A high-temperature blasthole temperature measuring device and a high-temperature blasthole temperature measurement method

A technology of high temperature blasthole and temperature measurement device, which is applied in the field of temperature measurement device and high temperature blasthole temperature measurement device, can solve the problems of affecting the thermocouple, cannot guarantee blasthole, slow temperature measurement response time, etc., and achieves improved speed and accuracy. stability, avoiding blind spots in temperature measurement, and the effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

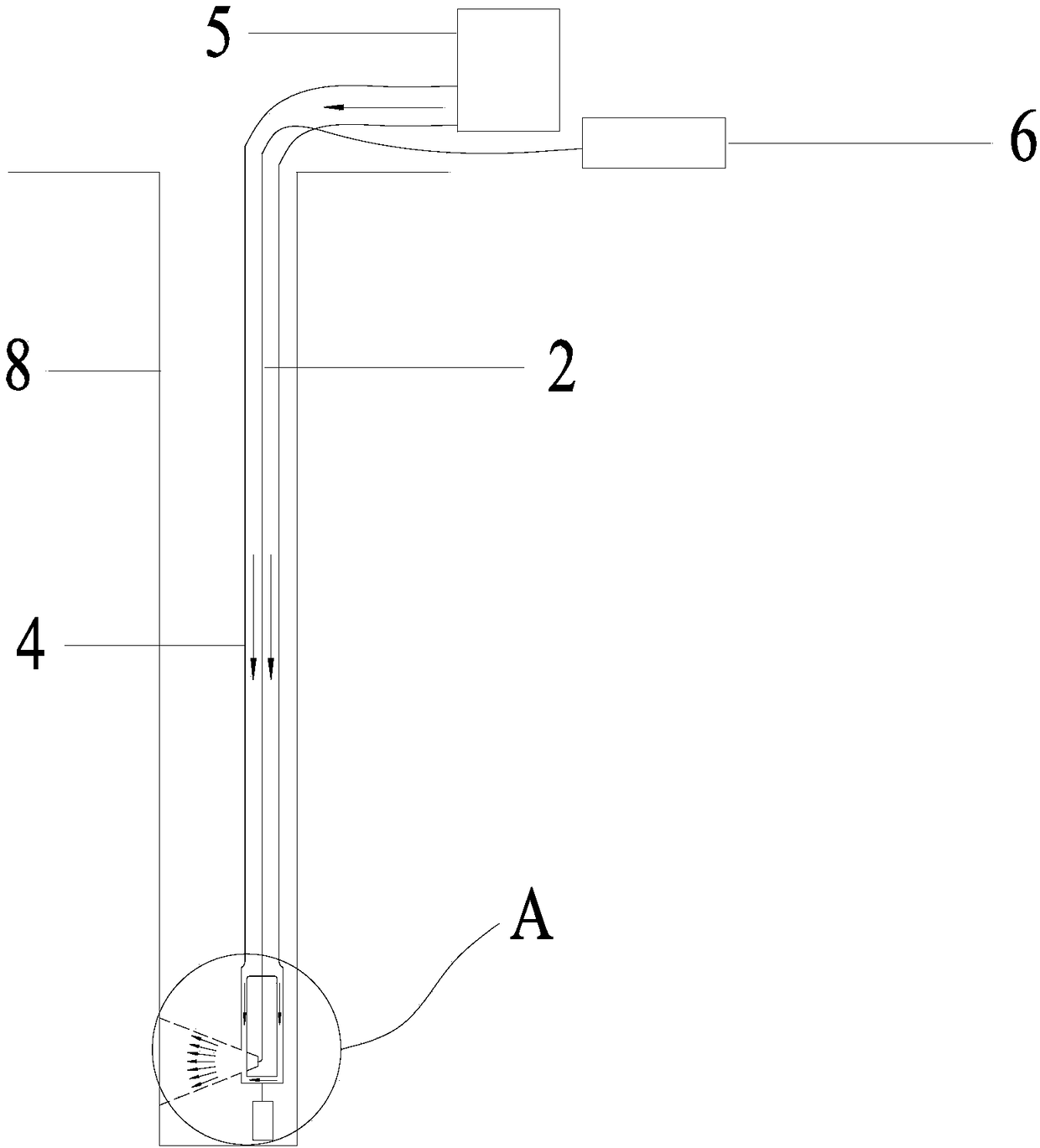

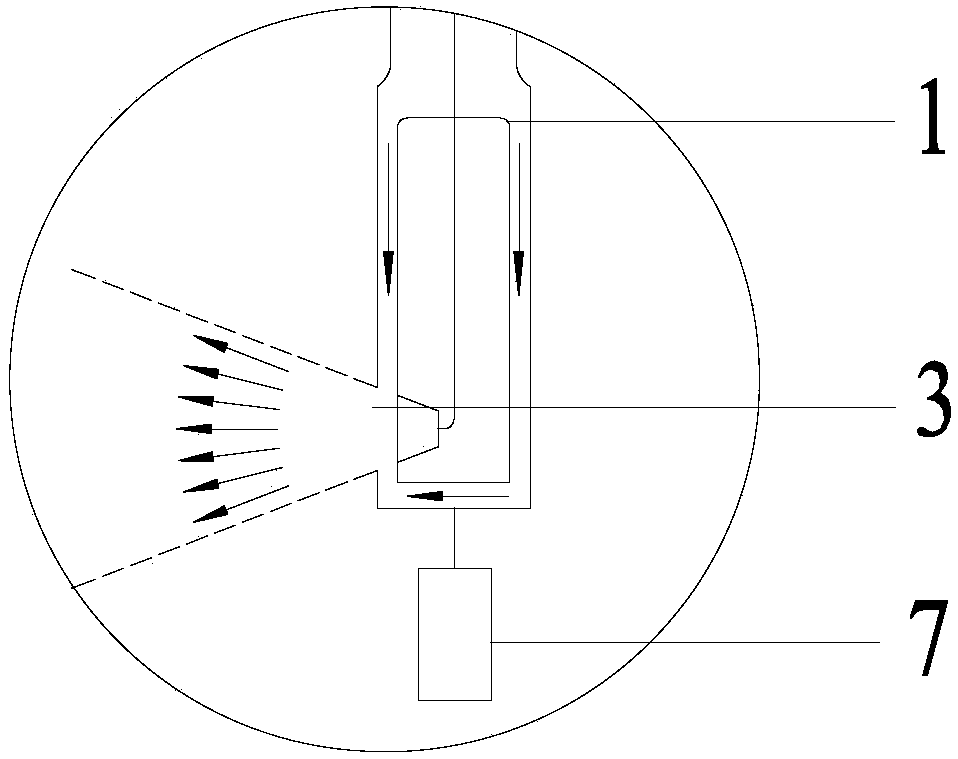

[0036] Such as figure 1 with figure 2 As shown, the present embodiment provides a high-temperature blasthole temperature measuring device, which includes an infrared temperature sensor 1, a cable 2, an air blower 3, a heat-resistant tube 4, an air pump 5, a display 6 and a weight 7 , one end of the heat-resistant pipe 4 is connected to the air pump 5, and the other end is connected to the air purger 3, the infrared temperature sensor 1 is fixed in the air purger 3, and one end of the cable 2 is connected to the display 6 The other end is connected to the infrared temperature sensor 1 after passing through the heat-resistant pipe 4, and the weight 7 is fixed below the air blower 3.

[0037] The air pump 5 can deliver air through the heat-resistant tube 4, and in addition to providing air for the air purger 3, it can also air-cool the infrared temperature sensor 1 and the cable 2, so that the entire temperature measuring device can be used in a high-temperature environment . ...

Embodiment 2

[0047] This embodiment provides a method for measuring the temperature of a high-temperature blast hole, comprising the following steps:

[0048] Step 1. Turn on the air pump to deliver air to the air purger through the heat-resistant tube;

[0049] In this step, the air volume delivered by the air pump can ensure that the air purger blows away the dust or water vapor around the measuring point, and ensures the air cooling effect of the entire temperature measuring device;

[0050] Step 2. After turning on the display, turn on the storage function and set the sampling frequency;

[0051] In this step, the sampling frequency set by the display matches the response time of the infrared temperature sensor;

[0052] Step 3. Lower the air purger fixed with the infrared temperature sensor into the blast hole steadily;

[0053] In this step, the lowering speed of the infrared temperature sensor matches the response time of the infrared temperature sensor;

[0054] Step 4. After the ...

Embodiment 3

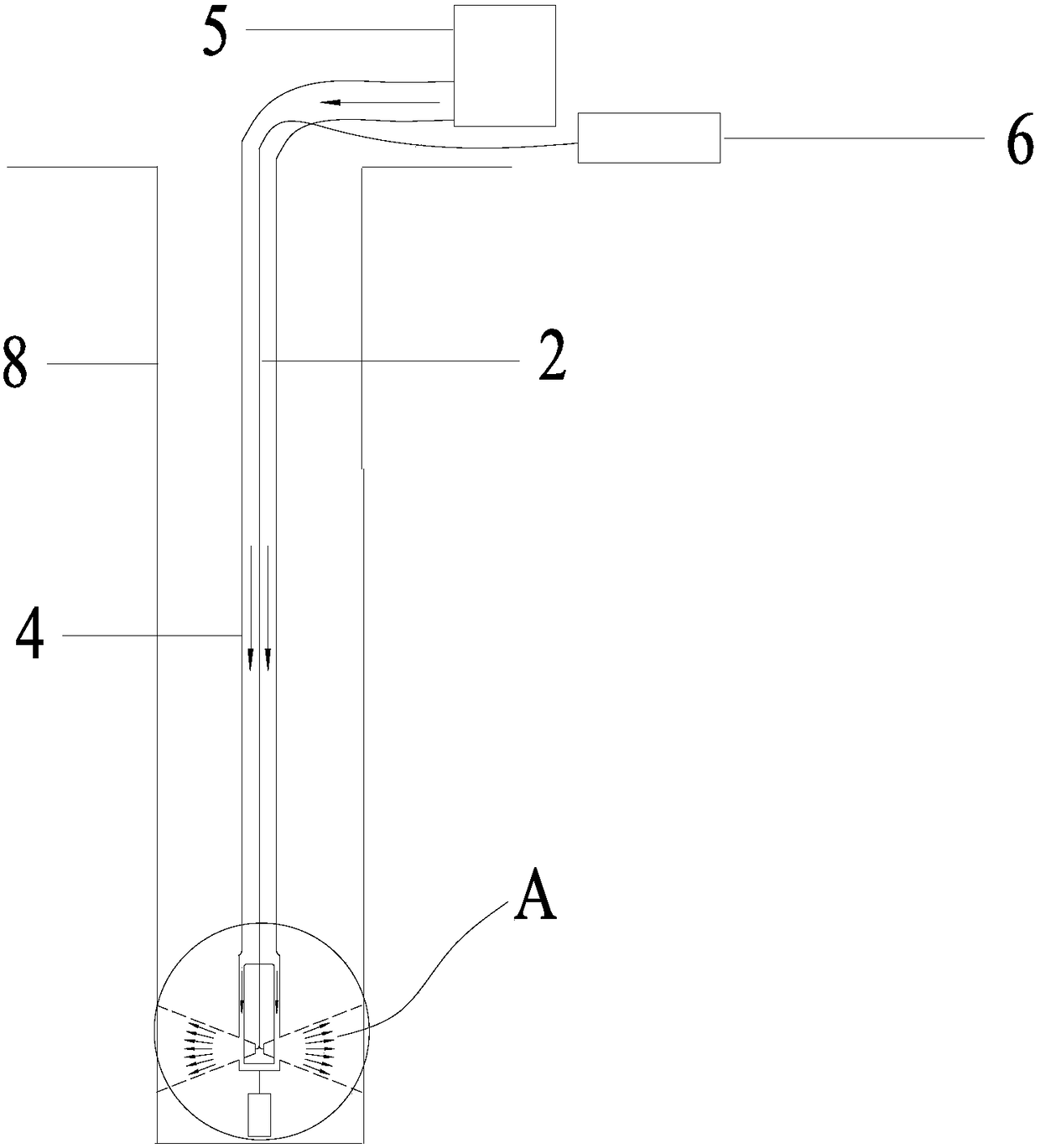

[0060] Such as image 3 with Figure 4 As shown, the present embodiment provides a high-temperature blasthole temperature measuring device, which includes an infrared temperature sensor 1, a cable 2, an air blower 3, a heat-resistant tube 4, an air pump 5, a display 6 and a weight 7 , wherein there are four infrared temperature sensors 1 and air purgers 3, each infrared temperature sensor 1 is fixed in an air purger 3, and the four air purgers 3 are circumferentially along the other end of the heat-resistant pipe 4 Symmetrical distribution, that is, an air blower 3 is set every 90 degrees in the circumferential direction of the other end of the heat-resistant pipe 4. In order to make the four air blowers 3 can effectively blow off dust or water vapor, the air pump 5 can be increased to deliver The amount of air; the symmetrical distribution of the air purger 3 is conducive to maintaining the stability of the infrared temperature sensor 1, and can measure four different direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com