Work method of roller shutter door lock

A working method and rolling door technology, which is applied in the field of rolling doors, can solve the problems of rolling doors without a special lock device, poor anti-theft effect, manual unlocking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

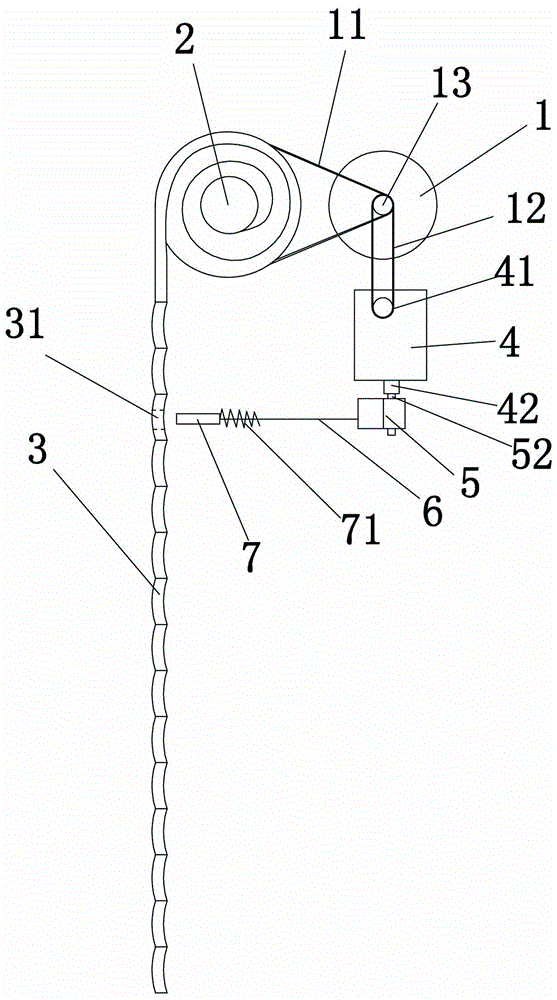

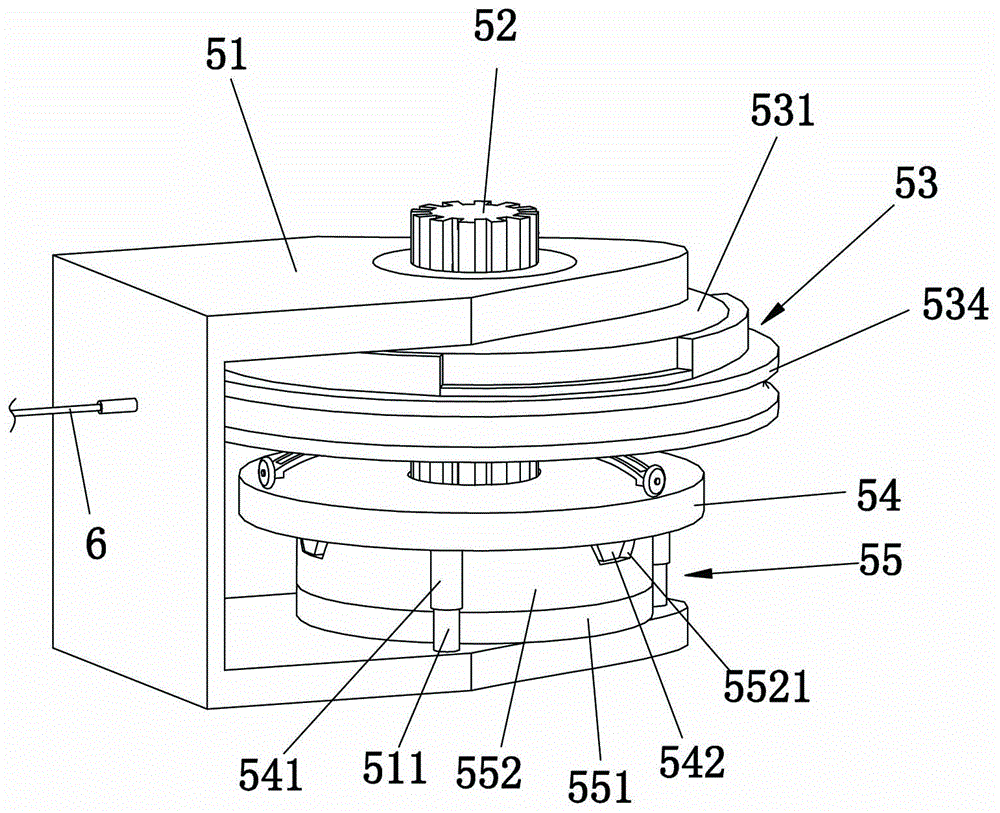

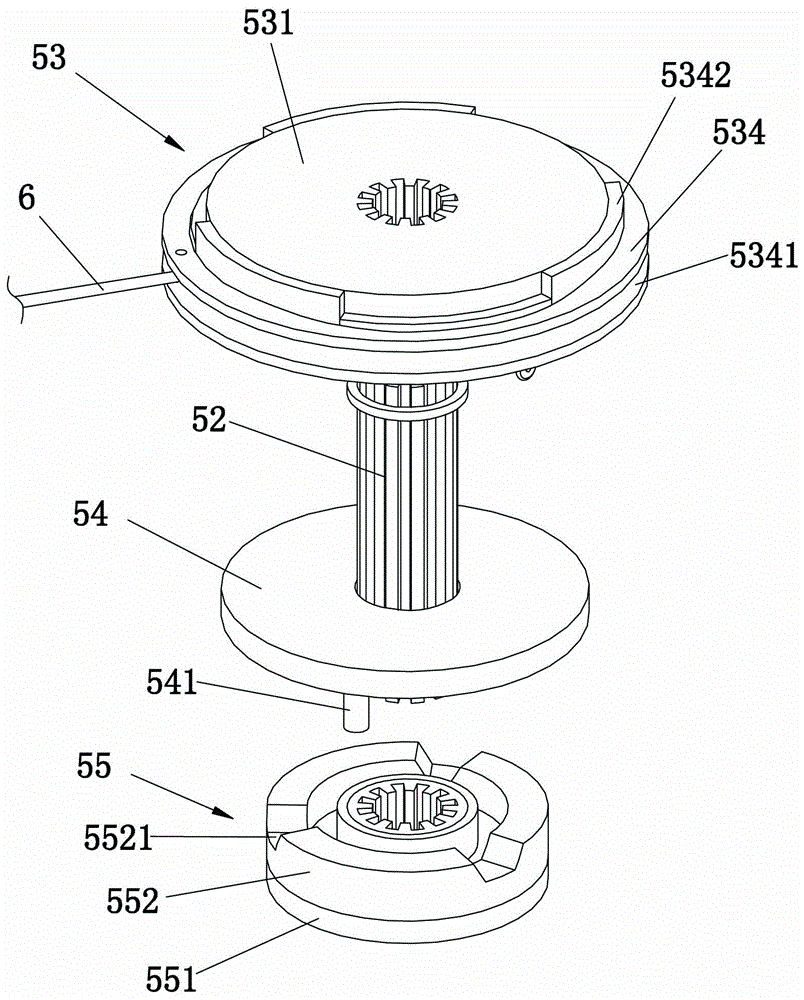

[0031] Reference Figure 1 to Figure 4 , A rolling door lock, comprising a lock core 7 and a spring 71 that moves the lock core 7 toward the rolling door 3 and locks the rolling door 3. The rolling door lock also includes a cable 6, a clutch device 5 and a motor. The clutch device includes a frame 51, a rotating shaft 52, a clutch assembly 53, a disc 54 and a damping wheel 55. The lock core 7 is a straight rod slidably arranged along its length, and the rolling door 3 is provided with an insertion hole 31 matching the lock core 7.

[0032] Reference Figure 2 to Figure 4 , The frame body 51 is in the shape of a letter and forms a mounting groove 512, and at least one column 511 is provided in the mounting groove 512.

[0033] Reference Figure 2 to Figure 4 The rotating shaft 52 is rotatably arranged in the mounting slot 51, and the rotating shaft 52 is driven by the above-mentioned motor.

[0034] Reference Figure 1 to Figure 6 The clutch assembly 53 includes a driving disc 531, ...

Embodiment approach

[0042] Reference Figure 7 , The rolling door lock includes a rolling door motor 1, an acceleration box 4, a clutch device 5, a cable 6, a spring 71 and a lock core 7. For the specific arrangement of the lock core 7, another specific implementation: the rolling door door lock also includes a holding block 10, a bracket 8 and at least one connecting rod 9. The lock core 7 is provided with a concave surface 32 that fits with the inner side of the rolling door 3. 的surface 72. One end of the connecting rod 9 is pivotally connected to the bracket 8, and the other end is pivotally connected to the lock core 7, and the lock core 7 is located obliquely below the bracket 8. The holding block 10 is held on the outer side of the rolling door 3 and cooperates with the lock core 7 to clamp the rolling door 3. When a thief uses a tool to pry open the rolling door 3, because the lock core 7 is arranged diagonally below the bracket 8 through the connecting rod 9, the more you pry the rolling d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com