A method of using an ultra-long anchor cable chute

A chute and anchor cable technology, applied in construction, infrastructure engineering, sheet pile wall, etc., can solve the problem that the anchor cable cannot be inserted into the anchor hole in a straight line, the pull-out resistance of the anchor cable fails to meet the design requirements, and the grouting of the anchor cable Insufficient section length and other problems, to achieve the effect of improving the success rate of decentralization, good economic benefits, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

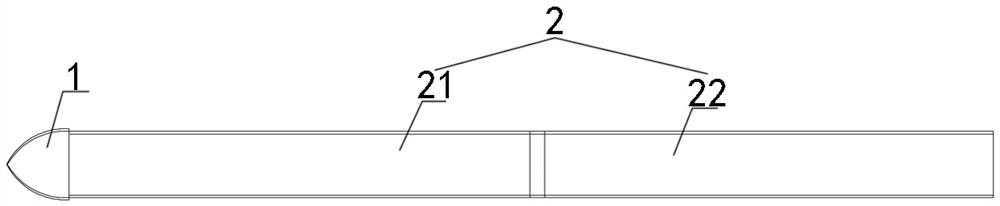

[0055] Embodiment one sees Figure 1-3 , 6, a super-long anchor cable chute, including a bar-shaped chute body, the chute body includes an end cap 1 and a chute section 2 connected sequentially from front to back, and the chute section It includes the first section 21 and at least one standard section 22.

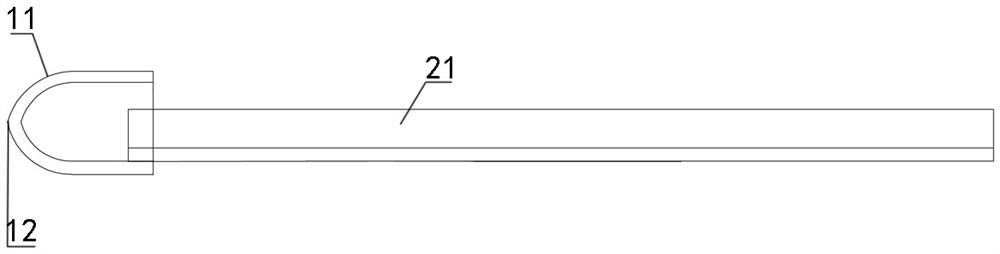

[0056] The end cap is a hollow cylinder, the end face of the front half of the end cap is a closed arc 11, the top of the arc is a tip 12, and the end face of the rear end of the end cap is open.

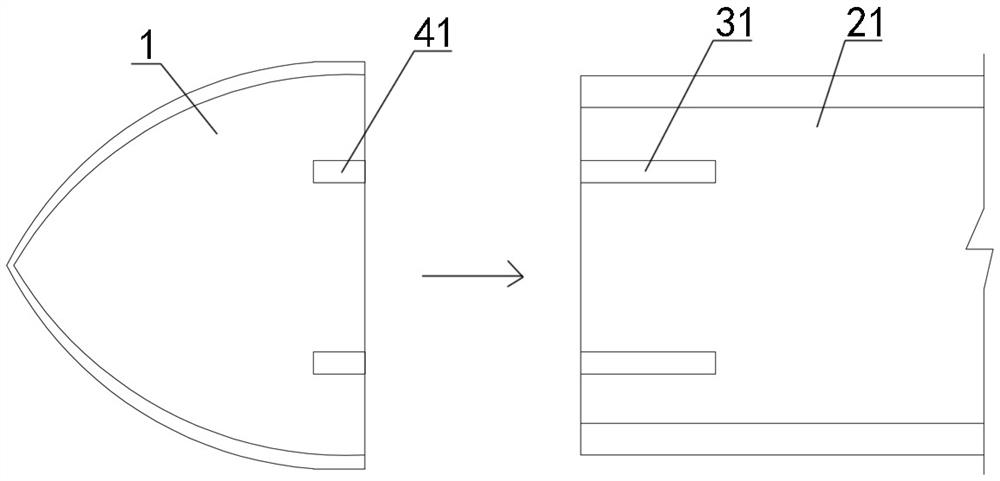

[0057] The front end of the first section 21 is connected to the rear end of the terminal cap 1 through a detachable connection structure. The detachable connection structure includes two grooves 31 arranged along the length direction on the lower side of the front end of the first section 21. It also includes that the position corresponding to the groove 31 on the inner wall of the second half of the end cap 1 has two ribs 4 matching the groove, and the lower side of the front ...

Embodiment 2

[0062] Embodiment two see figure 1 , 4 , 5, 7, and 9, the difference from Embodiment 1 is that the detachable connection structure includes that the front end groove bottom of the first section 21 has a clip parallel to the bottom of the groove and facing up and down, and the clip Including an upper clip 32 and a lower clip 42, the rear half of the upper clip 32 and the lower clip 42 are respectively fixedly connected with the upper and lower sides of the first groove bottom, the upper clip 32 and the lower clip 42 The front half of the head cap forms a receiving groove, and the rear end wall plate of the end cap is inserted into the receiving groove to abut against the end face of the front end of the first section.

[0063] The circular pipe is cut from a steel pipe, and the diameter of the pipe is slightly smaller than the diameter of the drilled hole. The connecting assembly includes a limit bolt 7 and a back plate 8 , and the lower side of the groove bottom at the head ...

Embodiment 3

[0066] Embodiment three see Figure 10-11 As shown, the difference from the second embodiment is that the chute section is formed by customized bending of thin steel plates, and the shape can be customized according to the needs, not completely circular arc shape, and the two upper ends of the segments form inwards. 14.

[0067] The connecting assembly includes a flange plate, flange bolts 6 and a protection plate, the rear chute section 2a is aligned with the connection end face of the previous chute section 2b, the flange plate is as wide as the chute section, and The bottom of the trough section is vertical, including a front flange plate 16 and a rear flange plate 17, the front flange plate 16 is fixedly connected to the tail end of the previous chute section 2b, and the rear flange plate 17 is fixedly connected to the rear chute At the head end of section 2a, flange bolt holes are respectively opened on the front flange plate 16 and the rear flange plate 17, and the flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com