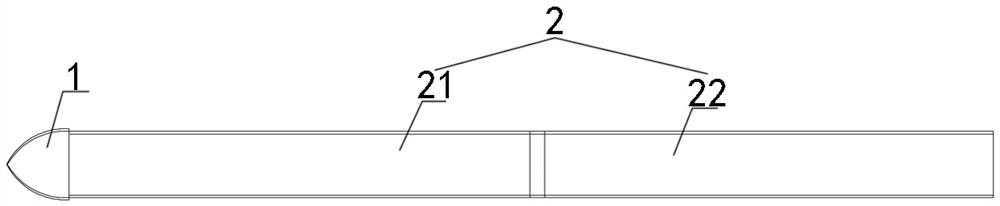

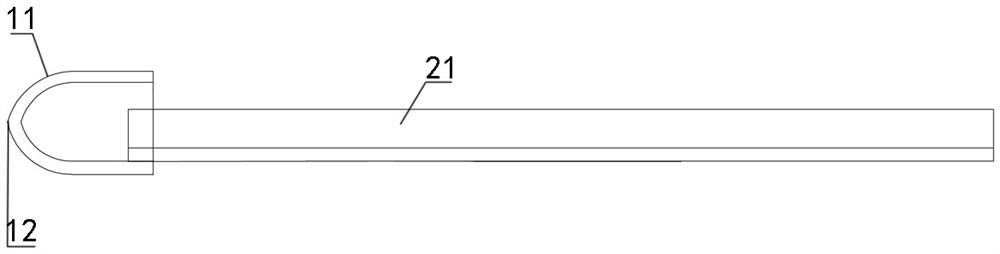

A method of using an ultra-long anchor cable chute

ActiveCN109898509BReduce collisionAvoid enteringBulkheads/pilesArchitectural engineeringEconomic benefits

The invention discloses a super-long anchor cable sliding groove and a use method thereof. The super-long anchor cable sliding groove comprises an end cap and sliding groove sections, wherein the endcap and the sliding groove sections are successively connected from front to back, the sliding groove sections comprise a first section and one or more standard sections, the front end of the first section and the rear end of the end cap are connected through a detachable connecting structure, the sliding groove sections are connected end to end to be lengthened, and the head end of the rear sliding groove section and the tail end of the preceding sliding groove section are detachably connected through a connecting assembly. The super-long anchor cable sliding groove is especially for super-long anchor cables, a lengthening mode which is easy in operation, quick in lengthening, convenient to stack, and capable of being recycled advantageously is adopted by connection between parts of the sliding groove, the designed anchorage length and required pulling resistance of a super-long anchor cable are guaranteed, the anchor cable construction quality is guaranteed, the super-long anchor cable sliding groove can be recycled and reused, energy conservation and environment protection are achieved, and the good economic benefits are achieved.

Owner:CHINA CONSTR FIRST GRP THE SECOND CONSTR +1

A rolling shutter door lock and its working method

ActiveCN105201300BEasy to operateNot easy to forgetDoor/window protective devicesNon-mechanical controlsRolling shutterClutch

The invention discloses a rolling door lock and a working method thereof, and relates to the technical field of rolling doors. The rolling door lock includes a lock core, a spring for moving the lock core toward the rolling door and locking the rolling door, a cable, a clutch device and a motor. One end of the cable is connected to the lock cylinder, and the other end is connected to the clutch device; the motor drives the clutch device to rewind the cable, so that the lock cylinder is separated from the rolling door and unlocks the rolling door; after the motor stops, the spring is stretched by the clutch device. Pull the cable to move the lock cylinder towards the shutter door and lock the shutter door. Beneficial effects of the present invention: unlocking or locking the rolling door does not require additional operations, and the operation of unlocking or locking the rolling door can be completed by itself only by raising and lowering the rolling door and the rolling door lock, which has the characteristics of simple operation and good anti-theft effect.

Owner:蔡为达

A controllable bidirectional pulp stop device for sleeve valve tube

ActiveCN113684831BTo achieve the anti-slurry effectNo stuck tubeSoil preservationSleeve valveEngineering

The invention discloses a controllable two-way slurry stop device for a sleeve valve tube, comprising a round table metal slider, a polyurethane slurry stop plug, a ring-shaped suction cup electromagnet, a limit stop and a reset spring group. When the iron is energized, under the action of electromagnetic force, the round table metal slider is sucked to the ring-shaped suction cup electromagnet, thereby squeezing the polyurethane slurry stopper to force its cantilever to deform, wedging the sleeve valve tube, and at the same time, the return spring group is elongated; When the ring-shaped suction cup electromagnet is powered off, the metal block of the circular table rebounds, and the return spring group recovers its deformation, which assists the metal block of the circular table to be disengaged from the polyurethane slurry stopper, so that the slurry stopper recovers its deformation and is connected with the sleeve valve tube. wall detachment. The grouting device of the present application can be manually controlled to open and close, thereby ensuring the smooth lowering and lifting of the grouting device, improving the grouting efficiency and the stability of the grouting effect.

Owner:THE THIRD ENG CO LTD OF CHINA RAILWAY SEVENTH GRP +3

A cage connection device suitable for sand control or well wall support in fishbone branch wells and its application method

ActiveCN111535746BReduce field work timeDecentralization smoothlyFluid removalDirectional drillingStructural engineeringControl theory

The invention discloses a cage connection device suitable for sand control or well wall support of fishbone branch wells and its application method. The structure of the cage connection device is as follows: the boom passing through the drill bit is fixed on the suspension ring; the two sides of the lower end of the boom passing through the drill bit are respectively provided with rod bodies; the top end surface of the suspension joint forms a number of grooves I, and each groove I Blind hole Ⅰ and blind hole Ⅱ are respectively provided on the two inner walls of the shaft. The inner diameter of blind hole Ⅰ and blind hole Ⅱ is slightly larger than the outer diameter of the rod body, and the depth of blind hole Ⅱ is greater than that of blind hole Ⅰ; ;By the cooperation between the rod body and the blind hole I and blind hole II, the connection between the boom of the drill bit and the suspension joint is realized; when the spring is compressed, the rod body can escape from the blind hole I; the lower part of the suspension joint is connected to the easy-drilling pipe . All the components of the cage connection device of the present invention are composed of easy-to-drill materials. On the premise that the strength meets the requirements for safely hanging the sand control pipe string, the screen pipe can be easily released after it is put in place, and can be quickly drilled through and broken by the PDC drill bit to continue drilling.

Owner:CHINA NAT OFFSHORE OIL CORP +1

A high-temperature blasthole temperature measuring device and a high-temperature blasthole temperature measurement method

ActiveCN105784122BEvaluate the cooling effect of water injectionHigh speedRadiation pyrometryWater vaporDisplay device

Owner:HONGDA MINING IND

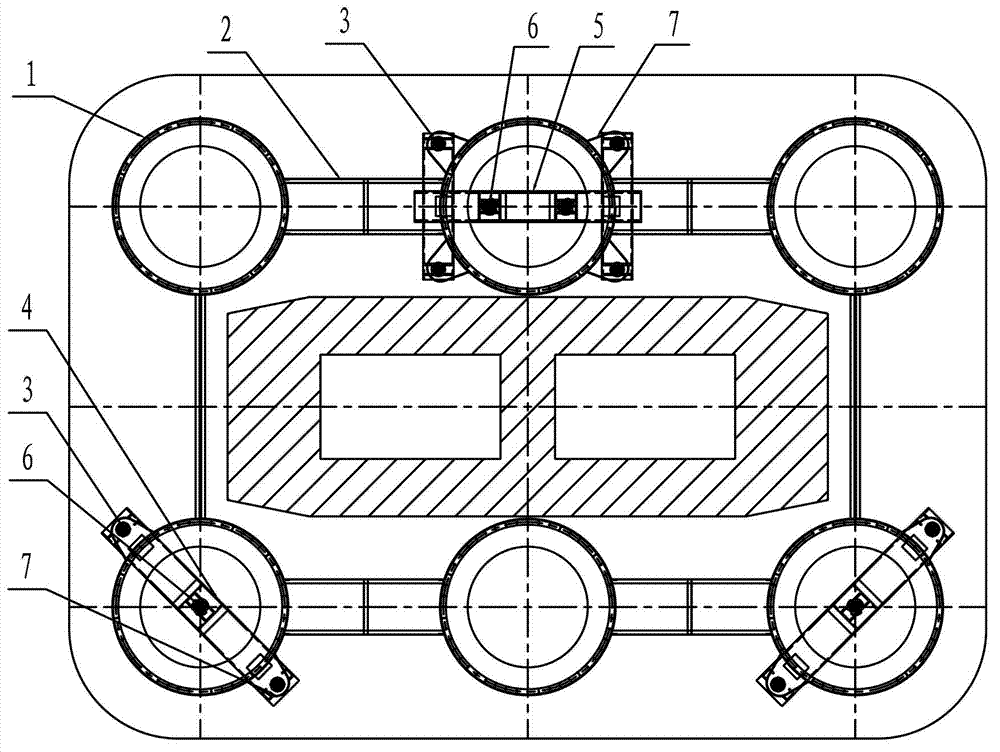

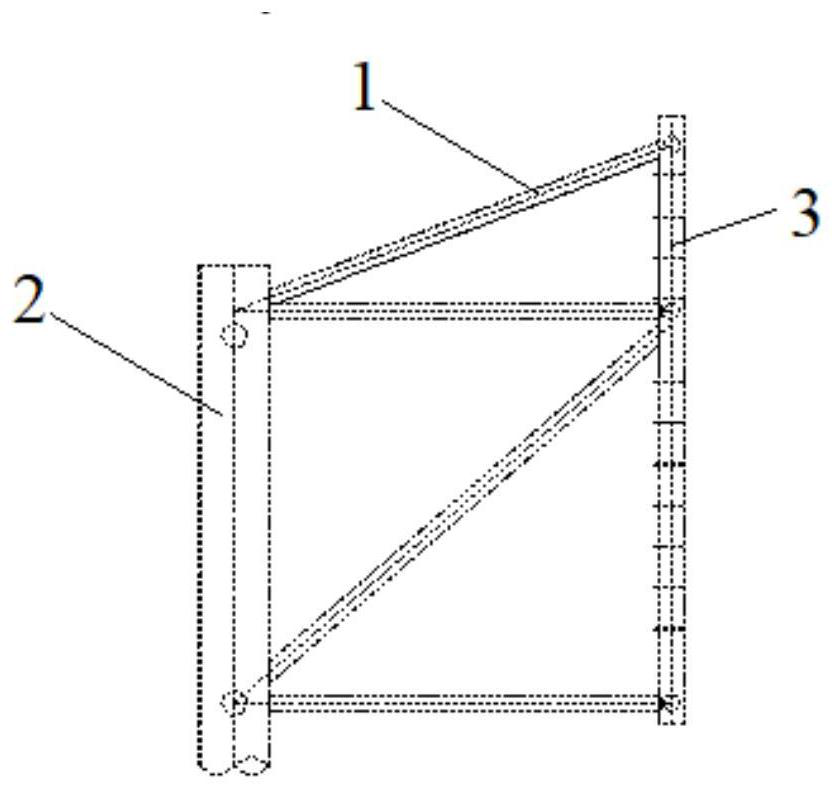

Jacket positioning device

ActiveCN113026750AAvoid collisionDecentralization smoothlyBulkheads/pilesStructural engineeringMechanical engineering

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Low specific gravity high performance wall retaining mud material for medium and long horizontal freezing drilling in silty clay and preparation method

The invention discloses a low-specific-gravity high-performance wall protection mud material for long horizontal freezing drilling in silty clay and a preparation method. The mud material is composed of basic components and externally mixed components. The control index of the mud material is: the water loss of the mud <15mL, mud specific gravity <1.05, mud viscosity 20s~50s. The preparation method comprises the following steps: (1) determining the control index, (2) screening the basic formula, (3) testing and testing, (4) orthogonal testing, (5) testing and checking, (6) determining the basic component and the externally mixed group The distribution ratio. The wall protection mud material of the present invention forms a mud cake at the interface between soft and hard formations, which well supports the stability of the borehole wall, and controls the offset of the interface between soft and hard formations to keep it within 3‰. After the drill pipe is pulled out, the mud, mud cake, air and the borehole form an underpressure balance system in the borehole. This balance system can maintain stability for a long time, maintaining the stability of the borehole for more than 9 hours, and realizing the smooth release of the frozen pipe.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

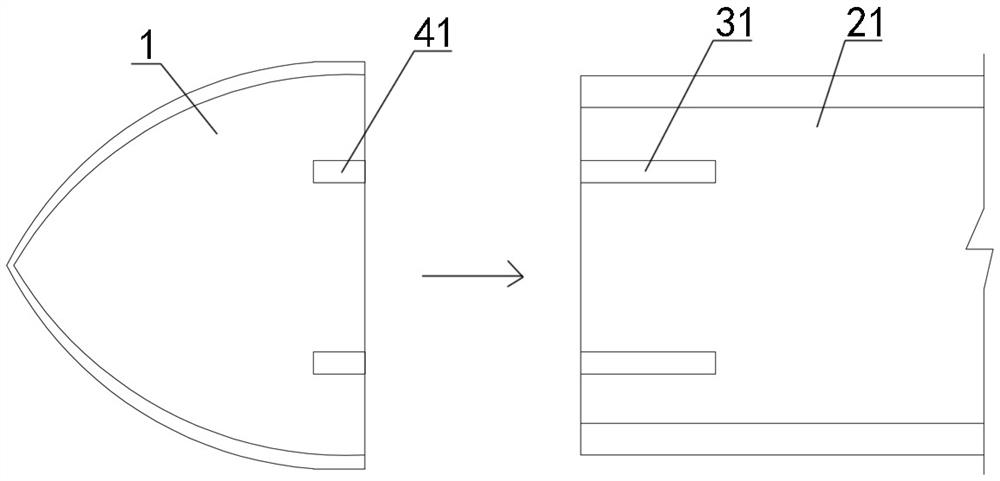

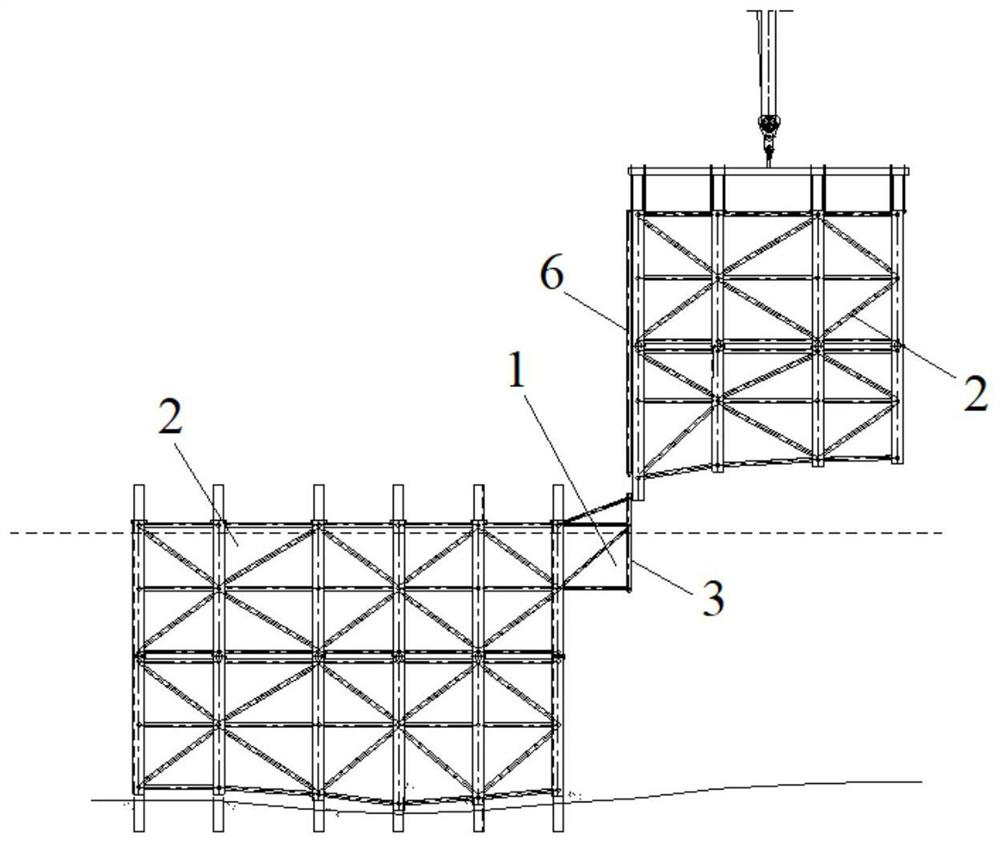

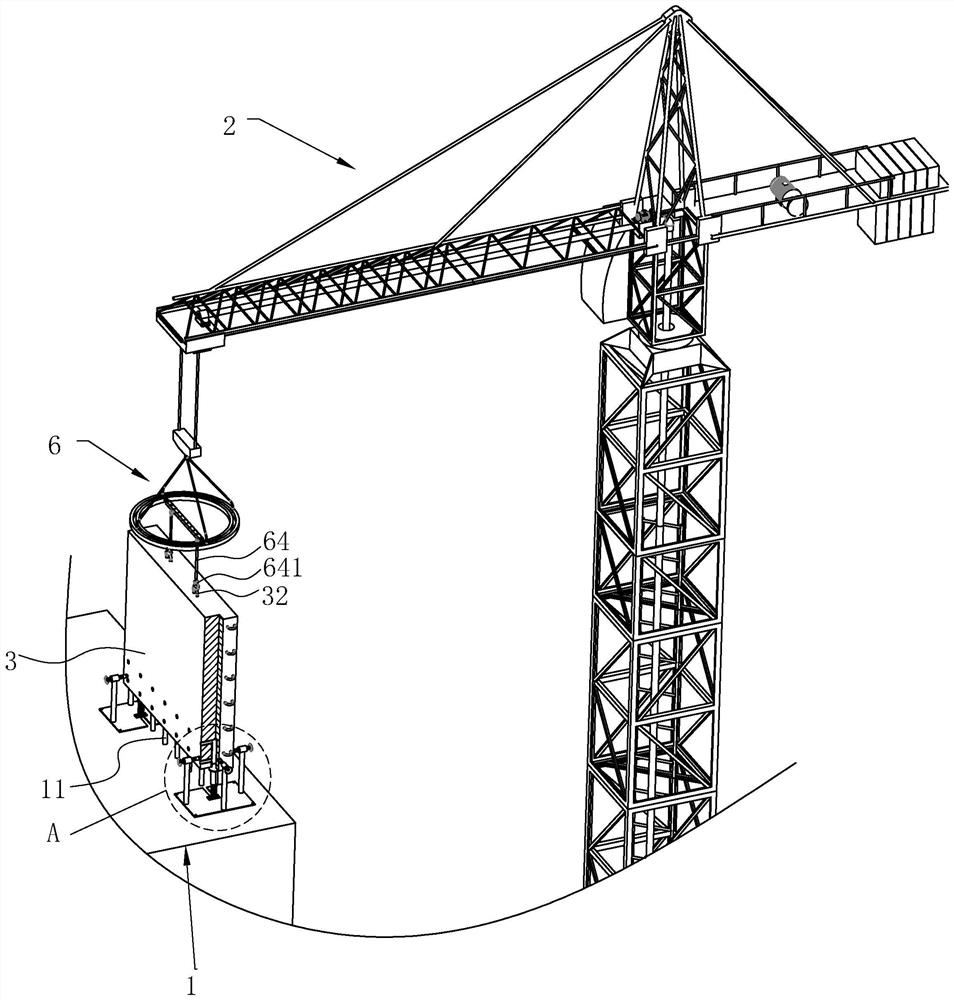

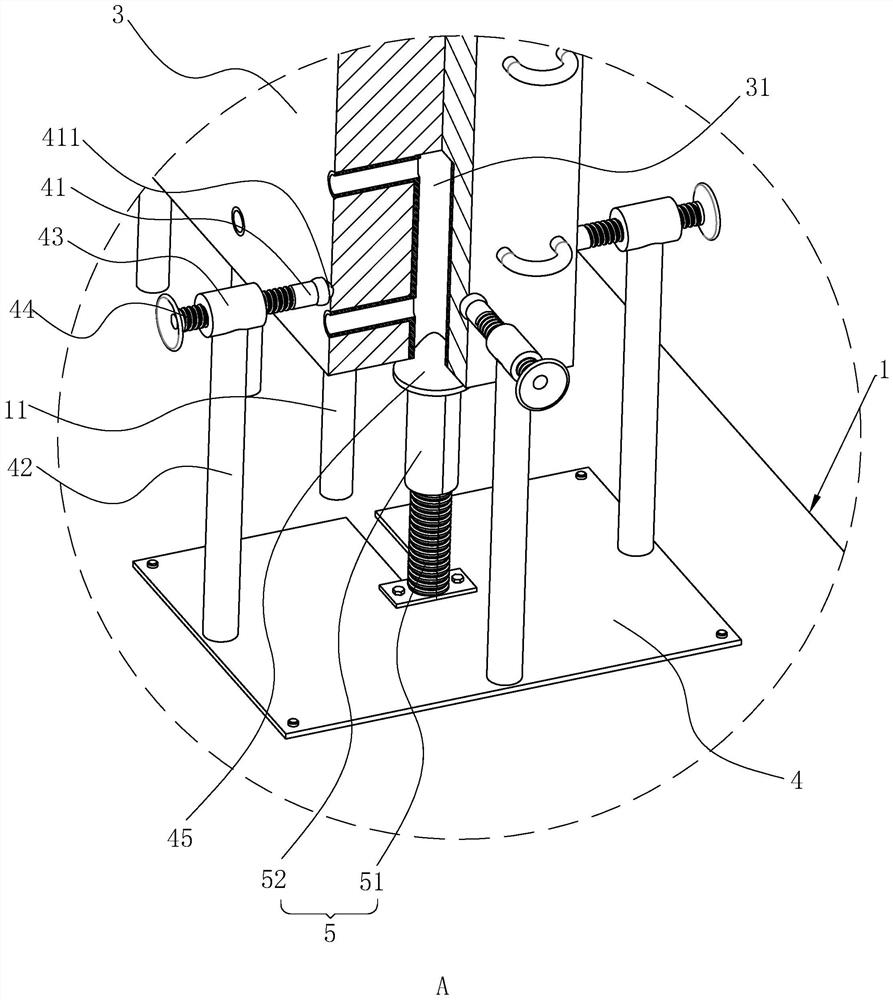

A jacket positioning device

ActiveCN113026750BAvoid collisionDecentralization smoothlyBulkheads/pilesCatheter/tube holderEngineering

The invention relates to the technical field of bridge substructure construction, in particular to a jacket positioning device, which includes: a guide frame, at least one lock female head, a lock male head, a vertical anti-collision bracket and a frontal anti-collision mechanism. Among them, the guide frame is set on one side of the jacket; at least one locking female head is arranged on the other side of the guide frame; each locking female head matches a locking male head, and the locking female head is arranged on the jacket to be connected One side; each lock female head is correspondingly provided with a vertical anti-collision bracket. The jacket collides with the female end of the lock from above; each female end of the lock is correspondingly equipped with a frontal anti-collision mechanism, which is sleeved on the outside of the female end of the lock and connected with the guide frame to prevent the jacket to be connected Hit the female end of the lock from the horizontal direction. It can effectively solve the problem in the prior art that the lowering of the jacket easily causes collision damage during the lowering process.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Movable hanging and hoisting construction method for steel structure fabricated wallboard

ActiveCN113802861AReduce frictionDecentralization smoothlyBuilding reinforcementsBuilding material handlingRebarWall plate

The invention relates to the technical field of wallboard hoisting construction, and provides a movable hanging and hoisting construction method for a steel structure fabricated wallboard. The movable hanging and hoisting construction method comprises the following steps that the wallboard is lowered, so that two groups of conical positioning pieces are firstly clamped into grouting sleeves at the two ends of the wallboard, and the wallboard is temporarily positioned; and then three groups of driving pieces on a bottom plate correspondingly drive three groups of abutting rod pieces to abut against the three side surfaces of the wallboard to limit the displacement of the wallboard in the horizontal direction, so that the grouting sleeve can be smoothly sleeved into the connecting steel bar in the subsequent descending process of the wallboard, and the hoisting of the wallboard is simpler and more convenient.

Owner:GUANGZHOU CITY POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com