Capacitor element protection box

A technology for protecting boxes and capacitors, applied in the field of capacitors, can solve the problems of damage to the right-angle side of square capacitors, wear and tear, reduce the thickness of the metal shell of square capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

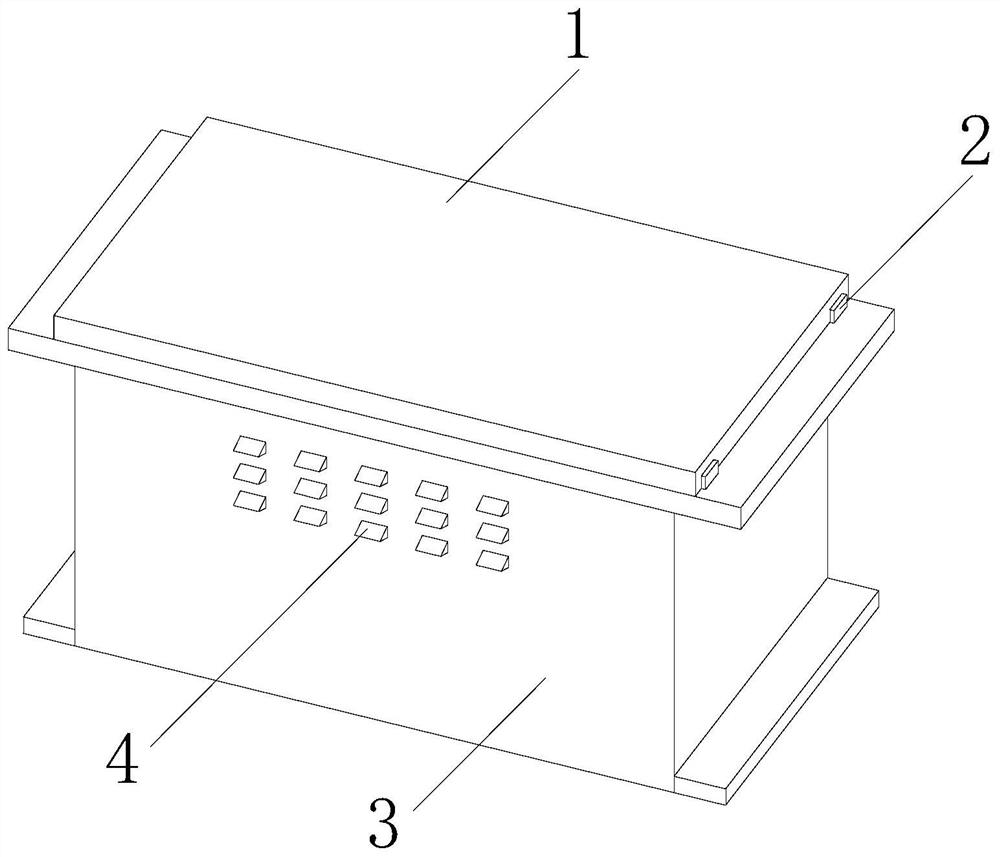

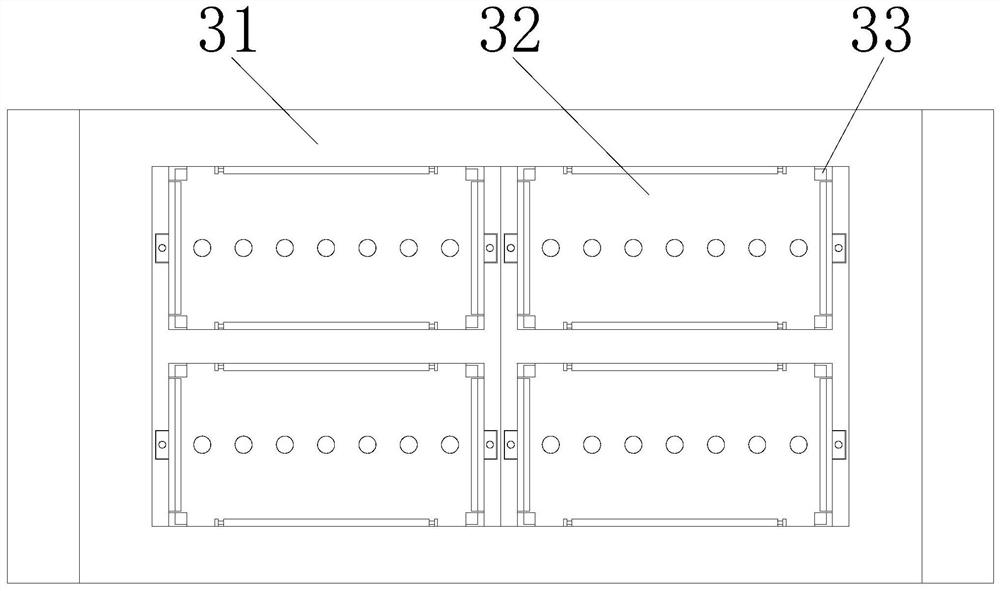

[0024] as attached figure 1 to attach Figure 6 Shown:

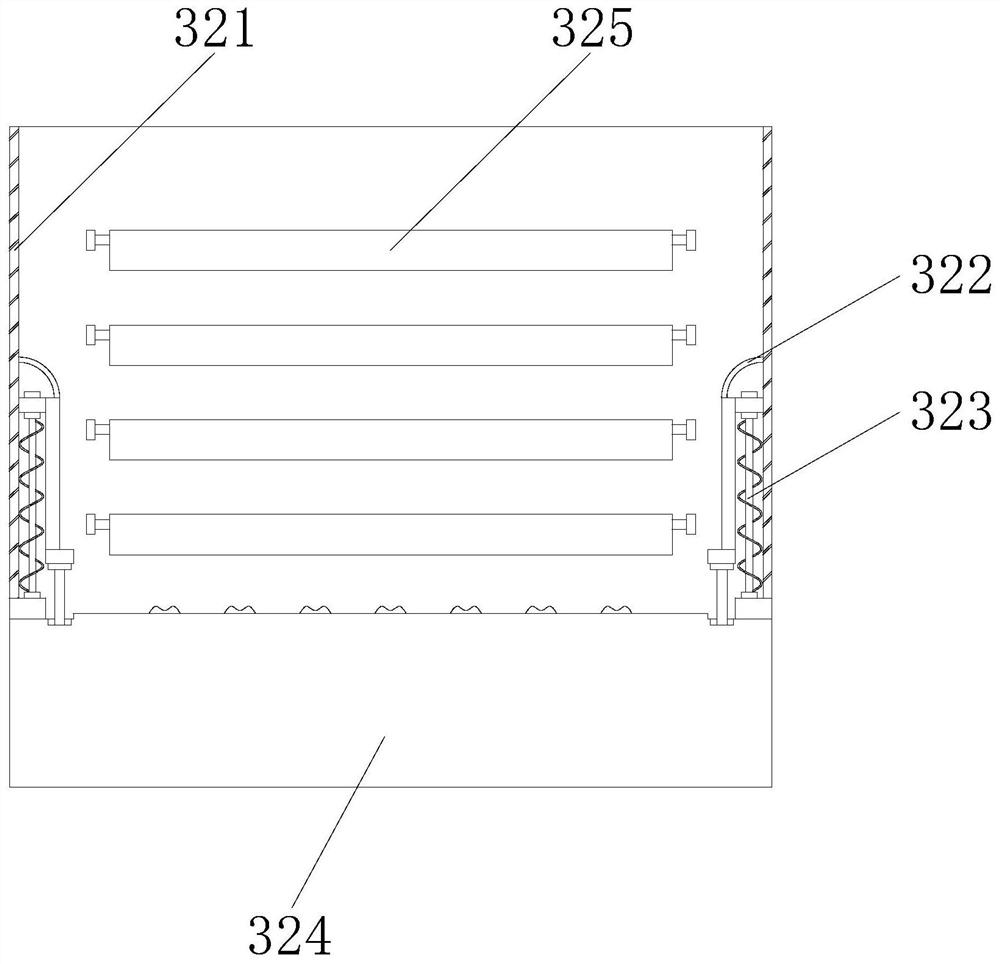

[0025] A protective box for capacitor elements according to the present invention, its structure includes a top cover 1, a slide bar 2, a placement box 3, and a cooling hole 4, the lower end of the top cover 1 is slidably connected with the slide bar 2, and the slide bar 2 is fixedly installed in the placement box 3 top, the front end of the storage box 3 is embedded with cooling holes 4, the storage box 3 includes a box body 31, a partition placement device 32, and an anti-collision device 33, and the upper end of the box body 31 is fixedly equipped with a slide bar 2, The partition placement device 32 is embedded inside the box body 31, and the four corners of the partition placement device 32 are provided with anti-collision devices 33, and the front end of the box body 31 is embedded with cooling holes 4, and the partition placement device 32 has a total of There are four, which is beneficial to separate and place ...

Embodiment 2

[0033] as attached Figure 7 to attach Figure 8 Shown:

[0034] Wherein, the anti-collision device 33 includes a right-angle supporting plate 331, a rubber block 332, a flexible hose 333, and a press-down buffer device 334. 332 is located on the inner surface of the right-angle supporting plate 331, and the rubber block 332 is fixed to the telescopic hose 333. The telescopic hose 333 is installed inside the right-angle supporting plate 331, and the press-down buffer device 334 is installed on the lower end of the right-angle supporting plate 331. On the upper surface, there are two rubber blocks 332 and two telescopic hoses 333, which are respectively arranged at the right-angle ends of the inner surface of the right-angle support plate 331, and are installed in a right-angle knuckle position, which is beneficial to the surface on both sides of the right-angle end of the square capacitor. Reduces wear on the right-angled ends of square capacitors.

[0035] Wherein, the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com